In a frame house, as a rule, there are 3 types of such structures: basement, interfloor and attic.

They are subject to various forces, and therefore their arrangement is carried out differently.

What types are there?

Flooring for frame-type house construction is a load-bearing structure that divides the free space of an object into separate zones in height, forming floors.

As a result, they are divided into basement, interfloor and attic.

Regardless of their location, their design must meet regulatory requirements, not be very massive and expensive , and in addition, meet regulatory criteria:

- in terms of rigidity, strength and reliability;

- have no deflections along the length;

- have excellent sound insulation and noise protection;

- have high resistance to heat loss;

- All components of the floor must be fire resistant.

Tsokolnoe

The basement floor is a building structure that isolates the basement of the house from the rooms on the 1st floor. It is formed before the construction of wall structures begins. Before installation, 2 layers of waterproofing are performed on the surface of the foundation . To create a powerful structure, double tying with lumber 150*150 mm, or 100*150 mm in one-story houses, is also used. Next, logs made of 100*150 mm timber are installed on the edge with a step between the beams of 80 cm.

Between floors (first, second)

An interfloor ceiling is a building structure between two floors, which serves as a ceiling in one lower room, and as a floor in the second upper room. They must have high structural strength, so high-grade lumber of increased cross-section is used for installation.

Experts advise choosing beams with a rectangular cross-section with a height to width aspect ratio of 1.4 to 1. The permissible dimensions of beams for interfloor floors are allowed in width from 50 to 200 mm, and in height - from 100 to 300 mm.

The distance between the beams is taken from 40 to 120 cm, the dimensions of the heat-insulating boards and lining elements must coincide with the pitch of the racks in the frame structure.

Important ! When choosing the standard size of lumber, the height of the beams is chosen so as to exceed the thickness of the insulation.

Attic

The attic floor is designed to protect living spaces from heat loss and is made quite durable so that it is safe to walk on it, place furniture and household equipment. It is made from almost the same lumber as interfloor ceilings, but more attention is paid to thermal protection, so it will be necessary to install thicker insulation of 100 mm or more, according to the calculated heat loss.

A vapor barrier must be placed on top of the heat insulator layer in order to prevent condensation from entering the heat-protective material. A boardwalk is installed on it for transitions through the attic space during roof installation and maintenance.

Selection of soundproofing layer:

- Fibrous materials, due to their structure, absorb most of the noise created. This material can be ecowool, mineral wool, balsam wool. In addition, at the same time they act as an effective insulation material.

- An additional layer of noise insulation can be provided by forming a subfloor using chipboard or OSB, while there is no fastening to the joists - the plates are attached to each other with nails or self-tapping screws. In the version of a house made of timber, they are subject to their own weight, and due to the absence of attachment to the main structures, the noise level is significantly reduced.

- Roll insulation, like felt, will help prevent sound penetration between the ceiling and the load-bearing wall, between the ceiling and the chimney.

- There are special foil films that are used when arranging the floor, which help to significantly reduce the number of perceived unpleasant vibrations.

Wooden floors in a house can be made of brick or aerated concrete, regardless of the wall material, they need sound insulation.

A common mistake when arranging a home is saving on joists, which can lead to an insufficiently strong floor frame as a whole, and, accordingly, sagging and vibrations of the floor/ceiling.

In the corners of the rooms, as a rule, there are through channels for ventilation. It is important to correctly follow the layout of their placement, not to arrange them on top of each other, otherwise even the best sound insulation will permanently deteriorate.

Standards and requirements

The basic document that regulates the standards for the construction of floors of these types of housing construction is SP 31-105, published in 2002.

Their design is chosen during the design process of the house and is directly dependent on the dimensions in plan and the greatest load created by its main structural elements.

It is allowed to arrange ceilings on beams, ribs, or to combine 2 modifications simultaneously in the same structure. This universal design can provide a span of up to 15 m. The beams of this option are laid with a large stroke and are fixed perpendicular to the placed ribs. For connections, steel clamps, construction staples and threaded fasteners are used .

It is allowed to set the span of the structure from 6 to 15 m. There are restrictions on the cross-section of the beams, for example, for the second floor, they must have at least 150 mm. When installing floors, the developer must comply with the following standards:

- The minimum distance from the chimney to the adjacent beam is 40 cm to ensure fire safety.

- The wood used for the installation of floors should have a moisture content of no higher than 8-12%.

- When installing a basement floor over an unheated basement, 50*50 mm bars are nailed to the bottom of the beams, onto which the thermal protection of the floor is laid.

