Thicknessing machines are designed for working with wood. This is a special type of planing machines designed to work with workpieces and adjust their thickness. Often parts are processed that have already gone through a jointer. If you live outside the city, or like to work with wood, check out our rating of the best thickness planers for the home workshop. It is important to choose equipment that is suitable in size and cost, and also pay attention to some characteristics. We will tell you what you need to pay attention to when purchasing.

What it is?

The cutting element of any wood planing machine is a knife shaft with 2, 3 or 4 knives. Its design is the same for any machine, jointer or surface planer. This made it possible to combine both functions in one unit, which is called a planer-thicknesser machine.

It works in two directions - from above it is a regular planer, but if you feed the workpiece from the opposite side under the work table, the unit works like a surface thicknesser. This design is compact and fully provides both functions. First, one plane (or edge) is processed, then it is fed from the opposite side with the processed surface down.

The broaching mechanism grabs the workpiece and passes it under the knife shaft, which removes chips to a given thickness. The ability to use one universal unit instead of two machines makes it possible to fully work in confined spaces. the quality of the surfaces meets all technical requirements corresponding to the class of the machine.

How to choose a thickness planer

Before deciding to purchase a thickness planer, there are several factors and features you need to consider. A woodworking machine is an expensive item, and in most cases you can get by with a regular plane or jointer. However, if wood processing takes a long time, or the production of furniture or wooden blanks was organized, then purchasing a thickness planer is the best solution.

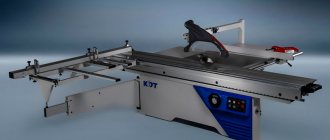

Wood processing machine

The main advantages of the machine:

- high performance;

- safety;

- quality of processing.

To purchase the best thickness planer, you need to pay attention to several factors:

price. High cost often becomes an obstacle to purchase, despite the fact that the device may be of high quality and excellent characteristics. An important nuance - buying a cheap machine does not mean that the device will not be of high quality, however, it may have less power or a reduced level of performance. By buying a machine for home renovation, you can save money, but if your plans include furniture production, then it is recommended to choose a high-quality model at a decent price;

place. Despite the fact that thicknessing machines are small-sized, they still require a special place for installation and storage. Sometimes buyers take into account the dimensions of the equipment, but forget to take into account the length of the boards that will be processed;

device specifications

When purchasing, you should pay attention to the width and length of the cut, the weight of the equipment and the shaft speed. Power is also an important indicator - for standard work, an average power of up to 1500 W is sufficient.

To work with hardwood, you need a device with a power of up to 1800 W.

In order not to make a mistake when purchasing, you should choose equipment in accordance with your goals. If you plan to make furniture, then the more powerful the machine, the better. For home use and the manufacture of simple wooden products from soft wood, a budget, simple machine is suitable.

Video - Selecting a thickness planer

Types of machines, purpose and differences

Every person who is seriously involved in wood processing sooner or later comes to the question of quickly and efficiently planing boards. To eliminate manual labor and improve the quality of work, there is a special unit - a surface thicknesser. This term hides a variety of equipment for different purposes and tasks.

It’s worth starting the division with the type of plane:

| View: | Description |

| Unilateral | A household model, working on one plane of the workpiece. Used at home. Prices vary, it is possible to choose an option with the optimal price-quality ratio |

| Two sides | Option for professionals. Work goes on both the lower and upper sheets of the workpiece. High power and speed |

| Multilateral | An industrial variety that processes wood from several sides at once. This is necessary to obtain ideal geometry and texture. Huge performance and exceptionally stationary development |

Classification by design

Devices for working with wood can be divided into 2 types:

- Mobile . The difference is in light weight and small dimensions. Most often they are mounted on top of the desktop. Used for processing small parts in a home workshop

- Stationary . Large and heavy option, used for large raw materials

Regardless of the demand for the model and its design, products in 99% of cases will be equipped with an automatic feed mechanism. The existing rollers press the tree against the shaft and advance it until it appears in the working area.

Average power ratings of products range from 1.5 to 8 kW. In addition, the models will differ not only in functionality, but also in the speed of rotation of the shafts, electricity consumption, number of cutting elements, cost and a number of other parameters.

