Are you faced with the task of leveling, raising or insulating the floor and you don’t know how to do it? Then you have come to the right place, because today we will look at how a floor is installed on joists and talk about its advantages and disadvantages. This technology has been used by people for a very long time, but it has still not lost its relevance. Of course, there are situations when it will not be possible to apply it - what we are talking about, you will understand after reading the entire article. So, let's go!

Floor on joists

What are lags for?

With most floor installation methods, the classic and often used one remains the option of using a structure made of logs. These are transverse supports that serve as a base on which the rough or finished finishing flooring is laid.

Purpose of the log:

- uniform distribution of load on the base base;

- reducing the deflection of the flooring;

- ventilation of the underground space.

The most popular material for logs is wooden beams or boards.

Timber and floor board

Tools

To install the beams, the following tools are required:

- electric drill or hammer drill;

- screwdrivers or screwdriver;

- electric circular saw or simple hacksaw for wood;

- plane;

- hammer;

- tape measure and level;

- fasteners.

Other tools may be required.

Log functions and requirements for them

Useful functions of the lag subbase:

- hiding utility lines;

- leveling level differences, achieving a flat horizontal surface for flooring;

- convenience in insulation - uniform placement of insulation into the cells without increasing the thickness of the base;

- sound insulation.

The structure of the floor on beams has sufficient rigidity for increased loads and laying of massive material.

Advantages of timber lag foundation:

- ease of repair of individual areas;

- maintaining the integrity of the flooring under seasonal influences of the external environment due to the same deformation properties of wooden elements - timber and flooring;

- insignificant load on supporting structures due to the lightness of the material;

- relatively low price of wooden beams.

With these positive qualities, it is worth considering that the lag structure reduces the height of the room.

Approximate indicators for reducing the height of a room

The log system refers to capital structures, and regardless of whether logs from boards are used or timber is used, the requirements for wood are:

- solidity;

- low resinity;

- absence of bark;

- low knotiness;

- lack of longitudinal-transverse curvature.

It is allowed to have a small number of healthy knots in the wood, fused with the base and not rotting.

The design features of the planned flooring system in a particular room and the type of flooring used determine the choice of logs - from timber or boards. Timber is used more often.

Important - the wood must undergo heat treatment (drying) in a drying chamber.

Advice from construction experts

It is necessary to build a support at the boundaries of the joints of the boards

It is recommended that the installed type of structure be solid and not consist of many sections, due to this the load-bearing capacity of the entire floor as a whole increases. It is necessary to build a support at the junction point. In general, it is best to secure the support in the form of a pillar. Usually the logs are connected using galvanized plates.

It is imperative to take into account the distance between the floor joists. Among experienced builders, the space used between two or more beams is designated as a pitch. Typically, the pitch size is directly related to the thickness of the black decking. The smaller the sectional size of the floor covering, the narrower the step between all the beams.

Using a special table located above, you can follow a certain sequence. If you use boards of increased thickness, then the distance will also increase proportionally.

Since a coating such as plywood is a resistant material, in this case the step must be increased. With a thickness of 20 mm, the step will be 42 cm. Each laid sheet should be secured to different logs. Do not forget about securing the edges and the center; in this case, you can extend to half the board. For all the details and useful tips on laying wooden floors, watch this video:

Everyone knows that logs are made from coniferous trees, because their resin content provides protection from moisture penetration and service life.

In order for the flooring on joists to be installed correctly in complex operational areas, it is necessary to use trees such as larch, because this type of wood has high moisture resistance.

Wood selection

Unplaned boards or timber made of deciduous or coniferous trees can be used under the logs.

Coniferous trees are cheaper, the most affordable are spruce and pine.

Coniferous timber

This material has sufficient strength, but is more susceptible to the destructive effects of a humid environment than hardwood. It would be justified to use pine needle material in heated, dry rooms.

Hardwood flooring is more expensive due to the higher price of the material. But a structure made from such wood has good biostability and is much better resistant to rotting processes.