- Interfloor ceilings can be without thermal insulation, but for sound insulation it is necessary to lay a layer of sand of at least 50 mm.

- All wooden structural elements are treated with antiseptics and fire-fighting compounds.

- Floors must be able to withstand temperature fluctuations, especially in the basement and attic, and not absorb room moisture.

Important ! Strength characteristics depend to the greatest extent on the high quality and cross-sectional size of the beams and beams. The cross-section depends on both the length of the spans and the spacing of the links.

To select the correct dimensions, the developer should be guided by the following table.

Preparatory work

The technology for installing the floor in the structure under consideration involves the creation of a two-layer structure consisting of a base and direct wooden materials. Traditionally, flooring is laid on joists or on top of floor beams. When choosing a specific method, you need to take into account, first of all, the features of the room being equipped and its location.

Before use, all wooden components are impregnated with special antiseptic and fire retardant agents. The base of the future floor structure must be waterproofed. Penofol is perfect for this job. If you do not have a sufficient budget, you can also use plastic film.

penofol

What materials and beams are they made of?

Coniferous wood, oak and larch are used for flooring. Pine, oak and larch are considered the most resistant to decay .

Types of materials used for floors of frame house construction:

- Standard board 200-300 mm wide.

Advantages: it functions well against deflection, has less deformation and cracks, and is an inexpensive lumber. - High-strength laminated veneer lumber is many times stronger than regular wood.

Advantages: significant length up to 12 m, the ability to evenly distribute the load, excellent strength and resistance to bending, dry material, has a long service life. Disadvantage: high price. - I-beams are the most reliable type of flooring on which conventional flooring can be laid.

The bottom is covered with plasterboard. Advantages: highest strength, ease of installation, versatility, can be used for any type of premises. Disadvantage: high price. - Attic trusses H = 350 mm - beams from ready-made wooden forms 100x50 mm, obtained by pressing.

There are metal plates installed inside that connect the structure into a single whole. It is allowed to place engineering communications inside such connections. Advantages: high strength, durability, ease of installation and the permissibility of internal placement of utilities. The disadvantage is the high price. - LVL beams are a new material for floors in frame houses.

They are produced by joining several layers of veneer using high-pressure gluing. High strength is achieved due to the fact that the fibers are arranged in parallel. Advantages: large selection of standard sizes, material is easy to process. In practice, you can use any cutting tool for this, an indispensable material for floors with large spans. Disadvantage: high price. - HTS beams are one of the new developments of German engineers in the field of frame housing construction. They are made in the form of an I-beam, in which the outer layers are wood, and the inner layer is OSB board. Between such layers, a steel profiled sheet 0.5 mm thick with a wavy configuration, treated with a polymer coating, is mounted.

The wavy shape of the internal protection creates high strength characteristics of the product and provides better bending ability. To ensure that such a structure does not twist inside, elements are built in that create a hidden cross-link.Advantage: high strength, durability, ease of installation, designed for large-sized frame house construction. The disadvantage is the high price.

Pie and scheme

In the project of such a building, as a rule, there is a section on choosing an individual pie for each of the 3 types of floors and the layout of the beams is indicated. The calculation results depend on the type of floor, the operational load of the floor and the additional load of the partitions. For example, for a subfloor with an OSB thickness of 22 mm and a total load of 350 kg/m2, such spans can be taken from the table.

Next,

based on engineering calculations, a beam layout diagram is developed , which indicates the section, their location and serial number, pitch and full parameters of the floors.

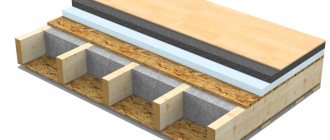

In general, for such floors one “pie” scheme is calculated, only for the basement and attic floors reinforcement is made for thermal protection, and for the interfloor floors - for sound protection and noise absorption.

In general, the “pie” of the design is made in this way, in the order of installation from bottom to top :

- wooden frame made of boards;

- film waterproofing;

- tiled heat insulator of the mineral wool insulation group; loose expanded clay is sometimes used for the basement structure;

- membrane vapor barrier;

- OSB or tongue and groove lumber;

- strengthening thermal protection with the installation of additional basalt slabs for the base and roof;

- leveling cement screed, final surface finishing.

Types of floors

For private housing construction, various types of floors are used, the most common are wooden beam floors and concrete floor slabs.

Monolithic floors without beams are used less frequently in independent house construction, since they are more labor-intensive to perform and require a large amount of preparatory work.

I will not consider them all in this article, but will talk about how frame floors are arranged; my house is frame

How to calculate the structure and its load?

