Any room must be equipped with a ventilation system, since without it, unpleasant odors will accumulate inside, and the air itself will eventually become unfit for breathing. It happens that there is no need to install special ventilation, for example, in houses made of logs or timber. But ventilation in a frame house is extremely necessary, since the service life of the frame structure directly depends on the movement of air in such a room. In this article we will try to reveal some of the nuances of this problem.

The importance of ventilation in a frame house

Frame construction in our country is a fairly young and modern business. And thanks to the fact that the walls are built without cracks, and plastic bags and sealed doors are installed on the windows, it seems that such a house does not breathe, and the air in it is stale.

Practice shows that buildings made of stone are no better, and that, in most cases, ventilation in buildings made of stone was carried out due to poor quality construction and cracks in window frames. Since the stone will also not be able to cope with all the moisture that is released from human activity.

The ventilation system will be quite expensive to assemble and install in a frame house, and doubts arise about the feasibility of its installation. The question of whether forced ventilation is needed in a frame house will arise especially acutely if the construction is decided to be done with one’s own hands, without the involvement of specialists.

For a seasonal (summer) frame house, ventilation is not required. Since it is warm outside in the summer, windows and doors are usually open, which in itself allows air to move.

The only thing that is necessary is to build a small ventilation window in the bathroom.

Recommendations for installation with a recuperator

Installation recommendations mainly concern the premises in which the recuperator should be installed. First of all, boiler rooms are used for this (if we are talking about private households). Recuperators are also installed in basements, attics and other technical rooms.

If this does not conflict with the requirements of the technical documentation, then the installation can be installed in any unheated room, while the distribution of ventilation ducts, if possible, should be installed in rooms with heating.

Ventilation ducts passing through unheated rooms (as well as outdoors) should be insulated. Thermal insulation is also necessary where exhaust air ducts pass through external walls.

Considering the noise the equipment can make during operation, it is best to place it away from bedrooms and other living rooms.

As for placing the recuperator in an apartment: the best place for it would be a balcony or some technical room.

If this is not possible, you can allocate free space in the dressing room for installing a recuperator.

Be that as it may, the location of the installation largely depends on the design features of the ventilation system, the location of the ventilation wiring and the dimensions of the device.

About ventilation in a residential frame house

In a house where people live on a permanent basis, it is extremely important to install a mechanical hood in such areas as:

- Kitchen, since during cooking there is a significant percentage of evaporation, and also other odors are created that, if stagnant, will spoil the atmosphere of the house;

- Bathroom - here there is no need to explain the need for an exhaust hood, since high humidity in a bathroom without ventilation is a source of destruction for the entire house;

- Well, and the toilet, here too there is no need to explain why a hood is needed.

It will be necessary to develop a plan for supplying heated fresh air, this will help avoid significant temperature changes that are inevitable with forced ventilation.

Installation of exhaust ventilation in the kitchen

The kitchen area is intended for preparing food, so it often experiences high humidity and a variety of odors accumulate. To neutralize them, an exhaust hood is provided above the stove. But does it cope with the ventilation of the room?

Using a hood

There are two ways to remove used air from the kitchen using a hood:

- by replacing the air. Fresh flow enters the room through leaks, or supply valves, and exhaust flow is removed by hood into the ventilation duct;

- by cleaning the air in the exhaust device and returning it back to the room. For this purpose, recirculation type hoods are used.

These methods have one drawback - the hood only removes exhaust air above and near the stove; it cannot cover the entire kitchen space. Therefore, in addition to the exhaust hood, it is necessary to additionally organize exhaust air removal in the food preparation room.

Other ways to organize kitchen ventilation

Ventilation ducts in apartments have a cross-section of 130x130 mm, so their throughput capacity is on average 130-180 m3/hour (maximum 300 m3/hour). If the exhaust power is higher, this will disrupt the functioning of the air exchange system in all apartments connected to this shaft (air stagnation will appear, odors will spread).

You can arrange kitchen ventilation in a natural way. To do this, the room must have two exhaust ducts - for removing exhaust air above the stove and for the rest of the room.

Advice: if the system for removing air from the kitchen naturally does not work, it can be forced by installing a fan in the ventilation duct.