The main disadvantage of this material is its low bending strength, so it is necessary to use logs made of deciduous trees with caution when large loads on the floor are planned. It is not recommended to use soft-leaved trees - linden and poplar.

Siberian larch combines all the beneficial properties for lags. This coniferous tree is not afraid of moisture and has good strength, which only increases over time. Even when building materials from Siberian larch are used in a bathhouse, the structure will last for several decades without loss of performance.

Siberian larch timber

Higher costs for such material are paid off due to its durability.

Wood moisture content

An important parameter of wood used in construction is humidity. It should not exceed 20%, the optimal value is within 12%.

There are several ways to determine the degree of saturation of wood fibers with water.

Visual method

The simplest, but not accurate, methods for determining the moisture content of a material can be:

- by sound when struck with a hammer: dry timber is louder;

- milling timber: when drilling, material that is too saturated with water leaves a wet halo around the hole, if it is overdried it smokes, but with normal humidity there are no traces left.

- removing thin shavings with a plane: the shavings of raw wood crumple, while those of dried wood, suitable for use, break and crumble.

- chemical pencil - on too wet wood, a line drawn with a pencil along a fresh cut will turn blue.

Knowing the type of wood, experienced carvers can determine the degree of its saturation with moisture by color, weight or transverse and longitudinal cracks.

Defective timber with high humidity

Calculation method

This method is based on weighing a test section of timber, before and after drying. The algorithm is as follows:

- At a distance of at least 30 cm from the end of the block, a segment up to 2 cm wide is cut out.

- The thoroughly cleaned section is weighed on an accurate scale, with an error of up to hundredths of a gram, and the resulting value is recorded.

- A piece of timber is placed in a dryer (chamber or oven) with a constant temperature within 100°C.

- After 5 hours, the sample is weighed and the result is recorded.

- Subsequent measurements are taken at intervals of 1-2 hours until there is no change in weight readings.

Next, the absolute humidity of the material under study is calculated using the formula:

W = (m – m0) × M0 × 100%,

where m and m0 are the mass of the test section before and after complete drying, respectively.

Using an electronic device

For instrumental, most accurate determination of wood moisture content, electronic moisture meters are used.

They can take measurements of any type of wood in various conditions. The principle is based on the dependence of the electrical conductivity of the material on the degree of saturation with moisture.

Needle moisture meter for wood

Contact (needle) and non-contact moisture meters are more often used in everyday life.

In the first version, the needles of the device are inserted into the wood and the moisture content is measured at this point, the readings are displayed on the indicator. Using the temperature correction table, updated wood moisture content results are determined.

Non-contact moisture meters analyze the dielectric constant of wood, based on which the percentage of moisture it contains is determined. The readings of these devices are not affected by the temperature of the wood and the surrounding air, so temperature correction is not required.

Using in practice knowledge about the moisture content of the timber from which the base for the floor is mounted is very important. Wood dried to normal values has significantly higher performance qualities:

- strength;

- resistance to decay;

- durability.

Structures made from damp wood create a greater likelihood of subsequent deformation, which can lead to damage to the flooring.

Floor deformation on wet timber

Some benefits

Lag installation diagram.

Laying the floor on joists has the following technical features:

- Thanks to the free space that forms the log, communication can be carried out.

- It is possible to raise the floors to the required level or level them.

- The floor finished with lag is distinguished by its structural strength. The beams can withstand up to 5 tons of weight.

- Installation does not require any special skills in the construction industry. You only need tools and accessories.

- Logs are characterized by their low cost. If you plan to do the installation yourself, you will save money.

What is lag? These are beams made of wood or polymer that are laid on a finishing surface. The versatility of such a beam is determined by the fact that it can be mounted on a wooden, reinforced concrete and earthen base.

What are the joists made of? The log is a beam that is made of metal, wood, plastic, reinforced concrete. However, wooden ones are especially popular.

