Classification of compounds in furniture products

The joining of elements into a furniture product is carried out in various ways. The choice of connection options is quite diverse. The designer, when choosing this or that connection, must remember that it must ensure the reliability and durability of the product, its manufacturability and aesthetics.

All used connections are divided into two main types: permanent and detachable.

Permanent connections do not require disassembly of the structure; The elements in them are connected using glue, nails, staples and screwless fittings. Detachable connections allow you to assemble and disassemble the structure.

Detachable connections are divided into stationary and movable. Stationary connections ensure a constant relative position of the connected parts of the furniture product. These include connections using ties, screws, and dowels without glue. Detachable movable joints ensure the movement of product elements relative to each other in a given direction. Movable joints include joints on hinges, rollers, and guides.

The strength of products depends on the strength of the connection between the parts. A variety of compounds are used in carpentry:

- tenon joints with glue;

- joints without spikes on glue;

- connections with screws, clamps, bolts, dowels, etc.

Connections using nails and fastening brackets

Nail joints are rarely used in furniture production. They are used for fastening parts made of thin sheet materials.

Nails are standard products. They come in different sizes in length and thickness. The cross-sectional shape of nails can be round, rectangular, notched, with a screw or ring thread. Depending on the material, steel, copper, aluminum nails, etc. are distinguished.

The strength of connections on nails is characterized by resistance to pullout. It depends on the size of the nail, the shape of the section and the material of the parts being connected.

Connection with staples is used when fastening parts made of thin sheet materials, fabrics, some polymer parts and springs. Connecting with staples is not labor-intensive, but does not have great strength. When fastening sheet materials, the height of the bracket must be at least three times higher than the thickness of the part.

Box connections

Box joinery joins the corner joint category. They are widely used in the production of furniture and carpentry. Such connections can be made using straight or oblique tenons. Their number depends on the width and thickness of the parts (boards). A spike is made at both ends of the parts being connected. The part that has an eye on the edge has one more protrusion.

Box-type connections can be blind, through, flush or semi-flush. The choice depends on the application of the products. Through joints are used for parts that are located inside the workpiece, as well as on the front sides if subsequent coating of the surfaces with plywood is planned.

If the part is open only on one side, the workpieces are connected in a semi-flush manner. If they are open on all sides, the hidden technique is used. Insert tenons can be used. But this type of joint is the least durable.

Box junctions are created using straight through tenons and grooves with a ridge. They can be rectangular, triangular, trapezoidal in shape. Grooves are used if it is undesirable to have protruding ends on the outer edge.

Corner connections

There are many other types of joinery joints. Corner joints are included in a separate group.

In this case, knitting occurs at a certain angle. Such connections are divided into box and frame types. The most commonly used joints of this type are:

- Overlay. This is a simple, but less reliable type of combining parts. At the end, choose material up to half the thickness of the workpiece.

- Frame straight tenon. This is the main type of corner joints. The thorn fits into the socket. It can be single, double or triple. The choice is made depending on the strength requirements of the part. The nest may be open on one side. It's called deaf. If the nest is open on both sides, it is called end-to-end. There are holes open on three sides. They are called an eyelet, which is located at the end. The nest may also be in the middle part.

- Oblique dovetail spike. This is a strong connection and is preferable to a straight tenon. A joint of this configuration is not sawed in a direction parallel to the edges. The base of the tenon should be 1/3 of the thickness of the bar. Its end should be 3/5.

- On the dowels. This is knitting on dowels or round insert dowels. The connection is less durable than a tenon connection, but at the same time it is more economical. In this case, there is no need to make an allowance.

- On the mustache. The ends are cut at an angle. This joint is used both for bars of the same and different widths. The angle of the cut may be different.

Splicing and extension

In lessons on carpentry tenon joints, much attention is paid to this particular type of joining. They have a lot in common. Splicing is the connection of two parts located horizontally along their length. Extension allows you to increase the length of parts that are vertical in relation to each other. This, for example, could be a pillar block.

Joining and joining is one of the main types of joints in carpentry. They are used to produce long beams and posts. Typically, long parts are not cut from one board. This technique is used in the construction process. Also, during the repair of joinery, extensions or splices may be required.

Using the presented technique, stair railings, building trim beams, skirting boards and other similar products are obtained.

