Perhaps fasteners for wooden structures are considered by some to be an unnecessary innovation, saying that a hut should be cut without a single nail, and such an opinion, of course, deserves respect.

However, various angles, brackets, brackets, plates, sliding fasteners and similar fittings make the installation of beams and logs much easier, and both the customer and the contractor benefit from this, because the time saved in most cases saves money.

We will now tell you what metal fittings for fastening lumber are, and we will give some examples of its use, as well as demonstrate a video in this article.

Wood fasteners

Mounting hardware

The variety of metal fasteners in the construction of wooden structures and furniture production is quite large. But such fittings are not the prerogative of any private or government organizations - they can always be purchased in furniture and hardware stores in our country.

Threaded fittings

- The most common types of fasteners for wooden structures are ring anchor nails, wedge anchors, universal and hex head screws, self-tapping screws, threaded rods, hex nuts and metal washers. Such fittings are often auxiliary not only for joining timber, but for other overhead fasteners, which will be discussed below.

- Often, instructions from the manufacturer state that all fittings of this type must be made of hardened steel, and for external work a galvanized coating is required. Black phosphated self-tapping screws are recommended for use exclusively for interior work, and even then, provided that there is no high humidity in the room.

- To install parts with perforated fasteners, it is recommended to use low-carbon galvanized screws with a conical head that is well recessed into the perforated surface of strips, corners and similar elements.

- For large parts (areas with high loads), it is recommended to use low-carbon galvanized screws with a hex head (using standard DIN571). Of course, the price of galvanized electrolytic steel is slightly higher than usual, but such fasteners allow you not to worry about the reliability of fixing the parts.

Note. Currently, professional builders often use corrugated (ring) and rafter nails. Unlike wood screws, each turn is closed, which provides greater tensile strength - it is almost impossible to pull them out after installation.

How does the installation work?

Before you start attaching the imitation timber to the wall outside or inside the house, it is subjected to acclimatization. The material is unpacked and left for 4-6 days where installation will take place. Only in this case will its humidity be equal to the humidity of the environment, and in the future the new cladding will not begin to deform.

Source master-saydinga.ru

While the material is gaining moisture, you will have enough time to prepare tools, fittings and components. At the same time, they begin to assemble the frame and the base for the cladding. The work is performed as follows:

- A wooden beam is selected, the cross-section of which coincides with the thickness of the heat-insulating layer. All wooden parts are pre-treated with an antiseptic.

- The beam is fixed on the wall, always perpendicular to the direction of the finishing material (in this case, vertically), with a given pitch.

- The insulation is placed in a prepared sheathing to imitate timber, and a vapor-permeable membrane is attached on top.

When the sheathing is ready, markings are applied to it and the false timber is installed, starting from the bottom. Outdoors it can only be installed horizontally. There is no direct prohibition on laying imitation vertically or diagonally. However, in this case, joining and fastening the parts is much more difficult, and such installation is only suitable for indoors. The sheathing can be installed in two ways, depending on the type of fasteners.

Source krepezhinfo.ru

Mounting corners

Fasteners for wooden structures - different types of angles

The well-known perforated metal corner is a universal device that is used both in the construction of wooden structures and furniture assembly, and in the arrangement of ventilated facades. They can be of different sizes, but this depends on their purpose, that is, the force of the load on a given unit and its configuration are taken into account.

Note! The smallest perforated corners are needed for assembling furniture, installing partitions, window and door openings, sheathing (frames) for insulation and cladding, and larger ones are needed for wooden beams.

In any case, such fittings should be narrower than the parts that are joined with its assistance, at least 2-3 mm on each side. In cases where the timber is attached to a concrete slab or block, the part must have holes for anchor bolts.

Reinforced corners with stiffening rib

When assembling units where large bending loads are subsequently expected, a perforated galvanized corner with one or two stiffening ribs is used, where the metal thickness must be at least 2.5-3 mm.

