Development of a lesson on technology in grade 5 “Species of wood, parts of wood. Types of lumber"

Municipal educational institution

"Savostinskaya secondary school"

5th grade

open technology lesson

topic “ Wood species, parts of wood. Types of lumber »

Savostino 2013

Outline

Goals:

- to familiarize students with the importance of wood as a structural material in the national economy of the country, its species, structure, main types of defects and uses, to teach how to identify wood species and types of defects by the appearance of samples.

- cultivate interest in learning.

- develop the ability to identify wood species by eye.

Tools and equipment:

sets of samples of wood lumber, veneer, plywood, samples of wood with defects, instructional and technological cards.

Time:

80 min (2 lessons)

During the classes.

I. Organizational and preparatory part:

greeting, checking readiness for the lesson, checking those present, telling students the topic of the lesson, the goals of the lesson.

1. Consolidation of the material covered.

After solving this crossword puzzle, you will be able to read the word that is the most important in what you learned in the last lesson. (Crafting table)

Questions:

Picture 1

- The wedge should protrude above the table top to a height less than the height. (blanks)

- What is the name of the discipline we are studying? (Technology)

- The base of the workbench is (underbench)

- It can be cutting and measuring. (Tool)

- The profession of a worker engaged in manual wood processing. (Carpenter)

- Serves to secure workpieces. (Clamp)

- Wooden blocks intended for supporting workpieces (Wedges)

2. Communicate the purpose of the lesson

II. Presentation of program material.

Forests occupy an area of over 700 million hectares in our country. Despite such enormous forest wealth, everyone must treat the forest with care, as it significantly affects the climate, flora and fauna. In addition, the forest is of great economic importance. Its main product - wood - is used in construction, furniture, match production, chemical industry, etc. Forest resources in our country are protected by law.

Let's compare the properties of wood and materials such as metal and stone.

We come to the conclusion that wood is a light, durable material that can be easily processed with cutting tools and has a beautiful appearance.

At the same time, we identify its negative qualities: easy flammability, warping when drying, rotting.

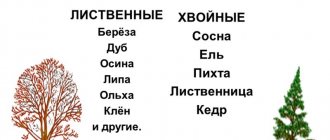

What tree species do you know and what types are they divided into? Deciduous and coniferous.

Trees with foliage are called deciduous, and those with needles are called coniferous. Deciduous trees include birch, aspen, oak, alder, linden, etc.; Conifers - pine, spruce, cedar, fir, etc.

What is a tree made of?

From a trunk, root, twigs, leaves or needles Wood as a natural structural material is obtained from tree trunks by sawing them into pieces Fig. 3

The tree trunk has a thicker part at the base and a thinner part at the top. The surface of the trunk (Fig. 2) is covered with bark (7). The bark is the “clothing” for a tree; it consists of an outer cork layer and an inner bast layer. The cork layer of bark is dead. The bast layer (6) is a conductor of the juices that nourish the tree. The wood of the trunk consists of many layers, which are visible in the section as growth rings (4).

Figure 2

What can you learn from them?

You can determine the age of the tree. The loose and soft center of the tree is the pith (1). Heart-shaped rays extend from the core to the bark in the form of light shiny lines (2). They serve to conduct water, air and nutrients inside the tree. Cambium (5) is a thin layer of living cells located between the bark and wood. Only as a result of the activity of the cambium does the formation of new cells occur. « Cambium

" - from the Latin "

exchange

" (nutrients).

To study the structure of wood, three main sections of the trunk are distinguished (Fig. 3). The cut (1) running perpendicular to the core of the trunk is called the end cut. It is perpendicular to the growth rings and fibers. The cut (2) passing through the core of the trunk is called radial

.

It is parallel to the annual layers and fibers. The tangential cut

(3) runs parallel to the core of the trunk and is some distance away from it.

Figure 3

Wood species

determined by their following characteristic features: texture, smell, hardness, color. (Show how to identify wood types using the poster.)

Another disadvantage of wood is its defects: knotty

(Fig. 4,a),

wormholes

(Fig. 4,6). They limit the use of wood in industrial production, but can be valuable in the manufacture of decorative products.

Figure 4

Let's move on to considering lumber and wood materials.

When longitudinally sawing tree trunks on sawmill frames, various lumber is obtained (Fig. 6): beams (a, b), bars (c), boards (d, e), plates (f), quarters (g) and slabs (h)

Figure 5

Lumber has the following elements: face, edge, end, edge

. (

Indicate on the poster. Plywood is widely used as a construction material.

)

How do you get it?

veneer - onto each other

.

Veneer translated from German means “ sliver

”. The veneer is cut (peeled) with a sharp knife of a special peeling machine while rotating a log about 2.0 m long (Fig. 6). In this case, the log, like a roll, is rolled out into a veneer strip. The veneer strip is cut into square sheets, which are dried in dryers, coated with glue and laid on top of each other so that the direction of the fibers in them is perpendicular to each other. The sheets are glued together under a press. This is how you get plywood.

Figure 6

Plywood is stronger than wood, almost does not dry out or crack, and bends and processes well.

Where is it used?

In construction, furniture manufacturing, mechanical engineering, aircraft manufacturing.

