Ideal ways to stabilize wood at home and not only

Wood is a noble material that has long been used for the manufacture of various products, home decoration, dishes and things useful in the household. Noble color, aroma, beautiful fiber pattern - the qualities of wood for which it has become famous.

But there is a big drawback that cannot be written off - moisture is detrimental to the material, because it causes great harm - it leads to fiber delamination, deformation, and swelling.

This can be prevented by stabilizing the wood.

Wood stabilization technique

The main goal of this process is to carefully protect the wood from the harmful effects of moisture. To stabilize the material, it is treated with a special compound, which gives the wood fibers much greater strength.

In industrial volumes, this method of stabilizing wood is practically not used, due to the too high cost of such processing.

Under the influence of a special composition that is used to process a piece of wood, all its biological processes stop in it, its durability seriously increases, and polymerization occurs on the fibers.

A special composition that acts on the material clogs the pores, and also fills all the empty space between the fibers.

Not all types of wood are suitable for stabilization. Only the following breeds can be easily processed with high quality:

- Beech;

- Maple;

- Birch;

- Hornbeam.

There are some breeds that do not lend themselves well to the stabilization process. In particular, under high pressure conditions, the following rocks are processed:

- Oak;

- Elm;

- Walnut or trees similar in wood density.

Valuable wood species such as amaranth or ebony cannot be stabilized under any conditions, so this technology should not be applied to them at all.

The basis for the qualitative transformation of wood is filling it through the pores with a special composition directed into unoccupied space. From the point of view of the technology used, the specifics may have some differences, directly depending on the special composition used.

And the polymerization of wood is carried out using varnish and under immutable vacuum conditions. The desired effect can also be achieved by narrowly targeted impregnation of wood with various resins or oils.

Pressure

We move it to a high-pressure chamber, where, using a compressor, we create a pressure of 3-4 atm (this is the recommended maximum for our tank). If your equipment allows more, great! Pump up to the safest possible maximum.

We leave the preparations in this state for another three days. On the Internet, many people write that a day is enough, but here it is better to be safe than sorry. At the same time, it is necessary to ensure that the pressure does not drop.

Treatment with Anacrol-90

The wooden product is completely placed in a special container, so that the composition of the product covers it completely. In addition, it is also necessary to create mandatory vacuum conditions in the chamber where this container is placed.

The process of impregnation is accompanied by the obligatory release of air bubbles from the wood - this means that the composition fully penetrates into the wood, getting rid of the air in it.

After the bubbles are released from the wood, the product must be kept in the solution, also completely immersed, for 30 minutes under required pressure. To achieve the required pressure level, a special pump or compressor should be used.

- After completing all stages of processing, it is necessary to repeat the entire process exactly.

- However, this treatment cannot be repeated before 30 minutes have passed.

- A clear indicator that the wood is filled with the necessary polymer composition is the complete deprivation of the wood of its buoyancy.

If the wooden product continues to float, it turns out that not all the free space was occupied by the solution used during the first procedure. Accordingly, you just need to repeat it, applying the same rules.

At the end of the process, the wooden product should be dried at a temperature close to 100 degrees. The use of additional dye to Aquarol-90 can lead to the appearance of an interesting color effect after stabilization is complete.

Vacuum installation options

In this section, we will touch on options homemade installations for impregnating wood using vacuum and excess pressure.

The simplest, most accessible and inexpensive way would be to purchase, for example, the following kit:

SLUM (a jar with a lid from the IKEA store) and the VAKS system (vacuum canning device), which includes: a pump for vacuum canning NVR-3 and lids KVK-82.

To create a vacuum, you can use a special container: a desiccator (with a tap).

The next “most popular” are AQUAFOR filter housings . The design of the housing allows you to create both vacuum and excess pressure without any modifications. The wiring in their upper part is “ideal” for this. However, the housing is only part of the installation. To create a vacuum and excess pressure you will need: a vacuum pump, a compressor and a body kit (fittings, hoses), as well as devices for monitoring pressure (for example: RGGL pressure and vacuum gauge).

Vacuum pumps - there are many options here, as budget ones we can offer the following: vacuum pump Z 1.2 B Mini (VPBW-1S); vacuum pump Z-1.5 (VPA 115); vacuum pump VE115N (Product: VALUE).

Compressor – you can use automobile ones (Vitol KA-U12050 “Hurricane”; Kachok K90 N, etc.).

If you want to save money (including on electricity), then you can use a Komovsky vacuum pump - this device can still be found on sale. This device allows us to create vacuum and excess pressure exactly in the range we require.

Important! For a more economical use of the impregnating composition Anacrol®-90 , as well as in order to increase the service life of the housings of your installations (for example, plastic filter housings are destroyed upon contact with Anacrol®-90 ), we recommend using additional containers (for example: plastic drinking bottles water). Anacrol®-90 is poured into these containers , wooden blanks are placed, after which they are placed in a vacuum chamber.

