Fasteners for wooden structures provide reliable fixation at the joints of wooden elements. These parts make it possible to obtain a durable structure that can withstand various vibrations and mechanical loads.

Various types of wood fasteners differ in size and purpose. They have an unusual shape and structure.

How to choose the right metal products that will help create a durable building? The answer to this question is presented in our detailed material.

Types of fasteners for wood

The following types of connecting elements for wood are distinguished. These include:

- connections with perforated base;

- anchor screws;

- "tenon and groove";

- three-dimensional slats;

- "hedgehog";

- self-tapping screws with KonstruX thread.

Each type of product differs in size, shape and material from which it is made.

Weatherproof steel

1. Chrome plated

When chrome plating, pre-galvanized steel parts are dipped in chromic acid, as a result of which a chrome film is formed on the products. It gives very good protection against corrosion to screws and other fasteners, which lasts, as after galvanizing, for approximately 40 years. Just like bronze fasteners, chrome-plated products in color match well with wood used outdoors.

2. Galvanized

When galvanizing, steel acquires a protective layer of zinc. During hot-dip galvanizing, parts are immersed in a bath of zinc heated to 450°C. When galvanizing, zinc is applied to the part.

in an electrolyte bath. Fasteners treated in this way retain their anti-corrosion properties for up to 40 years. True, salty air reduces this period to 25 years.

3. Stainless steel

High-quality stainless steel refers to types of steel that, due to the addition of chromium, nickel, molybdenum or titanium, become completely resistant to corrosion under normal atmospheric influences. At the same time, products with smooth surfaces are even more corrosion-resistant than rough ones, which is why some manufacturers subject their fasteners to special grinding. However, it is wrong to assume that products

made of stainless steel are not subject to corrosion at all. Even this type of high-alloy steel is susceptible to two types of corrosion: crevice and pitting. To maintain a decent appearance of stainless steel, regular washing of metal products with warm water and a surfactant is required.

4. Powder coated

Before applying the powder-varnish coating, the products are galvanized. The powder, then applied to the product, is melted in an oven at temperatures above 200°C. After cooling, a durable anti-corrosion coating is formed on the product. In order for the metal to retain its anti-corrosion properties for a long time, the coating must not be damaged.

Link by topic: How to make a stool-bedside table with your own hands

Perforated connections

This type of connection is used for fixing wooden and concrete parts. Most often they are hidden deep in the cavity of the structure being built. They are made from durable hardened steel. The thickness of each element ranges from 1.6 to 2.5 mm.

In specialized departments there are products made of low-carbon steel. As a rule, such models have a fairly high cost. They are considered stronger and more resilient.

They are mainly used when laying ceilings and floors. Such hidden fasteners for wood can be used in the construction of houses made of timber.

Main types of furniture fittings

When choosing furniture, it is important to pay attention not only to its appearance, because parameters such as durability and functionality will be more important. The fittings that are equipped with each product are responsible for these characteristics. There is a wide variety of details that simplify use and increase the service life of furniture.

For normal functioning, furniture is equipped with a variety of fittings

Door handles

There are three main types of pens, these are:

- stationary;

- with a push mechanism;

- rotary.

Stationary models are found exclusively on cabinet doors and bedside tables. They are not equipped with a lock; they allow you to pull or push the door and often have a decorative function. The remaining types are distinguished by the presence of a latch or lock, so they are much more common.

It is impossible to imagine a single door without handles

Wheels

Today on the furniture market you can find a lot of models of furniture on wheels. They are necessary for the free movement of the product around the house. Each type of wheel is different:

- adjustment parameters;

- fastening;

- rotation method.

When choosing such accessories, it is important to pay attention not only to quality and attractive appearance. It is necessary that the wheels match the style of the furniture (on which they will be attached) and the room as a whole.

Wheels for furniture come in different sizes

All types of wheels can be divided into two main subtypes.

- Swivel - allow you to move furniture around the house without much effort.

- Fixed - able to withstand heavy loads, but do not have good maneuverability, so furniture is much more difficult to move.