Apartment ventilation is an important factor in ensuring a healthy and comfortable life for all its inhabitants, maintaining the integrity and presentable appearance of furniture and premises. Coordinated, well-thought-out operation of air exchange, air conditioning and heating systems will create a favorable microclimate in housing with minimal energy consumption.

Natural ventilation and its installation in a frame house

Natural ventilation in a high-quality frame house cannot be carried out according to the old principles, since previously air entered the room through poorly made door frames and through loosely locked windows, and escaped through ventilation ducts located in the kitchen and bathroom.

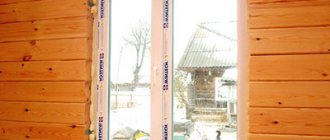

But modern frame construction occurs in such a way that when constructing such a house, cracks and gaps are absolutely excluded. Plastic bags on windows and high-quality doors and frames for them leave no chance for air to penetrate into the room through them. For this reason, specialized valves are installed in the wall to ensure natural ventilation of the room.

Inlet valves, as a rule, are built directly into the frame, which completely masks them and makes them invisible. Valves are made either of plastic or asbestos-cement pipe, less often metal is used for them.

The ventilation device (supply valve) in a frame house is a small, neat device that ensures air flow into the room. Most valves for natural ventilation are equipped with additional filters for air purification and an additional sound absorber.

On the street side, the ventilation outlet is equipped with a fine mesh that prevents various rodents, large insects or birds from entering the house.

A damper is installed on the inside, which is responsible for the intensity of air entering the room.

The operating principle of natural ventilation is based on the difference in pressure inside the house and outside the room, as well as on the difference in temperature. In the summer, the draft will be the least, since the temperature outside and inside the room is practically the same. For this reason, it is necessary to equip the exhaust ducts of the bathroom and kitchen with additional mini-fans. And in order for them not to work idle and at the same time clearly perform their function, hygrometers are connected to them, which, if necessary, start or stop the operation of the mini-fan.

Such ventilation in a frame house is the simplest, but such natural ventilation is only suitable if the house is small; in a huge building this type will not cope, and after a short time you will notice the air is stuffy and the presence of mold in the corners.

Stages of system construction

If the owner of a frame house decides to build a ventilation system on his own, he must adhere to a certain sequence of actions.

Selecting the type of ventilation

The ventilation system is selected depending on how the frame house is planned to be used. If the owner intends to live in it only during the warm season, it will be enough to install natural, organized ventilation.

A gravitational, or natural, ventilation system will not be able to ensure normal air circulation throughout all the rooms of the frame structure in the summer. But this is the simplest and cheapest option to build.

If the frame house is used all year round, natural organized ventilation will not be able to meet the needs of the residents.

In this case, you need to install a forced ventilation system that will be able to supply the required amount of fresh air inside the house, while simultaneously removing exhaust air containing harmful fumes.

Carrying out calculations for design

Sanitary and hygienic standards have been established for people's need for fresh air, according to which the owner of a frame structure must carry out calculations before installing a ventilation system:

- rest or sleep mode 20 m3/h;

- activity without loads 40 m3/h;

- increased activity or physical work 60 m3/h.

Knowing the number of residents of the house and their daily routine, it is easy to calculate the amount of air that should be renewed in a given unit of time.

Also, when calculating air parameters for the premises of a frame house, one should be guided by the following standards:

- SNiP 31-01-2003;

- GOST 30494.

Usually, the calculation of the required amount of air is carried out using both methods - by the number of people and by the multiplicity. The necessary techniques are easy to find on the Internet. To design a ventilation system, take the larger of the 2 values.

Standards establish the minimum air exchange rate for various rooms of a residential building. In order for the system to provide the required volume of air, calculations are made of the cross-section of air ducts and vents

In addition to calculating the amount of air, you will need to calculate the resistance of the air distribution network - this indicator will be useful when choosing fans.

Features of drafting a project

If the owner of a frame house decides to equip a combined ventilation system, he will need to design window or wall supply valves for air intake. Installing window valves is much more difficult than wall valves, since you will have to cut holes for the valves in the window frame or window sash.