Functional

In order not to make mistakes when choosing, it is worth studying the basic and additional options of a thickness planer for the home workshop and production. Which machine can you choose:

- Household . A compact and fairly lightweight model that can be placed in small spaces, has low or medium engine power and a reasonable price. Most often, minor processing is performed on it and a cut is made to a depth of up to 1.5 mm. Requires manual feeding due to the lack of power for deep cutting. To this should be added the need to exert significant body effort. Industrial use is not possible.

- Industrial . The best models have high speed and significant power, allowing for deep cuts. Occupies quite a large area. Has autofeed function by default. A 380 V network is used for power supply. The presence of high power determines the need for a cooling system. The blades can be mounted on both sides or on one side. Among the main structural elements you can find a double stand and a movable drum. It is possible to adjust the cutting depth using the control unit.

- Planer-thicknesser . It is used when there is a need for exceptional precision of parts or other products made from wood. Provides an ideal surface, reduces thickness longitudinally and eliminates various deformations, be it a splinter, a cut, a bulge, etc. Some manufacturers provide the possibility of reciprocating movements. Whether it's worth buying depends on the needs of the workshop. But it is definitely on the list of the best. There are both foreign and domestic manufacturing companies on the market. Every year you can find a new product that has fundamentally new functionality.

- Planer-thicknesser . Used for milling, processing bases using knives on the shaft. There are only two types - with one and two sides. In the first case, it occurs both in amateur carpentry and in serious industries.

Criterias of choice

What jointing and thicknessing machine do you use?

HouseholdProfessional

The choice of planer-thicknesser machine is made according to several criteria:

- Power.

- Width of working base.

- Estimated load.

- Power supply type.

Depending on these requirements, a suitable machine model is selected. It must be taken into account that as needs increase, the price of equipment increases. Small household models cost about 20 thousand rubles, and professional units will cost 100, 200 or more thousand. In order not to spend extra money, you should soberly assess your needs and intended tasks.

If the machine is needed to perform small jobs and will be used only from time to time, you need to choose a model from the household group. For the production of large batches of parts on a continuous basis, professional equipment with the appropriate parameters is suitable.

The type of power supply available must be taken into account. Not all workshops have a three-phase network connection. In such cases, it is necessary to purchase equipment powered by 220 V.

Main parameters and GOST

Planer-thicknesser machines, mostly manufactured in the Russian Federation, will comply with the set of technical characteristics. The latter are enshrined in the official standard GOST 7228-93.

Among the parameters you can find:

- dimensions of wooden blanks (taking into account the thickness and width of the raw material);

- permissible length, specific value;

- number of knives on the shaft;

- sides processed in one pass;

- shaft rotation speed;

- power plant power indicator;

- speed of progress of the operation;

- total weight of the product.

Most machines support the processing of wood raw materials in the following dimensions:

- 315-1250 mm - permissible width;

- 5-160 mm – minimum and maximum thickness.

These parameters should be taken as average and generalized; they may differ depending on the specifics of production. The minimum length of wood is indicated by the diameter of the drum. Modern values set the minimum possible parameter for a given value to be >30 mm.

Depending on the area of use, one or more knives will be attached to the shaft design, rotating at a frequency of five to ten thousand revolutions per minute. The value is average, by analogy with the others it can be higher or lower. For example, a desktop model rarely has a shaft rotation speed of 5,000 revolutions, but if necessary, in a somewhat universal device you should strive for this value. If you ignore this factor, you may encounter difficulties in completing the task.

The feed speed of workpieces for standard and professional devices will be in the range from 6 to 24 meters per minute. This is the optimal threshold value that allows you to create more than a hundred products within one shift. The weight of the structure will depend on the completeness of the equipment and the presence of additional optional blocks. When choosing a product for your home, it is better to focus on a desktop copy. Accordingly, the production apparatus should also have no compromises.

Types of thicknessing machines

By purpose, equipment is divided into household and industrial.

According to the installation method, machines are distinguished:

- Mobile models differ from stationary equipment in their lighter weight and overall dimensions. They are intended for small industries and home workshops. Such equipment does not take up much space and is easy to transport from place to place if necessary.

- Stationary machines are designed for installation in large woodworking enterprises. They are characterized by high performance. Some models are equipped with an additional working function - jointing.

What thickness planer do you use?

MobileStationary

Based on the number of surfaces processed, thicknessing machines are divided into:

Expert opinion Daniil Dmitrievich Korzhavin Designer of stylish home furniture

The last two types of machines belong to the class of professional equipment.