The perforations located at the ends of the element can be 5, 7, 11, and 14 mm in diameter - this variety allows fastening using self-tapping screws, screws and anchor bolts of different sections.

Fixing elements of this type, as in the top photo, are used when installing rafter systems for attaching rafter legs to the Mauerlat and for installing roof windows on a sloping roof. This corner eliminates the need to saw out (cut out) grooves on the beams, since the element itself consists of two parts that intersect at an oblique angle and can be shifted relative to each other.

Tapes and plates

Perforated tape is used to strengthen various nodes that are connected at an angle, for example, this could be the connection of rafter legs, where the tape fixed on top will not allow the joint to move apart. The thickness of the tape varies from 0.8 mm to 1.5 mm, and its use depends on the power of the loads that will be exerted on the unit being formed.

Read also: Why the soldering iron does not heat up

Perforated plates

Perforated plates are very similar to tape, but their thickness is much larger and reaches 2-2.5 mm, and they are used for almost any connection in the same plane, regardless of the purpose (this can be either hidden or open fasteners).

Such parts can be used outdoors in conditions of high humidity, since the steel here is galvanized. The elements are overhead and do not require insertion; they are fixed with nails or screws.

Supports

There is a type of fastener for wooden beams, such as supports, which can be screwed to the base or concreted; in addition, they can have a base for a column that will be adjusted with a jack, that is, the beam can be adjusted in height.

An adjustable support allows you to protect the butt of a wooden beam from moisture, and it also serves as a compensator for subsidence of the building in the first year and a half after construction. However, the main area of application of such a structural element is wooden houses designed for shrinkage and shrinkage.

Serrated plates and washers

Serrated plate (left) and washer (right)

Toothed fastening plates for wooden structures are used to tighten elements and prevent slipping instead of various screws or in combination with them; in the European Union they are labeled as BULLDOG. When joining, the teeth are pressed into the surface of the wood, providing additional strength to the joint.

Hidden fastener Snake for planken

The snake is used for hidden fastening of facade and terrace boards. The boards are fastened through holes in the metal plate (see photo). The top one is intended for fastening the board with a guide/joist (30 mm screw), the other holes are for fastening a metal plate with a larch plank board, etc. (16 mm screw). The snake fastener comes with or without a stopper. The stopper allows you to create a gap of a given size between the plank boards. We believe that there is no point in using a snake with a stopper, because... the gap between the boards can be easily set using spacers or improvised objects (pencil, nail, etc.). Recommended gap width is 4-6 mm. The hidden snake fastener for painted plank is good because there is no need to touch up its front part. The consumption of snake fasteners per m2 is about 20 pcs. The price for hidden Snake fasteners is based on three suitable self-tapping screws.

Perforated fasteners

The main material of the mounting elements is galvanized steel. The geometry of the structures may be different. A common feature is the presence of many holes. Perforation makes it possible to select the desired attachment point in the tree . Self-tapping screws are screwed in through it or screw nails are driven in. Advantages of this type of fastener:

- Saves time on connecting wooden structural elements.

- A small amount of waste when attaching units.

- Possibility of installing several hardware in one plane. This increases the load-bearing capacity of the fastening unit.

- Variety of types of installation products. Allows you to select the optimal solution for uniformly distributing the load on the wooden components of a building or structure.

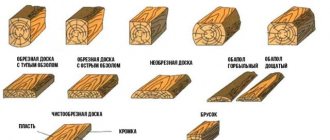

- Versatility. Suitable for all lumber.

- plates;

- corners;

- beam holders;

- three-dimensional slats;

- mounting tape.

Plates

Planks with many holes are used to fasten wooden elements in one plane. In terms of plan, parts can be of different shapes (for example, in the form of the letters T, Z). The plates are made of steel with a thickness of 1–3 mm or more.

The parts bend easily, which is convenient when joining wood at an angle of 90° or more. You can cut the plates with metal scissors.

