Articles

All photos from the article

An assortment is understood as a set of types and standard sizes of a particular type of product, that is, as far as boards are concerned, the most important criteria are the grade and size range. It is by these factors that all products of this type are divided; we will consider the basic information that every developer who selects lumber from the group under consideration should know.

The main types of elements prescribed in the regulatory documentation, of which we are interested in three types of boards

Characteristics of edged boards

These boards have a rectangular cross-section.

- Thickness – from 8 mm to 10 cm.

- Width – from 1.6 cm to 25 cm.

- The length of such boards can be from three to six meters.

- No edges.

- Features of selected grade boards

- There should be no rot on the surface of the boards.

- Cracks should not be more than ten percent.

- There should be no fungi on the boards.

Such boards are used for furniture production. Decks for motor ships are also made using edged boards. They are also used in the production of cars. In construction it is used as cladding. Can be applied in various places.

Very high quality. The price is expensive.

Hardness and density of wood

These are important indicators when choosing boards for construction, furniture making, decorative cladding, carved products, etc.

Table 1 shows the values of hardness and density for the most common wood species in Russia.

Table 1

First-class edged boards

These boards are very reliable.

- The humidity of such boards should not exceed 22 degrees. Boards with higher humidity belong to the very last group. Such boards are less valuable.

- There should be no hint of rot on these boards.

- There may be knots. Only they must be healthy. The presence of even one diseased knot is the reason why the grade of the board decreases.

- Shallow cracks can be no more than 25 percent.

- Such boards may tilt. But no more than 20 percent.

- Externally they are very beautiful. The flaws are almost invisible.

- There may be end cracks. Just no more than 25 percent.

- Used in construction.

- There may be mold, mushroom spots. But their number cannot be more than 10 percent. The quality of the boards does not deteriorate from this. After all, this is a natural process.

- Wane may also be present. But its size cannot be more than 1/6.

First-class edged boards are used in the construction of houses and various floors. Fences, floors, and roofing are built from such boards.

What to consider when choosing a variety?

Before making a choice, you need to determine the goals, objectives and conditions of use. Each variety has its own characteristics, features, strengths and weaknesses.

Once the required breed has been determined and the variety selected, the quality of the product must be checked to ensure that it matches the selected variety. It is recommended to first inspect the lumber for cracks and dents, blue areas (which is the first sign of fungus damage to the tree), areas affected by rot, as well as unnatural holes that may contain traces of insect activity. Additionally, you need to look at the level of moisture content, which is easily checked using a moisture meter.

There is no need to worry if several boards with the defects listed above are found in one batch (this is not uncommon for large batches). The most important thing is that most products strictly comply with all stated requirements.

Second-class edged boards

A second grade board may have flaws.

- There may be knots on the boards. Just no more than two pieces per linear meter.

- It is allowed if the wane is of an impressive size. Externally the board will not be very beautiful. But the quality will not suffer.

- It differs from first grade edged boards in that the requirements for the quality of the boards are slightly weaker.

- The boards may have resin pockets.

- Second-grade edged boards may be stained by fungi. There may be spots on blue boards. Their size cannot be more than five centimeters.

- The price is reasonable.

- The slope of the fibers in second-grade boards can be greater.

- The humidity of the board should not be more than 25 percent.

- In packs of second-grade boards you can also find first-grade boards. There are also boards of the third grade. After all, when sorting, they cannot review all the boards. Each edged board is selectively inspected.

Used in various fields. They are needed for the construction of internal partitions. It is also used when assembling formwork. Second-grade boards have proven themselves well in the construction of frames for outbuildings.

The cracks can be no more than one centimeter deep.

Types and species of trees

Conifers. These include:

- Spruce;

- Pine;

- Larch;

- Cedar;

- Fir.

Coniferous edged boards made from spruce and pine have a wide variety of applications: internal and external cladding of residential premises and outbuildings, for the manufacture of packaging, containers, formwork for foundations, subfloors, floors, roof sheathing, etc.

The material has earned popularity due to its good structural properties - it is easy to process, has satisfactory strength and resistance to rotting, and an attractive appearance.

- These trees are widespread throughout Russia. Spruce is slightly inferior to pine in strength and appearance due to the larger number of knots.

- Larch - has dense wood, is very resistant to moisture, and practically does not rot. Buildings made from it can last hundreds of years.

- Larch is used for the construction of house frames, utility rooms, floor and roof beams, open verandas, and stairs.

- Fir has more knots than even spruce - this reduces its strength and worsens its appearance.

- Cedar boards are less commonly made; it is mainly common in Siberia. This is a durable, soft wood, easy to work with, and resistant to moisture.

It should be taken into account that lumber made from pine and spruce release resin, especially when heated. Therefore, they are not recommended for finishing rooms with high temperatures - baths, saunas, etc.

3rd grade edged board

Cheaper than first and second grade boards.

- Heeling can be significant in planks.

- There can be up to four resin pockets per linear meter.

- Such boards may have a double core.

- Third-grade boards have one-sided growth.

- There may be sound spots.

- You can also see a wormhole anywhere on the board.

- The presence of formation cracks is allowed.

- There are more flaws on the surface than the first and second grades.

- There should be no rot on the boards.

- Such boards are used in the construction of temporary buildings only. Such boards are also used in the manufacture of boxes.

There are no requirements for humidity levels. This level should not be higher than 25 degrees.

What are there

There are several approaches to classifying lumber. Directions are distinguished according to the method of receipt (preparation), degree of processing and purpose.

By method of preparation

With this approach, the final moisture content of the material is taken into account. The most common concept is absolute humidity, which is the ratio of the mass of moisture to the mass of dry wood (per unit volume).

