A frame house is built very quickly. This is a simple and reliable technology, which is why it is very popular now. But the floor arrangement in a frame house is somewhat different from that in a classical building. It begins to be done immediately after the foundation is poured, and only then the walls and roof are erected.

Do-it-yourself floor of a frame house: what is needed for this

First of all, before starting construction, a project plan must be created according to which the house will be built. When the project is ready, the necessary tools and materials are purchased. To build the floor you will need the following:

- hammer;

- plane;

- chisel;

- Circular Saw;

- pencil;

- plumb line;

- level;

- screwdrivers;

- ladder;

- drill with drills;

- tassels.

It is important to make the floor strong, reliable and level, because it will support the entire house, including walls and other parts. The floors in a frame house on stilts, where the foundation is made in the form of metal pipes, and the entire structure rests on them, should be especially strong.

Before starting construction, you need to find out at what depth the groundwater lies. This will allow you to decide how many layers are needed - one or two.

Pie designs

First, a subfloor is made, which is also the ceiling for a frame house. Floor beams are secured to the foundation frame. At the same time, make sure that there is a layer of waterproofing between the foundation and the wood so that the wood does not begin to decompose due to natural humidity. To do this, lay a double layer of roofing felt or waterproofing material.

Next, they make the load-bearing base of the floor, using either only the main beams, or both the main and secondary beams.

Secondary beams or logs in a frame house are used to ensure that the pitch of the main beams is large. But at the same time, the consumption of materials increases, the thickness of the floor increases, and more work needs to be done.

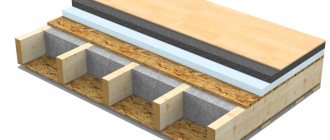

If there are no secondary beams, the main beams can also be used as joists. Then the floor pie looks like this (from bottom to top):

- cranial bars with a section size of 50x50 mm, fixed to the load-bearing floor beams;

- layer of boards - filing;

- protective elements from wind and moisture;

- load-bearing beams, between which there is insulation inside;

- vapor barrier layer;

- rough flooring made of boards or thick chipboard.

Video description

The rigidity of the structure is ensured by additional spacers, the length of which must correspond to the pitch of the joists (minus their thickness). How Larry Hong does this can be seen in the video below:

Racks and joists in one fastening unit Source stroiremdoma.ru

- The logs are attached to the strapping beam, for which special slots are made.

- The logs are attached to the frame beam on the inside using special brackets.

There is no clear opinion regarding the lag layout step.

A more “economical” option is 600 mm. And if we talk about the axial distance, then taking into account the thickness of the lag - 625 mm. But some experts recommend a pitch of 400 mm. And although the mats will have to be cut when insulating with mineral wool, the structure of the subfloor will be much stronger.

Important! In places where heavy equipment is installed (stove, fireplace, floor-standing boiler with boiler), the layout (step) of the log is further reduced.

What is a subfloor

This is a plank covering that is located in the space between the joists and provides a level surface for the installation of the finished floor covering. The construction of the subfloor involves the use of insulation, which makes it possible to additionally heat and sound insulate the building from below. And only in the attic is the rough flooring made the main one, since there is no need to spend extra money on parquet, laminate or floor boards.

When choosing a material for a subfloor, only minor attention is paid to quality, so you can purchase inexpensive types of wood.

The subfloor experiences almost no load. On top of it there can only be a layer of insulation (it is very light), as well as a front covering. After all the installation work is completed, it itself will be completely hidden, so its appearance is also unimportant.

Frame house floors

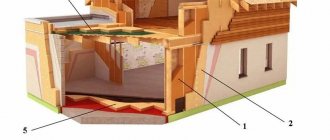

In frame buildings, a wooden floor between floors is made of beams, the height of which is 150-250 mm. The pitch between the beams is 60 cm. Thanks to the use of such floors, the load is distributed evenly. Thermal insulation of the floor is carried out when installing the rough flooring.

The ceiling between the basement and the first floor is usually made exactly the same as the rest. To do this, the subfloor is installed on logs that stand on stands. This allows the weight of the entire structure to be transferred to the foundation. Thanks to this method, less materials are consumed and the requirements for wood are reduced, so this solution is used most often and is even considered classic.

The insulation layer is laid in the same way as for interfloor coverings. Therefore, the principle of installing a subfloor is the same for all levels.

