People starting construction work purchase lumber ready-made. Different types of rocks are used to produce planed products. There are 4 types of lumber, each of which has its own quality and purpose. Based on the type of wood, its shape and type, a classification has been developed. Wood classification is a set of characteristics, after understanding which, the buyer will be able to choose the right timber for himself.

General information about lumber

The term "lumber" implies a range of wood products of certain sizes and qualities.

Wooden products are made by dividing logs into pieces and then cutting them. The result is blanks, wooden parts and the lumber itself.

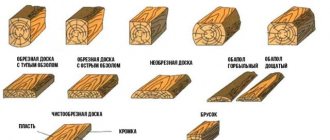

The category of lumber by assortment is divided into:

- Bars are products with a thickness of no more than 100 mm. The width is usually less than 200 mm. The bars are often used to make door frames. They are also used to level surfaces.

- Bars - have a width of more than 100 mm and are divided into two-, three- and four-edge.

- Croakers are remnants of the woodworking process. The product is a one-sided convex board. Croakers are used as a basis for the construction of fences, fences, subfloors, benches and design ideas.

- Obapoles are products obtained from the side part of a log after sawing it. This lumber is made from coniferous trees.

- Sleepers are large cross-section beams that are laid across the railroad bed.

The most popular type of wooden products are boards of various thicknesses and lengths.

Types of lumber by processing method:

- Faced - processed wood that has been given a specified length.

- Uncut - unprocessed from the end of the product.

- Calibrated - material dried to a certain moisture content and subsequently processed in accordance with the specified dimensions.

- Planed - obtained by planing one plane or two edges.

- Structural - materials made from hard wood (oak, larch).

According to the type of sawing, timber can be tangential and radial sawing. The first type of cut is made along tangents to the lines of the annual rings of the trunk at a short distance from the core. The second type is sawing, in which the cut is made through the core of the log.

Main design parameters

The assortment of wooden boards includes requirements for grade and size; we will consider the first criterion in more detail in the next section, and in the table below we indicate the generally accepted sizes of elements:

| Conifers | Hardwood | Permissible deviations | |

| Thickness | From 16 to 25 mm in 3 mm increments, 32, 40, 44, 50, 60, 75 mm | 19, 22, 25, 32, 40, 45, 50-90 with gradations of 10 mm | For thickness up to 32 mm +/- 1 mm, over 32 mm +/- 2 mm |

| Width | From 75 to 275 mm in 25 mm increments | 60-200 mm with 10 mm gradation, exact parameters are agreed with the customer | For widths up to 100 mm +/- 2 mm, over 100 mm +/- 3 mm |

As for the length, the generally accepted options vary from 1 to 6 meters; upon agreement, other standard sizes can be produced

All parameters are indicated by certain letters, which are indicated in the figure; this is a generally accepted option

General technical requirements

To determine the grade of edged and unedged lumber, there are generally accepted state standards.

Regulatory Requirements

Wood producers rely on the regulatory framework, which is regulated by such documents as GOST 24454-80, GOST 8486-86, GOST 2140-81, etc. All documentation is freely available, but some meanings are still incomprehensible to people far from the construction industry.

Since mostly softwood lumber ends up on construction sites, GOST 8486-86 is considered the most basic document.

Key excerpts worth paying attention to:

- Boards and bars are divided into 5 grades, bars - into 4.

- Wood moisture content should be no more than 22%. Drying wet wood is almost impossible.

- The roughness value parameter is set to 1250 microns, and for grade 4 - 1600 microns.

- The nominal length of the product should be 1.0-6.5 m, and deviations from it should be from -25 mm to + 50 mm.

GOST 8486-86 Softwood lumber. Specifications

1 file 440.08 KB

The grade of products is strongly influenced by the criterion for limiting natural wood defects. The general list of required parameters according to GOST is more than 30 items.

Norms and restrictions of natural vices

Each type of wood has its own standards and restrictions on natural defects. These characteristics are given in GOST in the form of a table.

GOST 24454-80 Softwood lumber. Dimensions

1 file 109.25 KB

Excerpts from the standards:

- Tree knots are divided into healthy, rotten, edge, and partially fused. Each type of wood has a strictly regulated number of knots.

- The slope of the fibers for the highest grade should not exceed 5%, otherwise the wood will be assigned grade 1.

- For selected wood, the presence of rot, mold, wormholes, fungal and cancer spots and foreign inclusions is unacceptable.

GOST 2140-81 Visible defects in wood. Classification, terms and definitions, methods of measurement

1 file 5.21 MB

There is also such a parameter as longitudinal warpage, which should be up to 0.20% of the width of the lumber.

What is an edged board?

Edged board is one of the most common rectangular lumber, which differs in a number of parameters, so its range of applications is very wide. This material is used in various fields:

- production of furniture and other interior items,

- external and internal decoration of premises,

- construction of formworks,

- production of fences, stairs, frames,

- construction.

Classification of lumber

Lumber manufacturers offer customers two types of boards: edged and unedged.

Edged board is a rectangular material made by special processing (planing). Careful sanding allows you to install edged boards directly to the desired area.

An unedged board is a material that has uncut edges on the sides. This type of product is several times cheaper than edged.

The grade of wood is determined according to various criteria, which include: size, humidity, presence of irregularities, etc.