Floor joist dimensions

Given the relative simplicity of installation of logs, it is necessary to carefully approach the preparatory stage associated with calculating the parameters of the beam and marking for its installation. The quality of the flooring, the reliability of its operation, and durability depend on this.

The basic data for the calculation are:

- Purpose and dimensions of the room.

- The type of base on which the beams are laid (screed, supports, foundation grillages).

- The location of the logs is one-sided or in the form of a lattice.

In corridors and walk-through rooms, it is better to mount the frame in the transverse direction to the movement. This will allow you to use a smaller beam.

Standard sizes

There are standard averaged values that are accepted for calculating the cross-section of the logs and the distance between them, in proportion to the span length.

Tables of ratios

These data can be used for refined calculations of the step between lags.

How to calculate size and section

To correctly calculate what size timber should be used for floor joists, you need to measure the dimensions of the room and choose the direction of laying the joists - along or across,

To compensate for seasonal expansion of the tree, the length of solid bars or a prefabricated structure is taken several centimeters less than the distance between the walls, perpendicular to which they are laid.

The choice of cross-section or thickness of timber is influenced by:

- wood material;

- thickness of the future flooring;

- distances between spans or beam support points;

- indoor traffic intensity;

- possible loads on the flooring.

For residential premises, the nominal value is taken to be a load of 300 kg/m2.

If the length of the room is less than 2 m, you can use logs with a cross section of 100 × 50 mm.

The optimal beam is considered to be one whose supporting edge is 1.5-2 times its width.

Standard timber

The advice is to choose logs with a margin in cross-section, taking into account the thickness of the insulation and the load.

Select pitch between joists

When making a more precise calculation of inter-lag distances, the height of the flooring and the load on it must be taken into account. The recommendations indicated in the table are given for empty rooms, therefore it is necessary to make appropriate amendments, depending on the specific conditions:

- In rooms with furniture (bedrooms, living rooms), with the same thickness of the flooring, the given walking distances are reduced by 5-10 cm.

- The thinner the flooring, the smaller the step.

Example. If the floorboard is 2 cm thick, then the distance between adjacent beams should not be more than 30 cm. For each increase in the thickness of the coating by 5 mm, the step can be increased by 10 cm.

Base made of concrete and reinforced concrete (laying on an uneven base)

Before installing the logs, the uneven concrete floor is leveled with a cement screed. This technology allows you to make a smooth and reliable base for parquet, laminate or floor tiles, as well as well insulate the floor and protect the room from external noise.

For most floor coverings, a spacing between joists of 60 cm is suitable, but floor tiles require cells measuring 30x30 cm because they are very fragile.

Reinforcing mesh in the screed and spacers between the beams increase the rigidity of the floor. Thermal insulation material can be placed in the resulting cells.

Installing floor joists

Despite the fact that logs, most often, do not directly interact with the external environment, wood is a material that requires protection, therefore, before installation, the timber must undergo antiseptic and fire-resistant treatment.

Preliminary antiseptic treatment of timber

The best strength of the joist structure for all types of foundations is achieved by installing the beam on the edge.

Various methods of installing lags also have some peculiarities of performing this work.

Installation on wooden floors

The most common type of flooring in a home is the ceiling on load-bearing beams. The construction of wooden logs on such load-bearing elements is considered very reliable for the entire floor. The method of fastening the beams depends on the type of beams:

- Rectangular or square.

- Round.

The evenness of the floor is achieved by leveling the beams themselves or by using joists.

Attaching to beams

If it is not possible to align the beams exactly, the beam is attached to their side. This method provides the best leveling of the entire structure horizontally, without the use of adjusting supports or pads.

Lateral attachment to beams

1 - Bearing beam.

2 - Lags.

3 - Self-tapping screws.

The timber is attached to the beams with self-tapping screws, a length 2.5 times greater than its width.

Laying across beams

Good rigidity of the system is obtained by laying the logs across the wooden floor.

