The reliability and aesthetics of complex wooden structures largely depends on the correct choice of the method of connecting its component parts. This is especially true for frame products and load-bearing structures, where safety parameters come to the fore.

High-quality connection of wooden parts is the key to durability, the basis for an attractive appearance of the product, an indicator of the skill and professionalism of the carpenter and joiner.

Selecting the type of connection

In general, there are a huge number of types of joints of wooden blanks, so we can only talk about some of them, the most common.

One of the easiest ways to extend a wooden part (timber, log, board) and increase its width is an end connection. There are several options for its implementation. A simple and functional half-thickness (half-tree) method is often used. Depending on the expected load on the part, the cut can be straight or oblique. In some cases, the joint is strengthened using figured cutouts - locks. This type of connection prevents stretching, twisting, and bending. This is how the beams are spliced together for the purpose of lengthening.

Creating three-dimensional frames or wooden frames requires reliable connections at various angles. In this case, it is rational to use a tenon-groove or tenon-eye connection. The nodes at the junction of parts can withstand displacement, bending and compression loads. If the structure requires high tensile strength, the cutouts are made trapezoidal.

Additional connections of frame products, which impart rigidity to the structure, are implemented using T-shaped or cross-shaped connections. The main load at the joints is compression, displacement and rupture. In special cases, the structure is additionally reinforced with metal corners, screws or nails.

To connect boards together into box-shaped structures at right angles, it is convenient to use a special box groove. As the name implies, this method is often used to create three-dimensional structures, including furniture boxes. A high-quality box joint looks monolithic, has an attractive appearance and can withstand impressive loads. When creating wooden furniture, dowel, dowel and domino joints are often used (when the groove is oblong, as opposed to a round dowel).

Delivery across Russia

Delivery to the regions is carried out through transport companies (hereinafter referred to as TC) at the expense of the client. The calculation of the cost of delivery, as well as the choice of shopping center is carried out by the buyer independently. Goods are shipped only to the TK terminal in Moscow several times a week. For delivery from Moscow to the destination city, the Buyer pays directly to the shipping company upon arrival of the goods at the terminal in the destination city.

We work with the following shopping centers:

- Energy (2 times a week)

- Business Lines (2 times a week)

- SDEK (3 times a week)

Delivery is made ONLY after advance payment of the invoice, for both individuals and legal entities. Attention: When sending through a transport company, additional packaging and courier delivery of the order to the transport company's terminal may be required. Packaging costs from 80 rubles and courier delivery costs from 250 rubles. These additional costs and their final cost will be indicated when issuing an invoice for payment of the order after it has been agreed upon!

Delivery is also carried out by Russian Post (at the expense of the client). But some products, for example tenon saws, are delivered exclusively by transport companies. Because There are restrictions on weight and dimensions for postal items.

Attention! We reserve the right to change the delivery method if it does not increase the cost of delivery for the client, but significantly improves the delivery conditions (for example: cheaper, or faster, or closer to the residential address).

Pickup is also possible at the address indicated on the website, but by prior agreement.

Tenon joint (tenon and groove)

The simplest and one of the most reliable is the tongue-and-groove connection. It is widely used in carpentry. In a similar way, wooden parts of window frames are assembled into a single whole, a wide variety of cabinet furniture parts and plywood sheets are made. The essence of this method is that a tenon is made at the end of one part to be connected, which is inserted into the groove of the other part and fixed in it.

For work, it is convenient to use a special lamellar router; in the absence of one, you can get by with a simple hand tool. You will need:

- hand saw with fine teeth;

- electric or hand drill;

- several chisels of different widths;

- sandpaper;

- measuring tool, square and pencil.

First, the blanks are marked. The parameters of the tenon and groove depend on the parameters of the wooden parts and the configuration of the product, however, it is worth considering several general recommendations.

Important! The thickness of the tenon should be approximately a third of the thickness of the part, the width should be 70-80% of the width, the length should be equal to the thickness of the workpiece being joined.

