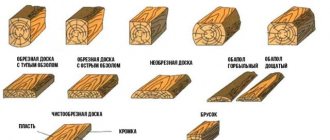

Edged boards are a material that is quite common in the construction market. It is produced by a huge number of enterprises. To properly understand this material, it is necessary to study its main characteristics. What is an edged board? It received this name because of the manufacturing method. The log is freed from bark, sawn and uneven edges removed . That is why the board is “edged”. Any edged log or board may contain wane. Wane is the remnant of irregularities. Let's consider the type of coniferous edged boards according to GOST.

Description of material

Standards have been established that indicate the percentage of wane content to the total area of the edged board. Such irregularities should in no case reduce the performance characteristics of the material.

Larch decking board price and other technical data of the material can be read in this article.

When choosing a timber material, the builder must consider what kind of wood the lumber is made from. After all, the indicators of strength and moisture resistance fully depend on this. Coniferous trees are most often used as material for the manufacture of edged boards. Spruce or pine usually act as the source. If all measures for proper operation are followed, coniferous lumber will last a long time. It is even known that such material was previously used as septic tanks in pipes; their service life was more than 100 years.

You can see what edged softwood boards look like in this article.

If you decide to buy edged boards from coniferous trees, then you need to pay close attention to their parameters. The standard length of the boards is 6 meters. The thickness and length may vary. Thickness can be 25, 40, 50 mm. The width can be 100, 150 or 200 mm.

But modern enterprises can also fulfill orders according to individual parameters.

In the video - edged softwood boards GOST 8486 86:

Terrace board dimensions, price and other characterizing data can be seen in this article.

General information about wood quality

Wood is a building material that has been used since ancient times. Now this material continues to be in demand in construction.

This material has the following positive properties:

- presence of high strength;

- low thermal conductivity;

- high resistance to chemical acids;

- glues securely and is easy to process;

- looks beautiful.

Properties such as high strength combined with lightness provide high quality during operation and use in construction. The texture of wood is of particular importance - the pattern formed by wood fibers and depending on a specific structure.

The texture directly depends on how the wood fibers are arranged and the color scheme.

The hardness of wood directly depends on what type of wood is available, on the conditions in which the tree grew, and the amount of humidity. Wood is considered a hydroscopic material, capable of absorbing moisture from the environment. At the same time, the moisture content of wood depends on changes in weather conditions. When humidity changes, it significantly affects the size of the planks.

The deformation of wood can vary, depending on the cut and how much tension remains after drying. A certain protection of wood is used, which is associated with protection from moisture, when varnishes or special oils are applied to the surface, intended to apply a protective layer.

To protect the material from moisture when it is transported, certain packaging is used that will well protect the wood from external physical influence.

The material is also impregnated with antiseptic agents under special operating conditions. To obtain excellent quality parquet flooring, the wood can be pressed, changing the density of the surface.

In order for the wood to last a long time and to make high-quality objects from it, optimal operating conditions for the coatings are created.

Wood has some disadvantages:

- surface heterogeneity;

- strong hygroscopicity;

- susceptibility to rotting;

- easy flammability;

- prevalence of vices.

These shortcomings can be eliminated if you comply with the requirements for technical measures and create favorable conditions for operation.

GOST standards for softwood lumber

There are no GOST standards for edged boards made of coniferous wood, so other standards are used. GOST 8486 86 and GOST 24454 80 are used. They talk about the general characteristics of all lumber. According to standards, lumber from coniferous tree species is divided into:

- selected variety

- first

- second

- third

- fourth.

Plastic decking board price and other data can be read in this article.

Selected variety

In products of this type, the presence of dry and rotten knots is not allowed. Fused but healthy knots, edge and rib knots are allowed. The standards tables indicate the quantities allowed for such lumber. Deep end cracks should be no more than 10%, and shallow end cracks should not be more than 16%. Any manifestations or signs of fungus should be absent. Minor warping or uneven edges should not exceed 1% of the entire area.