Corners

To connect wooden structures at right angles, equilateral, reinforced, double-reinforced, anchor metal corners are used. There are more complex products: Z-shaped, sliding, and other modifications.

Beam holders

The product allows you to connect beams and beams. The fastening is installed on self-tapping screws or self-tapping screws. The supporting part of the beam is fixed from the sides and bottom. The perpendicular planes of the steel part are fixed to the transverse beam. The photo shows one of the holder options.

Three dimensional slats

They come in different lengths. The design feature is that the connection elements fix the tree in three planes. The slats form a strong and reliable connection in the nodes . Metal longitudinal slats perform two functions: they bind the wood into a single system, they are load-bearing beams that take on a significant part of the vertical load.

Fasteners - T-shaped profile made of durable steel alloy . They are produced by the Italian company Alumidi. The slats are selected based on the cross-section of the elements being connected, the level of dynamic and static loads.

Mounting tape

Perforated galvanized steel tape is used as an auxiliary fixation when making complex joints of wooden structures. It is easy to cut into fragments. It is also used as fastening of non-metallic products to wood.

Read also: Why a hydraulic jack does not lift under load

About the features of the material

Imitation of timber is a simple way to give your home (or room) a presentable appearance in a fashionable environmental trend. The finished cladding is indistinguishable from a wall made of timber. The material is considered universal, as it is suitable for finishing houses with any walls: brick, block, stone, monolithic concrete.

It is never confused with eurolining; the latter is quite easy to identify by the longitudinal depression on the front side. However, it happens that confusion occurs in relation to classic lining. Therefore, I consider it necessary to emphasize the following features of false beams:

- The width of the wooden panels is in the range of 90-190 mm; There are options up to 250 mm wide, but there is little demand for them due to their high cost. A width of 135 mm is in demand; it is suitable for external and internal cladding.

Source elfa93.ru

- The length varies between 3-6 m, you can find lengths from 1 m and cheaper non-standard pieces. Thanks to the chamfer on the long side, the finished wall looks holistic and natural.

- The characteristic thickness is 18-34 mm. For exterior cladding, lumber with a thickness of 20 mm or more is suitable; for interior decoration, I recommend using thinner options.

- Each false beam is equipped with joining parts, grooves and tenons on its long sides, which help to obtain a smooth, crack-free surface.

- On the facade, the material is mounted only horizontally, while the lining can be placed at any angle.

Source rubankom.com

Hidden details "Hedgehog"

Steel washers have an internal thread at an angle. Through holes are drilled in the wood through washers. A washer is also installed on the reverse side. A pin is screwed into the channel, which tightens the tree.

Several studs are installed at the connection points at once . In solid wood, the rods occupy a crossed position. This creates a strong hidden fastening of wooden structures. Fastening is also carried out with long self-tapping screws, which are located at an angle in solid wood (usually 45°). This method is used when constructing a wooden roof.

Tenon and groove

The fastening is created by the material of the parts being connected. In one element, the wood around the protrusion (tenon) is removed, in another array a groove is cut out.

The tenon must fit into the groove with some force to firmly clamp the protrusion in the hole . Lateral stresses create frictional forces between the tenon and groove, forming an almost permanent connection.

Depending on the dimensions of the parts, the dimensions of the tenons and grooves are determined . In cross-section they can be rectangular, square, oval. To increase the load-bearing capacity of the components, the parts are lubricated with carpentry or synthetic glue. In some cases, fastenings are strengthened by installing additional metal fasteners.

Hot-dip galvanized nails for façade boards

As in the case of self-tapping screws, not every galvanized nail is suitable for external fastening of facade boards. We use the recommendations of Finnish experts, who recommend using hot-dip galvanized nails. This type of nails is made in cassettes for a nailer (nail gun), but they can easily be driven in with a hammer by hand. As with a self-tapping screw, the head of the driven nail should be flush with the surface of the painted board. We recommend using this type of fastener when attaching painted Scandinavian style façade boards. This board has a rough, sawn surface, due to this, tinting the nail heads can be done with a regular brush, without any visible differences. The consumption of self-tapping screws per m2 is about 20 pcs.