Legs

Almost all types of furniture must be equipped with legs/supports. Since they support the entire structure, the legs must be of high quality, but we must not forget about their design. This type of fittings can be divided into 3 groups.

- Regular, without height adjustment. They often represent an inexpensive support for furniture. They feature a laconic design.

- Models with the ability to adjust height. These legs are ideal for rooms with uneven floors, allowing you to level the furniture.

- Decorative - used as decoration. Models can be varied, for example, with threads, non-standard shapes.

Legs are usually present on the base of the cabinet, as well as chairs, tables.

Metal models are usually made from:

- chromium;

- aluminum

They are durable and strong. Such legs harmoniously combine with various interior items.

Wood is often used to create decorative models. It is better to choose legs made of expensive wood, since they differ:

- attractive appearance;

- high quality.

Plastic models do not differ in aesthetic appearance, however, they compensate for this:

- wide range of sizes;

- functionality.

An example of what adjustable legs look like

Loops

Furniture hinges refer to connecting fittings that allow doors to be opened/closed. There are different types of hinges, they depend on the configuration of the cabinets and their facades. Such fittings can be equipped with closers for silent and smooth operation.

Hinges are a mandatory part on the cabinet that ensures the functioning of its door.

Table 7. Main types of loops.

| View | Description |

| Invoices | The most common hinges that allow doors to open 110 degrees. Used on swinging facades. |

| Semi-overhead | Such canopies are used to equip cabinets, the doors of which are fixed on one side and swing open in different directions. They allow the door to open 110 degrees. |

| Domestic | Such hinges are used to equip facades that are located between two side parts. They provide door opening 100 degrees. |

| Corner | Ideal for a corner drawer. The door can only be opened 90 degrees. |

| Adit | They are attached to overhead strips located at the same level as the furniture facade. The doors can only be opened 90 degrees. |

| Complex | Used for corner boxes with L-shaped frames. The hinges are attached in the middle of the two facades, ensuring their synchronous opening. |

| Transformer | They are used in conjunction with complex canopies. The hinge is capable of holding two facades on itself at the same time and allows you to open the doors at a large angle. These hinges are also appropriate if the cabinet is equipped with a drawer. |

Furniture hinges with a closer are expensive fittings with a complex design. Thanks to the shock absorber built into the hinges, the doors will close independently. Would you like to get acquainted with the varieties of this fittings in detail? Then read our specially prepared article.

Locks

The purpose of this fitting is to allow the door to be fixed in one position. There are three types of locks:

- latch;

- lock with key;

- lock for the bathroom.

The latches have simple functionality - to operate them you just need to slam the door. Often, doors with a push handle are equipped with such a mechanism.

Locks look appropriate on furniture made of any material

Key locks allow doors to be locked to prevent unauthorized access. Models for the bathroom are a mechanism with a turntable that can be closed from the inside. This option is more appropriate for ordinary doors than for furniture.

Mortise locks will also be relevant for furniture. They have a high reliability index, and most importantly, do not spoil the appearance of the furniture. There are such locks:

- cruciform;

- cylinder;

- suvaldnymi.

Lever locks work on the principle of moving metal plates into grooves.

The simplest is considered to be a furniture lock. They can be mounted on furniture made of chipboard and glass. They are even suitable for double doors.

Hooks

This type of fittings must withstand heavy loads, so when choosing hooks it is important to pay attention to the quality of the metal from which they are made. The hooks are different:

- shape;

- style;

- sizes;

- functionality;

- design.

Among the most popular hooks are one, two and three-arm models. They can be attached independently to any furniture. The purpose of this accessory is to store various things, mainly clothes.

An example of what the main types of furniture hooks look like

Metal anchors

Anchor screws have huge advantages among most products. They can be used in conjunction with perforated connections. This ratio makes it possible to make the building resistant to climatic disasters.

These products are made from high-strength metal alloys. Most often they are re-hardened and plated with zinc. Galvanized wood fasteners can be used in areas with high humidity. They are resistant to corrosion and deformation during the driving process.

