Warehouse of finished products

The Institute for Standardization of Products Manufactured by Russian Enterprises pays great attention to the quality of manufactured lumber from coniferous trees. A large area of the state's territory is occupied by coniferous forests, which provides the forestry industry with immeasurable volumes of raw materials. In order to standardize the requirements for coniferous products and protect consumer rights, since 1988 on the territory of the USSR, GOST 8486-86 was introduced. All its provisions, as amended, continue to apply in modern Russia. The current standard covers all types of profile products made from softwood. The document includes technical requirements for lumber intended for use in Russia and for export.

Current GOST standards for lumber (edged boards, timber)

The production of lumber in our country is regulated by regulatory documents that were adopted back in the middle of the second half of the twentieth century. Participants in the domestic market use more than two dozen quite current GOSTs for coniferous and deciduous species, which allows the consumer to interact normally with manufacturers and suppliers.

The task of the GOST system in this area is to formulate clear rules for determining product quality, establish requirements for the production, storage, transportation and sale of a specific product. The most popular for determining the quality of edged softwood lumber are:

- GOST 8486-86 Softwood lumber. Specifications

- GOST 24454–80 Softwood lumber. Dimensions

This lumber is GOST

INFORMATION DATA

1. DEVELOPED AND INTRODUCED by the Ministry of Forestry, Pulp and Paper and Woodworking Industry of the USSR

2. APPROVED AND ENTERED INTO EFFECT by Resolution of the USSR State Committee on Standards dated September 30, 1986 N 2933

3. INSTEAD GOST 8486-66

4. The standard fully complies with ST SEV 2369-80

5. REFERENCE REGULATIVE AND TECHNICAL DOCUMENTS

| Designation of the referenced technical document | Item number |

| GOST 2140-81 | 2.2 |

| GOST 3808.1-80 | 4.2 |

| GOST 6564-84 | 3.1, 4.1 |

| GOST 7016-82 | 2.5 |

| GOST 9302-83 | 1.2 |

| GOST 10950-78 | 2.3 |

| GOST 16369-96 | 4.1 |

| GOST 18288-87 | 1.1 |

| GOST 19041-85 | 4.1, 4.2 |

| GOST 24454-80 | 1.2, 2.6, 2.7 |

| GOST 26002-83 | 1.2 |

6. The validity period was lifted according to Protocol No. 3-93 of the Mechanized State Council for Standardization, Metrology and Certification (IUS 5-6-93)

7. EDITION (September 2007) with Amendments No. 1, 2, 3, approved in December 1987, September 1988, February 1990 (IUS 3-88,1-89, 5-90)

An amendment was made, published in IUS No. 12, 2013

This standard applies to lumber of coniferous species and establishes technical requirements for lumber intended for use in the national economy and export.

The standard does not apply to resonance and aircraft lumber.

(Changed edition, Amendment No. 3)

Lumber GOST 8486-86

State standard 8486-86 in detailed tables describes the defects and defects of lumber with a moisture content of up to 22 percent (or wet antiseptic). It contains all the information to determine, based on specific criteria, which of the 5 categories (selected + 4 grades) an edged board/timber made of pine or spruce belongs to. The document not only lists the defects that determine the grade, but also indicates their permissible size, quantity, type...

Defects of wood according to GOST 2140-81

| Defects of wood according to GOST 2140-81 | Standards for limiting defects in lumber for grades | |||||||||

| selected | 1st | 2nd | 3rd | 4th | ||||||

| 1. Knots | ||||||||||

| 1.1. Healthy fused, and in bars and partially fused and non-fused healthy: | Allowed in size in fractions of the side width and in quantity on any one-meter length on each side, not more than: | |||||||||

| Size | Quantity, pcs. | Size | Quantity, pcs. | Size | Quantity, pcs. | Size | Quantity, pcs. | Size | Quantity, pcs. | |

| Slab and rib | 1/5 | 2 | 1/4 | 3 | 1/3 | 4 | 1/2 | 4 | Allowed | |

| Edgebanding: on lumber up to 40 mm thick | 1/3 | 1 | 1/2 | 2 | 2/3 | 2 | Full edge | 2 | Allowed | |

| Thickness 40 mm or more | 1/4, but not more than 15 mm | 2 | 1/3 | 2 | 1/2 | 3 | Full edge | 3 | Allowed | |

| 1.2. Partially fused and unfused | Allowed in the total number of fused healthy knots in size in fractions of the width of the side and in quantity on any one-meter section of length on each side, no more than: | |||||||||

| Size | Quantity, pcs. | Size | Quantity, pcs. | Size | Quantity, pcs. | Size | Quantity, pcs. | Size | Quantity, pcs. | |

| face and rib | 1/8 | 2 | 1/5 | 2 | 1/4 | 3 | 1/3 | 3 | 1/2 | 4 |

| edging: on lumber up to 40 mm thick | 1/4 | 1 | 1/3 | 1 | 1/2 | 2 | Full edge | 2 | Full edge | 2 |

| thickness 40 mm or more | 10 mm | 1 | 1/4 | 2 | 1/3 | 2 | 2/3 | 2 | Same | 3 |

| 1.3. Rotten, rotten and tobacco | Not allowed | Allowed in the total number of partially fused and unfused healthy knots of the same size and no more than half of their number | ||||||||

| The wood surrounding the tobacco knots should not show signs of rot. | ||||||||||

Note. The number of knots in beams is not standardized.