You've probably heard the word chipboard, but what does it mean?

Particle boards. They are obtained by pressing and gluing crushed wood in the form of shavings, sawdust, and wood dust. The slabs are made with a thickness of about 10-26 mm. They are durable, almost do not warp, and can be processed well with cutting tools.

What are they made from?

Furniture, doors, partitions, walls, floors. However, over time they release substances harmful to health, so they are not recommended for use in residential areas.

What is fiberboard?

Fiberboards. They are pressed into sheets of wood pulp that has been steamed and crushed into individual fibers. They have a pleasant gray color, smooth surfaces, and bend, like plywood. They are used for interior decoration: cladding walls, ceilings, floors, in the production of furniture and doors.

What is the common disadvantage of plywood, chipboard and fiberboard?

They are afraid of dampness.

Sh. Practical part

- Students use a regular knife to cut a block of soft wood (pine, linden) along and across the grain. As a result of this operation, they come to the conclusion that wood is easily split along the grain with little effort, but it is impossible to split across it, even with great effort.

- Students try to identify wood types from samples, look at samples of lumber, plywood, chipboard and fiberboard.

Check whether the samples can be easily processed with any tool (file, hacksaw, etc.).

IV. Final part.

Summarize the lesson, note the most active students during the discussion of the material.

Clean the workshop.

Andys Oksana Vladimirovna

MBNOU Lyceum No. 22 of Belovo

technology teacher

Lesson summary "

Wood.

Lumber and wood materials »

Class 5

Topic: Wood. Lumber and wood materials.

Goals

: to familiarize students with wood as a structural material, with the types of lumber and wood materials; teach to identify tree species by the appearance of samples; cultivate a caring attitude towards wood and timber.

Tools and equipment:

table “Structure of wood”; collection of samples of wood species; set of wood lumber, veneer, plywood, fiberboard, chipboard;

During the classes

Wood is a natural construction material. It is obtained from the trunks of felled trees of various species. The following tree species are distinguished: deciduous (oak, birch, linden, aspen, beech, etc.), and coniferous (spruce, pine, cedar)

Let's look at the structure of wood:

a tree consists of a root (1), a trunk (2), branches (3), leaves or needles (4).

The tree trunk has a thicker (butt) part at the base and a thinner part at the top. The top of the trunk is covered with bark. The bark consists of an outer cork layer and an inner bast layer. The main part of a tree trunk consists of wood. In turn, the wood of the trunk consists of many layers, which are visible in the section as growth rings. The age of the tree is determined by the number of growth rings.

The loose and soft center of the tree is called the heartwood. The medullary rays extend from the core to the bark in the form of light shiny lines. They have different colors and serve to conduct water, air and nutrients inside the tree.

Cambium is a thin layer of living cells located between the bark and wood. Only from the cambium does the formation of new cells occur.

Wood species:

Pine

- coniferous species.

Soft. Impregnated with resinous substances. The wood is reddish in color with a pronounced texture. It is used for the manufacture of windows and doors, floors and ceilings, the construction of furniture, ships, carriages, bridges. Spruce

is a coniferous species.

Soft. Impregnated with resinous substances. The color is white with a yellowish tint. Used for the manufacture of musical instruments, furniture, windows and doors. Birch

is a deciduous tree.

Solid. The color is white with a brownish tint. Used for making plywood, furniture, ouds, gun stocks, tool handles, skis. Aspen

is a deciduous tree.

Soft. The color is white with a greenish tint. Prone to rotting. Used for making matches, dishes, toys, paper. Linden

is a deciduous tree.

Soft. The color is white with a soft pink tint. It is used for making dishes, drawing boards, pencils, and products with artistic carvings. Alder

is a deciduous tree.

Soft. The color is white, turns red in the air. Serves as a raw material for the manufacture of plywood, dugout oud, and packing boxes. Oak

is a deciduous species. Solid. The color is light yellow with a brownish-gray tint and a distinct texture. On a radial section, the medullary rays are visible in the form of shiny stripes. It is used for the manufacture of furniture, parquet, cladding of valuable products, as well as in the construction of bridges and carriages.

Lumber:

Tree trunks, after trimming branches and twigs, are cut into logs. The logs are sawn lengthwise and lumber is obtained: edged and unedged boards, beams, whetstones, slabs. Lumber has the following elements: face, edge, end, edge.

Wood materials

:

In addition to lumber, wood materials are also produced and used: particle boards and fiberboards, veneer, plywood, etc.

Chipboard is made on special machines by pressing chips mixed with synthetic resin.

Fiberboard is pressed into sheets of shredded wood.

Chipboard and fiberboard are used for making furniture and in construction.

Veneer is thin layers of wood. It is obtained on special machines

Plywood is a wood material cured by gluing together three or more thin sheets of veneer.

Bibliography

- Derendyaev K.L. Lesson developments on technology (option for boys): 5th grade. – M.: VAKO, 2009. – 288 p.

- Tishchenko A.T. Technology. Industrial technologies: 5th grade: a textbook for students of general education institutions / A.T. Tishchenko, V.D. Simonenko. – M.: Ventana - Graf, 2013. – 192 p.