Even if you have the skills to work with glass, installing a window valve will not be easy. It is much easier to cut an opening for the valve in the wall of the room where you plan to direct the air flow from the street. They are usually placed in living rooms.

If you include supply or exhaust valves in the natural ventilation scheme, you will get an inexpensive but effective version of the combined system

In addition to the supply valves, it will be necessary to equip the exhaust air exhaust of their technical rooms. For this purpose, an exhaust duct is designed with access to the roof, and the outer exhaust pipe must be at least 0.5 m higher than the roof ridge. If the house has a chimney from a fireplace or stove, it can also be included in the system as an exhaust duct.

When the owner chooses a forced type of ventilation system, the air duct layout should be as rational as possible to avoid unnecessary heat loss. Air vents should not be too long, as this reduces the efficiency of ventilation.

Fans, recuperators and other necessary equipment are selected according to technical specifications, taking into account calculations of the need for fresh air and the resistance of the ventilation air distribution network.

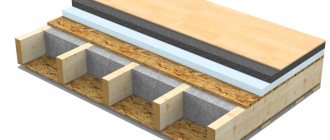

In addition to the air duct system, the owner of a frame house must design floor ventilation, which will prevent the accumulation of condensation and the appearance of mold stains.

All frame structures must be provided with a ventilation system. It is imperative to ensure the flow of fresh air into the basement through vents and its outflow through air ducts or ventilation grilles

When designing ventilation for a frame house, you should definitely take into account some nuances:

- All ventilation ducts must be made of non-combustible materials with a smooth inner surface so as not to impede the movement of air. Internal irregularities can cause a decrease in traction, resulting in an obstruction of the air mass.

- When installing ventilation ducts during the arrangement of a frame house, it is undesirable to use metal components, since as a result of the interaction of the metal with the material of the wall panels, the thermal insulation indicators are reduced.

- Exhaust equipment, especially those that remove air with an unpleasant odor from rooms, should be installed in different rooms with characteristic temperature fluctuations, vapor formation, and high humidity.

- Transit air ducts should not pass through living rooms and kitchens.

- Ducts in which condensation is expected to settle must be designed to slope and drain.

- When installing a fan, an air duct with an elbow will significantly reduce the noise level.

- It is recommended that the exhaust fan be equipped with a valve that will prevent cold air from entering the house when the fan is turned off.

For laying ventilation ducts, polymer air ducts that are lightweight and have sufficient plasticity to give the air duct the desired direction are best suited. Sewage plastic pipes are also often used for this purpose.

In order to be able to calculate the air exchange rate, select and calculate the necessary equipment for the ventilation device, you need a frame house plan and project. It is compiled taking into account all the nuances inherent in this type of building

It is recommended to place ventilation ducts between the elements of the house frame or between beams. In any case, the ventilation duct must have a cross-section of at least 100×100 mm and a length of at least 6 m so that the incoming air moves with the required acceleration.

Installation steps

With high-quality preparation, installation of the ventilation system is carried out without any particular difficulties in several successive steps:

- Supply valves are equipped by drilling holes of the required diameter in the walls and floor.

- A prepared air duct pipe is inserted into each hole, equipped on the outside with a fine grille that prevents debris from entering the channel, and on the inside with a duct fan.

- The joints are sealed with polyurethane foam.

- After the foam has hardened, an air filter and noise absorption equipment are installed in the right places.

- Following the installation of the supply valves, the channel distribution is installed with the sealing of all joints and fastenings. The ventilation unit is most conveniently located in the attic.

- Before sewing the channels into the box and starting interior decorative finishing, it is recommended to check the system. After finishing, repairs and debugging will be problematic.

Installation of the ventilation system must be carried out in strict accordance with the drawn up project.

Checking installed ventilation

After installing ventilation in a frame house, it is necessary to check its performance and, if necessary, carry out additional debugging and adjustment.

There are several ways to check the ventilation system:

- Check all rooms for the presence of foreign odors, mustiness and stuffiness. If all of the above are missing, the system is installed correctly.

- Inspect technical areas for mold and mildew, especially the bathroom and kitchen. The presence of mold indicates that ventilation does not remove excess moisture in the required volume.