MAIN PARAMETERS AND DIMENSIONS

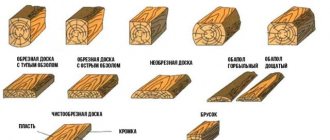

1.1. Lumber is divided into edged, unedged, boards, beams and beams.

Terms and definitions - according to GOST 18288.

1.2. Nominal dimensions of lumber and maximum deviations from nominal dimensions are in accordance with GOST 24454.

By agreement with the consumer, sawn timber with gradations in length, size and permissible deviations established in GOST 9302 and GOST 26002 are allowed for the domestic market.

(Changed edition, Amendment No. 2).

1.3. The symbol must consist of the name of the lumber (board, block, timber), a number indicating the grade, the name of the wood species (coniferous or individual species - pine, spruce, larch, cedar, fir), a digital designation of the cross section (for unedged lumber - thickness) and designations of this standard.

Examples of symbols:

Board

-

2

-

pine

-

32 ´100

-

GOST 8486

-

86

Board

—

2 hv

.

— 32

—

GOST 8486

—

86

Lumber GOST 24454–80

Standard 24454–80 regulates the production of both edged and unedged lumber. This document indicates the nominal cross-sectional dimensions of lumber with a moisture content of about 20 percent, as well as their length. The “main” table contains clear data on the width and thickness of all boards and beams produced for the domestic market and for export. But the most important thing is that the document describes possible tolerances for deviations in the cross-section of lumber.

For example, an error of +-1 mm in thickness is allowed for materials up to 32 mm thick, and +-2 mm for products that are thicker. And the width of lumber should not deviate from the nominal value by + - 2 mm for lumber up to 100 in width, and more than + - 3 mm for products that are wider than 100 mm.

It is obvious that lumber products that, taking into account tolerances, do not comply with the standards cannot be called “GOST lumber”. Such a product has its own name - TU, air, Armenian size, construction size, read the article on our website.

Table. Nominal dimensions of thickness and width

| Thickness | Width | ||||||||

| 16 | 75 | 100 | 125 | 150 | — | — | — | — | — |

| 19 | 75 | 100 | 125 | 150 | 175 | — | — | — | — |

| 22 | 75 | 100 | 125 | 150 | 175 | 200 | 225 | — | — |

| 25 | 75 | 100 | 125 | 150 | 175 | 200 | 225 | 250 | 275 |

| 32 | 75 | 100 | 125 | 150 | 175 | 200 | 225 | 250 | 275 |

| 40 | 75 | 100 | 125 | 150 | 175 | 200 | 225 | 250 | 275 |

| 44 | 75 | 100 | 125 | 150 | 175 | 200 | 225 | 250 | 275 |

| 50 | 75 | 100 | 125 | 150 | 175 | 200 | 225 | 250 | 275 |

| 60 | 75 | 100 | 125 | 150 | 175 | 200 | 225 | 250 | 275 |

| 75 | 75 | 100 | 125 | 150 | 175 | 200 | 225 | 250 | 275 |

| 100 | — | 100 | 125 | 150 | 175 | 200 | 225 | 250 | 275 |

| 125 | — | — | 125 | 150 | 175 | 200 | 225 | 250 | — |

| 150 | — | — | — | 150 | 175 | 200 | 225 | 250 | — |

| 175 | — | — | — | — | 175 | 200 | 225 | 250 | — |

| 200 | — | — | — | — | — | 200 | 225 | 250 | — |

| 250 | — | — | — | — | — | — | — | 250 | — |

Characteristics of softwood timber

Technical characteristics of coniferous timber include six items:

Assortment

The list shows two main parameters - width and thickness. Dimensions change upward in approximately 25 mm increments.

For boards, the minimum thickness is 16 mm, the maximum section height is 75 mm. The width of the edged board ranges from 75 to 275 mm.

The timber is produced from 30 x 30 mm to 250 x 250 mm. Also, the cross-section of the timber can be rectangular.