To find the thickness of the beams of the structure, you can use the integrated calculation method or determine them using formulas . The first option is the simplest; in this case, constant loads are assumed based on the thickness of the heat insulator, in the range from 210 to 230 kg/m2. For attic and basement floors, higher values from 255 to 315 kg/m2 are accepted, since a thicker layer of mineral slabs is laid.

On the contrary, variable loads are selected more for interfloor structures 200 kg/m2, and for attic structures only 100 kg/m2. After determining the total load, the cross-section of the beams is established in a tabular manner.

More accurate calculations are performed using the formula method.

An example of calculating the distributed and concentrated load of pine beams:

- Beam input data:

- Length, 6 m.

- Height, 250 mm.

- Beam width, 100 mm.

- Weight, 75 kg.

- Calculation results:

- Beam spacing, 500 mm.

- Area load, 300 kg/m2.

- Distributed load, 150 kg/m2.

- Maximum deflection of floors, 24 mm.

- Design deflection, 19 mm.

- Deflection reserve, 1.26 times.

- Ultimate strength load = 547.1 kg/m2.

Performing calculations

Find out exactly what communications are going on at the construction site in order to avoid future problems with neighbors and utility services. It is better to make calculations according to SNiP 2.02.03-85 Pile foundations. During the calculation, the bearing capacity and strength of the foundation are determined.

Values and characteristics taken into account:

- bases of piles and their shells;

- the values of the horizontal load when combined with the slopes of the structure;

- design features of concrete supports and foundation grillage.

A very important part of the calculations is the calculation of loads:

- The weight of snow on the garage roof, which is recommended to be 190 kg/m2 for the northern regions, 50 kg/m2 for the southern regions and 100 kg/m2 for the middle zone.

- Load from façade insulation and wall finishing.

- The load from the structure, not only from the roof covering, but also from the weight of the sheathing, insulation, rafters and other materials. Ceramic tiles - 60-80 kg/m2, asbestos-cement material - 40-50 kg/m2, roofing felt 30-50 kg/m2, sheet steel 20-30 kg/m2.

- Floor load, taking into account the weight of the insulation.

- Overall weight of the structure.

- Operating loads. This takes into account the availability of furniture, equipment, appliances, etc.

Calculating the foundation is a very complex matter, associated with a large number of formulas, calculation of dynamic loads, deformation and settlement, seasonal loads, the weight of the garage along with its contents.

And even a small mistake can lead to a big disaster, so to start quickly building supports with your own hands, you should entrust the calculations to professionals.

Installation instructions step by step

For each of the 3 types of floors in such a house, there are certain differences caused by the operating conditions of each of them, as well as their sizes.

So the thickness of the main lumber directly depends on the span length. When installing these structures, some general rules are followed. First of all, installation must be carried out strictly according to the project using materials, quality, range and dimensional parameters defined in its specifications.

All elements of the floors of a frame house are classified as fire hazardous materials and can be damaged by biological contaminants, so they must first be treated with antiseptic and fire-resistant impregnations.

Tsokolnoe

First, the developer must install strapping beams around the perimeter of the building ; floor beams will be attached to them in the future. The required dimensions are taken from the design diagram of the floors and the places for attaching the beams are marked.

The main stages of installing the 1st floor ceiling:

- Install the support shoes according to the diagram where the beams will be placed.

- At the bottom of them a cranial block is attached for mounting the sheathing boards.

- The beams are inserted into fixed shoes and secured with nails at the fastening points.

- The beams are installed so that the cranial block is at the bottom.

- The sheathing boards are mounted with support on it.

- A film membrane hydrobarrier is laid on top of the filing.

- Install the heat insulation slabs between the beams quite tightly so that there are no gaps, but also without jamming, and so that the insulation does not protrude beyond the top of the beam.

- The surface of the slabs is covered tightly with a vapor barrier with an overlap of at least 100 mm at the joints, securing the film to the beams with a stapler.

- A 20 mm counter rail is installed to create a ventilation gap and allow natural removal of accumulated moisture.

- A flooring made of different sheet flooring material with a thickness of at least 22 mm is placed on top of the counter-batten so that deflections are not created and vibration of the floor does not occur.

- The installation of the base “pie” is completed with a finishing coating.

Important ! In the case when a frame house is installed on a pile foundation, the basement floor is additionally insulated with sheet polystyrene foam, and a cement screed is placed on top of it.

The construction of a subfloor in such a house on screw piles is difficult due to the fact that the structure itself is located at a relatively small distance from the ground level. If the installation and assembly work is carried out incorrectly, the house will be cold and can only be used for seasonal living, since drafts will settle on the ground floor in any weather.