We did not consider options for using industrial installations, since, firstly, they have a fairly high price (a vacuum chamber costs about 60,000 rubles, a pump-compressor - from 20,000 rubles) and secondly, it’s all the same to use this equipment for stabilization wood, it will need to be modified.

PS

I would like to add that in order to obtain a high-quality and stable result, it is necessary to follow the stabilization technology and everything is important here: what type of wood you impregnate, the size of the workpieces and their quality, the amount of added dye, the time and conditions of impregnation, temperature conditions, subsequent grinding and polishing.

These are subtleties, but they are usually kept secret; they are what ensure high-quality results.

Special compounds used for stabilization

The most commonly used are special products that have a high polymerization ability.

Accordingly, the following means are most often used for stabilization purposes:

- Polymers;

- Resins;

- Oils;

- Paints and varnishes.

Liquid glass

It is a complete means for stabilization at home, at an affordable price.

- After treating wood with this product, a protective film appears on the surface of the wooden product, which performs additional protective functions, for example, preventing any additional dyes from penetrating into the product.

- Most often, liquid glass is used to stabilize wooden products that have decorative value, whose contact with various chemical reagents during use is quite possible.

This composition provides the best protection against mold and mildew, and also provides optimal protection against exposure to high temperatures, moisture or ultraviolet rays.

Epoxy resin

Can be used on any type of deciduous wood and is prohibited for use on coniferous trees.

- When stabilizing wooden blocks, special attention should be paid to the degree of fluidity of the solution used - this indicator will directly determine the speed at which the wood pores will be filled.

- It is better to pre-dissolve a resin composition that is too thick in alcohol. In addition, you should carefully monitor that the resin does not boil in a vacuum.

Brine

This composition is prepared very simply. For the required concentration of salt in the solution, you need to mix it at the rate of 1 tablespoon per 1 liter of water. This method of wood processing is the least expensive, but at the same time much more labor-intensive.

For example, to stabilize wood, the wooden product should be boiled in the solution for at least 2 hours.

Birch juice

It is deservedly considered the most environmentally friendly of all stabilization methods, since it does not form any toxic substances when boiled. Moreover, the juice is a very effective polymerizer.

- To ensure deep penetration of the stabilizing composition deep into the wood, the process must be carried out under vacuum conditions, and the processing must be completed in a chamber used for drying, at a temperature not exceeding 90 degrees.

- However, the main advantage of birch sap is, of course, its ability to be mixed with natural coloring materials.

Drying oil

It is considered the optimal means for stabilizing wood required for a variety of crafts, as well as for furniture and various outdoor decor items.

The required level of viscosity of this product can be achieved by mixing it with various solvents.

Application of dyes

For coloring Anacrol-90 , fat-soluble dyes are used (in our company you can purchase dyes in five colors: red, yellow, green, blue, black). To obtain other colors, it is recommended to mix the dyes until dissolved in the composition.

Recommendations for the use of dyes are as follows:

- The dosage of dyes is approximately (0.001 - 0.1) g per 1 kg of Anacrol-90 , no more, otherwise the whole mass will be dark and not piercing with light!

- For testing, you can add dye to the tip of a knife the size of half a pin's head.

- Add the selected dye to the desired saturation in portions of 0.01 g of dye per 1 kg of Anacrol-90 .

- Mix with a drill and attachment for at least 5-10 minutes after each addition of dye.

- Dyes can be mixed with each other to obtain the desired shade.

- When packing and mixing the dye, wear gloves, goggles and a respirator!

- Harmful for breathing, avoid drafts (so as not to scatter throughout the room)!

- It is almost impossible to remove dyes from clothes!

- You can wash your hands and face with alcohol or acetone.

- Store the dye in a closed plastic bag without access to air (to prevent moisture from entering) at normal temperature.

Important! The amount of dye added affects the stabilization process; the more dye added, the higher the temperature in the drying chamber should be.

Characteristic benefits of stabilization

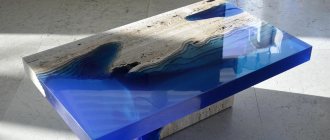

After processing, which led to the stabilization of wood, it becomes similar to stone not only in its own strength, but also in structure. This means that not only a constructive, but also a decorative advantage should be noted.

Generally stabilization using the materials listed above. And the ability to deeply influence wood fibers means complete processing of the structure.

For example, a similar effect is unattainable when the surface of the product is coated with only a layer of varnish that protects only the top layer.

Stabilization at home

Strengthening the wooden structure of the material can be done with your own hands and without any specialized equipment.

However, some features of processing carried out at home should be taken into account:

- Any wooden product must be completely immersed in oil throughout the entire polymerization process;

- Polymerization can take quite a long time - from 3 days to 2 weeks, which completely depends on the type of wood being polymerized;

It is necessary to clearly monitor throughout the entire process that the wood is fully impregnated, since partial stabilization will lead to increased fragility of the wooden object.