Density

Spruce and fir profiles have the minimum density. Their specific gravity is approximately 440 kg/m3 and depends on the level of humidity (maximum 12%). The average density of pine is 590 kg/m3. The heaviest coniferous tree species is cedar (650 kg/m3).

Weight

Softwood profiles are sold by measuring the product in cubic meters. To find out how much purchased timber weighs, just multiply the volume by the specific gravity.

Note: The weight of wood varies depending on the moisture content of the material. The parameter is adjusted using a special table.

Length

The maximum length of forest products produced from deciduous trees is 5 m. Coniferous trees have a lower specific gravity than other wood. Therefore, these lumber is produced up to 6.5 m in length. The lighter the wood, the longer the product.

Strength

The strongest coniferous wood is larch. It is 1.5 times stronger than pine.

Ecology

The internal fences of buildings lined with coniferous lumber exude a pleasant pine aroma. Wood fumes kill harmful microorganisms in the room atmosphere.

Lumber GOST 18288-87

GOST 18288-87, which defines the basic terms used in the sawmill industry, can be very useful for an inexperienced user. In particular, this standard explains the concepts of tangential and radial cutting, helps to determine the difference between face and edge, edge and end, edged and unedged product.

He describes what wane is. GOST 18288-87 contains information about the need to standardize load-bearing capacities for structural lumber; the document defines various types of boards, beams, beams...

General information about lumber

It is not enough to fell and remove the tree from the cutting area. It is necessary to cut the whip into separate ridges aligned in thickness in order to separate its parts as completely as possible. Unedged boards are obtained by sawing a log lengthwise and leaving sharp wane on the boards at the ends - the edge repeats the expanding silhouette of the cut.

From each trunk you can get a cut out tetrahedral core and external fragments in the form of 4 slabs - layers uneven in width on one side and an unbarked cylindrical surface on the other. The internal parallelepiped can be used as a tetrahedral beam or cut into boards - this is edged lumber.

The name of the fragments and their geometric relationships correspond to GOST 18288:

- face - a wide, long surface, inner and upper;

- edge - the outer boundary of two layers along the length;

- end - the distance between the layers along the narrow part;

- board – thickness up to 100 mm, width more than double thickness;

- timber – thickness and width more than 100 mm.

- block – up to 100 mm thick, up to 200 mm wide

It is customary to indicate the length of lumber in meters, thickness and width in mm.

It is important to know what type of cut the board was made from. Schemes for cutting central, core and side fragments are used. The best material is considered to be core timber or board for structures made from the central part. For finishing work, side blocks with a bright ring pattern are used.

Lumber GOST 2140-81

GOST 2140-81 “Visible defects in wood” makes it possible to understand what should generally be considered a defect (a defect that limits the use of lumber or reduces its quality).

For convenience, in this regulatory document, defects and defects are divided into groups:

- bitches

- cracks,

- Chemical stains,

- Fungal infections

- Defects in the structure of the trunk,

- Defects in the structure of wood fibers,

- Warping,

- Foreign inclusions,

- Processing defects and mechanical damage.

It is very important that GOST 2140-81 not only lists all existing defects in wood, lumber and wood parts, but also provides methods for measuring their size and quantity. Using the information from this standard, it is much easier to determine the quality of lumber, it is much easier to understand the tables of GOST 8486-86 - namely, what grade the board or timber belongs to.

Photos of visible flaws and defects in lumber

APPENDIX (required)

APPENDIX Required

| Grades (groups of grades) of lumber | Main purposes of lumber |

| 0, 1, 2 | Special shipbuilding - for plating and bracing of sea boats, dinghies, seagoing vessels, gliders, high-speed lake and river boats and 1st class sports vessels, flooring of external and internal decks of sea vessels |

| 0, 1, 2 | Agricultural machinery - for the manufacture of wooden parts of agricultural machines |

| 0, 1, 2, 3 | Car manufacturing – for the manufacture of wooden parts for railway cars |

| Shipbuilding | |

| Automotive industry – for the production of wooden parts for truck platforms, trailers and semi-trailers | |

| Bridge construction, road transport | |

| 1, 2, 3 | Construction and repair and maintenance needs, elements of load-bearing structures, parts of windows and doors, planed parts, parts of wooden houses, etc. |

| Production of various woodworking products, including furniture, staves for bulk and dry barrels, special containers | |

| 3, 4 | Container and packaging |

| 4 | For use on minor parts in construction, cutting into small workpieces for various purposes |

Site Map

Demand factor 151

Lumber GOST 3808.1-80

This standard is called “Softwood lumber. Atmospheric drying and storage." It states that purchased lumber of natural moisture must be treated with an antiseptic before laying it on site. GOST 3808.1-80 describes the principles of atmospheric drying and helps to properly organize the warehouse space (including the design of foundations and roofs).