- Pay attention to the window glass. If ventilation is poor, condensation will accumulate on them.

The draft in the exhaust system is checked by holding a paper napkin in one fold to the grille. If it is pressed against the hood, then everything is working normally. If not, then no pulling occurs. The test is carried out when it is about -5°C outside the window.

You should not bring a lighter or match to the ventilation duct in a kitchen with gas equipment. If there was a leak, an explosion could occur. In any case, before testing, you need to open the windows: both for ventilation and to establish gravitational draft.

Forced ventilation and its installation in a frame house

At the present time, there are very few craftsmen who can install high-quality ventilation in a frame house. And, nevertheless, forced ventilation is extremely important in a frame house, and its absence is unacceptable. Only with its installation can you create a truly pleasant microclimate in your home.

This type of ventilation, using the work of fans, perfectly copes with the inflow and outflow of air, providing the necessary circulation inside the room. Here are some forced ventilation schemes:

Forced exhaust of stale air will relieve the pressure in the room, and fresh air will enter the rooms through the supply channels, stabilizing the pressure difference;

Forced intake of fresh air will increase the pressure inside the house, and will put pressure on the exhaust air, pushing it through the ventilation ducts located in the kitchen and bathroom;

Fans installed for air inflow and outflow will simultaneously change volumes of air in your home at equal temperatures;

Forced ventilation with heat recovery is a modern solution for ventilation in a frame house. This is a cost-effective solution for warming incoming oxygen using exhaust, used air.

The last option is the most effective, although the most expensive, but is it worth saving on coziness and comfort? This is a purely rhetorical question. The installation of such ventilation must be carried out by a specialist. Those who have a frame house built from SIP panels do not need to think about installing ventilation.

Such panels already have ventilation ducts.

Optimal choice of air exchange: supply and exhaust

Since both of these systems (active and passive) have their advantages and disadvantages, a system was created that combines them into one.

It was called supply and exhaust. Today this ventilation is the most effective and inexpensive.

One air outlet

It includes:

- distributor block

- inflow channels

- outflow channels

- filters

- fans

The distributor block consists of two parts; it is a mechanism with installed fans.

The first part is responsible for the influx of fresh air and its distribution throughout the rooms, and the second for the outflow of used air outside.

One inlet and one outlet for supply and exhaust ventilation air

Thus, the supply and exhaust system has one inflow and one outflow to the outside, with installed fans and filters.

Between the tributaries there is a complex branching of channels through the rooms.

Ventilation ducts are hidden in the walls and must be installed during construction.

Combined ventilation schemes

High-quality ventilation of a frame house, as real-life examples show, can be installed without special costs using a combined ventilation system. With this scheme, the used air leaves the room through special ventilation channels. Here you will need to calculate the required number of such channels and their cross-section. So, for a house of 250 m2 you will need from 7 to 10 such channels.

Such channels are made of both plastic and asbestos cement, which is subsequently connected in a special metal manifold. A fan is mounted in this collector and is installed to extract air. It is this fan that ensures normal circulation and the necessary ventilation in a frame house; it can be either automatic or manually turned on.

There are complex connection systems, and then the fan is started either from humidity sensors, which must be installed in all rooms of the house, or from infrared sensors, which start the system when residents appear. When installing a fan using this scheme, you will need the recommendation of a specialist, since without experience and the necessary tools, it is difficult to calculate the required fan power.

The flow of air into the room is carried out only through supply ducts and nothing else; as a rule, they are mounted in the frame of a plastic window or, as mentioned earlier, in the frame of the house itself. The whole scheme is not that complicated and, with due care and compliance with all technological processes, it is quite doable with your own hands.

The negative quality of this type of ventilation is that in winter cold air will enter the house, which will affect heating costs.

Requirements and standards

The existing sanitary standards for private houses indicate air parameters that are considered normal for living:

- temperature within 22-24C;

- humidity 40-60%;

- the speed of movement of air masses is 1 m/s.

But the same standards determine such an indicator as air exchange. That is, this is the amount of air entering and, accordingly, exhausting within one hour. So the standard indicator here will be 3 m³/hour per 1 m² of room area. Disclaimer - if the ceiling height does not exceed 3 m. If the last dimensional indicator is larger, then the air exchange increases by 30%.

