The properties of wood, by which one type of wood can be distinguished from another without compromising its integrity, refer to the physical properties of wood. Physical properties include texture, color, as well as the smell of wood, and others.

Every type of wood has a smell, even if it is not detected by the human sense of smell, and each type has its own unique aroma.

The durability and richness of the aroma of wood depends on the amount of resins, essential oils and tannins it contains. During drying, the smell of wood is not perceptible to our sense of smell, whereas all freshly cut wood has a clear and rich aroma.

One of the important physical properties of wood is its smell.

Experienced craftsmen easily determine the quality of wood and attribute it to a particular type of wood just by smell alone.

Not only can you determine the type of wood by smell, but you can also judge the quality of the wood by smell. As an example: pine wood, if it has lesions in the form of fungi or rot, acquires vanilla-sweet notes in its aroma.

Cutting down a pine tree

Some types of wood have a persistent, pungent, and for some people, unpleasant odor. Also, there is wood that does not smell after drying, but when exposed to heat it begins to smell again. And there are breeds that have no odor to the human sense of smell, both after drying and when exposed to heat. Knowing these nuances, you can choose a material that will not cause discomfort when using it.

Lumber

Wood and unpleasant odors: cleaning products will help

There are many different cleaning products that can help solve odor problems. For example, it is especially difficult to remove the smells of the “interesting things” our pets can do on a wooden floor. There are cleaning products made specifically for this purpose, and this is where they probably work best.

However, you can also try wiping the wood with a rag soaked in a little ammonia. Moisten the second rag with clean water and then wipe off the ammonia. At the same time, make sure that the joints and edges of the piece elements remain dry. The water should be clean and the room should be well ventilated. This method also works well in combating cigarette odors.

Beneficial properties of wood aroma

The core of wood has the most intense aroma, since the bulk of the essential and tannic elements are concentrated in the core.

But not only each type of wood has a unique aroma. All aromas are united by their ability to purify the air in the room. Because, along with the aroma, substances with bactericidal and antiseptic properties are released into the air. This explains the fact that in a house made of wood it is free and easy to breathe.

Wooden house

The most used types of birch

There are more than 100 species of birch trees growing in the world. In carpentry and construction, only two are most often used:

- Birch is downy or pubescent;

- Silver birch or warty birch.

Both species are found in our country and often grow together. They occupy 2/3 of deciduous forests in Russia. Downy birch most often grows in the east and north, and silver birch in the south.

These breeds are distinguished by high performance and decorative properties. In particular, the greatest density and strength.

What do different types of wood smell like?

It is impossible to compare the smell of each type of wood with something or describe in words. Each of them is unique; for the human sense of smell, odors can be divided into pleasant and unpleasant.

Unpleasant wood includes poplar, laurel or teak. These breeds have a persistent, unpleasant odor.

And species with an attractive smell for humans include acacia wood, peach, cypress, juniper, rosewood, citrus trees and others.

tangerine tree

- Due to the large amount of resins in coniferous wood, it has the most persistent aroma.

- Hardwoods emit a less intense aroma. Its durability, again, is determined by the amount of tannins contained in the wood.

- For example, after drying and processing, linden wood has a very persistent odor due to the high concentration of the substance phraseol in it. The substance has a sweetish smell with hints of honey, so honey barrels are often made from linden wood.

- As we know, oak barrels are often used to store cognac, beer or wine. The sour aroma of oak wood, mixing with alcohol, gives the latter a unique shade of taste and aroma.

- But birch wood is practically imperceptible to the human “nose”. Therefore, birch wood is used to produce dishes and containers for storing cereals.

Birch log

Subscribe to our Yandex.Zen channel

Aromas of some wood species

Coniferous wood containing resin has the strongest odor. The smell of deciduous wood is much weaker and depends on the presence of tannins in it. In conifers, the smell of turpentine predominates. Juniper has a pleasant, strong scent. Rosewood and buckout smell like vanilla, and teak smells like rubber. Oak smells of tannins, while balsam poplar and sophora kernel smell like tanned leather. Interestingly, coniferous wood infected with the fungus Trametes odorata changes its odor and smells like vanilla.

When does Oak bloom?

Oak trees are blooming

usually at a mature age of 40 to 60 years, along with the emergence of leaves, usually in May.

Acorns ripen in September - October.

Oak bark has important medicinal value.

, since it contains a significant amount (up to 20%) of tannins, as well as flavonoids, pectin, tannin, starch, mucus and other natural antiseptics. A decoction of the bark, due to its tanning properties, has a strong astringent and anti-inflammatory effect.

Oak bark is most valued and used in medicine.

, especially the young ones. It is used mainly as an external remedy, sometimes internally, in the form of infusions, decoctions, and tea.

Oak bark and leaves

have

astringent, anti-inflammatory, anthelmintic, sedative, hemostatic

effects.