Table of comparative characteristics of planer-thicknesser machines

To understand which machine to choose for work – a jointer or a surface planer, you need to study their characteristics and technical features.

| Feature/Description | Jointer | Thicknesser |

| Processed material | Tree | Tree |

| Purpose | Straight planing | Flat planing |

| Cutting tool | Knife shaft | Knife shaft |

| Shaft location | Bottom of the workpiece | Top of the workpiece |

| Thickness calibration | No | Yes |

A jointer is perfect if you need to prepare the base plane of a wooden piece. The thicknesser allows you not only to level the board, but also to make the second side of the workpiece parallel to the first side.

| Photo | Place | Name/Model | Characteristics and features | average rating |

| 1 | Kraton wmt – 318 | Single-sided, semi-automatic woodworking machine | 10 | |

| 2 | Belmash SDR-2200 | Small machine with high productivity | 9.9 | |

| 3 | BISON RS-320 | Reliable, high-quality machine for wood processing | 9.8 | |

| 4 | PATRIOT TP 255 | Powerful machine with high workpiece feed speed | 9.7 | |

| 5 | DEWALT DW735 | Power – 1800 W. High-quality and fast processing of workpieces | 9.7 | |

| 6 | SR4-20M-01 | Designed for planar planing of wooden panels, boards and beams | 9.6 | |

| 7 | Makita 2012NB | Quiet, easy-to-use woodworking machine | 9.6 | |

| 8 | SPEC SRM-2000 | Equipment with a power of 2000 W. Warranty – 12 months | 9.5 | |

| 9 | Encore Corvette 222 | High quality machine for home workshop | 9.4 | |

| 10 | Metabo DH 330 | High-quality, convenient machine with a smooth table and good factory settings | 9.0 |

The board does not move well through the machine. What is this connected with?

In a correctly configured and properly functioning surface planer, the board is evenly pulled through the machine, resulting in a clean and smooth surface. But in reality this does not always happen. During processing, the board may move at unequal speeds, jerk or stop, continuing to move forward only after being pushed; and at the exit, fiber snatches or burns often form on its surface. These symptoms are not normal and may have several causes.

It's probably time to change your knives. Dull blades can significantly slow down the feed and cause burns if worn too badly.

Problems with the passage of the board can also be explained by the fact that chips get under the rollers, due to which the adhesion to the board weakens and slippage occurs. Only an external chip removal system can solve the waste problem most effectively.

The presence of surface contaminants is another reason for the pinch rollers to slip on the workpiece. If you notice that the rollers are heavily soiled with dirt or tar, wipe them with a clean rag soaked in white spirit or kerosene. You can do the same with the metal table of the machine.

What should a modern thickness planer look like?

At one time, the country's main thicknessing machine had one single analogue of a household thicknessing tool in the form of an ordinary plane. With the advent of high technology in the world, the situation has changed dramatically and today anyone who wants to get a perfectly smooth wooden blank at home for its further use in everyday life can buy a thickness planer for their workshop.

A modern thicknessing machine is an inexpensive woodworking device with a minimum of capabilities for the home, or complex equipment for wood processing on an industrial scale. The choice of models and manufacturers is amazing, so especially for you we have made a selection of the ten best thicknessing machines for a wood workshop, based on dozens and hundreds of reviews and features of each of the equipment under consideration.

Comparison of thicknesser and jointer machines

In addition to the surface planer, carpentry professionals actively use a jointer - a device with an elongated frame, designed for installation in a workshop. The main advantage is working with a long board. However, the thicknesser is not inferior in popularity. To understand why, you need to familiarize yourself with the advantages and disadvantages of each.

| View: | pros | Minuses |

| Jointer |

|

|

| Thicknesser |

|

|

The best thicknessing machines for wood

A simple, reliable design is the main advantage of a classic thickness planer. The equipment is designed for surface planing and is equipped with practical cutting elements designed for large volumes of work. Amateur and professional models are available. Our experts tested 7 popular brands and chose 3 surface planers, equipped with reliable motors and tables with impeccable surface geometry.