Useful: Ceiling in a frame house

Preparatory work

The technology for installing the floor in the structure under consideration involves the creation of a two-layer structure consisting of a base and direct wooden materials. Traditionally, flooring is laid on joists or on top of floor beams. When choosing a specific method, you need to take into account, first of all, the features of the room being equipped and its location.

Before use, all wooden components are impregnated with special antiseptic and fire retardant agents. The base of the future floor structure must be waterproofed. Penofol is perfect for this job. If you do not have a sufficient budget, you can also use plastic film.

penofol

Subfloor and floor joists

From under the base the house can have a negative impact due to its proximity to the soil, high humidity, etc. Therefore, when the lower floor in a frame house is close to the foundation or to the ground, the wood is isolated from concrete, brick or soil. This reduces the likelihood of condensation and also prevents wood decomposition.

The materials used in the construction of the coating must undergo similar treatment. Waterproofing work is quite simple, you can do it yourself. The waterproofing layer must be laid before installing the insulation to prevent it from becoming damp and destroyed.

Why is it better not to use a tile screed?

Reinforced concrete slabs are used to construct such a floor. Such a floor requires additional ventilation in the foundation - it is necessary to form vents.

It is better to make them through for sufficient ventilation under the slabs. The minimum height from the ground to the bottom of the slab should be half a meter. Therefore, the foundation must be high enough.

Using slabs for flooring

For low-lying foundations, which are most often built for frame houses, this type of screed is not suitable.

Moisture emanating from the soil will lead to premature destruction of the slabs, making their operation unsafe.

To lay the unused part of the foundation, it is necessary to lay it with bricks, which leads to additional costs and difficulties in the work.

Foundation with vents

That is why it is better not to use dry tile screed for frame houses.

Use of bulk aggregates

Bulk insulation of frame houses is very popular, because with the help of various substances (slag, sawdust, perlite, expanded clay) you can fill the entire space between the beams. Such flooring can withstand even increased loads.

Loose aggregates are typically used to fill the basement of a frame house when the subfloor is installed on joists. It is enough to install cranial bars 50x50 mm, as well as OSB 15-20 mm thick, and this design will be enough to withstand large expanded clay or other thermal insulation materials.

This type of insulation is convenient in that it is carefully distributed over the base until the desired thickness is achieved. You can fill it yourself, which allows you to save a lot at this stage.

It is better to use heavy filling materials only on the basement floor, so as not to load the building structure with additional weight.

Instead of expanded clay, you can also use ecowool. This insulation is of organic origin, it is very light, so it does not overload the frame. As for other fillers (sawdust, perlite), they are either very expensive and rarely used, or are considered an outdated option.

Laying vapor barrier - types of materials

A vapor barrier layer is necessary to prevent moisture from entering the floor structure from inside the room. This is quite possible in case of plumbing accidents. Thermal insulation materials, if wet, dry very poorly and lose their ability to retain heat. Such insulation is installed using polyethylene, polypropylene, and breathable diffuse membranes.

When laying polyethylene, which is absolutely impenetrable, and polypropylene, leave a 7-10 centimeter gap between it and the insulation to ensure ventilation.

Membrane films form a high-quality and durable coating and allow the room to breathe. In addition, laying such a film does not require a ventilation gap between it and the insulation, which is required when using other materials.

When installing, it is important to ensure correct installation. If the film contains the manufacturer's branded inscription, it should be on top; the metallized film is laid with foil up; in other cases, the film is laid with the smooth side facing the insulation, unless there are additional recommendations from the manufacturer.

Installing the membrane film on the wrong side will give it the ability to transmit moisture to the insulation and will devalue all the efforts of the builder. An overlap when laying a vapor barrier is required, and the film can stick together or “weld”. The vapor barrier material must be placed on the walls around the perimeter to a height of 15-20 cm. It is attached to wooden elements using nails or staples and mounted without sagging.

If vapor barrier materials are used, it is necessary to provide good ventilation in the rooms to avoid increased humidity.

Piece and roll insulation

This type of insulation includes mineral wool and polystyrene foam. They have the advantage of minimal volumetric weight. These materials need to be used in small quantities to make the house warm (the middle layer is 10-15 cm thick).

Therefore, such insulation does not create a serious load on the floor frame. To install it, it is enough to additionally use only thin boards or even particle boards, which are installed on thin skull blocks measuring 30x30 mm.