The length of the elements varies from 5 to 10 cm. The diameter is about 6 mm. Such models are used to create roofing or flooring. There is a screw thread along the entire length, which ensures tight fixation inside the wood.

Execution options

Classification according to this criterion is carried out according to the appearance of the outer part of the hardware, which remains visible after its installation. Here, wood anchor bolts are divided into 4 groups:

- Anchor bolt. A classic hex head fastener designed for virtually any application. This can be used to hang a kitchen set or securely fix one or another element.

- Stud anchor. The most popular application is splicing or extending timber building materials. For example, a mauerlat or other element from the roofing or ceiling system of a country house. It is inserted into a previously drilled hole, after which it is tightened with a wrench or wrench.

- Anchor hook. The device is not used to splice or connect two elements. Due to the hook on the outside, it is used as a suspension. The most popular example of purpose is hanging a SIP cable on the facade of a building. Garden lanterns, chandeliers, and hanging shelves are also fixed in this way.

- Ring anchor. Performs functions similar to the above. The difference is that a closed circle (ring) does not allow an object suspended on it to jump off during any movement in space. An example is a swinging children's swing. There are also anchors with spring or threaded carabiners.

Tongue and groove system

This variety is produced by a German company. The product is made of durable aluminum alloy. One part has spikes, and the other is equipped with an additional groove. They are installed according to the dovetail principle. Thanks to this connection, it is possible to reduce the load on the building during operation.

A similar model can be used for both hidden and closed connection points. It is recommended to install metal parts in pre-prepared holes. They should be firmly attached inside the wooden base.

The main disadvantage of this model is their high cost. This is directly related to the complexity of the structure and its reliable fixation of wooden parts.

Fasteners with complex threads

Unusual self-tapping screws, which make it possible to save time and money, since this option does not require metal parts. Self-tapping screws are equipped with threads, which help create a high degree of resistance when pulled out, and are also tightly screwed into an array, which completely changes their traditional functioning.

In this case, the work of the screws occurs exclusively by pulling out, which gives them the opportunity to absorb most of the forces that fall on the connection. So, you can fasten elements at an angle, combine parts, minimizing their deflection, as in the photo of wood fasteners below.

3D slats

Specialized departments provide a detailed catalog of the best wooden fasteners. One of these connections is three-dimensional slats. They are connected perpendicular to each other. As a result, a T-shaped connection is formed, which is considered the strongest.

They are made from durable metal alloys that can withstand all kinds of loads. They have a length from 60 to 750 mm. There are cuts and protrusions along the entire plane of the iron model.

- Lanyard for rigging work

Crab system for profile pipes: features of the selection and use of fastening systems and connecting elements

What is a rigging shackle? Size standards, modern types, rules and features of choice

During the installation process, one edge of the part is fixed in one of the parts of the wooden beam. Next, small cuts are made on the logs, equal in length to the protruding part of the three-dimensional lath.

The choice of such a product should be made in accordance with further loads during operation.

Terms of cooperation

In our company, we offer to buy metal fasteners wholesale and retail for individuals, individual entrepreneurs and commercial organizations of all forms of ownership; we are interested in long-term cooperation. We maintain long-standing partnerships with leading manufacturers of metal fasteners; product prices are affordable, without intermediary markups.

The catalog contains fastenings for wooden structures between each other and to various bases, as well as mounting elements for communication systems. Delivery of goods is organized, any types of payments are acceptable.

Products "Hedgehog"

They are a large washer made of low carbon steel. Galvanic coating is applied along the entire perimeter. They are designed for self-tapping screws. The diameter of the washer is from 50 to 85 mm.

There is a small recess in the upper part, drilled at different angles. This provides different connection depths during the installation of wooden parts.

Rules of operation and care

To maintain fasteners in working condition, they need to be inspected and repaired periodically. Usually the beams and straps are changed. Elements fail due to excessive wear - this is immediately noticeable upon inspection.

After skiing, it is necessary to clean the mechanism from snow so that it does not melt and water does not get inside.

Using the information received about snowboard clamps, you can choose the ideal option for yourself at the right price.

Did you manage to solve your problem using the recommendations from the article?

Yes!