But the standards contain another designation for air exchange, which is related to how much time a person will spend in the room. If he spends a lot of time in the room, practically he is in it constantly, then in one hour at least 60 m³ of fresh air masses should enter the room. If the room is not used constantly, then this figure is reduced to 20 m³.

The ventilation device is based precisely on these values. Therefore, when the developer is faced with the question of correct calculation, he can use a fairly simple formula:

L=VxKr, where:

- L is the volume of air required for complete exchange;

- V – volume of the room;

- Kr – air exchange rate.

The latter indicator is recorded in the tables of sanitary standards and is a constant value. But we must also take into account the fact that the tables show coefficients based on the purpose of each room and the time when it is used in two modes: working and non-working. For example, in bedrooms the multiplicity value during operating mode is 1 m³/hour, and during non-operating mode it is 0.2. Kitchen - 60 m³/chach, and in non-working mode 0.5.

Therefore, the ventilation of a frame house is arranged based on the table values. Of course, it is necessary to take into account the parameters of the premises themselves.

Ventilation is not working, why?

If the ventilation does not work or does not work as well as necessary, this will be revealed by the following signs:

- There will be heavy stale air in the room, it will seem like you can’t breathe;

- In rooms such as the bathroom and kitchen, mold or mildew forms in the corners, this indicates that the ventilation in the frame house cannot cope with high humidity;

- The formation of condensation on the windows also indicates that the air humidity in the room is increased, while air exchange is either minimal or absent at all.

Features of bathroom ventilation

Due to its purpose, the bathroom always has high humidity. Therefore, in addition to the standard supply and exhaust ventilation, you can install an additional exhaust fan. It comes in handy when the main system cannot cope with its tasks or is under repair.

For convenience, this additional ventilation in the bathroom can have different ways of being turned on and off:

- using a separate switch;

- in parallel with turning on the light and turning it off 6-8 minutes after turning off the lighting;

— based on a motion sensor;

- using a humidity sensor.

It is desirable that the fan be sufficiently powerful and low-noise, and that the ventilation duct have a large cross-section, providing an air flow of 60-160 m3/hour.

Details about recuperators

Recuperation is a revolutionary solution for ventilation in a frame house and in individual rooms. These devices are installed directly in the wall. Interestingly, it is the wall with the recuperator that has the right to be called a “breathing wall.”

This device is a small ceramic heat exchanger with a fan that draws in outside air and blows out exhaust air.

When the warm exhaust air is blown out, the heat exchanger, made of ceramic, heats up.

Ventilation of external wall structures

No less than reliable ventilation in a house is the protection of its building structures from damage and aging. Here the ventilation gap between the outer skin and the windproof layer (often made of non-woven material) can play a role. To construct it, wooden planks are vertically fixed on top of this layer, to which the outer skin is nailed.

Entrance openings are made along the perimeter of the house below, and exit openings are made under the roof canopy. Then there was always air movement in the gap. This will prevent the formation of condensation in it, which will have a beneficial effect on the safety of building structures.

Video review of a forced ventilation system with a recuperator:

Ventilate and clean the air in the room

If the house is not located in the most environmentally friendly area, then the ventilation system in your frame house is supplemented with special devices. At the moment, you can find a variety of air purifiers on the market that will perfectly cope with dust, unpleasant odors, and even the obsessive smell of tobacco.

Some products of this kind are even equipped with heating elements, which allows you to regulate the temperature and humidity of the incoming air. The only disadvantages worth noting are the rapid contamination of filters and the need for frequent replacement.

Air recovery

Warming up the air is an energy-intensive task. If it’s -20° outside and you need to put +22 in the room, then an air handling unit with a capacity of 330 m3/h will need about 5 kW for this!

To ensure heating occurs most economically, a recuperator is often used. In it, the warm flow from the rooms, before leaving, transfers part of its temperature to the incoming cold one.

Ventilation with heat recovery - diagram

There are different types of recuperator designs. In most of them, exhaust and clean air do not mix with each other. The efficiency of devices varies from 45 to 90% depending on the model.