Gigant TPJ-320-1600

A lightweight planer for wood for a home workshop with a 1.6 kW motor powered by a 220 V household power supply. Despite the low power, the electric motor rotates the planer shaft at a high speed of 9000 rpm. The board is pulled at a speed of 5 m/min, which ensures high productivity. The size of the portal allows you to work with a board 31.8 cm wide and 15 cm thick.

The weight of the equipment is 30 kg, ensuring mobility during transportation and sufficient stability on any surface. Ergonomic handles are provided for carrying. The shaft is equipped with two knives made of structural steel, which provide a planing depth of 3 mm. The ideal geometry of the work table surface ensures easy feeding, which has a positive effect on the quality of the finished product.

Advantages:

- Convenient handle for changing the height of the cutting head;

- Possibility of connecting a vacuum cleaner;

- Good equipment;

- Knife adjustment bar;

- Low price.

Flaws:

High noise level.

The woodworking machine was developed for the home workshop. The equipment is not designed to operate continuously for several hours, but with a short rest every half hour it can easily handle several cubes of wood

The developers paid special attention to ease of adjustment: any beginner can adjust the work with high accuracy

Patriot TP 330

Compact thicknessing machine for home with a 2 kW motor that rotates the shaft at a speed of 8000 rpm. Power supply from household power supply 220V. The shaft is equipped with two cutting elements made of structural steel, which provide a planing depth of 3 mm. On the front panel of the machine there is a measuring scale for performing high-precision operations.

The planing machine is lightweight - 29 kg. This makes it easy to carry and transport. The heavy frame reduces vibration levels, and the presence of holes in the base allows you to quickly and securely attach the equipment to the support. The dimensions of the portal allow processing boards 33 cm wide and 16 cm thick. High engine power for its class makes it possible to work with hardwood.

Advantages:

- Quick engine stop system to ensure operational safety;

- Part feed speed 6 m/min;

- The minimum thickness of the processed board is 5 mm;

- Quick setup;

- Overload-resistant electric motor.

Flaws:

No spare knives included.

Metabo DH 330 0200033000

Portable planer for wood with a 1.8 kW electric motor. Features: high shaft rotation speed – 9800 rpm and rapid workpiece feed – 7 m/min. Technical characteristics guarantee high quality of surface planing. The portal is designed to process boards 33 cm wide and 15.2 cm thick.

The large thicknessing table made of cast aluminum provides a high level of comfort while working. The two HSS knives with a cutting depth of up to 3 mm are made of 18% tungsten steel and can be used for working with hard wood. The thicknesser's weight of 38 kg makes it stable, helps reduce vibration and does not cause problems during transportation.

Advantages:

- Precise adjustment of planing depth;

- Alloy steel table cover;

- Good security system;

- Connection pipe for vacuum cleaner;

- Easy maintenance.

Flaws:

- Overcharge;

- Expensive knives.

Rating of the best premium class machines

For professional carpenters.

BELMASH P380ARB 230 V

BELMASH P380ARB 230 V

A Belarusian-made product that uses a 230 V network for operation. Automatic feeding stands out among the features. The speed of the gear shaft can be adjusted between 5 and 9 meters per minute. The receiving shaft is of one-piece construction. Thanks to two table rollers, friction on the desktop area is reduced. Additional tables are also equipped with casters. Planing shaft with three knives that can be replaced with a helical shaft. It is possible to independently replace knives thanks to the presence of a special device.

Characteristics:

- power - 3050 W;

- asynchronous motor;

- shaft at idle speed - 5,000 rpm.

Pros:

- desktop clamp;

- helical shaft installation;

- the speed of automatic material feeding may vary;

- high precision.

There are no cons.

It works in many industries without causing any complaints.

Helical BELMASH P380ARBH (400 V)

Helical BELMASH P380ARBH (400 V)

In general, it has a similar design as the previous version. But to work you need a 380 V network.

Characteristics:

- power - 2200 W;

- special head - 75 knives on the shaft.

Pros:

- simplicity;

- reliability;

- functional.

Minuses:

- quite a complex cutting component.

Users are satisfied, there are no breakdowns.

JET JWP-208-3 5.5 kW

JET JWP-208-3 5.5 kW

In first place is a surface thicknesser from the Swiss brand Jet, which is intended for professional use in production. The machine is connected to a 380 V network, so the workshop must have a three-phase input. The model has its own base and bed with rollers, so it does not require a workbench.