51.52%

27.27%

21.21%

Voted: 33

Methods for fixing floorboards

The floor covering experiences quite serious loads, so it is necessary to approach the choice of fastening method with all responsibility. If some floorboards are not secured well enough, then after some time they will begin to loosen.

As a rule, this happens after a short period of time. The floorboards move, the initially flat floor begins to make an unpleasant creaking sound, and often it simply collapses.

There are several most common ways to attach floorboards:

- secret method, that is, the use of screws or nails;

- using glue;

- fastening with clamps.

Next, we will look at how to fasten floorboards using each method.

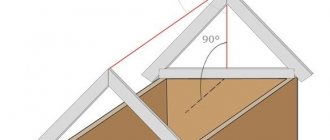

Scope of use of supports

The process of shrinkage of wooden houses is especially intense during the first few years of operation. Changes in the shape and size of the structure are mainly due to changes in temperature and humidity levels. In this case, the height of each individual log or beam changes, resulting in a general change in the height of the wall, which consists of changes in the parameters of each element separately. From the above, we can conclude that as the height of the wall increases, the degree of its shrinkage during operation also increases. The wall located under the ridge has the maximum height, which means its shrinkage is the greatest.

The walls that serve as support for the rafters located along the edges of the house are subject to less shrinkage. Over time, this process leads to a change in the angle of the roof. For this reason, it becomes necessary to take into account the data of geometric changes when attaching rafters and ensuring the mobility of connections.

The rafters located in the ridge are created to rotate relative to each other, securing them on both sides with the help of metal-based plates on studs.

The lower edges of the rafters present a certain difficulty, since during shrinkage they not only rotate, but also move relative to the wall. The device of a rigid and fixedly fixed fastening of the rafter leg to the wall will lead to its bulging as a result of shrinkage.

For rafters, it is necessary to ensure the possibility of a not very large, but still noticeable rotation and a certain shift along the wall without reducing the degree of strength of the fastening. In earlier times, annealed wire was used for this purpose. With its help, the top log was tied to the rafter leg. This technique ensured the mobility and reliability of the created fastening .

Sliding supports for rafters have become an effective, most convenient in terms of installation and a replacement for the described method that meets all requirements. When using it, the rafter leg is securely fastened to the beam or log of the mauerlat. If laminated timber is used in the rafter system, this method becomes the only one that simultaneously provides the necessary mobility and strength. The location of the fastening is the area along the displacement of the beam. To do this, the wood of the top beam is ground down. The result is a platform - the fixed lower part of the support is attached to it.

When performing installation, the support must be positioned in such a way that its shift reserve is the maximum possible.

As a rule, the rafters are fastened on both sides of the rafter leg, however, with a low roof and a small slope of the roof slopes, you can limit yourself to one fastening.

The rafter leg, which has intermediate supports between the mauerlat beam and the ridge, must also be secured with a sliding support.

How much do wood screws cost - review of prices per 1 kg

The price for wood screws is indicated by suppliers both per piece and per kilogram. But if you need to purchase, for example, 2000 pieces of such fasteners, no one will count them. Either they will sell it in original, unopened packaging, or they will calculate it by weight. In any case, let's consider the cost according to several parameters.

| Type of self-tapping screw | Price per piece (as of June 2022), rub. | Price per kg (as of June 2022), rub. |

| Phosphated | from 1.8 | from 180 |

| Black oxidized | from 1.9 | from 195 |

| Galvanized | from 2 | from 200 |

| Yellow-passivated | from 2.1 | from 210 |

| With press washer | from 1 | from 8 |

| Galvanized capercaillie | from 4 | from 500 |

| Roofing | from 1.23 | from 220 |

| Confirmations | from 1.38 | from 150 |

As you can see, the price of such fasteners is not so high compared to the benefits and convenience that they bring when used. Moreover, even a beginner can work with them. All you have to do is choose the right one and you can get down to business!

