Wood, under the influence of negative factors, over time loses its natural attractiveness and deteriorates its performance characteristics: it fades under the influence of UV; deformed from excess moisture; rot when pathogenic microflora multiply.

To give a rich shade, preserve the structure, protect against destruction and extend service life , a special wood stain is used. Read more about what types of compositions there are, how to prepare them and what are the features of processing wooden surfaces.

What is stain used for?

Stain, or stain, is a special deep penetration composition that allows you to preserve the natural structure of the wood and give it the necessary shade . It can also be used to treat surfaces made of plywood, fiberboard, chipboard and MDF.

The main difference between stains and decorative enamels and paints is the deep penetration of tinting components , which allow you to color the wood from the inside, maintaining its texture and without forming a protective film on the surface.

You need to stain a tree to achieve the following goals:

- painting wood in a certain color or imitating expensive species;

- protection of wood from rotting and internal destruction due to the negative effects of moisture, infection with mold and pathogenic microorganisms;

- restoration and restoration of old and damaged wooden surfaces;

- giving wood a natural attractiveness;

- increasing strength and weather resistance;

- increasing the service life of the material;

- decoration by combining different shades.

When choosing impregnation, it is important to consider that not all compositions have the above characteristics.

Multi-colored dyeing

Wood stain, what is it for? It would seem that the technology and material have long been known. But the question remains open for many. Staining wooden surfaces is done in order to give them a certain shade that emphasizes the texture of the wood. In addition, stain makes the wood stronger and more resistant to damage from dampness, mold, fungi and wood-boring insects. But the possibilities of staining do not end there. Using stains of different colors you can create various effects on a wooden surface:

- whitening;

- aging;

- colored stains.

To create a bleached surface, two compositions of different qualities are used. First, a continuous coating is made with white water stain, which is thoroughly dried. And then all the recesses and pores are filled with an oil-based stain with the addition of hard wax. In this case, a very thin waxy film is formed, which highlights only the pores in black or gray, while the rest of the surface remains whitish.

If it is necessary to obtain a multi-colored effect, then first a test is made to select shades on a separate piece of sanded board. When it is possible to achieve the desired color combination, we begin processing the product. First, the main background is applied. Then chaotic or ordered strokes are made over it with other color shades of stain. The finale will be a final coating with clear or tinted varnish.

Types and composition

Modern impregnating stains can be classified according to their composition . The following types are distinguished:

- aquatic;

- oil;

- alcohol;

- acrylic;

- waxy.

Water based

Such impregnations are produced in powder form (soluble in water) and ready-made liquid formulations. This is an environmentally friendly and safe product with an impressive range of shades.

Water stain does not have a pronounced odor, so it can be used to treat interior and exterior wooden surfaces. In addition, it is characterized by high elasticity and adhesion to wood .

Despite its safety and practicality, the composition has some disadvantages.

The main one is that it is not suitable for processing wood with a high resin content . This may cause dark spots to appear.

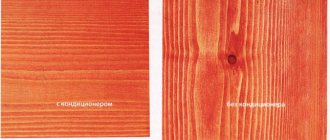

The next drawback is that when painting, wood fibers rise, which entails mandatory surface sanding . To eliminate this drawback, a non-aqueous wood stain is used.

Another disadvantage is a decrease in the moisture-resistant characteristics of wood with prolonged contact with moisture. They are quickly washed out by water, so they are not able to provide reliable protection of the material.

Oil based

Oil stains are based on coloring solutions in linseed oil or drying oil.

They are easy to apply with any available tool and have good resistance to fading, high humidity and temperature changes.

In addition, they do not lift wood fibers or fill them with excess moisture when stained .

Due to its high performance characteristics, this type of composition is suitable for treating structures inside and outside, forming a moisture-resistant protective film.

Thickened stain is diluted using white spirit.