More often, hardwood is used to create long parts. Small bars are cut from it, which are glued together in width and length. The process of creating such blanks even involves the use of business waste from the woodworking industry.

You will be interested: Pavel Yakovlevich Golovachev: biography, participation in battles, awards

Carpentry joints of parts of the presented type are also used to create door panels and window frames. In this case, coniferous wood is more often used. Modern adhesive compositions are highly durable. With their help, it is possible to create an almost invisible seam.

There are several main methods of extension and splicing:

- Back to back. In this case, the elements are connected at the ends. They are cut flat at a right or other angle.

- Half-wood overlay. The part most often has a square or rectangular cross-section.

- Spikes. This is a special protrusion of the appropriate shape. The second part has a recess that corresponds in configuration to the protrusion. The joint tenon can be round, flat, or oblique (for example, a dovetail joint, which is often used during construction work).

- Wedge-shaped lock.

Permanent connections

The most common group of permanent connections are connections using glue. Thanks to them, structures of various shapes and purposes are created. Adhesive joints have a number of positive qualities: they are quite technologically advanced, have high strength, increase dimensional stability, and reduce the likelihood of cracking.

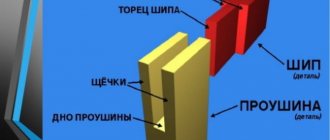

Tenon joints are widely used in furniture products. The main elements of tenon joints are a tenon, a socket, an eye, a tongue and a tongue.

A tenon is a protrusion at the end of a part that has a certain shape and size. The tenon fits into a socket, eye, or tongue.

A socket is a hole or depression in a part.

An eye is a hole at the end of a part, open on two or three sides. The shape and dimensions of the spike correspond to the shape and dimensions of the socket or eye.

A tongue (groove) is a recess in a part along its entire length.

A ridge is a protruding part of a part that matches the shape and size of a tongue. The main elements of tenon joints are shown in Figure 1.

Rice. 1. Elements of tenon joints: 1 – flat tenon; 2 – nest; 3 – eye; 4 – end face of the tenon; 5 – tenon shoulders; 6 – side edges of the spike; 7 – ridge; 8 – groove; 9 – round insert tenon (dowel)

The shape of the spikes is flat, round, trapezoidal (“dovetail”) and jagged. Spikes can be solid (made directly at the end of the part) or inserted (being independent parts). Inserted round tenons are called dowels. The planes of the lateral edges of the spines are called cheeks.

The ledges that form the transition from the bar to the body of the tenon are called shoulders.

The length of the tenon is the distance from its end face to the shoulders, its thickness is the distance between the cheeks of the tenon, the width is the transverse size of the cheek.

With the help of spikes they form connections:

- corner end;

- angular middle;

- corner box;

- along the length and along the edges.

Tenon joints are:

- through (the end of the tenon extends onto the visible surface with its end edge);

- open (after connection, the surface of the upper edge of the tenon becomes visible);

- with darkness (after connection, all side edges of the tenon become invisible);

- with semi-darkness (after connection, only part of the upper edge of the tenon is visible);

- on a straight tenon (the edges of the tenon joint elements are mutually perpendicular);

- miterwise (the end faces of the joined bars are cut at an acute angle - most often at an angle of 45°).

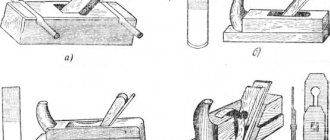

The main types of tenon joints and their dimensional relationship are regulated by GOST 9330-76 (Fig. 2, 3).

Rice. 2. Main characteristics of tenon joints: tenon design: 1 – solid; 4, 6 – plug-in; number of spikes: 1 – single; 2 – double; tenon axis direction: 1, 2 – straight; 5 – oblique; spike shape: 1, 2, 5 – flat; 3 – “dovetail”; 6 – round; corner end connection: 7 – with an open tenon; 8 – with a closed tenon; middle connection: 9 – through; 10 – with non-through tenon

Rice. 3. Main types of tenon joints and their dimensional relationship: S0 – thickness; B – width; for a dowel l, the length is 20–30 mm; l1 = l + (2–3 mm); d = 0.4 S0; S1 = 0.4 S0; for a spike l = (0.5 – 0.8) V; h = 0.7 V1; S2 = 0.5 (S0 – S1); b ≥ 2 mm; l1 = (0.3 – 0.6) l; for box tenon S1 = S3 6, 8, 10, 18 mm

The strength of tenon joints depends on the area of gluing and the density of contact of the joints. Corner end, middle and box connections are used to create volumetric structures (frames, boxes, drawers). Straight, open, single, double or triple tenon connections differ in strength, and, therefore, the choice of connection will be determined by the magnitude of the loads during operation.