Interfloor

Such ceilings have advantages in terms of temperature, since they are not subject to harmful fluctuations, in addition, they simultaneously perform two functions of ceiling and floor.

When choosing insulation, the emphasis is on soundproofing characteristics , that is, such a protective material must first of all have an acoustic modification.

For these partitions, LVL beams are often used. They rest on all load-bearing walls and are fixed with temporary jibs. After installing the LVL beams, floor joists are installed from the boards. Using LVL nails, beams are strengthened with boards along the outer perimeter and to the top of the frame of load-bearing wall structures. When producing long purlins, the boards are connected with 80 cm overlays.

Installation of the interfloor ceiling is carried out in the following order:

- Logs are installed to the frame and beams at intervals of 500 mm or according to the size of the heat-insulating material slabs.

- The bottom of the frame is covered with a vapor barrier membrane.

- They nail down sheet building material, which will serve as the basis for thermal protection and will become the basis for finishing work on the ceiling.

- Acoustic heat insulator slabs of at least 100 mm are placed in the frame, tightly without gaps.

- A vapor barrier film is fixed on top of the heat insulator with a stapler.

- The protective layers are covered with boards or slabs as the subfloor of the 2nd floor.

- The ceiling and floor are being finished.

Attic

This type of flooring is considered the basis for the roofing system. For the upper room it is the ceiling, for the attic it is the floor . It is subject to special requirements for strength characteristics, heat resistance, hydro- and noise protection.

Taking into account that the main flow of heat from the interior rushes upward, drawing cold air from under the roof, the thermal protection of such structures is reinforced, with a high layer of thermal insulation over 100 mm.

The attic floor usually has the following design:

- roll-up or plank boards;

- membrane vapor protection;

- ventilation gap;

- heat protection plates;

- auxiliary vapor barrier;

- flooring.

Soundproofing

Various materials are used as soundproofing for floors; let’s look at the main ones:

- Mineral wool – these include all types of mineral wool used for sound insulation. It is recommended to use a denser one, although sound waves are well damped by light glass wool. Still, only an integrated approach will save you from impact noise.

- Bulk - various backfills, for example, ecowool, sawdust, sand, expanded clay and other materials with soundproofing characteristics.

- Sheet materials in the form of vibration-isolating sheets, special floor coverings for finishing, cork coverings. They are more often used in complex sound insulation methods.

- An integrated approach to eliminating noise consists of a combination of various solutions, for example, the use of layers of different densities and strengths.

Enhanced

For frame floor beams, excess deflection is considered a very dangerous indicator. In the case when a 2.5 m long beam bends by more than 1 cm, the structure requires reinforcement. There are two options for increasing the load-bearing characteristics of the floor beam:

- increasing the section size;

- reducing the span of load-bearing parts or the total load.

In case of serious deformations of the beam, it is recommended to use 2 existing options simultaneously.

Most often, reinforcement of floors is carried out using the first method, strengthening the floors with spliced beams, with a joint installed on the inner wall of the house. For the second option, the operating conditions of the floor are changed, the span is reduced, and additional racks or struts are installed.

Of what?

Sustainable structural strengthening is achieved by installing wooden, steel overlays or prostheses . Recently, the method of strengthening beams with carbon fiber has firmly entered this list. To make supports you will need a wooden or metal support.

How to build?

Increasing the cross-sectional size of a beam using carbon fiber is quite simple; it is lightweight, flexible and fixed with glue, which makes installation very easy. This material is non-flammable, which increases the fire resistance properties of beams and other structural elements made of wood. This method is especially relevant when protecting timber from deflection when work is carried out in cramped conditions. The above-mentioned innovative composite building material is tightly glued to the beam in three or four layers , which makes it possible to strengthen wooden floors very efficiently and firmly. The carbon fiber is glued together with epoxy-based glue, covering the joints of the strips with transverse layers.

After the glue hardens, the structure turns into a durable and rigid frame, with characteristics almost equal to metal, so this reinforced structure can withstand loads well.

Penoplex insulation on the outside

External insulation with polystyrene foam is characterized by the speed of work. The method for installing a thermal insulation layer includes the following steps:

- preparing the frame - cleaning it from dirt, eliminating existing irregularities;

- installation of a layer of waterproofing material (for example, polyethylene film or special membranes);

- laying penoplex (first the slabs are placed on glue, and after 3-4 days they are additionally fixed with “fungi”);

- creating a vapor barrier layer;

- external decorative finishing.