The sequence of laying such a base is:

- bars are laid on opposite sides of the ceiling;

- each of the bars is leveled horizontally;

- the bars are aligned with each other in the same plane by placing wooden wedges or metal plates under one of them;

- the remaining crossbars are laid along a cord stretched between the control logs.

This option makes it possible to use a bursa with a smaller cross-section.

Transverse installation of logs on beams

The beams are connected to the beams with self-tapping screws or using metal corners.

Depending on the type of wooden floor, there are different requirements for the use of insulating materials:

- On the interfloor structure separating residential areas, it is enough to lay sound-absorbing material (this can be a subfloor made of chipboard or OSB) and install a vapor barrier. As a vapor barrier membrane, you can use a polyethylene film, which is attached to the beams with an overlap of 15 cm.

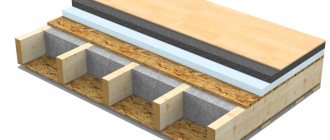

- A “pie” is created on the wooden floor separating the living space from the basement or attic.

Its main function is to cut off the cold coming from unheated rooms or the basement.

Wooden floor pie

The thickness of the insulation layer and insulating materials are selected depending on the specific requirements for the flooring.

Installation on concrete

When installing joists on a concrete screed, you must adhere to the following sequence:

- Prepare the base - clean it from dust, treat it with a primer.

- Place the waterproofing material with an overlap of at least 15 cm on the walls and between the rolled sheets, and connect the joints tightly with tape.

- Align the logs horizontally, secure them to bars against opposite walls, at a distance of 3-4 cm from the walls.

- Pull the beacon cord between the control logs.

- With a calculated step, lay other beams on the base.

- Drill holes in the concrete for dowels or anchor spacers, at a distance of no more than 70 cm from each other, fix the bars on the screed.

Achieving the correct level of the base along the beacons is done with wooden posts, plastic wedges or the use of bushings that regulate the height of the beams.

Adjustable lags on bushings

Installation on the ground

Before the finishing coating, insulation and vapor barrier material is laid between the joists.

As an option, the step-by-step technology for laying lags on a soil base looks like this:

- Compact the soil well and level the base.

- Fill and compact a drainage layer of sand, gravel or granite chips.

- Make a foundation for the support columns - fill the wooden formwork with a layer of concrete, with a reinforced mesh.

- Cover the hardened concrete with roofing felt and lay out support columns from bricks.

- For waterproofing, lay roofing felt (2-3 layers) on the posts and coat with bitumen.

- Place the logs on posts and secure them.

You can install skull blocks between the joists or make a bottom lining for laying the subfloor.

Column mounting

Waterproofing (roofing felt or film) is laid on the rough base and any type of thermal insulation material is laid. The insulation is separated from the finished floor by a vapor barrier membrane.

General recommendations

Make sure the wood is dried and treated with antiseptic or bitumen.

This will significantly extend the service life of the structure. When the humidity is more than 20%, the tree can become warped, compromising the integrity of the structure. Boards brought from a warehouse should lie at room temperature for several days. This is especially true during the winter season. It is not recommended to lay the floor when the air humidity is less than 60%. You should not saw or plane boards in the room where the floor is being installed. Sawdust can cause rot.

Use the rule after installation. Lay it across the beams, remove gaps, leveling the height. This is easy to do with the help of special modern adjustable fasteners that have appeared on the construction market. The floor is laid only after all leveling procedures.

The smaller the pitch, the longer the floor will last. However, the main indicator of durability is the material of the coating and base. The most durable wood is larch.

The installation of beams is usually carried out along the window, i.e. across the room. The floor boards are then placed along the length of the room, i.e. from the window. However, this is just a recommendation and a matter of taste.

A board is attached to each beam. Holes for screws should be drilled in advance to avoid delamination.

The most common option for the space between the joists is from 50 to 56 cm. As a rule, it does not exceed a distance of 69 cm.