First grade

Such lumber must have the correct geometric shape. Compared to the previous variety, the indicators change slightly. The number of knots of healthy origin is 10% more. And the number of shallow cracks is 26%. Mold, fungal staining and heart stains should occupy no more than 10% of the total area.

Rotten places should be completely absent. Such defects are appropriate for breeds in the summer. Therefore, they do not carry any consequences; the structure of the wood will not be destroyed. Let's say a “pencil” wane. In length and edge it should be no more than 10% of the length. Grade 1 edged boards are used in the installation of roofing, construction of houses, beams and ceilings.

Edged oak boards are used for the purposes indicated in the article.

Second grade

The most important positive side is the low cost. The fiber inclination value is much greater than that of grade 1 boards. Resin pockets are also acceptable for such boards. Wane can be significant. Fungus staining and blue spots are typical for type 2 boards. The material is used for formwork and lathing.

Third grade

Resin pockets are allowed here in the amount of 4 pieces. per 1 meter of length. A double core and significant heel are characteristic of such boards. 20% core stains are acceptable. Through cracks that extend to the end and healthy and unhealthy knots are typical for such boards, but the number should not be more than half the area of the board. As a result, all the properties of coniferous boards are significantly reduced. Therefore, the material is not used everywhere.

All floorboard sizes can be found in this article.

Usually used if you need to build a temporary building, a change house, usually used for making pallets.

Fourth grade

The number of black spots increases to 6 per meter. Rot is allowed in an amount of 10% of the total area. The wane can be blunt or sharp, warping and winging are also allowed.

According to GOST, the external surface and linear parameters must have the following characteristics:

- the roughness of the ends should be no more than 250 microns, this also applies to the rough side;

- roughness of the front side, as well as longitudinal edges, no more than 40 microns;

- deviation in thickness of 1 linear meter is no more than 0.3 mm;

- in parallelism, the deviation of the edges from the side is no more than 0.3 mm;

- relative humidity or when selling from 12 to 15%.

How many edged boards 50x150x6000 are in one cube can be found out in this article.

Now let's look at each variety separately.

Extra - complete absence of defects with a perfectly smooth surface, as they say, no hitches. No resin pockets or defects, making this grade the most popular among wood finishes.

Lining calm larch Extra grade

Prima (A) - the difference between this variety and extra is that it has a small knot, which is regulated by no more than 1-2 per linear meter. For the most part, this grade contains all the material that did not fall into the highest grade. The presence of small light knots and resin pockets only gives the tree an even more natural, natural look.

Lining calm Angarsk pine grade Prima (A)

AB (B) - this grade represents an unregulated number of knots of 2 or more per linear meter with minor wood defects. Resin stripes, pockets and small defects on the edge are also found in this grade. But all these points in no way spoil the beauty of the finishing panel and the appearance of the wood.

Calm pine lining grade AB (B)

BC (C) is the most budget option in terms of grade, which is well worth paying attention to, no worse than its above-mentioned leaders, as they say, the third grade is not a defect. This variety contains everything that is not included in other varieties, and for lovers of natural style, these minor defects that do not affect performance will not look critical, but on the contrary, they will show themselves quite worthy as a material

Planken straight pine grade BC (C)

Material characteristics

An important indicator is relative humidity . Depending on this, the materials can be:

- raw

- wet.

You can see what a 20x100x6000 edged board looks like here.

Raw boards are made from fresh tree canes that have just been cut. The humidity of such material is 22% or more. Dry boards have a moisture content of 8 to 14%. Despite these parameters, you need to know that wood is a hygroscopic material. Therefore, during storage it can absorb more moisture, the percentage will change.

All scientific characteristics may not be understood by the average person. Therefore, you need to learn to understand and distinguish between certain types of coniferous boards.

- The material is considered to be of high quality if many annual rings are visible and they are located close to each other. Also, high-quality boards are made using radial sawing, in which case many rings will be visible. Wood is much stronger if its annual growth is small and the rings are close to each other. Basically, these parameters depend on the area in which they grow. In cold climates, trees are much stronger.

- The core is better not to have it at all. This is the most sensitive and soft part of the tree. Fungus and mold often appear here. There is no need to fall for marketing gimmicks. The manufacturer tries to advertise such boards as a design step, etc. But you should know that the larger the core, the lower the quality of the board.

