Every person who has used a circular saw at least once knows how difficult it is to make an even cut. To somehow simplify this task, some use a special guide. This design will help you make perfectly straight cuts. Create a guide for a circular saw with your own hands.

A circular saw is often used in the household for cutting wood.

Guide bar - what is it?

Before you create such a design yourself, you need to familiarize yourself with its main features.

A guide bar is a special rail that is responsible for sliding the saw forward and backward. At the same time, it limits the movement of the tool and therefore it cannot be directed to the left or right.

This device is used not only to ensure an even cut. It also helps reduce the number of chips in places where the saw came into contact with the wood being cut.

Additional Information! Sometimes guides are included with circular saws from Bosch and Interskol.

Criterias of choice

The existing selection of circular saws allows you to implement various approaches to obtain the required cut quality. It must be borne in mind that specialized saws for working exclusively with plexiglass are extremely rare.

Some types of circular saws with a guide bar

Almost all devices are multifunctional and are suitable for cutting other materials after installing a suitable blade configuration.

Circular saw 2000 W

A multifunctional and productive purchase for the home and small-scale production are 2 kW circular saws. They are suitable for cutting a wide range of materials, including plexiglass. Saws of this power are used as a stationary machine, since the increased dimensions reduce the possibility of remote work.

The 2000 W circular saw can only be used when powered by a mains cable. Portable battery-powered versions have lower power consumption and more modest performance. The power of the saw is more than enough to cut thick pipes or sheets of plexiglass more than 20 mm thick.

Circular saws

When comparing models of circular saws, you should pay attention to the following parameters:

- power , which naturally regulates performance, ensures longer runtime and allows the use of larger diameter discs;

- safety - modern versions of circular saws require simultaneous pressing of two operating levers (buttons). When one of them is released, the device automatically turns off, reducing the risk of injury to the worker;

- electronic control and monitoring mechanisms . Models with a built-in computer will be useful in industrial use, while in everyday life they will not be much more effective than simple circular devices;

- possibility of changing cutting angles . The ability to make cuts at different angles significantly increases the range of available products (aquariums, kitchen stands, transparent shelves, technical products, etc.).

Saw with set teeth

The quality of the resulting material and work productivity depend on the shape and size of the teeth. Classic blades have straight teeth running parallel to the saw blade. This arrangement avoids their damage and accelerated wear.

Blades with set teeth are used much less frequently in circular saws. Their main purpose is to increase work productivity.

The quality of the resulting cut turns out to be low, so discs with set teeth are usually used in the production of organic glass for interior openings, cottages, greenhouses, etc. Not very neat edges of the glass are covered with glazing beads at the installation site.

Guide rail functions

There are several main functions that these structures perform:

- increased accuracy when sawing large materials;

- improved quality when creating a curved cut;

- simplifying the creation of parts in accordance with a certain standard;

- the ability to manufacture several parts using one template;

- increasing safety when using circular saws.

Also, with the help of guides, it will be possible to make cuttings with high accuracy.

What role does the guide play?

The circular saw guide guides the sliding of the tool along the cutting line and prevents its deflection. The correct design of this part determines the even cut of the workpieces and the absence of defects in the processing areas.

When using a circular saw, the worker controls the movement process.

To comply with safety regulations, he must:

- securely fix the electric saw;

- secure the workpiece.

It is easier to ensure safety and quality of work using the second method. When the parts are not in the package with the saw, you can make them yourself.

Advantages of a homemade guide bar

The guide allows you to make straight cuts.

Many people think that homemade splints have no advantages. However, in fact they have a number of advantages:

- ease of use;

- repeated use;

- durability;

- versatility.

Homemade designs also have their drawbacks. The main disadvantage is that they are not easy to make. Therefore, to avoid problems, you need to figure out in advance how to make guides for a circular saw with your own hands.

External carriage on bearings

To make your work easier and get a better result, you can use a self-made circular saw carriage with bearings. By using a carriage, you will not need to worry about the tightness of manually pressing the saw to the workpiece, thereby greatly increasing its permissible width.

To make the carriage you will need metal plates and a corner. The cutting width is adjusted using wing clamps, which are installed in movable grooves on top of the carriage. The carriage is mounted on an aluminum profile, the configuration of which must ensure the fastening of a C-shaped clamp inside the guides. The saw foot is attached to the carriage on one of its sides.

A tire of this design allows cutting large workpieces. Thanks to the use of bearings, feeding is easy and smooth. This is done using a guide rod or hands.

Required materials and tools

Before you begin manufacturing the structure, you need to familiarize yourself with the list of necessary tools and materials:

- wooden blanks: boards, plywood, laminate;

- wooden bars with a thickness of 10 cm;

- self-tapping screws, screws, bolts or nuts;

- drill with drills;

- screwdrivers or screwdriver.