The most commonly used type of recuperator is a plate type, which you can even make yourself.

If the house uses a boiler and a water jacket, installing a water-heated heat exchanger will be even more profitable. Coolant from the heating system enters it and heats the air from outside without spending a single watt of electricity.

Installation nuances

Only you can answer how to make the right ventilation for you in a frame house, since it depends on many factors, including financial capabilities, the area of the rooms, and the number of people living in the house. Due to the unusual nature of the frame structure itself, ventilation ducts can be installed directly into walls and ceilings. Some manufacturers of such houses fill in the necessary holes during production.

When installing air ducts, it is worth using a plastic pipe, since a metal one will serve as a cold bridge, and metal does not resist condensation well. Horizontal ducts must have a cross-section of at least 100x100 mm, vertical air ducts must have a cross-section of at least 120x120 mm. If the building has an air duct from a fireplace, stove or gas boiler, then the ventilation is located nearby.

Ventilation system design

The tightness of the building, which is an indisputable advantage and ensures the heat and water resistance of the structure, is at the same time an obstacle to the penetration of fresh air inside. It also complicates the outflow of excess moisture and carbon dioxide formed during the life of people living in the house.

Any ventilation system consists of 3 main parts, regardless of the presence or absence of additional devices and mechanisms, these are:

- Supply channels and/or openings.

- Exhaust ducts and/or openings.

- Overflow, overflow grids, holes, gaps.

Supply channels provide fresh air from the street into the house, which is supplied directly to the living quarters. On the street side, a grating is installed on each channel. In case of mechanization, it is replaced by a supply valve equipped with an air filter and sound insulation.

According to the type of organization, ventilation in a frame can be ducted or ductless. According to duct diagrams, air is supplied and discharged through air ducts. In a ductless system, everything happens through vents, gaps and holes

Exhaust ducts serve to remove stagnant “exhaust” air saturated with carbon dioxide, moisture and other volatile components harmful to health. At the same time, the fumes generated in the house where people live are utilized.

A well-designed hood, installed in a frame house, must be in utility and utility rooms such as a kitchen, closet, bathroom, pantry, shower, toilet.

Flow in the ventilation system is necessary so that the air entering the house can be freely distributed throughout all rooms.

The ventilation system includes systems for air supply, exhaust and air flow. Each component plays an important role

If necessary, the main air movement channels are equipped with additional equipment - fans, heat exchangers, air heaters, exhaust devices, and measuring devices.

Fans are installed to achieve the required air exchange. They are selected according to technical specifications after carrying out the necessary calculations, taking into account the volume of the room, the number of people living and other important inputs.

Recuperators serve to increase the temperature of incoming air. Inside the recuperator, the cold air is heated from the wall of the supply channel, which is in contact with the wall of the channel that removes the heated used air from the room.

The use of recuperators significantly increases the energy efficiency of a frame house.

Heaters in ventilation systems are used mainly in northern regions, where winter temperatures often reach -40 degrees

In addition to ventilation of rooms in a frame house, floor ventilation must be installed. To do this, vents are installed in the underground space, and holes with a diameter of 0.04 m2 are cut in the floor itself. Floor ventilation can be carried out either through air ducts or without them.

Ventilation equipment on the modern market

At the present time, the ventilation systems market is represented by leading manufacturers, each of which has occupied its own niche. Ventilation equipment is divided into three areas of use:

- Household and semi-industrial;

- Industrial;

- Mechanisms of alternative meaning.

Ventilation in a frame house specifically relates to semi-industrial and domestic areas. Such devices allow for high-quality air exchange in an area not exceeding 600 m2.

Under the floor

Such an important aspect of providing clean air to a frame house as floor ventilation is often neglected. Its organization is necessary in order to prevent rotting, the appearance of fungi and mold. With its help, you will prevent the accumulation of musty odors in the premises.

When organizing ventilation of the underground space, holes are cut out in the floor with a cross-sectional area of at least 0.04 square meters. In this case, the total area of such holes must be at least a quarter of the floor area. Air vents are installed in the lower part of the underground space and partitions. The latter should be located opposite each other.