Characteristics:

- table length - 654 mm;

- workpiece - 500 mm;

- jointing - 5 mm;

- broaching — 10 m/min;

- chain transmission;

- workpiece - 200 mm;

- four knives;

- stationary stand.

Pros:

- does not need a table or workbench;

- support rollers on the edges of the frame;

- the operator hardly feels the vibration;

- simple controls.

Minuses:

- voltage required 380 V;

- high price;

- consumes 5.5 kW per hour;

- Difficult to transport due to weight of 300 kg.

Powermatic 209

Powermatic 209

Belongs to the category of powerful and durable planes. The manufacturer claims a three-phase connection. Planing width is up to 500 mm. The shaft is equipped with conventional straight knives. It is equipped with a segmented spiral drum with carbide blades. The cast iron construction is durable and vibration is virtually eliminated. The height of the table is adjusted using a handwheel. The model is equipped with all the necessary settings and functions that ensure stable and comfortable operation for a long time. Ranked among the best.

Characteristics:

- 400 V;

- planing depth along the entire passage - 2 mm;

- workpiece length - 170 mm;

- thicknesser - 664 mm;

- thicknesser extensions - 1420 mm;

- exhaust fitting - 127 mm.

Pros:

- multifunctionality;

- reliability;

- high quality products;

- ability to work with wood of various densities;

- efficiency;

- user convenience.

- power;

- height adjustment;

- the wheeled chassis is equipped with a brake for easy movement around the workshop;

- well-thought-out basic and additional (auxiliary) functions by the manufacturer.

There are no cons.

T-600J

T-600J

Thicknesser PROMA T-600J is used for planing flat surfaces of wood workpieces with a rotating knife shaft. The model is equipped with a motor with a power supply voltage of 380 volts. The equipment of the production company PROMA is distinguished by the high quality of the work performed and a long service life. The quality cast iron work table is raised and lowered using a large handwheel.

Characteristics:

- width - 630 mm;

- thickness - 205 mm;

- length - 220 mm;

- planing depth - 5 mm;

- 4 knives.

Pros:

- powerful engine;

- stable design with no vibration;

- fast and accurate installation of knives;

- high-quality processing of workpieces thanks to a shaft with knives made of high-quality steel;

- convenient location of controls.

There are no cons.

A fairly unpretentious technique, while having good characteristics. No weak points found.

The best bandsaws for wood

Wood band saws can cut large sizes of wood, unlike other similar products. A cut made with the help of such products has increased accuracy and quality of material processing. Such devices are divided into professional and household. The former are used to carry out a large volume of work and have high productivity, while the latter are used at home.

Ryobi RBS904 5133002854

This band saw from a Japanese wood company is manufactured in a Chinese facility. Its power is 350 W, the speed of the blade is 660 m/min, the maximum thickness of the processed material is 80 mm. With such a device, you can cut in a straight, transverse direction, cut at the required angle, with the desired slope. For operator safety, the sharp parts of the band saw are covered with a protective housing.

Pros of the saw:

- Excellent quality desktop.

- There is no vibration.

- Low noise operation of an asynchronous motor.

- Compact table dimensions: 305x305 mm.

- Possibility of connecting a dust and chip remover.

Cons of the saw:

- Complex equipment setup.

- There are no bearings in the mechanisms, pins are installed.

- Unfinished belt tension system.

- Inconvenient location of the lighting lamp.

BISON ZPL-350-190

The Russian company pleasantly surprised consumers with the modern, attractive design of the model and the compact dimensions of the device (L/W/H): 430x400x700 mm. Motor power – 350 W, belt speed – 882 m/min, maximum cutting width – 190 mm.

Pros of the saw:

- Possibility of sawing wood material at an angle of 45°.

- Large thickness of processed wood: 700 mm.

- The cutting width of 190 mm is sufficient for many jobs.

- Acceptable price for buyers.

Cons of the saw:

- The original tape is of poor quality, you need to install another one.

- Large vibration of the belt when sawing.

- There are no bearings, pins are used in the guide units.

- Flimsy, plastic body.

Metabo BAS 318 Precision WNB 619009000

The band saw of a well-known German company made in China has a power of 900 W and a maximum cut length of 170 mm. The product also stands out for its solid dimensions: 665x980x1600 mm and weighing 79 kg. Lighting with an LED flashlight adds convenience to work. Its long working life allows you to use one lamp for a long time.