Based on the absolute water content, the following are distinguished:

- dry lumber (air-dry or natural moisture) - contains no more than 20% water and is widely used in construction and construction. The obtaining of an air-dry state of a tree is preceded by its prolonged exposure to air;

- chamber-dried wood - obtained by drying in a closed box at elevated temperatures. The moisture content of the material can be 10-14% or less, depending on the consumer's requirements. Absolutely dry wood must be treated with protective compounds to prevent moisture absorption.

When stored for a long time in a humid environment, the wood becomes wet (contains 100% or more moisture). Boards made from freshly cut wood have a moisture content of about 50-100%.

By purpose

The following types of lumber are distinguished according to size and shape, as well as mechanical properties:

- timber - characterized by a thickness and width of more than 100 mm, is the main load-bearing element of many building structures and is used in assembling the base;

- boards – have a thickness of less than 100 mm, and their width is more than two thickness sizes. Along with beams, boards are the most common lumber and are widely used for industrial, household and other purposes. Boards are produced by longitudinal cutting of logs and beams;

- whetstone - made from boards, which is why it is small in size. The thickness of the bar should be no more than 100 mm, and the width should be less than twice the thickness;

- Sleepers are short beams used for railway purposes as supports for rails. Sleepers are usually treated with a persistent mixture of petroleum or coke-based antiseptic, which is highly toxic. It is highly not recommended to use impregnated sleepers at home;

- obapol - is an “unfinished” version of the board, in which only one face is flat. The width of the obapola can vary along its length, due to which the longitudinal section along the sawn face has a pronounced irregular shape;

- croaker - refers to an intermediate option between the board and the floor, which has one flat face. The untreated surface on the opposite side has a regular cylindrical shape (truncated), so in a longitudinal section the slab is a rectangle.

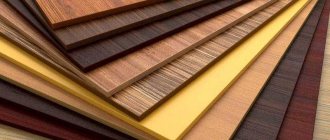

Photos of different types of lumber

Beam Boards

Bar Sleepers Obapol Gorbyl

By degree of processing

The simplest version of lumber has two parallel faces and two untreated wanes (side edges) of a semicircular shape (the outer roundness of the tree). Two layers are often not enough to implement a number of construction and design tasks. Wane processing improves the aesthetics of wood and makes it more expensive.

According to the degree of processing, the following types of lumber are distinguished:

- unedged - have unprocessed wane, freed from bark and rough knots;

- edged - wanes are cut parallel to each other, giving the transverse profile a rectangular shape;

- planed - the surface of at least one of the faces (face or wane) is planed to reduce roughness. Such boards or beams are used to create floor and wall surfaces, seats and other outdoor structures.

4th grade edged board

The lowest grade of edged board.

- Their quality is low.

- There can be up to six wormholes per linear meter in edged boards.

- 10 percent rot may be present.

- The wane of such boards can be blunt or sharp.

- There may be winging on the boards.

This type of board is used to build temporary fences and formwork.

Determination of variety

If there are many different defects and knots, then the board will not be of the best quality.

- Varieties are determined by moisture level. For good boards, the humidity cannot be more than 25 percent.

- The selected variety has no flaws. These boards are good for everything.

- First grade edged boards have isolated flaws. Such boards are suitable for making windows and doors. You can lay them on the floor.

- Second-grade edged boards have a small number of defects. They also have single knots. They are used to make furniture.

- Pallets are made from third grade boards.

Edged boards of the fourth grade are of the poorest quality. They are suitable for various rough jobs. There are a lot of knots and defects.

Conclusion

Having studied the listed features, we can come to the conclusion that a third-grade board can have a lot of defects, many of which will be extremely undesirable. The standard recommends using these boards for the construction of carriages, car platforms, for the construction of bridges, for the manufacture of window parts, etc.

At the same time, the main advantage of such a board is its price, which is significantly lower in comparison with boards of higher grades.

Secrets for choosing a quality board

The annual rings of the trees should be clearly visible.

- It is better that the rings are located close to each other. Because such boards are durable and have good moisture resistance.

- The harsher the climate where the tree grew, the better the quality of the boards.

- There should be no cores on edged boards. It is she who is often covered with fungal diseases. This is the most vulnerable place in trees.

- Humidity should not be more than 25 percent. The optimal level is 22 percent. But three percent down or up is allowed.

- It is better not to buy dry boards. These boards are more expensive. But it does not affect the quality in any way.

- It is forbidden to buy wet boards. This is a very poor quality board.

- Sellers should store boards in a dry place or in a shed that is well ventilated.

- When knocking, wet boards make a special sound.

- After purchase, the boards should be stored in a dry place.

- It is better to buy from trusted sellers.

- There should be few knots. After all, over time, the knots break and a void forms inside it. Therefore, it is not recommended to make furniture or use it for finishing.

The higher the strength, the higher the grade.

Cutting lumber

Also, pay attention to the cutting (primary processing) of the boards:

- radial (the cut passes through the center of the trunk). Such boards have a uniform texture, are durable, and resistant to external factors. These materials are quite expensive because the consumption of raw materials is significant.

- semi-radial (tilt angle = 45 degrees). They are cheaper, less durable and may be subject to deformation.

- tangential (the cutting line does not pass through the core). There are a huge number of materials of this type, their price is several times lower, they have a rich texture, but can swell and are less durable.

The appearance, stability, resistance to moisture and shrinkage of your product depends on the type of cut. Also, the color of the material depends on what type of primary processing it is (the core is lighter, and the further the cutting line goes from it, the darker the wood).

When choosing an edged board, you must take into account exactly what you need it for. You should not save money and purchase lumber with low strength, because they will not last you long.

It is better to immediately buy more expensive, higher-quality material; there is also no need to buy the most expensive types of wood to build a shed or construct formwork; cheaper ones are also perfect for this. It is also important to find a trusted supplier from whom you can purchase quality material.