Adhesive solutions are designed for use at temperatures not lower than 5°. When working at lower temperatures, reliable fastening should not be expected.

The use of vapor and waterproofing materials allows you to create a so-called ventilated façade. This technique prevents the penetration of moisture and dampness from both the inside and outside of the wall. This prevents the destruction of the insulation and reduces the penetration of cold air into the room. Most often, this technology is used to create a thermal insulation layer when decorating walls with siding.

Complete insulation of a house is impossible without insulation of the roof. In this case, the insulation boards are laid on top of the rafters. Nails are mainly used for installation.

Wall junction unit

Frame house construction units are critical places that are performed with extreme precision so that they work in accordance with the established technology. For junctions, the most important nodes are the place where the vertical posts are attached with the strapping, as well as the points of connection of the posts with the strapping beam.

What are they made of?

Western technology for assembling frames is based on connecting nodes exclusively with nails. Therefore, it is strange for them to hear that frame objects are assembled using steel angles and self-tapping screws. In our country, most specialists adhere to the same rules, the nail is the basis of such assembly structures, especially when working with trusses, they use “shoes” to fix the frame joist or terrace to the beam from the side.

To obtain house-building components, 90 mm nails are used for load-bearing elements and 60 mm for rough and finished floors. Large nails are not required , even if the board thickness is more than 50 mm. Excessive reinsurance of the customer will only lead to an increase in the cost of installation work.

How to do it right?

To complete the floor assembly of the 1st floor and the corresponding wall, two structures are connected in such a way as to prevent the formation of “cold bridges” from the frontal board. From the outer plane of the wall, OSB is attached to the frame racks with 60 mm nails. A heat insulator is placed between the racks, and an additional layer of it is laid over the counter-lattice.

Between the main and auxiliary layers, a vapor barrier is fixed along the rack to prevent condensation from appearing inside the frame wall and thereby preventing the formation of a “cold bridge.”

Ceiling lining

My ceiling has not been hemmed yet, for the first time I plan to sheathe it with boards or gypsum plasterboard sheets over the sheathing. There, under the plasterboard, I will place the electrical wiring leading to the lighting.

To be honest, I have not yet decided how I will make the ceiling, so the frame interfloor ceiling is still in question. I depicted the option in the picture below. Think.

My attic ceiling is already ready, although it’s only a rough one for now. It still needs decorative finishing, there are a lot of options here, so I’m not worrying about it yet.

Difficulties and errors during installation

The biggest mistake that developers make when constructing such buildings is working without a design.

In such house construction, the cost of errors is especially high and leads to excessive consumption of materials, high labor costs , and, consequently, to the high cost of the construction project.

The small cross-section of beams and their rare spacing in floors will lead to the destruction of all structural elements of the building. Therefore, initially the developer must have a specific project and control the progress of construction in accordance with the drawings and technological map.

In addition, when assembling frame objects, performers make the following mistakes:

- When attaching beams. They must clearly rest on the upper part of the frame of load-bearing wall structures, on the purlins.

- Reducing the cross-section of the beam by means of a joint cut, it is better to fasten it using a backing support block or using steel supports.

- The excess pitch of beams is over 60 cm, with the norm being up to 40-50 cm.

- The rigidity of the transverse beam ties is weak; it can be increased by installing rigid transverse ties every 120 cm; they will subsequently become supports for interior partitions.

- Low-grade lumber is used to assemble the frame structure.

- Lumber has a high humidity above 12%, as a result of which wooden elements are subject to significant shrinkage, which will lead to unacceptable deformation of important house structures.

- The internal ventilation system has not been installed.

- A material is installed as thermal protection that is not allowed for installation in residential premises and is vapor-tight, for example, polystyrene.

- There is no sound-absorbing layer at the interfloor ceiling.

- The lumber has not undergone antiseptic and fire protection treatment.

- Failure to install parts using black self-tapping screws, which leads to the rupture of such unreliable connections, which have rather low shear strength.

Content:

- Floor structure in a wooden house

- Attaching beams to the wall

- Wooden floor technology

- Stages of arrangement of floors

- Calculation of wooden floors

- What is noise and sound insulation

- Types of noise

- Selecting a soundproofing layer

- Do-it-yourself wooden floors in the house

- Video on the topic of roofing in a wooden house

Floors are one of the main components of the frame of a wooden house, its horizontal part of the structure. That is why the strength, reliability, safety and service life of your building, as well as the comfort of life in it, depend on their quality, construction technology, hydro-, steam- and noise insulation.