Pros of the saw:

- There are two sawing speeds: 440 and 880 m/min.

- Universal use – the saw can be used to work with wood, plastic, and non-ferrous metals.

- Possibility of quickly changing the blade without using tools.

- Easy operation with two control buttons.

- Easy to move with wheels.

- Durable cast iron base.

- Quiet operation.

- There is a web tension indicator.

- Restart protection has been installed.

Cons of the saw:

- The presence of play on the protractor, rod, tension selection lever.

- Poorly chosen lighting location.

- Poor quality of fabric.

- There were many defects during assembly: a crooked table, a defect in the rubber of the upper pulley.

- Without the tension of the thrust bearings, the tape hardly lands on the rear bearing.

BELMASH WBS-228/2 S048A

The Belarusian-made machine was liked by consumers due to its attractive appearance, good technical parameters and affordable price. Motor power: 350 W, maximum cutting depth: 90 mm. Using this installation, you can process any type of wood: wooden blanks, plywood, chipboard, MDF, fiberboard.

Pros of the saw:

- A comfortable handle and relatively low weight allow you to conveniently transport the machine to the desired location.

- Possibility of cutting at an angle of 45 degrees due to the tilt of the table.

- High equipment protection class: IP20.

- Makes little noise.

- High quality build.

Cons of the saw:

- Poor dust extraction.

- The rip fence was not executed successfully.

- Poor quality of guide bearings.

The best razors with replaceable cartridges

A luxurious shave, soft and smooth skin can be provided by razors with replaceable cartridges. Although their cost is comparatively higher compared to disposable instruments, they are of higher quality and have a longer service life.

Gillette Fusion Proshield Chill

This five-blade men's razor provides an incredibly comfortable and easy shave. The tool will be an excellent solution for those with sensitive skin. The razor blades have anti-friction coatings, and on either side of them there are lubricating strips that protect the skin and cool it. The tool also boasts a thoughtful and stylish design and FlexBall technology, which ensures perfect contouring of the face and shaving of every hair.

Average cost: 737 rubles.

Gillette Fusion Proshield Chill

Advantages:

- shaving without irritation;

- special FlexBall technology;

- high quality.

Flaws:

BIC FLEX&EASY

Despite the discreet design and low cost, the razor is of high quality. The tool has three movable blades and a special moisturizing strip with aloe extract.

Equipped with a floating head, which makes shaving easier and safer. The thoughtful design makes it possible to quickly and easily change cassettes. It is convenient to take the razor with you when traveling, as it is small in size and weight.

Average cost: 420 rubles.

BIC FLEX&EASY

Advantages:

- low price;

- optimal quality;

- attractive appearance.

Flaws:

Gillette Fusion5 ProGlide Power Flexball

A world-famous brand that breaks all records in sales of shaving accessories. The model is an innovative development of manufacturers. Thanks to the unique patented FlexBall technology, the tool blades are able to move in absolutely any plane. Thanks to the tool, absolutely all hairs are shaved perfectly, and the skin remains smooth.

The model is equipped with five super-thin blades and a strip of mineral oils, which perfectly lubricates the skin and ensures smooth glide without irritation. The rear of the razor is equipped with a trimmer, which reduces the pressure of the machine on the skin and prevents irritation.

Average cost: 1169 rubles.

Gillette Fusion5 ProGlide Power Flexball

Advantages:

- comfortable handle;

- attractive appearance;

- high quality;

- safe shaving;

- movable head.

Flaws:

SCHICK HYDRO 5 POWER SELECT

Specially designed for a comfortable and high-quality shave. The skin after using this razor is smooth, elastic and moisturized. The tool is equipped with especially thin blades, making the process pleasant and convenient.

The new generation razor boasts several vibration modes. There is a display on the case that displays information that it is time to change the batteries.

The razor also has a moisturizing gel strip that is activated upon contact with water and helps reduce friction and prevent the development of irritation.

Average cost: 1190 rubles.

SCHICK HYDRO 5 POWER SELECT

Advantages:

- high quality;

- shaving without irritation;

- the presence of a softening gel;

- unique blade coating.