Removing joists and wooden floors is quite simple. It is necessary to remove all the furniture from the room, remove the baseboards, and open the boards or sheets of chipboard. After inspection, the old boards are replaced with new ones. The logs themselves can be partially replaced. Simply cut out a piece of rotten wood and install a new one.

Don't forget to use a protective impregnation on new boards. Check the ends of the beams for rot, and inspect the base insulation, if any. Repairing the floor can be a reason to insulate your home.

How to strengthen genital lags

Reinforcement of the joist system is carried out to increase the safety margin or strengthen its individual sections if they are damaged.

There are several options for strengthening:

- installation of one or more additional supports under the beam, first leveling the system in a horizontal plane using a jack;

- installation of wooden or metal plates on one or both sides of the beam, fastened with bolts and washers;

- replacing the damaged area with a prosthesis made of a metal rod or channel;

A modern way to strengthen the beams is to reinforce the timber with carbon fiber, fixed with epoxy glue.

Reinforcement of beams with carbon fiber

Carbon fiber is glued in several layers until the required rigidity of the beam is achieved. Light weight, which does not burden the structure, and ease of operation make this material popular.

Installation of boards

After installing the joists, you can continue laying the floorboards. For aesthetic reasons, it is best to start the entire process from the wall with the window.

- The boards must be fastened with screws, the thickness of which should be twice their thickness.

- After attaching the first boards, install the next ones.

- After installing several pieces, insert insulating material - mineral wool into the gap between the floor and the boards.

- Repeat the process until the entire floor is covered with planks.

The penultimate step is to place finishing skirting boards at the corners and joints. They must be glued to the floor with wood glue. Make sure they fit snugly against the wall.

Finally, you should sand the floor surface twice and paint or protect it with varnish. Instead of varnish, you can also use stain or oil, which not only protects the floor surface, but also gives it a deeper color.

Mounting methods

Previously, logs were simply attached to a concrete slab or beams with nails. Not the best and not long-term method was replaced by fixation using galvanized metal corners. The instructions on “how to attach joists to the floor” read:

- The corners are fixed with self-tapping screws. One of the planes of the corner is attached to the beam. The depth of penetration of the screw into the beam is 3-5 cm. The corner is attached to the beam of the bottom frame in the same way. To a brick support or concrete grillage, which must be covered with a layer of waterproofing, fastening is done with dowels.

Instead of a corner, a U-shaped fastening device can be used.

U-shaped device used to fasten the beam

It often happens that the standard length of the timber is not enough. Elements can be joined in two ways:

- close to each other; by cutting, called “into the floor of a tree”.

Attention. The joints should be strengthened by nailing 1 m long pieces of lumber to one, or better yet, two sides of the beam.

Methods for connecting timber into a log floor

When installing the beam, the distance between the connection points of the beam should be at least 50 cm.

Video example of the work

It is not very easy to construct a multi-layer floor pie on wooden joists, but it is precisely this that significantly reduces the construction or repair budget. In addition to minimizing material consumption, the pace of finishing production is also increased. Thorough adherence to the technologies for arranging this floor construction scheme and compliance with the recommendations guarantees long-term operation and aesthetic appeal.

- Author: Alesya_SAPrint

Sources:

- www.supersadovnik.ru

- www.laser-level.ru

- 1poderevu.ru

- pol-master.com

There are no similar posts, but there are more interesting ones.

Geometric guidelines for installation

Orientation in space is a significant component of the correct floor arrangement. Those who want to know how to lay joists on the floor correctly should follow the following building rules.

- The flooring of boards in rest rooms and living rooms is carried out along the direction of the flow of natural light. The logs are arranged “cross” to the direction of the boards. In vestibules, hallways and other rooms with heavy traffic, the boards are laid according to the direction of movement, the logs, naturally, in the direction perpendicular to the direction of the flooring elements.

The logs are laid “cross” to the floor boards

Note. If the floor structure is strengthened by installing two layers of timber, the top layer is laid “cross” to the previous one.