The construction of a subfloor in a frame house depends on the type of foundation on which it stands. And the type of foundation of even such a light structure depends on the nature of the soil. And here there are no restrictions on materials - it can be concrete floors on the ground, or wooden floors on joists. But the first option, if used, is only on a slab or strip foundation. Although for strip foundations, subfloors on joists are more common. And taking into account the fact that a frame house is usually placed on a screw or columnar foundation (if the geological features of the site allow), a rough wooden floor is the most common.

All enclosing surfaces of a frame house are constructed similarly - thin-sheet sheathing with insulation in the middle Source k-dom74.ru

Types of floors in frame houses

In principle, all types of flooring can be installed in frame houses, with the exception of natural stone tiles due to their heavy weight.

Wood and laminate

Wood floating floors are constructed as a structure using multiple layers of wood, with the top visible layer being made from hardwood.

Cheaper types of flooring have a layer of wood veneer of about 1 mm, more expensive ones have a layer up to 4 mm thick, so it can be sanded and repainted over time, just like parquet.

A wooden floating floor is more expensive, more delicate and more difficult to maintain than laminate, but it is significantly more durable and has a representative appearance.

Laminate floors tend to imitate wood very well, and are available in all colors and decors.

Linoleum, marmoleum

And over the years, linoleum has enjoyed great success, especially due to its practicality and aesthetics, which allows it to fit into any interior.

Linoleum is supplied in plastic rolls; its younger “brother”, marmoleum, is simply linoleum made from natural ingredients, which can also be supplied in rolls.

- Both types of coating are considered the same in operation. In the room where linoleum or marmoleum will be laid, the surface must also be perfectly flat, hard, dry and clean.

- The covering you wish to install must be placed vertically in the room no later than 24 hours before the event. The material must be adapted to the conditions in the room and at the same time it will work better with it.

Cork and bamboo

Cork is a material created by nature itself for floors. There is no need to place additional insulation under a floating cork floor; such a floor already has a base installed at the bottom of the slat.

However, if the base layer is concrete or anhydrite (cast base of binder gypsum), a vapor barrier should always be used.

- Fashionable bamboo flooring is available in building supermarkets.

- They are popular due to their mechanical strength, hardness and impeccable appearance.

Manufacturers claim that bamboo flooring is twice as hard as oak flooring. It has a unique appearance and does not require surface treatment.

Insulation of floors

Several types of materials are used to insulate floors. There is no limitation on strength, since the insulation is placed between the joists and does not take up the payload.

Among the insulation options that are widely used are:

- mineral wool;

- Styrofoam;

- extruded polystyrene foam (“Penoplex”);

- penoizol (in the form of foam).

Mineral wool has become a popular option. This is justified by the favorable cost of the material, its availability and simplicity of technology. Another advantage is vapor permeability; wool does not interfere with the natural ventilation of the building. To avoid having to cut the slabs, it is recommended to set the lag pitch so that there is a clear distance of 580 or 1180 mm between them. This will allow you to lay the insulation tightly and without cuttings.

Mineral wool floor insulation scheme

The disadvantages of mineral wool include its ability to absorb moisture. In this case, the material loses its ability to perform its function. To protect the insulation from moisture, good waterproofing and vapor barrier is sufficient. Read the detailed article about floor insulation with mineral wool.

There are several types of mineral wool. Basalt in rigid slabs is best suited. Glass wool is inconvenient to work with, and slag wool is made from industrial waste.

The thickness of the insulation is determined by calculation depending on the climatic region. On average, this will be a value from 5 to 15 cm. For accurate calculations, it is recommended to use the TEREMOK program. It is easily available in the public domain as a desktop application or online version. For calculations, you will need to select a settlement from the list, the type of structure being calculated, the thickness of the insulation and its thermal conductivity. The last characteristic is easy to find out from the manufacturers.

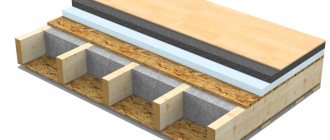

Floor structure in a frame house

The floor structure is made of impregnated wooden beams covered with windproof and vapor-permeable film. This structure is actually a frame for insulation.

The whole thing is covered with oriented strand board.

- Horizontal floor insulation forms a moisture barrier between the concrete foundation layer and the foundation beams.

- It is usually made from 1 mm thick plastic tape. This tape is resistant to low and high temperatures and UV radiation.

- Alternatively, the insulation can be made from strips of insulating or bitumen felt.

It is important that no element of the wooden structure has direct contact with the foundation.

The foundation beam consists of horizontal wooden beams with a cross-section of 15 x 5 cm, placed on those elements of the foundation wall on which the structural beams and the front beam will rest.

The floor was laid on an insulating layer so that it was not exposed to moisture from the foundation wall (foundation strip).

Sex bases by joists

As a rule, the basement floor is located quite close to the soil, there is a danger of moisture penetration, the formation of cold bridges and other negative aspects. In such situations, the wooden structure of the floor base requires additional protection: hydro- and thermal insulation. This will extend the service life of not only the floor itself, but also the frame building as a whole.