Oak bark infusion

taken for stomach diseases, diarrhea, gastritis, colic, intestinal inflammation, colitis, ulcerative colitis, gastrointestinal bleeding, liver disease, spleen. Warm infusion improves digestion.

Does the wood still smell? Have you tried coffee grounds, cat litter, and baking soda?

If the methods listed above do not work, you can try other types of absorbents. For example, coffee grounds, cat litter and baking soda - they do a good job with such tasks.

Try applying a thick paste of baking soda and water for several hours. Remember to keep edges and joints dry.

What does Oak look like?

It is not difficult to distinguish an oak from other trees by its powerful stature.

Oak is a large tree, usually with a powerful crown and a powerful trunk. Reaches a height of 20-40 m. It can live up to 2000 years, but usually lives 300-400 years. The growth in height of Oak stops at the age of 100-200 years, the increase in thickness, although insignificant, continues throughout life.

Oak Crown

dense, spreading, with thick branches.

Oak bark

thick, durable, wrinkled in an adult tree, dark in color.

Oak Leaves

oblong with large rounded teeth.

Oak slowly blooms its leaves - sometimes only by the beginning of June. And sometimes - on the second try, when the first leaves are eaten by the caterpillars.

Oak Flowers

collected in long hanging earrings 2-3 cm long.

Oak Acorns

usually oblong, growing from 1.5 to 5 cm. In summer, acorns are green, in autumn they turn yellow and fall off. The acorns are smooth and neat to the touch, which makes them want to be collected, especially by children. The acorn caps are also beautiful. Inside the oak acorn there are 2 segments of yellowish or reddish color, bitter in taste.

Acorns

, the fruits of Oak, sit in special “glasses” - plush.

Wild boars and domestic pigs love to feast on acorns, so already in the Middle Ages people grazed herds of thousands of pigs in oak forests. In Ivan Krylov’s fable “ The Pig under the Oak,

” an ungrateful pig, having eaten acorns, begins to undermine the roots of the tree, harming it. From a biological point of view, the fabulist is mistaken: by digging up the soil and destroying pests, pigs brought only benefits to the oak forests.

You can “imprison” the smell inside

If all the methods you have tried have not helped get rid of the smell and achieve the desired result, you can try to solve the problem differently. Namely, to “lock” the smell in the wood. This can be accomplished by applying several coats of waxless shellac with a little sanding after each coat.

Shellac is an excellent sealant, but it is not resistant to water, so if the product is exposed to moisture, an additional coating, such as a polyurethane varnish, will be needed.

With these simple tips, you may be able to save some items that you were about to give up! Wood absorbs odors well, but, as we found out, there are still some ways to combat this annoying nuisance. To find out even more useful tips, stay tuned to our website!

The properties of wood, by which one type of wood can be distinguished from another without compromising its integrity, refer to the physical properties of wood. Physical properties include texture, color, as well as the smell of wood, and others.

Every type of wood has a smell, even if it is not detected by the human sense of smell, and each type has its own unique aroma.

The durability and richness of the aroma of wood depends on the amount of resins, essential oils and tannins it contains. During drying, the smell of wood is not perceptible to our sense of smell, whereas all freshly cut wood has a clear and rich aroma.

Birch is a durable and elastic material that is easy to process and has a low specific gravity. Man has long used it in the production of furniture, kitchen utensils and in housing construction. Today, modern technologies make it possible to realize complex architectural concepts and design projects using birch in every component: load-bearing structures, exterior and interior elements.

Since school, we roughly know what a tree is made of, and we remember what important function it performs in nature. Properties of wood and how they affect performance indicators. Hardness is an indicator of wear resistance. This indicator is important during the installation and operation of parquet. Humidity affects the strength and further changes in the volume of products. Shrinkage stability must be known in cases where different rocks are used together. The degree of oxidation indicates the change in color of the wood. There are many nuances and for each breed they depend on various factors. It is important to know them, because they all reveal themselves differently both during processing and during operation.

Disadvantages of birch:

- unequal properties in different directions;

- easy rotting and flammability;

- high hygroscopicity;

- the presence of various defects;

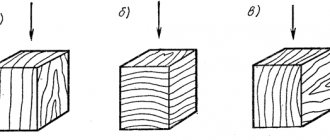

Structural elements of buildings are made from birch: thermal insulation and finishing materials. From waste: sawdust, shavings, wood chips and slabs, fiberboard, crossbow, fiberboard, chipboard and wood-composite plastic products are made. Birch is a perennial plant; it consists of a trunk, crown and roots. The trunk is the most valuable part of the tree; the quality of the wood depends on the structure of the trunk. The tree trunk is examined in three main sections (transverse end, radial longitudinal (along the radius or diameter) and tangential longitudinal (along the chord).

The trunk is the most valuable part of the tree; the quality of the wood depends on the structure of the trunk.

Wood species used in construction

Hardwood:

- birch - plywood, parquet, carpentry and furniture;

- oak - makes carpentry, parquet, furniture;

- ash - carpentry and furniture;

- bug - parquet, furniture, carpentry;

- aspen - plywood, thin roofing boards, containers.