The groove parameters must also meet these criteria. In any case, it is important to ensure that the dimensions of the tenon and groove match. The parts should connect easily, without pressure, but not fall out under their own weight. There should be no backlash, cracks or distortion.

The groove is cut out first, this sequence is due to the fact that the tenon is much easier to fit into the groove than vice versa. Cuts are made using a saw, excess wood is removed using a drill, the bottom of the groove and the walls are leveled with chisels.

Next they make a spike. The block is clamped in a vice and the excess wood is removed with a hand hacksaw. The tenon is adjusted to the required size using chisels and sandpaper.

In most cases, only wood glue is enough to fix the parts; screws or nails will help ensure maximum strength.

Half-tree connection

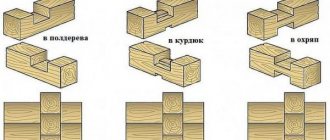

Quite often in carpentry they use various options for half-timber joints (simple or straight lock). This type of assembly of wooden structures is characterized by ease of manufacture and high reliability. The following varieties are distinguished:

- cross connection;

- half-tree - dovetail;

- gusset;

- on the mustache;

- half-tree splicing.

The first two methods are used to connect parts that intersect at right angles. Especially popular is the dovetail, in which the neckline is trapezoidal and the sides are not at right angles. The lock groove widens slightly from the end, providing a more reliable fixation. It should be noted that a tenon joint can also be called a dovetail if the tenons are cut in the form of trapezoids.

The second and third methods form a completed angle. Splicing is used if it is necessary to increase the length of the workpiece.

Payment Online.

You can pay an invoice using the details specified in it through your personal account on your bank’s website or through your bank’s mobile application. To pay, go to the website (for example: Sberbank Online .) On the “Payments and Transfers” page, click on the “Organization Transfer” link (note: in the bank’s mobile application this menu item is called “Payment by details”). Fill in the details of the payment recipient (see previous paragraph). Attention:

- The “Account number” field corresponds to the current account;

- In the “Recipient’s Bank” block, select from the directory the name of the bank in which the recipient’s account is opened. To use the directory, click on the “Select from directory” link. In the window that opens, check the box next to the desired bank and click on the “Select” button. As a result, the “BIC” field will be filled in automatically.

- In the “Purpose of payment” field (if required), enter the order number. It is assigned after successful ordering. Check the entered data and confirm the operation with a one-time password. After this, the payment will be sent to Sberbank for processing. The payment is credited to the recipient's account no later than the next business day after the payment is made.

- When filling out the Full Name field - you must enter your Last Name, First Name and Patronymic

- In the address field - you enter your address.

How to make a cross connection

One of the simplest is the cross connection. It is easy to manufacture; even a novice carpenter can master its intricacies. The work is performed in the following order:

- markings are made. The parts to be connected are placed on top of each other. Using a ruler, draw a cutting line. Thickness markings are applied using a thickness gauge;

- the first part is clamped in a vice. Using a hand saw, carefully cut along the lines to the mark left by the surface planer. The workpiece rotates. A second cut is made;

- the workpiece is removed from the vice. Using a sharp chisel and a wooden mallet, remove part of the wood between the cuts;

- the second part is processed;

- The planes are leveled using sandpaper or an abrasive stone.

Now you can join wooden blanks. The connection must be tight, without backlash or gaps. If the product is one-piece, the joints are coated with wood glue, and the structure is additionally reinforced with screws.

How to combine several of your orders into one?

Open the desired order. In the order control panel, click the “add to cart” button. Then click the “archive” button or the “cancel order” button - so that there is no confusion. That. you can transfer the contents of all your orders to the basket, and then opening the last order, add the entire contents of the basket to it, as described in the previous paragraph. If, in the process of combining several orders into one, you need to add something from the site catalog itself, then you can also add the necessary products to the cart or remove unnecessary items from the cart and then transfer the contents of the cart to the desired order. IMPORTANT!!! This operation is available for orders with the “preliminary” category. If the order category is different, then this operation is not available!