- It is not recommended to buy materials that are too dry, although they are more expensive. After all, during use the humidity will still increase. It is also not recommended to purchase materials that are too wet. Pay attention to how the seller stores the boards. All products should be stored under a canopy where air flows well, or in a very dry room. Using the method of knocking on wood, you can also understand what quality the material is.

Of course, all these methods are not a panacea. After all, sometimes even a professional cannot understand what quality of material he is offered to buy. No one will examine every board. Therefore, try to buy edged softwood boards from the most trusted suppliers. Study and read forums, consult with friends.

You can find out how many edged boards 40x150x6000 are in one cube in this article.

Why can’t we get quality lumber?

The topic of wooden house construction in our country is worth returning to again and again, and again it should be recalled that this topic is most relevant specifically for Russia, and not for Canada, Finland or Japan. Due to our much harsher climate, it is completely impossible to use construction technologies that are successfully used all over the world. But many of our apologists for “cheap housing construction” are starting to argue about something they have no idea about.

And they have no idea at all about the quality of construction wood we sell today. The following fact should be cited: in no store with us you will not find the highest quality wood, even for a lot of money. Such wood is exclusively imported, consumed exclusively by elite developers, and its share in the market is very negligible. Moreover, it is so tiny that there is no point in talking about any statistical error.

And our domestic wood, even that which goes under the “extra” grade, does not meet not only Western criteria, but also domestic ones, in particular the former Soviet ones. And this is not even talking about lumber, which only “budget” developers can afford. Those are generally of terrible quality, although they often visually look like nothing.

It is not profitable for manufacturers to produce high-quality lumber

And it should be repeated again and again: it is simply not economically profitable for our manufacturers to produce high-quality lumber, even the “extra” grade - and that is defective. And if someone suddenly starts telling you that domestically produced wood can be found, albeit at a high price, then this is also a lie. Today, due to the unprecedented rise in prices for building materials in general and wood in particular, all “extra” goes exclusively to Finland and other European countries, and those worse grades go to China.

As is well known to everyone involved in the construction industry, the elite sector in the individual housing construction market (individual housing construction) in Russia occupies less than 1%, that is, there is simply no demand. And in conditions of such low demand, what fool would produce elite wood? That's right - none. If there is no demand, then even the social security authorities will not invest money in expensive equipment and pay salaries to super-duper specialists, for whose skills there is no demand at all.

Lack of high-class specialists

Another point follows from this. Since there is no demand for a quality product, there are no super-duper specialists who know how to make such a product. Where will they come from if all our specialists make money from cheap consumer goods? This is how it turns out that in the absence of demand, high-quality lumber can only be bought abroad, at exorbitant prices and with a long delivery time.

Well, there will always be some well-informed patriots who probably know the location of the factory where high-quality lumber is produced, and will begin to distribute to everyone around them the addresses of stores where such lumber can be bought.

But this is all just waving his arms purely for visual effect. Nobody is interested in playing conspiracy theories on the domestic lumber market, because any fool can understand why we don’t have high-quality construction wood - it’s a lack of demand.

However, this is already a journey in a circle and repetition of the material covered. Therefore, this article should end with one more fact - that’s why we don’t have frames that would last more than 5-10 years, because they are all made from low-quality lumber. But we don’t build frame houses from high-quality imported lumber. If they build, it is only from timber, and then only laminated veneer lumber. And this is luxury construction, which occupies less than 1% of the domestic construction market.

To understand this, all you have to do is study official statistics, and not spread around some conspiracy stories that are very far from reality.

Dimensions of edged boards

The dimensions of edged boards are measured in millimeters. The width, length and height are determined. Examples of boards: 25 by 150 by 4000 mm, 50 by 200 by 3000 mm. If the height and thickness are the same, then it is already timber. The manufacturer is guided by the GOST application, which lists all acceptable values. But it is worth knowing that any manufacturer can deviate from the norms, making the sizes requested by the customer. To select the required size of wooden beams, you need to know the basic parameters of the product. Today, a length of 6 meters has become the standard. The width of the edged board can be 75, 100, 125, 150 to 275 mm. Material thickness 16, 19, 22.25, 32, 40, 44, 50, 60, 75 mm. Approximate prices are from 6,000 to 8,000 rubles per cubic meter.

