Lumber is widely used in the construction of residential and industrial buildings. Wood is a durable, reliable, safe material. New technologies and processing methods ensure a long service life of wooden products. In the construction of buildings, they are used in the construction of foundations, partitions, ceilings, stairs, doors, and window frames. Lumber is the main raw material for making furniture.

In this article you will learn:

- Definition of the term "lumber".

- Varieties.

- Edged board.

- Wooden beam.

- Wooden block.

Definition of the term "lumber"

Lumber is a log sawn longitudinally, having specified shapes and dimensions, and having the following properties:

- moisture resistance;

- strength;

- good machinability;

- low thermal conductivity;

- no toxic emissions.

These qualities determine the scope of application of a particular type of lumber. The properties of the material depend on the type of wood used.

Why are GOSTs needed?

GOST requirements for quality and size of products

The state standard contains a list of requirements for the quality of commercial lumber products; it specifies standards for services and work of inter-industry significance. GOSTs are developed on the basis of scientific discoveries and practical experiments, taking into account current international standards. GOST confirms that commercial products have been tested for compliance with standards and meet safety requirements.

GOST differs from other documents that also contain regulatory requirements:

- TU (technical conditions);

- technical regulations;

- OST (industry standard).

Technical conditions were allowed for production during the formation of a market economy. The purpose of introducing specifications was to standardize those goods that were not covered by GOSTs. Such conditions are developed by the manufacturing companies themselves, they are their property.

The technical regulations contain a list of standards that ensure the preservation of human health and life during the operation of lumber. It specifies the requirements for transportation, storage, and sale of products. GOST provides dimensions of lumber, quantitative parameters, and technical regulations determine the conditions of use.

OST regulates the requirements for softwood products at the industry level. Such documents are developed if it is necessary to clarify certain provisions that are not clearly stated in GOST. The requirements apply only to one industry or related divisions.

Varieties

The construction market offers a significant range of wood materials.

Kinds:

- plates;

- boards;

- lagging;

- bars;

- sleepers;

- croaker;

- bars.

The greatest demand in the construction market is for edged boards, timber and lumber.

Classification

According to the classification, edged boards are:

- With blunt wane;

- With sharp wane;

- Clean cut.

Wane is a defect in wood sawing, a part of the side surface of a log preserved on lumber or other wooden parts after sawing it. A sawing defect may occur on one or more edges of the edged board. A wane that occupies part of the edge is blunt. The wane, which occupies the entire edge, is sharp.

A board without a wane is clean-edged. This board has an ideal rectangular shape when cut. A sawing defect limits the scope of use of wood, requiring additional processing.

Therefore, edged boards are the most popular lumber used in many fields of activity. Due to its ideally even shape, the cost of an edged board exceeds the cost of an unedged board.

Edged board

An edged board is obtained from a log, having processed it on all sides. The product does not have edges covered with bark. The board is cut from a single log. Its edges are located strictly at right angles to each other. This is a condition for the exact fit of the boards to each other. The main types of wood for the production of edged boards are coniferous species. For interior decoration, valuable types of wood are preferable.

The dimensions of the building material are important for the consumer. These indicators are established by GOST.

Standard sizes offered by manufacturers:

- length – 3000, 4000, 6000 mm;

- width – from 75 to 275 mm in increments of 25 mm;

- thickness – 16, 19, 22, 25, 32, 40, 44, 50, 60, 75 mm.

The length of the edged board is measured as the minimum distance between the ends. Width and thickness are measured at any point, departing from the ends by more than 150 mm. There are edged boards of non-standard dimensions on sale.

Information about the product can be gleaned from the tag on the package. The material (board), grade, type of wood, dimensions, GOST are indicated there.

Blank parameters

Bars

When performing construction work and forming home-made structures, it is useful to know the standard sizes of semi-finished products. GOST defines technical requirements for products made from coniferous and deciduous trees intended for export and the domestic market.

High-quality wood and the right processing method make it possible to saw a large amount of productive material. Semi-finished products are of the following types:

- edged and unedged boards; beams.

Coniferous wood is divided into 5 types, and deciduous wood into 3. According to GOST requirements, the name is formed from the following parts:

- product name; digital designation of the corresponding type; wood species; cross-sectional and length dimensions; standard designation.

The highest quality lumber is called selected, and is marked with a horizontal stripe or the letter “O”. The remaining grades of materials are indicated by numbers from 1 to 4 or the corresponding number of dots.

Suitability and compliance are analyzed by edge or side with defects. The grade is determined by the presence of cracks, deformation, and quality of processing.