The exhaust duct is located 150 mm higher than the supply duct. In this case, insulating material can be inserted into the holes to provide thermal insulation. Mineral wool is considered the best option. The external ventilation outlet, as in the case of ventilation valves, is covered with a protective mesh.

It is worth noting that the location of the vents significantly depends on the size of the underground space. If it is no more than 30 cm, then they must be installed directly in the floor. But at the same time, they should not be covered by either floor coverings or furniture.

Floor ventilation can also be organized according to a natural or forced principle. Both options are no different from the use of these methods in room ventilation.

How to calculate the required parameters for a home

To ensure high-quality ventilation in a private home, many factors must be taken into account. If you want to install it yourself, you need to remember at least 2 formulas. The first formula is as follows: Lpr = Lvyt. This means that the amount of air removed from the house is equal to the amount of air drawn into the house.

The second formula is as follows: L = (Sx3+nx60+V/2)/3. In this formula, S is the area of the room in which ventilation occurs, n is the number of people using the room, and V is the volume of the room. However, let us remind you that all these data are approximate, and for more accurate calculations it is better to contact experts.

Useful video on this topic:

Metal roof ventilation

There are a variety of materials used for exterior roofing, but one of the most popular is metal roofing. Metal roofing does not allow air and moisture to pass through well and tends to form condensation, so ventilation is necessary to create a comfortable atmosphere in the room. Lack of circulation leads to deformation and corrosion of the metal, rotting of the rafter system, and overheating of the coating. To eliminate such consequences, continuous ventilation is optimal, which is provided by a special gap and break in the ridge area. An additional perforated insert is installed in the area of the roof ridge, and fans are installed at a distance of 60 cm from the ridge.

A set of aerators complements the natural ventilation system and creates additional air circulation in the ridge area.

Installing a ventilation duct on metal tiles is not technologically difficult. The main steps are as follows:

- Mark the location where the ventilation pipe exits to the outside, but not lower than 60 cm from the ridge. The template included in the finished pipe kit must be applied to the roofing and outlined with a marker. Holes are drilled along this contour and part of the roofing sheet is cut out. The installation site is cleaned and degreased. Make sure the flashing fits snugly against the roof surface.

- Cut a hole in the housing for passage. The hole size should be 25% smaller than the cross-section of the pipe. This will ensure a tight connection between the components. Insert the pipe into the casing and completely assemble the structure.

- Apply sealant where the aerator meets the roof. Then there should be no gaps that could make this structure ineffective. Secure the transition assembly to the roof using self-tapping screws.

- Align the pipe and repair it. From inside the attic, ensure that all components are properly secured and correct any deficiencies found.

Installation is not carried out in rainy weather. The height of the pipe together with the reflector must be at least 50 cm from the roof surface.

Opinion of residents of houses

Not all frame houses are designed wisely. There are serious problems with airtightness, so take a look at reviews of real tenants who suffer from lack of ventilation. Lack of fresh air is a blow to human health. The rooms are stuffy and you can’t breathe.

By the way, if your house has a residential attic floor, then you definitely need to ventilate it. Read more about this here.

On top of that, there is a terrible stench from the bathroom and toilet. If we are dealing with hot weather, the humidity level increases. In winter, in turn, fungus on the walls begins to actively develop. Mold grows and cleaning supplies must be collected quickly.

Why does condensation form?

The formation of condensation is mainly due to fluctuations in the average daily temperature. For example, if waterproofing membranes are used when laying a roof, the condensation will be divided into two parts: the first will collect under the roof, and the second will collect outside.

Another reason is warm air that rises from the premises to the roof and collects under the roof according to the laws of convection. In regions with frequent precipitation, ventilation of the lining material is important - moisture easily penetrates joints and seams and contaminates the facade. And in frosty weather it will turn into ice and fill pipes and drains with it.

Roof vents eliminate these problems, provide checks, and perform many other important functions.

Thanks to ventilation:

- The temperature balance under the entire surface of the roof is constantly maintained;

- Water vapor is removed from the room itself;

- The likelihood that the sun's rays will overheat the roof surface in the summer is much lower;

- no icicles, no frost in winter;

- the need for repairs is postponed for a long time.