Read about how much is 100 by 100 in a cube of 6 meter timber.

TRANSPORTATION

4.1. Lumber and blanks are transported by rail, road and water transport in accordance with the rules for the carriage of goods in force for this type of transport.

4.2. Lumber and blanks are transported in packaged form. Package sizes are in accordance with GOST 16369, packaging is in accordance with GOST 19041. Transportation of lumber and blanks in unpackaged form is permitted by agreement between the manufacturer and the consumer. During transportation, unpackaged lumber and blanks are placed in stacks separated by horizontal spacers and vertical posts 65-70 mm thick. Horizontal spacers are laid every 1200 mm, vertical posts are installed in the middle of the width of the stack. It is not allowed to overlap lumber and workpieces.

4.3. When transporting lumber and blanks in open vehicles, they must be protected from precipitation and pollution.

Manufacturers

- Lindexport LLC is a company that began to develop back in 2004. Now the lumber market is developing dynamically and conquering it. The company is located in Belarus, in the Minsk region, or rather 50 km from the highway. They are engaged in logging, woodworking and the production of various lumber. Of course, they also produce edged boards.

- Private Unitary Enterprise "Khompil" – private enterprise in the woodworking industry. They have been working on the market for about 15 years. They supply their products to Belarusian markets and Western partners. The company produces lumber and assembles wooden containers. The company also engages in carpentry and timber cutting. The enterprise is located 30 km from the city of Brest.

- Lestorg LLC – has been producing lumber for about 14 years. The company works directly with customers. Delivery is carried out anywhere in the world.

- OJSC Sokolsky Woodworking Plant – produces not only lumber, but also produces finished houses. In 2008, 35 thousand square meters were produced.

- AltaiForest LLC - an enterprise that produces lumber from coniferous trees in huge quantities. In the Altai Territory, he has the largest production facility.

Edged boards are used in a wide variety of applications. The base of the foundation, which rises 30 cm above the ground, may require formwork. But only if it is not a whole cast block. For subfloors, boards are also used, which are laid on pre-prepared joists. But edged boards can also be used for laying white floors. And hardboard or plywood sheets are laid on top. Class A lining is often used for lining interior rooms. The next layer involves laying laminate or linoleum. Partitions with further cladding are also built from edged boards, which are cheaper than dry profiled timber. Here you can make thick walls, which can later be insulated, but first leave a distance between the boards.

How many pieces of 25x150x6000 edged boards fit in one cube can be found out in this article.

The material can be used in a variety of fields using its various forms. The most important thing is to know that raw materials made from natural ingredients require special care.

It is worth considering that the natural coating should be topcoated with fire-retardant varnishes and anti-bioaging agents.

Profile parts

For profile parts in Belarus, STB 1074-97 “Profile parts made of wood and wood materials for construction is used. Technical conditions", in Russia GOST 8242-88 with the same name. These standards do not use the concept of grade and divide lumber into lumber for a transparent coating and lumber for an opaque coating and a non-face surface. Often, to determine the type of wood, the norms of the European standard DIN 68126/86 are used, which uses a letter definition of wood types - Extra, A, B, C.

The definition of lumber under a transparent coating includes sawn timber of the first and partially second grade, in the European classification A and B. Lumber under an opaque coating is respectively the second and third grade, as well as B and C.

Since the DIN 68126/86 standard is quite difficult to find in Russian, after studying the experience and interpretations of this standard by other enterprises, as well as adhering to STB 1713-2007 standards, based on the fact that the first grade corresponds to grade A, the second - grade B, the third - grade C and knowing the special love of our people for classification according to the ABC principle, we have developed a procedure for determining the grade of wood according to the ABC principle as close as possible to our GOSTs, which are more demanding on boards than DINs.

www.lhp.by