Alcohol based

Impregnations are special solutions consisting of aniline dyes and denatured alcohol (alcohol base). They come in powder form and in the form of ready-made formulations.

Deep penetration of dyes into wood fibers leads to rapid coloring and drying of the surface .

To evenly stain wood with alcohol stain, it is recommended to use a spray gun . This will avoid the appearance of characteristic stains and stains.

Such compositions provide reliable protection of wood from negative atmospheric influences, and therefore have long been used to treat surfaces that are used outdoors .

Important! The main disadvantage of alcohol stains is the presence of a strong chemical odor.

Acrylic and wax based

Acrylic and wax impregnations are practically free of the disadvantages that are characteristic of traditional types . The compositions allow you to paint surfaces in any shade and increase their water-repellent properties.

The stains contain special acrylic resins and natural wax, which create a thin film to protect against the negative effects of external factors.

- Acrylic stains. They are environmentally friendly, fireproof and practical materials designed for various types of wood. They do not have a pronounced chemical odor, dry quickly, and have a wide color palette. To obtain a high staining result, it is better to apply the stain in two layers, the thickness of each of them should not exceed 3-4 mm.

- Wax stains. They are designed for treating painted wooden surfaces. Provide reliable protection from high moisture and temperature changes. The compositions are applied using a soft cloth in a circular rubbing motion.

Varnish for coating wooden surfaces

What varnish to cover pine floors with?

Varnishes that are used to coat wood come in several types:

Alkyd varnishes must be diluted with a solvent

. The surface treated with this product is protected from fire and water and does not fade in the sun. Thanks to acrylic varnish, a film is formed that does not allow the wood to wear off and slows down the aging of wood.

Nitrovarnishes, although they dry much faster, however, are not able to withstand the negative effects of ultraviolet radiation and moisture for too long. Polyurethane varnishes are characterized by increased wear resistance

and form a durable film on the wooden surface that dries very quickly.

Relatively recently, oil-based varnishes were very popular, but nowadays they are used most often for treating floors. Their main advantage is their low price. Such varnishes must be diluted with drying oil, and they take a very long time to dry. Such a new product as acrylic varnish, which is universal and easy to use, has proven itself well on the Russian market.

It is used for both external and internal work. This varnish should be diluted with water, and it does not have a strong odor. In its protective qualities it resembles alkyd varnishes, but is much more economical to use

. But alcohol varnishes are used only for the restoration of antique furniture.

Preparing the wooden surface

It is recommended to apply stain and varnish only to smooth and sanded surfaces. Regardless of whether the coating should be painted - new or old, it must be carefully inspected. All detected cracks, seams and knots should be processed and eliminated

If gaps are also found between the joints and seams, they are sealed with a special putty

. As soon as it dries, to remove possible unevenness, the putty areas are sanded again using fine sandpaper.

One should take into account the fact that it makes no sense to putty on raw or under-dried wood, much less treat it with stain or varnish it. This tree begins to deform

and the applied layer always becomes unusable.

How long does it take to dry?

Each type of stain has different drying times , which are indicated on the packaging or in the instructions for the selected composition.

- When applied to a surface, water stains dry from 12 to 20 hours;

- alcohol compositions dry quickly, up to 5-7 minutes. In low temperature or high humidity conditions, drying time may be 30 minutes;

- oil impregnations dry in 1 to 2 days after application;

- acrylic compositions dry within 60 minutes;

- Wax stains dry for 12-14 hours after application.

Application rules

The wax emulsion is applied with a brush.

In conclusion, we would like to give some practical tips on applying stain to a surface. In each specific case, the instructions will have their own characteristics, but we will try to consider the most general points.

So, let's start by reminding you: stain is not paint, it must be absorbed into the pores to a certain depth, so the most favorable conditions for this should be created.

Basic application methods.

First of all, you should prepare the surface. It must be cleaned of any coatings, dirt and dust, and also treated with fine abrasive sandpaper to open the pores. It must be remembered that they will be open for no longer than two hours, so grinding must be done immediately before starting work.