For softwood lumber, dimensions and maximum deviations from the norm are regulated by GOST 24454-80. By agreement with the consumer, deviations in the length of materials established by additional standards are allowed for the domestic market.

Wooden beam

This lumber has a rectangular or square cross-section, a thickness of at least 100 mm, and a considerable length. Almost all load-bearing and enclosing elements in private construction are made of timber.

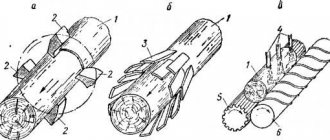

Type of material depending on side processing:

- double-edged, two opposite sides are cleaned, the rest are left rounded;

- in the three-edged one, three surfaces are cleaned;

- in a four-room beam, all the edges are flat.

The beam can be made from solid wood or glued together from separate parts - lamellas.

The standard length of the timber is 6000 mm; upon request, we can produce material with a length from 2000 to 9000 mm. The length of laminated veneer lumber reaches 18,000 mm. The thickness of the timber varies from 100 to 250 mm in increments of 25 mm. The beam has a width from 100 to 275 mm. At the customer's request, timber of other sizes can be manufactured. A product with a cross-sectional shape of 50 x 50 mm is called half-timber. The most popular material is with a cross section of 150 mm. A house built from which timber retains heat well and does not create excessive load on the foundation.

The importance of making the right choice

When building a log house, it is very important to first determine the thickness of the wall structures and the volume of lumber required. As a rule, these 2 parameters affect:

The degree of thermal insulation of building walls, which decreases as their thickness decreases.- The total weight of the structure, which increases with the size of the beam, which necessitates the use of a more powerful and bulky foundation.

- The total cost of building an object, which falls as the thickness of the timber decreases.

In order to make the right choice among all these interrelated indicators, a technical and economic calculation of several options is performed. As a general rule, selecting the required size of timber should be reduced to establishing its smallest value, which will be able to provide the calculated thermal insulation coefficient at the lowest winter air temperature for a specific climatic region.

As a rule, developers either take timber with a smaller thickness, trying to save money, or, to be on the safe side, significantly increase it. In the first case, the house will turn out to be cold. Even installing a powerful heating system will not save the situation, and in addition will cause a significant burden on the family budget in terms of heating.

In the second case, the house will be expensive due to overspending on lumber and a reinforced foundation. Thus, an erroneous selection of material characteristics for the construction of a building invariably leads to useless financial costs.

Wood block

A bar is a smaller version of a beam. These small logs, sawn and finished on all sides, are a popular building material. The section can be in the shape of a square, rectangle, or figured profile. There are edged and planed timber. Planed bars have a maximum variation in parameters, reaching up to 25%. Curvature and poorly processed edges are also possible. This explains the low cost of the material. The bars are used in the construction of supporting structures, floors, stairs, railings, window sills, bathhouses, sandboxes, and gazebos. The finished product must be processed to impart the necessary decorative and protective properties to its surface.

The length of the bars ranges from 3000 mm to 6000 mm. The difference between a beam and a block is in size; a block can be less than 100 mm thick. According to standards, its width can exceed its thickness by no more than 2 times. The width and thickness of hardwood timber is 19.22, 25, 32, 40, 45, 50, 60, 70, 80, 90 and 100 mm.

Knowing the dimensions of building materials allows you to accurately calculate the volume of purchases.

Wood moisture content

The moisture content significantly affects the quality of wood. One of the stages in the production of lumber is drying, which can be natural, that is, the wood dries in the sun, or can occur in a drying chamber.

Well-dried wood will be of better quality, and therefore boards made from it will cost more.

According to the degree of moisture, boards can be divided into:

- Raw, containing more than 22% moisture;

- Antiseptic, which contain more than 22% moisture, but treated with special agents that protect lumber from the formation of mold, mildew, and disease;

- Dry. This group includes boards containing less than 22% moisture.

When determining the grade of an edged board, not only its appearance and the presence of defects are taken into account, but also the percentage of humidity, which affects the quality of the board, as well as the quality, durability and reliability of the future product.

Areas of application

Each industry has its own lumber and products made from it.

Wood is used:

- in shipbuilding and mechanical engineering as the lining and frame of boats, vessels, lifeboats, lake and sports transport, decking, for bodies, and other machine parts;

- in agriculture, machine parts are made from wood, outbuildings, warehouses, and hangars are built;

- In the construction industry, lumber is needed for repair and maintenance work and for the construction of capital structures, surface finishing, manufacturing window and door fillings, and carrying out auxiliary work.

Lumber of a certain quality is used in the furniture industry and in the production of packaging .