The developers paid special attention to the rules for the formation of packages and stacks, where they indicated:

- methods of relative arrangement of lumber;

- the size of the necessary gaps to ensure ventilation;

- type, dimensions, location and number of spacers.

Having familiarized yourself with the provisions of GOST 3808.1-80, it will not be difficult for you to finish drying the lumber yourself. You will be able to store the purchased board/timber at your site without loss or understand whether the seller handles his product correctly.

Regulations for lumber storage

Content:

- Advantages

- What do you need to know before purchasing?

- Determination of variety

- What to consider when choosing a variety?

Edged board is a sought-after lumber that is widely used in construction due to its large number of varieties.

In this article you can find out what an edged board is, what types of this lumber exist and how they differ from each other, as well as where they are used. Edged board

is a natural material obtained from wood, which has a rectangular cross-section and a thickness of less than one hundred millimeters. The width of this building material is approximately twice its thickness. When sawing a solid log, the correct geometric shape is set, followed by the removal of bark residues. Despite this, defects cannot be excluded, which is why the edged material is divided into several grades. Its processing is minimal, so the lumber is affordable. It is not only dry, but also characterized by natural moisture.

Due to the presence of minimal processing and practical form, the product has received a wide range of applications, unlike other types of lumber. At the moment, almost no construction (including brick and stone) can do without this material. Due to its practicality and low cost, the board is actively used during rough and auxiliary work.

Varietal characteristics and how to choose the right grade of edged lumber.

In accordance with the standards, edged boards and bars are divided into 5 categories: selected, 1, 2, 3, 4 grades. In terms of humidity, all coniferous assortments except grade 4 must be at least 22, deciduous 20%. In terms of roughness, assortments up to grade 3 must be within the range of 1250 microns, and for grade 4, roughness up to 1600 microns is allowed.

The timber does not have 4 grades, since its main purpose is to withstand loads. If there is even one through knot, the timber is rejected.

Selected variety

Extra-class products are almost never found on the domestic market. A smooth, smooth surface without dry and rotten knots can have healthy edge or edge knots up to 2 pieces per linear meter. Deep end cracks are possible up to 10%, surface cracks up to 16%. Rot, dull wane or deflection of more than 1% is not allowed.

A board made from the heart-shaped part of larch for the floor is called “extra”. No defects are allowed here.

The requirements are the same for all types of wood. Oak and linden boards that meet quality requirements are exported.

The grade is marked on one of the ends in the form of a dash or the index “0” on the face.

First grade

Sometimes the assortments are called grade A. On the surface of healthy knots up to 3 per linear meter, 25% shallow cracks, fungal damage is allowed on 10% of the surface. A small amount of blunt wane is acceptable.

Existing defects do not violate the structural properties of the lumber. Hard wood is used for rafter systems, beams, and interfloor ceilings. Soft varieties are suitable for cladding a room.

Assortment marking is a dot or an inclined vertical strip on the end, one line on the plane.

Second grade

Grade B board has up to 30% shallow cracks, knots, including rotten ones, and resin pockets. There is blue rot and mold on the surface up to 20%. It can be used for laying subfloors or cladding walls and partitions for decorative cladding.

Each board is marked with either two dots or two stripes.

Third grade

Boards pierced through with 16% through and surface cracks reaching half the length and with rotten knots and resin pockets look unpresentable. They can be warped in diameter up to 2%, be tortuous, and have a sharp wane.

The wood has lost its structural properties and is used for formwork, canopies, and the construction of removable scaffolding. They cut boards for boxes from it and knock down pallets.

The material is inexpensive and is marked with three dots on the end or three stripes.

Fourth grade

The board is not marked in any way. Wood with high humidity, sharp wane, and a large number of defects of various types can be used. Since such material does not have the proper load-bearing capacity, grade 4 timber does not exist. The boards are inexpensive and suitable for creating temporary shelters and formwork.

Classification of lumber

All types of lumber are divided into categories according to the method of preparing the goods for sale. If the wood is end grain, it will be stacked with equal lengths of logs. The cuts are smooth, directed perpendicular to the axis. Uncut wood is represented by trunks of different lengths, with uneven cuts.

Calibrated building material consists of stacks that have been air-dried before cutting. For deciduous trees the humidity norm is 20%, for coniferous trees – 22%. One of the operations may be antiseptic treatment.

Planed logs - sanded for better drying, planed flat or in fragments. Structural materials are called hardwood - oak and larch.

Based on the thickness of the log, it is unraveled in accordance with the developed cutting map, providing a greater yield of sized edged boards or timber.

Receive:

- two-, three-, four-edged timber;

- a clean edged board with a blunt or sharp wane;

- bar;

- both floors are slab and plank;

- edged sleeper.

The grade of cut assortments is regulated by relevant standards.