Flaws:

XIAOMI H600

The original shaving machine, produced under a well-known Chinese brand, provides high-quality hair removal without irritation. The razor is made of impact-resistant plastic and features anti-corrosion protection. The model is also equipped with a floating plate. A high-quality and thorough shave is ensured thanks to six trimmer blades. A special protective pad prevents scratching the skin and causing irritation during use. The machine also contains a water-soluble gel strip, which is necessary for a comfortable shave.

Average cost: 1700 rubles.

XIAOMI H600 machine

Advantages:

- high quality;

- perfect shave without irritation;

- easy storage thanks to the included stand;

- does not rust.

Flaws:

Metabo TKHS 315 C 2000 WNB

Main characteristics:

- Power – 2000 W

- Disc diameter – 315 mm

- Disc mounting diameter – 30 mm

- Rotation speed – 2980 rpm

- Cutting depth – 85 mm

- Tilt angle – 45°

Sawing table and accessories. The main structural elements of this machine are made of galvanized steel, which guarantees their strength and durability. The work table, measuring 800x550 mm, can be increased in length by adding an extension. The base consists of four stable legs and a pair of wheels for increased mobility. Precision cutting is ensured by a parallel stop with applied markings.

Motor and saw blade. The 2000 W induction motor with a rotation speed of 2980 rpm is suitable for long-term professional work. The machine is equipped with a 24-tooth carbide disc measuring 315x30 mm, which provides high speed cutting of wood.

Engine Metabo TKHS 315 C 2000 WNB.

Functionality. The disc offset is adjustable from 0 to 85 mm. The rotation axis is tilted by a convenient rotating device with a lock at an angle of up to 45 degrees. There is a connection point to an industrial aspiration unit.

Safety

The risk of injury due to careless handling is reduced to a minimum when using a protective casing and a standard pusher with a comfortable handle. There is a lock against jamming and overheating of the electric motor

Protective cover Metabo TKHS 315 C 2000 WNB.

Pros of Metabo TKHS 315 C 2000 WNB

- Lightweight and movable design.

- Wheels and handles for moving by one person.

- Large table surface with the possibility of extension.

- Good dust removal.

- Reliable engine.

Cons of Metabo TKHS 315 C 2000 WNB

- There is no miter gauge with protractor.

- Side support play.

- In terms of cutting accuracy, the machine is more suitable for construction rather than carpentry work.

The best planer-thicknesser machines

There is no need to choose between the principles - you can combine them in one product, obtaining a budget-friendly and reliable tool.

CALIBER SSR-1600 1.6 kW

CALIBER SSR-1600 1.6 kW

The best model in the price-quality category. A simple and unpretentious surface thicknesser from a domestic manufacturer.

Characteristics:

- table length - 268 mm;

- table width - 208 mm;

- workpiece width - 204 mm;

- the maximum thicknessing depth parameter is 2 mm;

- workpiece feed - 6 m/min;

- maximum workpiece height - 120 mm;

- two cutting edges.

Pros:

- no initial setup required;

- cuts exactly to size.

There are no cons.

The product is one of those tools that require minimal modification with your own hands, after which it can serve for years.

BELMASH SDR-2200

BELMASH SDR-2200

This is a reliable model, which is designed for planing and thicknessing. All operations are performed quickly and give the workpiece the desired shape and size. Feeding is carried out manually, which is convenient and safe. The design is made in such a way that it makes it possible to easily move the product without special tools. The device has a wide table and a convenient start button.

Characteristics:

- equipped with a single-phase electric motor with a power of 2.2 kW;

- the shafts rotate at a speed of 7700 rpm;

- depth of planing and contouring - 3 mm, feed - 6 m/min;

- the table has dimensions of 425x260 mm, which will make it easier to work with large workpieces.

Pros:

- the plane shafts do not leave marks on the wood, and the sliding bushings have a long service life;

- the guide allows you to chamfer at an angle of 45 degrees along the entire length of the workpiece;

- The rip fence can be installed on both sides of the table.

Minuses:

- “extra functions” - difficult to figure out when using at home.

Owners complain about the need to adjust the legs after purchase.

Thicknesser selection criteria

By analogy with other woodworking machines, the functionality and performance of this equipment, along with the price, depend on the permissible dimensions of the workpieces and the service life of the components and engine. But it is not advisable to buy expensive and heavy-duty equipment for a home workshop; in this case, preference is given to models with average characteristics rather than maximum ones. The criteria taken into account when choosing include:

1. Machine power. In general, for high-quality planing of workpieces at home, 1500 W is enough, but 1800-1900 is recognized as the optimal recommended value; this is the resource that allows the surface planer to process dense types of wood. Models with a power of 2 kW and above should be chosen only if frequent and long-term processing of damp or hard wood is necessary, for example, when preparing furniture pieces from beech or ash.

