Increase in height

From the name it is clear that the essence is to lengthen the beams or logs in the vertical direction. The axes of the elements are on the same vertical line. Types of extensions are:

- End-to-end extension. To absorb random loads, a barbed pin is inserted on the sides.

- Extension with one or two spikes. The width and height of one tenon must be at least one third of the thickness of the timber. The depth of the nest is slightly greater than the height of the thorn.

- Half-tree extension. The ends of both logs need to be cut to half their thickness by 3-3.5 diameters in length.

- Tongue building. In one beam you need to cut a fork into which you need to insert the correspondingly cut end of another piece. The connection itself must be wrapped in tin.

Necessary tools and equipment

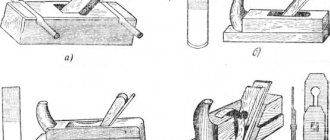

The tools for execution are very diverse. They are selected depending on the type of work performed. Since in carpentry the elements being processed are larger than in carpentry, therefore, the tool must be suitable.

To connect wooden parts use the following:

- axe;

- plane, straight and curved planes, bear, sherhebel - more thorough surface treatment;

- chisel - chiseling holes and sockets;

- chisel - for cleaning cuts;

- drills with different tips - for through holes;

- various saws - for sawing lengthwise and crosswise;

- hammer, hammer, sledgehammer, mallet;

- square, compass, level and other auxiliary tools;

- nails, metal staples, bolts with nuts, screws and other fastening products.

Length splicing

This type of joining of wooden parts has some nuances. At its core, this is the elongation of elements in the horizontal direction. Splicing can be:

- Butt-end - the ends are cut at right angles and aligned with each other. A bracket is hammered into both beams (logs).

- Oblique butt - the cuts are made at an angle, and the ends are fastened with a pin or nail.

- End butt with ridge.

- Direct overlay - the length of the cutting is 1.5-2 times greater than the thickness of the timber (log).

- Oblique trim - the ends are cut at an angle and secured with bolts.

- Overlay with an oblique cut - at the ends of the parts, end ridges are made, having a width and length of one third of the thickness of the beam.

End connection

This type of joining of wood material has another professional formulation - extension. A characteristic feature of this connection is the increase in the length of the building component due to the knocking together of wood elements in the gable part. Considering the method of fastening parts, products of this type of production endure significant loads when wood is deformed: compression, bending or tension. The board obtained as a result of extension can be stronger than solid wood.

The building of wooden elements that resist compression can have several variations in structure. A distinctive feature of this extension is the bars, which have both a groove and an overlay, often having the same dimensions in thickness and length. By experimenting, it becomes possible to join the material with a straight overhead part in half a tree, or to join it with an oblique overhead part. For maximum strength of the element, you can complicate it with spikes or several types of joints. To create this type of joint, you will need auxiliary adhesive fixation or fastening with screws or nails.

Essentially, the end extension resists tension and has an overlay part in the lock. To perform this type of joining, the overlay must be drawn out and, therefore, a groove must be cut on one of the parts and a tooth on the other. Such a lock will make it possible to avoid uncoupling of parts and maintain the reliability of the structure. This type of joining can have either a straight or an oblique overlay. You can use glue, screws and nails as a safety fastening.

Curvature-resistant end extension at the base of the fixation uses an overlay with an oblique or stepped joint. A characteristic feature of the first method is cutting the end sides of the element at an acute angle. It is worth noting that when cutting the ends, you should not violate the cut angle. The difference between the second type and the first is the presence of small grooves and teeth on the gable sides. Both types of joints of elements must have a flat surface for the overlays.

To build large houses from wooden beams, iron or wood fastenings are used to fix them. Wood fastenings are made using inserted or hollowed-out tenons, while iron fastenings are made using clamps and fastenings with iron wire. Most often, beams are fastened with iron bolts.