As a basis, we take a value that can specifically designate the object that we are measuring. When the question arises of how to calculate the cubic capacity of a board, we are no longer talking about the mass of the object, since wood has a completely different density, and one tree is different from another. In addition, boards of the same species will have different weights based on their moisture content.

For the convenience of calculating the cubic capacity of a board, volume measurement formulas are used.

From the knowledge of a schoolchild

It is enough to remember school mathematics and the necessary formula by which to multiply width, length and height. For the calculation to be correct, it is necessary to adjust all parameters to one value, for example in centimeters or decimeters. It is most convenient to use meters as a basis. Thus, multiplying in meters three times, we get m³ or cubic capacity.

Note. To calculate the cubic capacity of the board, special formulas are used.

Board cubic capacity

Boards may vary in width, length, and thickness. In addition, they are sold unedged and edged. Often, lumber has its own generally accepted standards, which make it easier to calculate cubic capacity.

For normal sizes of material, there are already calculated volumes, which are systematized in tables for measuring the cubic capacity of boards. Therefore, to determine the volume of material, you simply need to open a table with the indicated dimensions and calculate the volume.

But, in order to do this, you need to have these tables with you. Otherwise, in the absence of such, the cubic capacity of the edged board is calculated by first determining the thickness and length. These are the main dimensions that meet the requirements for lumber. They are different for each individual material. For example, to create lathing, a board is used whose thickness is 25 mm, and for subfloors 50 mm. Next you need to measure the width of the board.

In the case of edged boards, everything is simple, since the material is cut to give it the same width. Next, using a calculator, all values are multiplied among themselves. With a board length of 5 m, thickness 50 mm and width 25 cm, the volume of material will be:

5 x 0.050 x 0.25 = 0.0625 m³

After multiplying the resulting number by the number of boards, we get the total volume of material.

Formula for calculating the cubic capacity of boards

V = L x h x b

L – length

h – height

b – width

Determining the number of boards per cubic meter

1 m3: V = N

In order to determine the cost of a specific type of board, with known volume values: V x price of 1 m3.

There is one more point that you need to pay attention to when determining the cubic capacity of the boards - the nominal length is exactly 6.1 - 6.2 m, but this is not taken into account when selling. This often matters when purchasing a large amount of material. For example, let's take a board with dimensions 150 x 20 mm.

Having made simple calculations, we get the number of boards in 1 m 3 - 55.5 pieces. So, in the cubic capacity of 6 m boards there are exactly 55 pieces, in total when calculating we get the value of 0.99 m3. Essentially, the overpayment for the cubic capacity of the board will be 1% of the exact price. For example, at a cost of 4,995 rubles, we pay 5,500 rubles.

Technology for calculating materials for fences

There are also no big difficulties here and even, according to experts, you can do without drawings. It is enough to remember a few important nuances:

- the main support pillars are installed in each corner + along the edges of the gate and wicket openings;

- the number of auxiliary supports depends on the estimated width of the covering material;

- The height of the fence directly affects its cost.

We calculate the footage of the log based on the length of the profile and the design quantity (3 m each). Simple math also works here. We divide the total footage by 3, rounding up and multiply by the number of joists used in the fence (usually 2 or 3 rows).

Next, we place a table that gives the basic calculations for making fences in. Here you can clearly determine how much a fence of 10 acres costs for a house within the city or a fence of 6.8 acres (a standard summer cottage).

Calculation for a plot of 10 acres with a perimeter of 130 m

Unedged board

Calculation features

Calculating the cubic capacity of an unedged board is somewhat complicated, since the material does not have the same width between different boards, but also in each board individually. This is explained quite simply - the tree does not have the same diameter.

It is clear that it is wider at the bottom and narrower at the top. Thus, the width of the edged board does not fall under any standards. What to do in this case? Use different formulas to calculate. The width of the board is measured for convenience in the middle of the length. This gives you the average width. This calculation method works well if the batch of material is small.

For industrial volumes

This method is not suitable because the work will proceed very slowly, and this is not profitable. For such cases, experts have developed the so-called unedged board cube. The volume in it is obtained by measuring and experimenting, in other words, using many measurements and calculating the average width.

Of course, this cannot be called a super accurate method, but the deviations are so insignificant that they are not worth paying attention to.

Some wood processing companies use the stack measurement method in practice. This does not require pre-sorting the wood by width. Specialists take measurements of the length of the board, the average width and height of the stack. The obtained values are multiplied among themselves, and the result is multiplied by a coefficient for calculating the cubic capacity of the board, which has an average value of 0.67.

Weighing method

In order to measure the cubic capacity of an unedged board, obtaining the most accurate result possible, the weighing method is used.

Before doing this, it is necessary to measure the moisture content of the material and the dense wood. Considering that edged boards are the cheapest material used on objects with the least degree of responsibility, complex calculations are not very justified.

Also, you should take into account that the result that you get will not differ much from the one that can be obtained using a cubeturner.

Areas of use

Lumber with dimensions of 150 by 40 mm and a length of 6000 mm is invariably in high demand among both builders and furniture makers, although it is most often used in finishing work and roofing. Often, boards are used to create walls in pits, protecting their surfaces from crumbling and destruction. In addition, lumber is used for flooring, scaffolding, or can be used as raw material for finishing lining.

As a rule, boards with dimensions of 40x150x6000 mm tend to bend well, so this lumber can be used for making parquet or furniture products. Considering that the board is resistant to moisture and, when planed, is even and smooth, the material can be used for assembling wooden stairs.