Supports

These are two supporting steel plates, pulled together by a pin. Installed between the bottom of a wooden house and the foundation. The upper platform is fixed with screws and bolts to the lower wooden structures of the building. The bottom plate rests freely on the base of the house or is secured with hardware or welding. The structure plays the role of a jack . By turning the studs, the horizontal level of the floor is adjusted. This type of fastening makes it possible to prevent upward penetration of moisture and creates a reliable support system for the house.

Decorative overlays

Designed for finishing seams in joints made of timber and boards. Curved plates are installed indoors, on the facades of wooden houses.

Fastening components of various modifications allow you to easily construct various structures made of wood. With such elements, the construction process goes much faster and at the same time the amount of the construction estimate for materials is reduced, since the percentage of scraps is reduced. Today, for the construction of a structure made of wood, a large number of connecting components of any modification are provided.

Briefly about the main thing

The design of the facade and interior using imitation timber requires the arrangement of sheathing and thoughtful fasteners. When choosing hardware, you should focus on the labor intensity of the process, the cost of the material, the reliability and external aesthetics of the result.

Fastening can be carried out in an open (facial, on the facade) and hidden (in interior work) method. Suitable fasteners include nails (construction nails, screws, finishing nails) and self-tapping screws (screws). The use of self-tapping screws reduces the risk of wood cracking. Clamps are suitable for fixing thin wooden panels; they are rarely used in exterior decoration.

Question

Write in the comments what do you think, is there a way to avoid (or reduce the likelihood) of cracking of imitation timber during nailing?

What is fastener for wooden structures?

Connectors for wooden structures are a metal product that can come in different shapes and models. This component is used both for connecting wooden products to each other and for fastening to other components.

Generally, wood fasteners are used to connect and fasten the following products.

- Rafter and sub-rafter systems.

- Foundation systems.

- Facades.

Fasteners for wooden products can be mounted either with self-tapping screws or with nails and bolts, depending on the complexity and severity of the structure.

Today, there are many manufacturers of connecting parts on the building materials market that produce the following types of fasteners.

- Supporting. It is actively used in the construction of timber buildings. Used for fixing roofing beams. Such fasteners belong to perforated types of connections.

- Couplings. Since bursas of even a small cross-section shrink by 3%, fastening components such as a coupling can compensate for this process. As a rule, they are installed at the corners of the beam.

- Nagel. A stick-shaped element that is used to fasten wooden beams of any section. It is one of the main elements in the construction of log houses.

These products are also divided into the following classes.

- Steel. Such connections include self-tapping screws, nails, dowels, anchors and bolts. Such elements are used to connect and fasten wooden structures. Such elements are made from steel alloy of various lengths and modifications.

- Metal. They are made in the form of metal plates and various geometric shapes, such as corners, squares, etc. Also, such fasteners contain many holes for convenient fixation. Such products can be used to fix and connect wooden structures.

Read also: Do-it-yourself segment bending machine

All of the above fasteners are, as a rule, used in the construction of a roof truss structure of any complexity.

You should be aware that holders for wooden elements have the following requirements and restrictions for use.

- The thickness of the timber when using metal holders must be at least 5 centimeters. This is due to the length of the screws and nails required to use this connection.

- In cases where nails are used for fastening, it is necessary to use rough nails instead of regular ones. This is necessary in order to prevent the fasteners from loosening during the drying process of the timber.

- In most cases, when using most connecting elements, it is recommended to install them in pairs parallel to each other.

Perforated holder

This holder has a very wide application not only in construction, but also in furniture making and in everyday life.

Perforated fasteners have gained high popularity in the construction industry and not only due to their undeniable advantages such as.

- Easy to install.