You can waterproof the base yourself using roofing felt. It is carried out primarily and is intended not only to protect the wooden elements of the floor structure, but also the thermal insulation material.

Floor insulation in a frame house

The insulation supporting mesh ensures the correct placement of insulating material in the structural spaces of the floor.

- The best option is a mesh made of galvanized wire with a mesh size of 5 cm.

- The insulating material is attached to the horizontal planes of the first floor and the building beams.

- Before laying the mesh on sandy soil, sheets of black construction foil are laid between the foundation strips.

This treatment is aimed at preventing the penetration of moisture from the ground into the space under the floor.

Layered cake"

By putting together all the elements of the floor, we get a kind of pie consisting of several layers. The lowest part, the filing, is designed to hold the “filling” of the pie. It is made of sheet material or assembled from thin wooden slats. A wind barrier is laid on top of the filing - a layer of thin polymer material that prevents the movement of air between the room and the outside environment. This significantly reduces heat transfer through the floor. It is advisable to use reinforced polyethylene or polyvinyl chloride film as wind protection.

A layer of insulation is placed on top of the windbreak. Without it, the cake will cool down very quickly, so you need to take both the selection of material and its installation very seriously. The thicker the layer and the more evenly it is laid in the space between the joists, the more comfortable the microclimate in the house will be

It is fundamentally important to eliminate all cracks: when insulating with mineral wool, they are carefully plugged with pieces of the same material, and when insulating with polystyrene foam, they are filled with polyurethane foam

The cake ends with the installation of wooden flooring. It can itself be finished as a finished floor, or carry another coating that best satisfies the desires and capabilities of the home owners.

Installation of sheathing and insulation

When creating a floor in a frame house, it is necessary to install alternating battens to prevent lateral deformation of the beams and ensure that the beams do not twist, providing equal spaces for insulation.

- Alternating the slats allows you to attach them to the construction beam using 4- or 5-inch nails (not necessarily notched). Instead of partitions located longitudinally in relation to the supporting beam.

- The most popular insulation is rolled mineral wool. The use of this type of thermal insulation material allows flexible and dense placement of cut sections of wool in the floor structure.

When installing insulation, special attention should be paid to preventing it from getting wet.

Vapor barrier film (vapor permeable) ensures controlled movement of moisture. Connections of individual insulation elements are made with metallized self-adhesive tape. It is very important to connect the foil joints accurately and tightly.

General terms

In principle, there are two types of wooden subfloor on the first floor of a frame house:

- load-bearing ventilated structure on a strip or pile (screw) foundation;

- lattice structure on a slab or concrete screed.

In the first case, the horizontal level must already be maintained at the level of the base, grillage or trim, in the second - when pouring the base.

If there is a subfloor in a shallow strip foundation, vents for ventilation must be installed in the load-bearing walls of the base along the perimeter and inside it.

Note : Vents should also be left when arranging the base of the pile foundation.

To protect the wood from rotting when in contact with a concrete or metal surface, the places where the load-bearing floor beams rest on the foundation are isolated using rolled bitumen waterproofing.

A wooden beam must be isolated from contact with concrete Source metasold.com

All wooden elements must be treated with antiseptics, the metal fasteners used and fastening points must have an anti-corrosion coating.

Floor screed in a frame house

The floor sheathing is also the base for the floor itself (floor board or floor panel). The most rational option is a 22 mm thick oriented strand board with a rebate.

The use of rebated boards guarantees a stable connection of the boards in the connection lines. OSB boards are attached to the beams of the structure with screws along a length calculated according to the rule - from 2 to 2.5 times the thickness of the laid material.

Rough screed

Rough concrete screed is performed on slab or strip foundations. In the tape version, the rough screed assumes the absence of a subfloor or other empty space under the ceiling of the first floor. In a slab foundation, the slab itself can serve as a rough screed.

Rough floor screed.

Concrete subfloor is the most durable flooring option. You can install any equipment, heating devices, or heavy musical instruments on it. Cables and underfloor heating pipes can be laid in the concrete base.

Concrete floors have low thermal insulation. Concrete itself is “cold” and requires insulation. The concrete floor creates discomfort and “cools” the feet, so it is covered with a “warm” coating - wooden parquet, cork panels, insulated linoleum. Or they install a “warm floor” heating system in it.

On a note

If the house or interior spaces have an area of more than 4x4 m2, then the concrete screed is strengthened. To do this, a reinforcing metal mesh is laid before pouring. Such strengthening is also necessary if there will be a piano, grand piano, large gas or wood-burning boiler, bathroom, or other heavy devices or objects in the house.

In addition, by strengthening the concrete screed, you can vary its thickness, and thereby save concrete. Thus, the use of reinforcing mesh ensures the strength of a thin concrete screed 3 cm thick at the level of a thicker screed 5-6 cm thick.

Decorating the floor with linoleum

The room should not be below 18°C and the humidity should not be too high. Rolls must be from the same delivery. Make sure that different rolls are not used on the same surface.