Polyurethane foam insulation can also be applied to the resulting floor covering. Although this option has many disadvantages (the need to involve strangers and equipment, the high cost of materials), this insulation is considered the best option for insulating a subfloor on a basement floor.

As soon as the foam finishes forming, a continuous volumetric coating is obtained, which has sufficient rigidity and the ability to protect the structural element from high humidity and other negative phenomena.

How to make a floor with your own hands: step-by-step instructions

Even if you are not going to do the construction yourself, study the algorithm to properly control the performers.

Preparing to create a floor in a frame house

First, check whether the foundation is level. To do this, measure the height of different sections and check the diagonals. If there are inaccuracies, they are eliminated. Next, holes are made in the foundation along the perimeter of the building and anchor bolts are installed there to secure the beds.

Then the foundation is waterproofed by coating it with an appropriate solution or installing a waterproofing film.

Laying the beds

Floors are boards or beams that are secured with anchor bolts along the entire perimeter of the building. They must be level and fastened securely and accurately. The requirements for the beds are that they have a thickness of at least 50 mm and a width of at least 150 mm.

Next, install the beds:

- Lay the boards directly on the concrete slabs and mark where to cut off the excess.

- Calculate the best places to drill bolts

- Preparing holes in concrete.

- Lay waterproofing

- Install the boards and secure them with anchor bolts. After installation, check that the horizontal plane is maintained. If it is not there, the work is adjusted.

Floor supports and beams

Beams are the main supporting elements that support the entire floor structure of a frame house. They must be treated with protective agents.

Useful: Wind protection of a frame house

Installation is performed as follows:

- Mark on the house plan exactly where the supports will be located and what their height will be. Then they install the supports and pull the string to make sure that everyone is the same height.

- According to the measurements specified in the first paragraph, cut a beam with a cross-section of 100x100 mm and place it in the areas indicated in the plan. A waterproofing layer is laid under the timber. Secure the supports with nails.

- They begin to place the beams with their ends in the pocket. To install them in height, special inserts are used. It happens that workpieces turn out longer than expected. Then the excess is cut off. And if the length is insufficient, the beams are joined on the support.

- The beams are secured to the beams using corrugated nails. If their height exceeds 1 m, it is necessary to use wooden slopes.

Strapping and logs

To perform the strapping, boards with a thickness of 50 mm are used. The width is determined depending on the thickness of the insulation and the expected load. The installation is done like this:

- Lay the trim along the sides of the house, installing the boards parallel to the floor beams. Place the material on the end, aligning it with the outer edge of the bed, and then hammer it in with nails in increments of 20 cm.

- Mark where the logs will be located. To do this, measure 40 cm from the strapping board near the corner. The boards for the joists are immediately placed on the beams and placed on their sides, aligned according to the markings.

- If the board is long enough, similar markings are made on the opposite side. The logs are trimmed and secured to the beams and strapping, as well as to the beams if they intersect them.

- If the length is insufficient, overlap the joint. The joint must be on the floor beam.

Floor insulation

It is best to insulate the floor in a frame using mineral wool. It has only one drawback - loss of thermal insulation properties when wet. Therefore, it is important to make high-quality hydro, wind and vapor protection.

If the density of the insulation is small, a liner treated with bioprotective agents is installed under the joists.

- They begin to sew a waterproofing membrane across the joists. All joints are sealed with tape, and the film itself is attached to the wood with a stapler.

- Insulation is placed between the joists so that there are no gaps. With a double layer of insulation, it is necessary that it overlaps.

- A layer of vapor barrier is laid on top of the insulation and also secured to a stapler. It is needed to prevent the insulation from getting wet due to moisture that may come from the house.

Selection of structural elements and materials

The reliability, durability and thermal efficiency of the floor largely depend on the materials used. Let's consider acceptable options and indicate unacceptable solutions.

Attention to the quality of floor beams

In frame house construction, wood is mainly used for tying screw piles. Usually softwood lumber is used: larch, pine and spruce.

Useful: Wood impregnations: effective compositions for interior and exterior work

The main requirement is the use of dried materials. The moisture content of the timber should not exceed 12%, otherwise deformation of the structural parts may occur after their installation.

Arrangement of the grillage is possible in several ways:

- Laying a monolithic beam measuring 20*15 cm. When constructing a two-story house, you can use a beam 20*20 cm.