You should also prepare the stain. It can be heated to a temperature of 40 - 50 ˚С, so it will be more fluid and better absorbed into the material. It is especially important to ensure the permeability of dense wood species; for this, the composition can be diluted with water, and if the wood stain is non-aqueous, with a solvent.

Applying the solution with a brush.

When working with aqueous solutions, in order to avoid raising the fibers, which is fraught with loss of protection from moisture, the surface is pre-wetted, and then wait a while and sand it with sandpaper. This allows you to neutralize the unwanted effect.

When applying the material with a brush, work along the grain lines. Thick formulations and gels should be rubbed in thoroughly; for this you can use cotton swabs wrapped in cotton cloth or gauze.

Oil and nitro stains are quite toxic, so when working with them it is better to ventilate the room or go outside. Gloves and eye glasses are also a good idea.

To create the effect of aged wood, the stain is first applied liberally and then wiped off with a cloth. This way the texture becomes especially expressive and varied. For this work, you should use oil or wax.

Alcohol compounds are poisonous.

Important! Alcohol solutions are made on the basis of ethyl denatured alcohol, which can contain up to 10% methanol, which is a dangerous poison.

Color spectrum

In accordance with the international classification, each color is assigned its own code and name .

For example, “pine”, “walnut” or “fruit wood” stain.

To choose a wood stain in a suitable color scheme, you need to carry out a test painting of the wood and take into account:

- natural shade and type of wood subject to processing. Painting with stain can lead to the appearance of new shades;

- the color range stated in the catalogue. Colors under the same code from different manufacturers can produce shades of different depth and saturation on different types of wood. The same composition on pine will look lighter than on red wood. This can be explained by the fact that such wood has a more saturated natural shade;

- quality of stains. Compositions in the same color from different manufacturers can give different coloring effects. Therefore, you should not choose products of dubious quality;

- density of stains. The lower the density, the more the composition is absorbed into the wood. This results in a less saturated and deep shade.

The following colors of water-based wood stains are considered the most popular:

- “oak” – rich brown shade;

- “mahogany” – a noble burgundy shade;

- “pine” – the shade is close to the natural color of the wood;

- “natural” – natural light yellow shade;

- “light walnut” – practically does not change the natural color of the wood, and is used as a protective composition;

- “cherry” – light red and rich burgundy shade;

- “mahogany” – brown with light shades of red;

- “Wenge” – dark shades of brown;

- “larch” – from dark yellow to orange hue.

Creating effects

Alcohol or water stain can create an imitation of the naturalness of the coating without obvious traces of processing. When choosing a material for protection and painting, focus on the desired effect: choose a shade of oak, pine or ebony (as in the photo) - the interior will instantly be ennobled.

Products made from ash or oak do not need to be tinted - leave their structure and shade open, choosing the shade of this species that is as close to nature as possible.

Properly stained wood should retain its natural appearance. Only acrylic or wax stains stand out, the color range of which goes beyond naturalness.

The properties of each type of wood are different. In order not to make a mistake when purchasing, pay attention to the flower palette: the composition is applied to planks of different types, where you can see the final result.

How to make it yourself

You can prepare a simple stain for wood processing at home:

- from plant ingredients;

- from tea and coffee products;

- from chemical components.

Based on plant materials

- Decoction of onion peels to obtain a bright red hue.

- A decoction of walnut peels to obtain a rich brown hue. To do this, the shell is crushed to a powder and boiled for 12 minutes in water. Add 1 tsp to the finished strained broth soda _ To obtain a red tint, potassium bichromate is added instead of soda; for a gray color, vinegar essence is added.

- Decoctions of oak, willow and alder bark give a rich black color.

- A decoction of buckthorn berries will paint the wood an attractive golden color.

From coffee, tea and vinegar essence

- To get a rich brown tint, it is enough to combine natural ground coffee and soda .