Forming miter angles

One of the best ways to create corners of various volumetric products is a miter joint. It allows you to create a monolithic structure, hide the fibers of the end, thereby providing an attractive appearance. This method is suitable for a wide variety of products, but is most often used for the manufacture of frames and cabinet furniture parts.

To create a joint, cuts are made in each of the wooden parts at an angle equal to half the angle at which the workpieces meet. Most often, this angle is right, therefore, cuts are made at 45 degrees, however, the angle can vary widely. The work is performed according to the following algorithm.

First, mark out the details. It is important not to forget that the markings are made along the long side, otherwise you may not guess with the dimensions.

On the edges that will be connected, draw a line at the required angle. Using a combination square, the markings are transferred to each side of the workpiece. Then the cut is made, for which it is better to use an electric miter saw, but you can also work with a hand tool. When working with a hacksaw, it is important to control the cutting angle; it would be useful to use a block as a guide.

The finished parts are placed next to each other, checking the accuracy of the fit. Unevenness will have to be smoothed out with a hand plane, and the angle will have to be adjusted using sandpaper. Wood glue is applied to both surfaces, and the product is fixed using clamps. Additional strength can be achieved using nails. When working with a hammer, it is important to control the impact force so that the workpieces do not move.

Particularly critical connections are reinforced with bars that are glued into the inner corner. A joint that will not be visible can be additionally reinforced with a metal square.

The result of quality work will be a perfect seam. If a small gap has formed, it can be hidden by straightening the adjacent wood fibers using a smooth cylindrical surface. The shaft of a regular screwdriver is suitable for this.

Spike in eye

Corner and T-shaped (example: T-shaped connection of a window frame) intersections are conveniently performed using the tongue-to-ridge method. In this case, the eye is made at the end of the vertical part, and the cuts for the tenon are made in its horizontal component.

The work begins with marking the eyelet. The thickness of the workpiece is divided by three. With a thin hacksaw, cuts are made to a depth equal to the width of the other workpiece. Excess wood is removed using chisels, and the walls of the eye are smoothed with sandpaper.

Mark the second workpiece. The width of the tenon should be equal to the width of the first workpiece, the thickness should be equal to the thickness of the tenon. The cuts are made with a hand hacksaw, carefully controlling the depth and angle of inclination. Remove excess with a chisel.

The final adjustment of thickness is carried out using sandpaper. The parts should connect with light force and not fall apart under their own weight.

Types of connections in joinery and furniture products

To ensure that the tenon is integral with the bar, the end part of the latter is processed accordingly.

The tenon is made from a separate piece of wood of the same species as the bars being joined, or from more durable wood. In both cases, the direction of the fibers of the tenon wood should be proportional.

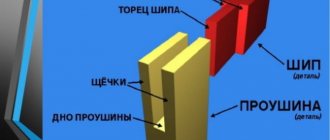

The spikes are flat, round, rectangular and trapezoidal. A tenon that passes right through a block is called a through tenon. A thorn that does not pass through is called hidden.

Flat tenons are usually integral with the bar, while round tenons are most often inserted. A spike, the side edges of which widen towards the end, is called a “swallowtail” or “nagrat” . If only one side edge of a tenon expands, it is called a one-sided “burst.”

The side edges of the spine are called cheeks ; the cut end parts of the bar, forming a tenon, are shoulders ; the end part of the tenon is the end . The length of the tenon is the distance from the shoulder to its end (end), the width is the transverse size of the cheek, the thickness is the size between the shoulders of the tenon (Fig. 11).

Rice. 11. Elements of a tenon connection: 1 - tenon; 2 - shoulders; 3 - cheeks; 4 - eye; 5 - nest.

The strength of a tenon joint largely depends on the correct choice of tenon sizes. The main dimensions of the spikes are determined by GOST 9330. Thus, the thickness of a single spike is S = 0.4 S0; double tenon thickness S1 = S3 = 0.2 S0; triple S1 = S3 = 0.14 S0, where S0 is the thickness of the part (Fig. 12).