The wood classification has 5 grades, ranging from selected boards to wood scraps.

- Selected variety is the highest quality and most prestigious of all. The material does not have knots, stepsons, cracks from shrinkage and bark residues. It also lacks putrefactive lesions and other similar defects. The boards are used in automotive production and shipbuilding. They are used to make masts for yachts, deck coverings and high-quality luxury furniture.

- 1st grade is a popular and sought-after product. This includes lumber with a minimum number of knots and cracks. The boards are free of putrefactive damage, through holes, traces of parasites, as well as mold and other foreign elements. First grade wood is used for the manufacture of critical structures, door and window blocks.

- 2nd grade - this category includes lumber with small “defects” that do not spoil the appearance of the product. The presence of deep cracks, rotten knots, and rottenness is not allowed. Acceptable defects include the presence of loose knots with a diameter of up to 20 mm. Such boards are used to lay sheathing or build wooden panels.

- 3rd grade - a group of lumber with low quality. The products are intended for the production of transport packaging boxes, decking or pallets. The main requirement is the absence of large fused knots and deep cracks. Traces of wormholes, through cracks, tobacco knots and mold are quite acceptable. In addition, this type has a fairly low load-bearing capacity.

- Grade 4 is the cheapest class of lumber, which involves a large number of flaws. Products are often used for the construction of temporary fences and enclosures, sheds, and outbuildings. Acceptable defects: roughness, wingedness, general rot damage, fused knots, presence of wane.

The varieties listed above differ in cost and quality. However, any product always finds a use. The first 3 types of wood are suitable for construction needs, and all the rest are used for cladding or flooring, or for the production of containers.

What are the differences between types of wood?

There are four groups of varieties:

- Extra;

- Prima;

- AB;

- Sun.

Division into types presupposes work done in advance when selecting ready-made material. All wood was produced and dried equally from the total quantity of the entire batch. Experts distribute wood based on each product's standards. The varieties differ according to the characteristics presented below.

Extra

It ranks first among all other types of wood and is distinguished by its high price. When choosing this variety, it is worth considering that the material will be completely free of any possible errors, with the same structure over the entire surface and have a uniform color, the most saturated tones. To make this type of wood, the butt part of the trees is taken.

Prima

The variety has ideal characteristics, has an ideal structure, and is even cheaper in cost than the “Extra” variety. There are minimal errors during operation; this type is used in the manufacture of machines or other equipment.

AB

The cost is cheaper than the first two types, but there is a significant disadvantage, which is the presence of knots and cracks.

Sun

One of the cheapest types of wood, but savings greatly affect the quality. There are strong cracks, many knots, used exclusively for minor parts.

Quality and regulatory documents

Immersion in the topic of determining the quality and grade of timber and lumber offered on the market must begin with the basics, which are clearly defined in the relevant regulatory documents:

- GOST 18288-87 defines all terms related to the technology and products of sawmill production - an industry associated with the production of the entire range of round timber.

- GOST 24454-80 informs about standard sizes and permissible deviations from them for lumber (unedged and edged) used in all sectors of the national economy.

- GOSTs 19041 and 16369 will be useful for studying materials for packaging blanks and lumber for further transportation.

- GOST6564-84 explains the rules for control, acceptance and labeling.

- GOST8486-86 (for coniferous wood), GOST2695-83 (for hardwood) - on the criteria and technical requirements for determining the grade of boards, bars, beams. To ensure that the information in the standard does not cause difficulties and misunderstandings, it is recommended that you first study the materials of the following document in this list.

- GOST 2140-81 - here is comprehensive information about possible defects (natural) of wood, processing defects and the influence of these factors on consumer characteristics. The theoretical part of the document can be considered the basis for expert determination of the quality of wood and the grade of blanks made from it. A detailed description of the nature of each defect or defect (a list of 181 items), methods for measuring it and its role in reducing certain properties of wood will help to accurately determine the quality factor and the scope of possible application of the materials under study.

Application area

Appearance is the main disadvantage of grade 2 products. This explains the limitation of their use in finishing work. In other respects, they are not much inferior to first-class materials. Where decorative value is unimportant, the use of a cheaper, but sufficiently reliable and durable material is justified. Main areas of use:

- House interior partitions, arches, stairs intended for cladding with other building materials.

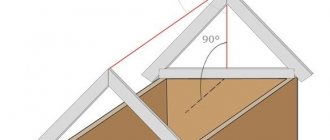

- Elements of the roofing system - slats, sheathing, sheathing and others.

- Laying the base subfloor for floors.

- Restoration and repair work of residential buildings.

- Production of scaffolding.

Wooden scaffolding made from grade 2 material

- Production of containers and furniture elements.

- Obtaining formwork for subsequent pouring of the foundation, floors, and walls.

- Various “temporary buildings” at construction sites - change houses, storerooms, toilets, and so on.

- Street and garden buildings, structures, fixtures (fences, supports, benches, partitions, canopies).

- Agricultural buildings – paddocks, greenhouses, sheds, fences.

- Manufacturing of body parts for wagons and agricultural machinery.

- Expensive boards are used for finishing and interior design.

It will be useful to watch a video about the use of 2nd grade boards in the country:

A private developer for irregular purchases is unlikely to have a proven supplier of quality lumber, on whose reputation and experience he can rely. Often you have to choose the right product yourself. And now it will be done competently.