- To stain light wood, you can use a strong brew of black tea .

- To obtain a deep black shade, you need to place metal nails in a container and fill them with acetic acid . Leave for 5-7 days in a dark place.

Based on chemical components

- The brown tint is obtained after treating the wood with a solution of slaked lime .

- A deep cherry tint is achieved by applying a solution of potassium permanganate . To do this, you will need 60 g of potassium permanganate, which is diluted with a liter of heated water.

- A rich yellow tint is obtained by treating the surface with a decoction of barberry roots , to which alum is added.

- The herbal color will be obtained by combining 60 g of verdigris and vinegar essence . The mixture is boiled for 10 minutes.

- The dark brown color is obtained by combining wolfberry with copper sulfate . Glauber's salt with these berries gives a red color, and soda gives a blue tint.

With whitening effect

Bleaching stains are used as a base before painting wood, allowing you to achieve unusual color solutions . For example, apple wood can acquire a noble milky hue, and walnut can acquire a red or light pink color.

Whitening stains can be prepared as follows:

- Composition based on oxalic acid. To do this, 6 g of acid is diluted with 120 g of warm water. The finished stain is suitable for processing light or bleached wood. After application, the surface is thoroughly washed with the following solution: 4 g of soda and 16 g of lime are diluted in 110 g of water.

- Hydrogen peroxide based solution. To do this, you will need a 30% peroxide solution, which is available for sale at any pharmacy. It is suitable for bleaching various types of wood. However, it should not be used on oak, rosewood or mahogany.

Flow calculation

The main indicator that must be taken into account when calculating consumption is the degree of porosity of the base material. Any stain has excellent absorbency. On average, one liter of composition is required per 15 m2

It is also important to consider the intensity of the shade. Conifers have low absorbency, so they will need to be processed in several layers to achieve the desired pattern, which will at least double the consumption

The amount of material used is affected by the shape of the surface to be painted, the presence of corner locks, and hard-to-reach places. On each container of the mixture, manufacturers indicate how much mixture must be used to obtain a certain pattern. The exception is oil compositions, the task of which is to saturate the wood until the pores are completely filled. In this case, the type of tree and its condition are taken into account.

Dealing with defects

It happens that the stain is applied to the surface incorrectly. Here are the main ways to eliminate defects:

- For numbness. Immediately after tinting the wood, you need to cover the area with varnish, which will dissolve the stain. Then clean the treated area with a rag. When the drip has already dried, it will have to be softened with white spirit or ground off with sandpaper.

- For stains. If we are talking about plywood, you will have to remove all the veneer using a plane. Solid wood is also processed with this tool, removing the thin top layer.

How can I remove stain?

The easiest way to remove water stain from your hands or treated wood. Of course, you can only remove the top layer, because such stains are distinguished by deep penetration. Stained clothes can be washed with regular powder, then rinsed with conditioner. If necessary, use oxygen bleaches, and chlorine bleaches on white items.

If stain gets on linoleum, wipe off the stain with acetone or white spirit. You must work carefully so as not to discolor the surface of the material. You can get rid of stain stains on the skin using vegetable oil or by frequently washing your hands with soap. It is much more difficult to remove non-aqueous types of stains from surfaces; you will have to remove the top layer of wood along with the tinting coating.

Painting while preserving the structure

How to paint the lining to change the color but maintain a pronounced wood grain? You can use the brushing technique, which in this case involves processing the lining in several stages:

- First, pigmented oil, wax or glaze is applied to the surface.

- Then the selected varnish or paint for the lining is taken in a small amount, applied along the entire length of the board and gently shaded.

- After 10 minutes, use a soft, lint-free cloth to remove most of the oil.

The result of such manipulations will be a bright and expressive wood pattern, emphasized by the pigment remaining in the grooves and recesses. This method is great when using lining in different interiors: country, Provence and many others.