The calculated thickness is rounded to the nearest larger nominal size: 6, 8, 10, 12, 16, 20 and 25 mm. The length of the through tenon should be equal to the width of the bar, the length of the blind tenon should be half the width of the bar. The depth of the socket is made 2-3 mm greater than the length of the spike. It is recommended to bevel the end faces of the tenon on both sides at an angle of 25-30° so that the tenon fits better into the socket and the glue is less likely to run off the cheeks of the tenon.

In double and triple tenons, the gluing area increases by 2-3 times and the strength of the connection increases.

The dovetail tenon is strongest at an angle of 10°. At a larger angle, the cheeks of the tenon chip off, and the connection becomes less strong.

In the manufacture of furniture, round insert tenons (dowels) are increasingly used. The main advantage of joints on such spikes is the simplicity and strength of corner ties. The use of dowels makes it possible to mechanize and automate production processes.

The strength of the dowel connection depends on the following factors: the amount of interference (clearance) in the connection; the depth of pressing of the dowel into the end of the bar and into the edge of the paired bar (for example, connecting the drawer of a chair with the leg); method of applying glue: only on the walls of the hole or dowel or on both surfaces to be connected; the type of wood from which the dowel is made; dowel diameter.

According to GOST 9330, the total length of the dowel is L = 2.5-6d, where d is the diameter of the dowel.

- Back

- Forward

Thorn in socket

A more complex connection is the tenon-to-socket method. It requires more skill, but is much more reliable and durable. The scope of use is the same as in the previous case, namely T-shaped joints. The difference between this method is that the tenon is made at the end of the vertical part, and a socket is cut out in the body of the horizontal part.

This is one of the most common furniture connections. There are connections with a through tenon and with a blind one. The difference is that in the first case a through socket is cut out, in the second the slot is made to a certain depth.

How to buy several products with one order?

Find the product you need. Click on the Add to Cart . Please indicate the quantity. After this, the product will appear in your cart. Similarly, place all the necessary items in the cart. Then click on the trash icon in the top right corner. After this, you will find yourself on the page with the selected products. If you don’t need to change anything, then click the buy , fill in your contact information and click the Send at the bottom of the window. If you need to remove something from your cart, click on the cross at the beginning of the line with the desired product.

Features of Japanese joinery

Japanese masters have reached unprecedented heights of carpentry art. Using traditional techniques and combining different types of joints, they create precise and reliable joints without the use of nails or other fasteners. The joining of various wooden parts is carried out solely due to the force of friction.

The reliability of these connections is based on precise cutting. The perfectly matched locking lines on both mating parts allow you to create a connection with impeccable precision. Complex lock configurations require a lot of experience, knowledge and ability to use the tool, but if you want, all this can be learned.

Placing the boards together

High-quality wood is expensive, and it is not always possible to buy a good board with the necessary parameters, and it is not always necessary. To make, for example, a tabletop, it is not at all necessary to look for a table-wide board; with carpentry skills, you can create an ideal wooden sheet with the necessary parameters.

There are many options for bonding. A board with a tongue and groove, the so-called lining, is widely used. It allows you to create smooth wooden surfaces of a large area. A simplified version of it is often used - a board with a quarter joint.

Joining on a smooth fugue (butt)

The simplest method that does not require additional elements. The side edges of the boards are jointed; it is better to do this in pairs, clamping both adjacent boards in a vice and processing them at the same time. This treatment will create a precise surface on which the unevenness of one board will be compensated by the unevenness of the other. Both boards are coated with glue and fixed until it hardens completely.

Using additional connections

This method provides a more reliable design, but is not particularly complicated. The boards for it are also leveled, but symmetrical holes are made in the connected ends for installing dowels or pins. It is possible to strengthen the resulting fabric using driven-in metal staples. Of course, the staples are driven in from the inside of the product.

Bonding load-bearing elements

There are several ways to lengthen (build up) a board that is part of the supporting structure. The simplest and most reliable is a half-timber connection followed by overlaying reinforcing strips at the junction. Non-critical areas can be reinforced with plywood.

The same method is also used to join boards at different angles. Precisely made cuts of the jointed parts make it possible to do without reinforcing linings; it is enough to secure the boards at the joint with screws.