Main design parameters

The assortment of wooden boards includes requirements for grade and size; we will consider the first criterion in more detail in the next section, and in the table below we indicate the generally accepted sizes of elements:

| Conifers | Hardwood | Permissible deviations | |

| Thickness | From 16 to 25 mm in 3 mm increments, 32, 40, 44, 50, 60, 75 mm | 19, 22, 25, 32, 40, 45, 50-90 with gradations of 10 mm | For thickness up to 32 mm +/- 1 mm, over 32 mm +/- 2 mm |

| Width | From 75 to 275 mm in 25 mm increments | 60-200 mm with 10 mm gradation, exact parameters are agreed with the customer | For widths up to 100 mm +/- 2 mm, over 100 mm +/- 3 mm |

As for the length, the generally accepted options vary from 1 to 6 meters; upon agreement, other standard sizes can be produced

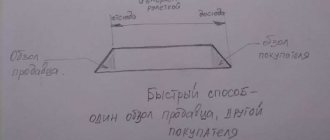

All parameters are indicated by certain letters, which are indicated in the figure; this is a generally accepted option

Types of cuts

A radial cut is a cut in which the cutting plane passes through the core of the trunk. The wood of such boards is quite uniform in color and texture, the inter-ring dimensions are minimal. Radial cut boards are resistant to external influences, are practically not subject to deformation and have high wear resistance. The radial cut board has a shrinkage coefficient = 0.19% and a swelling coefficient = 0.2%. These indicators for radially cut lumber are twice as good as for tangentially cut boards. For a radial cut board, the process of shrinkage and swelling occurs along the width of the fibers - the thickness of the board, and for a tangential cut along the width of the board because the fibers of the “tangent” are located along the width. Accordingly, floor boards, parquet boards, imitation timber, block houses, and radially cut linings have virtually no cracks compared to similar tangentially cut products. Since the yield of radial cut boards is 10 - 15% of the total volume, their cost is quite high.

Radial cutting of wood is a method of cutting a log in which all the fibers in the board run along the direction of the annual rings. When radially cut, lumber has the best physical and mechanical properties. The strength and hardness of wood with radial cutting is higher than with tangential cutting.

The yield of radial cut boards is usually small (does not exceed 30%). On the UP-700 longitudinal sawing machines, the yield of radial cut boards reaches 60%. This high rate is achieved thanks to the cutting optimization system. By choosing among the optimization criteria the maximum output of a radial cut board, the conditions of radial and semi-radial cutting, the technologist determines the percentage of output of the radial board.

Radial cutting can also be done using other equipment. But the percentage yield of a radial cutting board on other equipment depends on how the operator cut the log. Typically this figure is significantly less than 50%. Due to the microprocessor control system and optimization system on the UP-700, you can obtain the maximum possible number of radial cut boards.

| Cut texture: 1 - tangential cut; 2 - radial cut; 3 - semi-radial cut. |

Areas of use

More durable boards 40x100x6000 mm are used to create stairs, residential structures, outbuildings in the garden, and roofing. But for these purposes it is better to use samples made from pine, oak or larch, because such wood has the greatest strength and durability.

And also such boards can be used in the manufacture of various furniture and exterior decoration. For the latter, models made from more beautiful and decorative wood species with natural patterns and unusual colors are used.

Such boards are also suitable for landscape design. From them you can build entire gazebos, small verandas, and decorative benches with your own hands. If desired, all this can be decorated with beautiful hand carvings.

Unplaned or unedged cheap boards are often used to create spacious containers. After all, such products do not require processed smooth lumber with a more attractive appearance.

Peculiarities

Planks are special lumber whose width is more than 2 times the thickness. In this case, the wide part is called the face. It can be either external or internal (depending on the location relative to the central part of the log). The narrow edges of the boards are called edges. Such structures also include end elements.

Today, in specialized stores you can find natural or kiln-dried lumber. The second option is considered preferable, as it has higher strength and reliability, as well as lower weight.

Kiln-dried boards measuring 25x150x6000 mm can weigh differently depending on the type of wood from which they are made. Thus, the weight of oak models will be 16.2 kg, pine – 11.2 kg.

These wooden products have a relatively small mass, which simplifies the installation process. They are an environmentally friendly building material. Their light and pleasant woody aroma will create a favorable indoor microclimate.

To produce such boards, various species and varieties of wood are used. This must be taken into account when choosing this lumber.

All these boards must undergo appropriate processing and drying during manufacture. Most often, special chamber drying is used, which significantly reduces the humidity level. Sometimes these materials are dried naturally, but this option is not considered preferable, in this case the board will not have maximum strength and durability. They must also be impregnated with special protective substances and antiseptics.

Calculation of boards and timber in one cubic meter - formulas, calculation examples, tables

When carrying out construction work on the construction of a residential building, a specialist must perform a large number of different tasks, one of which is: drawing up and calculating the estimated cost before the final finishing of the premises of a residential building. It is mandatory to calculate the required amount of various building materials, which is quite difficult to do.

Therefore, such knowledge - how many boards are in a cube - is very important for a specialist who is engaged in the construction of a residential building and wants to complete the work with the highest quality and quickly in time.

Determining the budget for building materials

As a rule, determining the required amount of timber to build a house is carried out in order to calculate the construction budget. Even if you only have this goal, you still need to calculate the quantity of material and then perform a budget calculation taking into account the cost of the material in your region.

Just don’t forget that the total construction estimate includes not only building materials (the cost of which you will determine), but also a lot of other work and materials. You will probably need to take into account, for example: the cost of insulation, the cost of dowels, finishing materials, etc. If you add up all these factors and calculate the consumption volumes for each material, then you can determine the total budget for building a house made of timber.