- They must be cut with a special knife and placed in one direction, the belts must be smoothly connected and tightly secured.

- For gluing, it is better to use glue intended for a specific material, applied with a notched trowel.

- We always push each air bubble from the center to the edges.

Be sure to use a pressure roller. Manufacturers recommend welding due to the need for a tight and watertight seal. It is welded with a special gun at a temperature of about 350 ° C.

Video about installing floor beams

Strapping and logs

We also make the strapping from 50 mm boards, the width depends on the planned load and the thickness of the insulation.

- We lay the trim along the sides of the house, parallel to the floor beams. We place the boards on their ends, align them along the outer edge of the planks and fasten them to them with nails at 20 cm intervals.

- We mark the location of the logs. We measure 40 cm from the corner along the laid trim board. We lay out the boards for the joists on the beams, place them on the side plane and align them according to the markings.

- If the length of the board covers the length of the building, on the other side we carry out the markings in the same way. We cut the logs and fasten them with nails to the frame and planks, check them and fasten them to the beams at the intersection.

- If the size of the building is larger, then we overlap the logs. The joint should be on the floor beam. We cut 30 cm intermediate joists and nail the joints together, using the scraps as spacers. Then we fix the logs to the floor beams.

Floor insulation

The optimal material for insulation is mineral wool. Its disadvantage is the loss of thermal insulation ability when wet. Therefore, we protect the insulation layer with a vapor-waterproofing and windproof film.

If low-density insulation is selected, we sew a subfloor treated with bioprotection under the joists.

- We lay the vapor barrier film across the joists with sagging, which will allow us to lay insulation between the joists. We glue the joints of the strips with tape and secure the film with a stapler.

- We place insulation boards between the joists, leaving no gaps. When laying insulation twice, use a second layer to cover the joints of the first.

- We put a waterproofing film on top of the insulation and fasten it with staples, protecting against liquid leakage in the house.

Photo of the floor in a frame house

The order of laying the logs

- When laying logs directly on the foundation, the boards are waterproofed from the foundation with a layer of roofing felt or glassine.

- All logs must be treated with fire-retardant compounds to prevent the appearance of mold.

- The two outer beams are laid, their level along the length and relative to each other is controlled. Twine is stretched between them to control the level of the intermediate beams.

- The logs are laid with a planned step under the insulation.

Sergey Yurievich

Construction of houses, extensions, terraces and verandas.

Ask a Question

The lags are fastened to the concrete base using anchors. The logs are attached to the wooden frame using fastening angles and self-tapping screws. Before insulating the floor, you need to worry about protecting your home from rodents and pests. To do this, you can use a fine-mesh mesh. In the case of constructing a strip foundation, it is also necessary to ensure ventilation of the base. In houses on a pile or columnar foundation, vents are made during the process of covering the base.

Guidelines for performing thermal insulation work

Insulation of buildings and structures is carried out during their construction. In the project and construction schedule, these activities, as a rule, are allocated in a separate section. Control over the actions of workers is carried out by foremen or other employees of the company’s engineering and technical services. Construction customers, as interested parties, have the right to verify the completeness of technological operations.

When erecting a frame structure yourself, the closest attention should be paid to thermal insulation work. Insulating a frame house with your own hands is not particularly difficult, even in the complete absence of any experience. It is enough to carefully read the proposed instructions and recommendations of specialists.

Finish floor coverings

The finishing of the floors of both the first and second floors is limited only by your imagination. We examined the preparation of floors for any of the finishing options.

You can use:

- tiles or porcelain stoneware,

- Self-leveling floors,

- laminate and parquet boards,

- linoleum and carpet.

We would like to make a special mention of solid floor boards and engineered wood-polymer composite boards. These materials do not require additional preparation, and they can be installed directly on the joists.

Advantages of floors on joists

- High-quality sound and heat insulation. An impressive layer of insulation not only keeps the house warm, but also provides a breathable sound vacuum that blocks loud sounds from the street, even if they arise directly under the floor. It is more pleasant and warmer to walk barefoot on a wooden floor, which is a significant priority for people who like to walk barefoot in their home.

- Budget cost. The cost of wooden floors on joists will be much cheaper, unlike concrete floors, which will also need to be insulated and screeded to level the floor for finishing.

floor frame on joists

- Ease of communication and simple dismantling. In the event of unforeseen damage that requires repairs or additional communications, the floors on the joists can be disassembled independently, the necessary openings for sewerage and other communications can be cut, and assembled in the same manner. In the case of reinforced concrete foundations, this possibility is absent or is performed with significant labor costs.

floors on joists are simply dismantled

- Environmental friendliness. A wooden floor is installed from natural wood, and if you use natural rather than synthetic materials as insulation, then the environmental friendliness of the base of your floor is close to maximum.

- Wooden floors on joists are safer than concrete floors. Wood is softer than stone, and if you fall, the risk of serious injury is much less. Tactile sensations are also important; it’s pleasant to walk barefoot on a wooden floor.