Additional Information! The above tools must be prepared in advance so that they are at hand while creating the guide.

Detailed instructions for manufacturing

To make a circular tire yourself, you need to familiarize yourself with the basic rules for its manufacture in advance.

From plywood

Plywood is often used to create a tire.

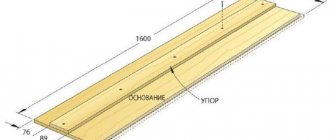

The plywood structure is made in several sequential steps:

- Disconnect the circular saw from the power source.

- Measure the distance from the saw blade to the groove located on the support platform.

- Cut the plywood strip so that its width is a millimeter less than the distance obtained in the previous step.

- Fasten the strip to a wide piece of plywood.

- Attach the second strip parallel to the base of the instrument.

Important! Before you make a guide yourself, you need to create a drawing with accurate calculations.

Aluminum profile tire

Some people want to make a more durable and high-quality structure. For this they use an aluminum profile. The only serious difference between such products and plywood is that a U-shaped aluminum profile is installed in the guide gap. With its help, it is possible to significantly increase the rigidity of the entire structure. Thanks to this, the cutting accuracy also increases.

When creating aluminum busbars, thick plywood is often used as restraints. However, it is better to install several fluoroplastic plates instead. This material is more efficient because it has a low coefficient of friction.

Other varieties

The construction rule is often used as a guide.

You can make a guide bar for a circular saw with your own hands from a miter box rail. Most often, this device is used for cross-sectioning materials. It consists of two corners that are connected in parallel to each other. Their ends must be attached to an iron or plywood base.

If the rail miter box will be used in a circular saw, it must be attached using metal pins or bolts. The structure must be installed higher so that it does not come into contact with the work surface.

Additional Information! Some people use a ruler from the building code as a guide bar. However, this design is not very convenient, since it must be configured before each use.

DIY accessories for a hand-held circular saw

This article discusses several simple but useful devices that the master made for his hand-held circular saw. At the end of the publication, for clarity, there is a video tutorial by the author of the channel “Do it yourself carpentry”.

This Chinese store is a haven for woodworkers.

The saw used is Boch GKS 165 CE. This is, first of all, a traditional standard rip fence included with almost any hand-held circular saw. The remaining devices are various guides. This is a device for perpendicular cross cutting and banding of workpieces. This is a guide bar for cutting sheet material. Two bars - probably the most useful auxiliary devices in the work are installation bars, which allow you to accurately place any guides, such as a straight-edge strip, a painting rule, any straight pipe or profile, or the factory edge of any sheet material. And finally, an adjustable guide for cutting at a given angle. I made all these devices with my own hands a long time ago, when, with the help of a hand-held circular saw and an electric planer, I learned the basics of carpentry and joinery during dacha construction. And they still serve faithfully.

Particularly useful for working with large, long material. That is, with long boards and large sheets that are inconvenient to process on a circular saw or miter saw. The first part is about the first three devices, as the most popular. The remaining two will be covered in the second part.

Products for inventors Link to the store.

So, the simplest and most common device for a hand-held circular saw is a standard stop, designed for longitudinal cutting of workpieces to a given width. But this fence has one drawback - to ensure safety, it is designed so as not to interfere with the operation of the saw guard. As a result, the stop does not allow cutting with a width less than a certain specified value. It is different in different models of circular saws. For a saw it is 22 mm. That is, with the help of this stop it will not be possible to cut slats with a thickness of less than 22 mm. Somehow I needed to quickly cut a large number of slats, 10-15 mm thick, for spacers between boards in a stack. The only tool available was a circular saw. It turned out that it was impossible to do this with the help of a standard stop. Therefore, I took the first block with parallel edges that came to hand and temporarily attached it to the stop with self-tapping screws. I've been using it ever since!

Using the workpiece, you can saw off slats of any width, up to several millimeters. When working with such a modernized fence, especially when sawing less than 15 millimeters, increased safety precautions should be observed. With a small sawing width, the protective cover rests against the block and does not cover the rotating disc. Therefore, when handling a saw, in order to avoid injury, you need to be extremely careful and attentive. Using the device is simple: set the stop to the required cutting width, secure the workpiece, press the block firmly against the edge of the board and guide the saw along the workpiece. Since such a stop can be installed almost close to the disk, replacing the pad with a longer one, about 40-50 cm, the saw can be used as an improvised jointer to quickly align the edge of the edged board. The result is quite acceptable!

DIY electronics in a Chinese store.

The next device is a guide for making perpendicular, transverse cuts.