2. The rotation speed of the shaft with cutting knives, the higher this indicator is, the more accurately and smoothly the chips are removed. In the case of household and semi-professional thicknessing machines, the optimal range is considered to be 8000-10000 rpm.

3. Depth of planing of the workpiece in one pass. This characteristic varies between 1-3 mm and has a direct impact on the cleanliness of the processing. Its low value is not of primary importance, but it increases the frequency of passes when working with curved surfaces and indirectly reduces the productivity of the thicknesser

In addition, attention is drawn to the ease of setting cutting parameters, the presence or absence of appropriate scales and the system for measuring them. Almost all modern models are equipped with stops with the ability to control the immersion depth of the knives, but this parameter should be clarified

4. The presence or absence of an automatic workpiece feeding unit, which has a direct impact on the processing accuracy.

5. Cost and availability of components, ease of changing knives.

Recommendations before purchasing

In addition to the listed indicators, before purchasing this equipment, it is worth clarifying the terms of its delivery and the validity of the warranty, visually assessing the quality of the coating and the integrity of the body, the evenness and grinding of the table (which is especially important when purchasing machines in used condition) and taking into account its dimensions when planning its location in the workshop, not forgetting the length of the facing boards. Errors when selecting the latter are typical; many users are based on the size of the assembled model or ignore the need of this equipment for a stable and level base that dampens vibrations.

For the same reason, it is worth considering the presence of rubber pads on the legs on thicknessing machines and their quality, overall rigidity and stability of the structure. For obvious reasons, household and portable models do not have multi-stage claw protection, but it is not recommended to skimp on the rest. Correct devices should have a blocking mechanism against ejection of workpieces, overload or accidental starting of the engine, simple and accurate adjustment of planing parameters, ideally with indication and/or the ability to visually monitor processes.

Recommendations for choosing a lathe

Price issue. The place to start when looking for a lathe is your budget. Since there are many professional models on sale, with the help of the upper price bar it will be possible to cut off complex high-performance equipment for metalworking plants

However, it is important to consider the functionality and completeness of the package. Otherwise, purchasing additional devices and equipment will cost a pretty penny.

Weight and dimensions.

Depending on the installation location of the lathe, the weight of the model and its overall dimensions are selected.

- The heaviest floor-mounted machines weighing more than 100 kg are intended for stationary use. They are characterized by good stability and processing accuracy.

- Mobile models are lightweight (30-80 kg); they can be installed on a table or workbench or moved to other rooms. Such models are not highly accurate, but are simple and easy to use.

engine's type

. All lathes are equipped with electric motors.

- Motors with a voltage of 380 V have the maximum power (up to 5 kW). But not all consumers have a power supply, which makes the scope of application limited.

- Models with 220 V motors have an affordable price and a wide range of applications. But such engines require smooth feeding, since they have a small power reserve (up to 1.5 kW).

Spindle speed adjustment.

Depending on the operation being performed, the turner selects the optimal operating modes of the machine. To achieve this, manufacturers equip their products with smooth adjustment of spindle speed. Typically the upper limit reaches 3000 rpm. Unfortunately, many household models with 220 V engines do not allow processing metal at low speeds (300-500).

The size of the workpieces. When choosing a lathe, you should know the size of the workpieces being processed.

First of all, it is important to take into account the maximum diameter of metal semi-finished products. Serious equipment can handle workpieces with a diameter of up to 350 mm when working on the bed and up to 200 mm when working on the support

For household models, these indicators look more modest.

Control

. To obtain a part, it is not enough just to turn on the lathe. You need to learn how to manage it.

- The simplest budget models are equipped with mechanical controls; the feed amount is determined on a metric scale.

- More modern models are equipped with a digital spindle speed display and automatic feed (longitudinal and/or transverse). These functions make the turner's work easier.

We have selected 11 of the best lathes for review. All of them are sold in the trading network of our country. When allocating places, the editors of the expertology magazine relied on the opinion of the expert community, taking into account the reviews of home craftsmen.