- Long service life. Since the fasteners are made of galvanized steel, they are not subject to corrosive and chemical attack.

- The use of these elements allows you to significantly save building material. The high strength and flexibility of the material allows the beams of the roof rafter system to be sewn together, which makes it possible to avoid cuttings.

- No special tools are required, which significantly speeds up the installation process.

Consequently, the use of perforated connections can significantly save time and financial costs in the construction of wooden structures.

Perforated fasteners are produced in the form of wide and narrow corners, plates and other geometric shapes. In addition to the rafter system, this type of connection can be used for the construction of the following structures.

- Wooden houses.

- Gazebo.

- Wood façade finishing.

Hidden fasteners

This type of connection is usually used to attach boards to facades and terraces. The advantage of this type of fastener is that it allows you to hide the components that secure the boards, which adds elegance to the structure. Hidden fasteners come in the following types.

- Lock holder . The principle of operation is that one board closes when installed into another, thereby hiding the fasteners.

- Snake holder. Allows you to install boards with or without a gap.

- Spike holder. It is attached to the joist and to the board being laid, the next board is placed on the holder's tenon.

- Groove holder. This element is attached to the joist, and the joint flanges fit into the grooves of the board. Among the features, it can be noted that this type of fastener is the fastest.

Each of the holders described above has its own modification, which is selected based on the complexity and weight of the structure.

Decorative fasteners

This type of connection is preferably used when decorating a room with wood to give it an aesthetic appearance. The decorative holder is made of both plastic and metal; in appearance it resembles a plug that fits onto any type of connecting element.

The decorative connector can be made in the form of a full-fledged hardware or as a plug of a certain shape and various patterns. As mentioned above, such fasteners are used for interior decoration, but can also be used for exterior decoration, when it is necessary to hide the connecting element and it is not possible to use hidden ones.

Price for board fasteners

| Name | Size, mm | Price, rub | Note |

Hot dip galvanized nail | 2,8*75 | 3.20 RUR/piece | Made in Germany. In a cassette for nailer (angle 21o). You can also drive in manually. Consumption 20-23 pcs/m2 |

Stainless steel self-tapping screw | 4,0*50 5,0*60 | 9.2 rub/piece 10.1 rub/piece | Made in Sweden. Highest weather resistance. The tip of the self-tapping screw has a special drill, thanks to this the board does not crack. Packing 100 pcs. Consumption 20-23 pcs/m2 |

Self-tapping screw with special coating | 4,5*55 4,8*75 | 5.0 rub/piece 7.5 rub/piece | Made in Sweden. A worthy answer to stainless steel. Yellow color. The tip of the screw with a drill, thanks to this the board will not crack. Packaging 250 pcs. Consumption 20-23 pcs/m2. |

Hidden Snake Fastener+ 3 screws (2*16 and 1*30) | 190 | 16.5 RUR/piece +2 rub/for 3pcs | Steel with zinc galvanic coating. Supplied complete with 3 screws. Consumption 20-23 pcs/m2. Packing 100 pcs |

Kleimer | 5-6 | 70 rub/80 pcs | Nails of size 1.2x16-25 mm are also included with the clamps. Packaging 80 pcs |

Price

Regarding the question of the feasibility of using fastening components for wood from the financial side, there are obvious advantages. Since the use of such fastening during roof construction can save 20-30 percent of material from the standard norm. Consequently, when purchasing material, you can purchase 1-2 cubic meters of wood less, thereby recouping the amount spent on fastenings.

It should also be taken into account that the cost of an experienced carpenter is much higher than a less professional one who can be hired when using connecting elements. For deeper savings, you can carry out the construction of the roof yourself, as when using fastening elements there are no special difficulties when installing the roof. Therefore, after calculating all the benefits, we can summarize that the use of metal fasteners is economically feasible.

The connection of wooden elements can be done in various ways, therefore, everyone can choose the type of connection independently based on financial capabilities and preferences.