- Grillage made from assembled boards. A budget option. Each beam is formed from two to three boards. The output should be a beam with a cross section of 20*15 cm.

When the boards are securely fixed, the “batch” method is not inferior in strength to strapping made from solid beams.

Bottom trim options

When choosing material for the base, you must remember that it is not advisable to overload screw piles. Therefore, the skin should be strong enough, but not heavy. Its main task is protection from wind and moisture.

What's suitable? Here are several options:

- OSB. An affordable material that has good strength, but is vulnerable to water. Before installation, it requires treatment with a composition designed to protect wood. The weak point is the joints of the slabs. They must be coated with acrylic sealant.

- Chipboard. Easy to process, but like OSB it is vulnerable to moisture. Inferior to the previous material in terms of environmental friendliness.

- Multilayer plywood. It is permissible to use only moisture-resistant sheets marked FK or FSF. The composition contains formaldehyde resins - they increase the resistance of the material to aggressive environments.

Very often, ordinary flooring made of boards with a cross section of 5*10 cm is used to install a subfloor. This option cannot be called economical, but its strength and environmental friendliness are beyond doubt. The main requirement is pre-treatment of the wood.

Insulation is the basis of floor insulation

When choosing a thermal insulation material, the main focus is on the possibility of its operation in a humid environment. The most rational solutions:

- Mineral wool. The best solution is basalt fiber mats. Pros: environmentally friendly, non-flammable, low thermal conductivity, resistance to deformation, minimal water absorption - 2%. Over time, stone wool shrinks by only 5% - with proper installation, cold bridges do not form at the joints with the joists.

- Extruded polystyrene foam. Leader in insulating properties. Additional advantages: elasticity and resistance to deformation, lack of water absorption, biostability, ease of installation. Disadvantages: high cost and flammability.

- Expanded clay. A budget alternative to sheet insulation. It is somewhat inferior in thermal insulation characteristics to mineral wool and expanded polystyrene. An important plus is fire safety.

Foam plastic is sometimes used to insulate the floor in a frame house on screw piles. Main advantages: good thermal protection and low cost. However, upon contact with moisture and under the influence of low temperatures, the material loses its structural integrity. This solution is applicable in warm regions.

Warm floor in a frame house

When planning a frame house, you need to immediately decide whether it will have a heated floor, and if so, where exactly (for example, in the bathroom, throughout the house, in the living room, etc.). After all, heating equipment must be installed in advance, at the stage of floor installation.

There are many options for underfloor heating, so you need to explore them and determine which one is right for you.

To organize a heated floor system for water heating, plastic pipes are used, which are laid inside the ceiling throughout the house and organize a system control center to regulate the operation of all elements.

With electric heating, it is most economical to use infrared heated floors . It consumes less electricity than cable, is easier to install and is more convenient to maintain.

How to save money on flooring

In order not to spend a lot of money on organizing the ceiling in a frame house, you can use one of the following methods:

- the use of wood that has already been in use;

- using door panels instead of boards.

Not new boards are no worse than newly purchased ones. Moreover, they are already dried, so their use is sometimes considered more profitable. Moreover, such a board is several times cheaper than a new one.

As for door panels, this is also the best option. They are smooth, durable and no worse than a rough board. A finished floor (for example, a parquet board) will be installed on top, so no one will know that you have a lot of door panels below. But this will allow you to significantly save on material without losing quality.

Floor insulation - important details

Before starting the insulation procedure, it is necessary to carry out preparatory work. To do this, you will need to nail support bars measuring 50x50 mm to the side of the bottom of the joist. They need to be tapped along the entire length of the joists. The next step is to lay the bead using an uncut second-grade board. It is recommended to pre-treat it with antiseptic materials.

The thickness of the boards in this case should be 25 mm. OSB can also be used for this purpose. To make the wooden skeleton pie more durable, we recommend nailing the roll to the support bars. Next, it is necessary to cover the constructed wooden flooring with a waterproofing membrane. It is not recommended to use conventional waterproofing or vapor barrier films for this purpose.

A membrane with a steam transmission capacity of more than 850 g/m2 is best suited. Such material will protect the insulation from moisture, and at the same time the wooden “pie” of the floor will be able to breathe freely. Now you can begin laying the insulating material. It is recommended to use breathable insulation materials. Mineral basalt wool is most often used.