It consists of the guide rail itself and a stop perpendicular to it. The cutting line is determined by the edge. The author of the idea has been using it for about 4-5 years, so the edge is very worn out, and soon we will have to make a new one. The device is made for a specific saw blade; I wrote down the parameters of my blade for memory. On the other hand, there is a guide for a manual router, with a 12 mm cutter, but it is used extremely rarely. He made this device to perform a specific job, namely to make carved columns for the terrace of his house. It was necessary to make many shallow perpendicular cuts on each side of the beam. Next from 5 minutes. And the continuation in the second part.

Additional guide bar functions

Using a guide bar, it is extremely difficult to damage the material being cut.

Such designs have a number of additional functions that you should familiarize yourself with before using a homemade guide bar for a hand-held circular saw:

- protects the sawn material from damage;

- allows you to adjust the exact length of the cut;

- significantly speeds up the process of sawing wood;

- securely fixes the wood to the work surface.

Additional Information! Both branded guides and homemade designs can boast of the above additional functions.

Features of plunge-cut saws

Depending on the design, a plunge-cut circular saw may have the following features:

- the presence of a tilt function of the cutting part. Used for the manufacture of wooden blanks of complex shapes;

- number of disks - 1 or 2 (in the second case, the boards can be made of different widths, making two cuts at the same time);

- the lower base is spring-loaded, which allows you to regulate the degree of clamping of the saw part, and if there are foreign elements in the workpiece (for example, nails, etc.), stop work in time;

- the presence of additional devices, such as guide rulers of various configurations and sizes.

Most models of submersible type saws, to prevent clogging with chips and wood dust, have a special socket for connecting a chip vacuum cleaner, which forcibly removes the cutting products.

How to adjust correctly

Before you start working, you need to properly adjust the structure. You will have to independently choose the optimal location and point for further fixation.

It is necessary to position the device so that its edge lies flat against the cut line and without distortion. After this, you need to adjust the placement of the saw blade. It must be torn off from the casing and aligned perpendicularly to the cutting line.

When the disk and guides are adjusted, the structure is fixed with clamps. This is done to minimize vibrations that may occur while the saw is running.

Important! To cut wood at an angle of 45 degrees, you will need to adjust the saw blade or adjust the angle on the bar itself. This must be done very carefully to avoid mistakes when adjusting the tilt.

Methods for cutting plexiglass

The most common methods for cutting plexiglass include:

- working on a machine with a circular saw is a convenient and functional way to cut polymer. The saw can be mounted on a guide rod that maintains the angle of inclination of the disc blade and the specified dimensions;

- cutting on a machine with a moving sheet of material is the simplest and cheapest mechanized way of working. The rotating disk is fixedly fixed on a support plate along which the material is fed;

- intermediate options obtained by combining available equipment and disk blades. There are special attachments for drills, made in the form of a shaft with a saw blade mounted perpendicular to its axis. The cutting blade is attached to the grinder instead of a standard abrasive wheel.

Conditions for obtaining a high-quality cut when cutting with a disk:

- maintaining optimal cutting speed. At low speed, the plexiglass overheats, which leads to clouding and melting of the edges of the cut. Too high a speed causes numerous chips to appear;

- use of discs suitable for a particular material. As the thickness of the polymer layer increases, it is necessary to use stiffer and thicker saws;

- supplying a soap-water emulsion to the point of contact between the saw and plexiglass during intensive work. This will reduce friction and accompanying overheating, resulting in the most beautiful and high-quality cut.

Useful tips

Blank templates make the work much easier.

There are several useful recommendations that will help beginners use a circular saw with a guide:

- It is necessary to use special blank templates. With their help you can quickly make identical parts.

- Before starting work, you need to adjust and configure everything in advance. Only with a properly configured tool will it be possible to cut wood efficiently.

- Do not work at the circular saw for too long. The tool must be turned off periodically to prevent it from overheating.

- The tire must be securely attached. It must not slide on the work surface. Bolts or screws can be used as fastenings.

- If, during sawing, the circular saw begins to sharply slow down, it must be turned off. This often happens when a tool works continuously for a long time and begins to overheat.

Important! If you need to cut an even cut, you must use a guide. Without it, it is quite difficult to do this.

A circular saw is an indispensable tool that allows you to quickly cut wood products. People who want to do quality work should use special guides. Such designs can be purchased or made independently.

Plunge saw "Makita SP6000"

In addition to the configuration of this model, there is something to brag about. The tool runs on household power, has high power, and has a large number of customizable parameters.

The Makita SP6000 plunge-cut saw with guide bar has a soft start function that allows you to perform high-quality cuts without much effort or effort from the operator. The design of the tool is equipped with an excellent sawdust removal system, which can be used even without connecting a vacuum cleaner.

Maintenance of the Makita SP6000 is so simplified that you can do it yourself. Users can easily cope with replacing carbon brushes and saw blades.

This plunge-cut saw with guide bar has a fairly compact and ergonomic design. The surface of the holder handles is rubberized, which makes the tool safe to use.