Conifers:

- pine - wooden load-bearing structures, joinery, plywood are made;

- larch - makes hydraulic and underground structures, sleepers;

- spruce and fir - building structures and joinery used in dry conditions;

- cedar - carpentry and furniture production.

Other hardwoods used in construction include: poplar, alder, linden, maple (for the manufacture of temporary structures, scaffolding, etc.).

Physical and mechanical properties of wood

The Brinell hardness of Birch is 3.6 HB (The unit of measurement for hardness is HB (Hardness Brinell). 1 HB is equal to 10 MPa or 10 N/mm².)

The physical and mechanical properties of wood are color, texture, density, humidity, hygroscopicity, shrinkage, swelling, thermal conductivity and resistance to aggressive environments;

The resistance to mechanical stress is not the same in different directions due to the fibrous structure.

The mechanical properties of birch largely depend on its moisture content.

The presence of defects in birch wood significantly worsens its mechanical properties.

Vices of Birch

A defect is a deviation of the structure of birch wood from normal, a violation of the external shape of the trunk.

Ways to increase the durability of wood

- Drying;

- Antiseptic;

- Application of resistant fire-retardant materials to the surface;

- Design measures to prevent dampness;

- Application of glued structures.

- Protecting wood from rotting

- Insulation from soil, stone or concrete foundation;

- Installation of special channels for ventilation;

- Protection of wooden structures from precipitation;

- Installation of ebb and flow sills on external window sashes;

- Protection of wood by treating with antiseptics (chemical compounds).

For antiseptic use, water-soluble and oil-based septic tanks and antiseptic pastes are used. Apply in various ways: spraying, impregnation in hot and cold baths, impregnation under pressure in autoclaves, coating with pastes.

Types and products of wood

Wood building materials are divided into:

Untreated (logs).

Processed (lumber, chipped materials, veneer).

Wood products

Based on coniferous and hardwood trees, planed moldings (plinths, platbands, cornices), products for parquet floors, finished furniture blanks, furniture panels, and floor boards are made.

Planed molded products are:

- birch floor boards;

- tongue and groove birch boards;

- rebated birch boards;

- birch baseboards and fillets;

- birch handrails;

- wall cladding;

- platbands for window and door frames made of birch;

- birch window sill boards;

- steps and risers made of birch.

Products for parquet floors are:

- Birch piece parquet;

- Birch mosaic parquet;

- Birch parquet boards;

- Birch parquet panels;

- Artistic parquet - birch panel parquet on a frame made of bars;

- Wooden checkers made of birch for end floors.

Roofing materials are:

- Roofing tiles - wedge-shaped planks;

- Shingles are wedge-shaped planks with a groove along the length along a thick birch edge;

- Roofing shingles;

- Roofing shavings (chips) Wood roofing materials are used for roofing buildings in rural areas;

- Plaster shingles.

Wood veneer made from birch and other materials is used for the manufacture of plywood, blockboards, and surface cladding of wood products.

Plywood is divided into:

- Regular plywood;

- Plywood covered with sliced veneer;

- Decorative plywood;

- Bakelized plywood (made from sheets of peeled birch veneer glued with waterproof resorcinol glue).

Joinery boards consist of slats covered on both sides with veneer or plywood; they are made from it:

- Window block;

- Balcony block;

- Door block;

- Window sill boards;

- Carpentry partitions.

Glulam board and plywood structures include:

- Beams;

- Frames;

- Arches.

A furniture panel is a product made from lamellas by gluing them together.

Furniture board is a natural product, inexpensive, beautiful and environmentally friendly. It handles beautifully! You can easily make shelves, window sills and tabletops, as well as tables, cabinets, cabinets, kitchens. Since birch furniture board is made from 100% solid wood, many people trust their health to it, and not to phenol-based products.

Furniture boards made of birch of various thicknesses, sizes and grades;

Glued laminated birch timber of various thicknesses, sizes and grades.

Application of Oak

Oak bark decoction

and leaves (1:10) are taken for kidney diseases, kidney bleeding, bloody urine, frequent urination (in small doses), and inflammation of the urinary tract.

Oak leaf infusion

used for bedwetting (enuresis). Decoctions are also used for rinsing for inflammation of the oral mucosa, bad breath, inflammation of the tongue, for lotions for bedsores, frostbite of the hands and feet (baths), burns, wounds, skin inflammation, eczema, scrofula.

For sweaty feet, make baths from a decoction of the bark (2 tablespoons per 1 glass of water, boil for 1-2 minutes, leave until cool), and also pour crushed bark into socks for the day.

Coffee from Oak acorns: the acorns must be peeled, boiled, drained immediately, then coarsely chopped into pieces and fried until browned. Let cool and grind in a coffee grinder into powder. Brew like coffee, or can be used as a dietary supplement. This drink is given to children with diseases of the cardiovascular and nervous systems.