Watch this video on YouTube

Previous Building materialsStrong flooring for every home: laminate or linoleum - which is better Next Building materialsWhat the walls of new buildings hide: modern technologies for constructing buildings made of porous brick

Installation technology

The process of assembling a roof truss frame using movable fasteners is not much different from the standard procedure. However , it requires maximum dimensional accuracy in the manufacture of elements, as well as maintaining the same angle between the base of the roof and the end of the rafter when installing it. The rafter system is installed in the following order:

- First, the mauerlat is laid on the load-bearing walls of the house. This element of the roof truss frame performs supporting functions, evenly distributing loads between the supports and transferring them to the foundation. In log or timber houses, the functions of the mauerlat can be performed by the upper crowns.

- They make a template for the rafter leg, which will become a model for the manufacture of all other rafters of the structure.

- At the end of each rafter leg, a cut is made under the mauerlat. Experienced craftsmen note that under no circumstances should you make cuts in the Mauerlat, as this reduces its strength and load-bearing capacity.

- First, install the first and last pair of rafters, carefully checking the angle between the elements using a verified building level.

- The sliding support for the rafters is attached to the lower end of the leg. To ensure reliable fixation, it is necessary to secure the guide and slider with 2-3 fasteners.

- The upper ends of the rafter legs in the area of the ridge connection are fixed with nails or metal plates connected with a pin, which ensures the mobility of the structure.

- A cord is pulled between the first and last pair of rafters, and then the remaining structural elements are installed.

Remember that the choice of the length of the movable fastening guide bar depends on the possible amount of shrinkage of the house. The higher the moisture content of the wood used for construction, the larger the size of the sled should be.

Installation of sliding fasteners

Movable skate

If the angle between paired rafter legs can change, then it is necessary to arrange their mutual connection accordingly. They are connected at the ridge, so the usual options for implementing this unit (with cutting the rafters in different ways and using perforated plates) will no longer be suitable.

As usual, there are several solutions. One of them is to assemble adjacent rafters with an overlap in the ridge area, and for mutual fixation they can be twisted with powerful bolts.

The second option works in structures where the rafters rest on a ridge girder or on a load-bearing intermediate wall. It consists in using a movable bracket, which wraps its plates around the rafter legs and allows them to move slightly relative to each other. Each bracket of this type can be assembled from four perforated plates and three bolts.

It should also be noted that if the roofing system of a log house includes various auxiliary elements (crossbars, struts, etc.), then they must also be connected to the rafter legs and to any stationary structures with the ability to slide. To do this, you will have to use the methods presented in the article in one form or another.

Movable skate Scheme of operation

Manufacturing of sliding supports

In most cases, these parts are operated at high humidity and often come into contact with water and condensate penetrating under the roof slope. When manufacturing sliding supports, it is necessary to take into account the strong impact of these and other negative environmental factors. For this reason, they are pre-coated with a layer of molten zinc, additionally alloyed with other substances to reduce susceptibility to corrosion and improve strength characteristics, thereby increasing the overall load-bearing capacity of the structure.

The sliding supports themselves are manufactured by cold stamping on the basis of a fairly strong and ductile material - low-carbon steel grade 08 PS. The percentage of carbon in it is 0.08%, which makes it possible to stamp the material with high quality. Balancing the strength characteristics of the element is carried out by deoxidation.

Installation of corner posts

You can install the corner posts yourself. Installation is carried out in two ways:

- Metal corners. Corners made of hardened steel are suitable for these purposes. It is recommended to choose zinc plated fasteners.

- Wooden dowels. A dowel is a round pin. It is hammered in at the stage of creating the corner of the lower strapping beam, having previously drilled a hole for it. In this case, the dowel should rise above the surface of the harness by at least 8 cm. The frame stand is installed on it. This solution ensures high strength of the connection between the rack and the harness.

The second method requires serious physical effort, but has a number of advantages:

- High reliability compared to threaded fasteners, which weaken after a while because the wood dries out.

- Absence of metal products in the design that are susceptible to corrosion.

Holes equal in diameter to the dowel are made in the surface of the stand. Their depth must be at least 8 mm. After this, the element is connected to the dowel and fixed with braces. Fastening made using homogeneous materials is more ductile and resistant to lateral impact.