Tenon joints with darkness and semi-darkness (through or non-through) are inferior in strength to open tenon joints. But they protect the bars from turning out during assembly.

In all non-through connections, a gap (at least 2 mm) is provided between the end of the tenon and the wall of the socket. This is done in order to avoid destruction of the structure at the time of inevitable deformations caused by the hygroscopicity of wood.

Dowel connections are the most common in furniture products. This is explained by their positive qualities:

- minimal labor intensity in manufacturing connection elements (making a hole and a dowel) compared to the labor intensity in manufacturing other standard connections;

- the use of dowel joints in wood products, which allows saving up to 10% of the original material;

- the required strength for connecting parts made of particle board to the dowel.

Miter connections are used in structures where it is necessary to hide the ends of the parts being connected. Mustache joints are inferior in strength and manufacturability to right corner joints.

Of all the box tenon joints, the most durable is the dovetail tenon joint. Connections along the length make it possible to produce full-fledged parts from small-sized waste. This leads to an increase in the useful yield of wood. Of all the methods of joining along the length, the most common are serrated adhesive joints (GOST 19414-79). This is explained by the fact that they provide high tensile and bending strength, and are technologically advanced, since there are high-performance specialized lines for their creation (Fig. 4).

Gear connections, depending on the exit of the tenon elements to the face and edge, can be vertical (exit of the surface of the tenon elements to the face), horizontal (exit of the surface of the tenon elements to the edge); diagonal (the surface of the tenon elements extends to the face and edge).

The strength of a toothed connection depends on the length of the tenon and the slope of its faces. The slope must be at least 1:8, which ensures optimal assembly conditions.

Rice. 4. Scope of application of the Hoffmann dovetail key and its overall dimensions

A group of edge connections is used to increase the width of parts. The most technologically advanced connection is a smooth fugue. It is advisable to use edge connections on dowels for joining narrow parts. The connection along the edges to the insert rail is quite strong and technologically advanced. The lath can be made of plywood or wood with transverse grain.

Longitudinal and wedge-shaped joints have high strength, but require significant material consumption and are labor-intensive. When using tenon joints, the strength is influenced by the quality of the wood, the accuracy of the processing of parts, the quality of the glue and gluing conditions, the shape and size of the tenon. The larger the gluing area, the less roughness of the bonded surfaces and the thinner the adhesive seam, the stronger the adhesive joint.

In addition to wood, as is known, production uses materials obtained by pressing from crushed wood: particle boards, MDF boards, OSB, etc. Due to their structure, they cannot serve as the basis for a tenon that carries mechanical loads. In this case, only the eye is made, and the connection elements such as round and flat dowels or various ties are used as a tenon.

Corner joints are an integral part of almost all joinery products. How to obtain a connection that is as technologically advanced as possible and less dependent on operating conditions? Obviously, such a connection should have a number of advantages.

The open end-to-end tenon connection is durable and easy to manufacture. But the thorn is visible on both sides. This significantly worsens the appearance of the product, as it darkens the ends during finishing. It is used only for wood and has limitations for small material thicknesses.

An open, non-through tenon joint has a smaller gluing area and is therefore less durable. Easy to make. The end is visible on one side. For increased loads, for example in doors, it is used in combination with round dowels.

The round dowel connection is quite strong and easy to manufacture. Dowels are made from hardwood. The diameter of the dowel should be equal to 0.4 of the thickness of the material.

A non-through miter connection with inserted round dowels is less durable and more difficult to manufacture. Provides a beautiful appearance of the product, aesthetics, uniformity in finishing, since there are no open ends. Used for connecting profile parts.

The miter connection with a flat non-through tenon is simple and quite strong. The product looks beautiful. When assembling frames, difficulties arise when fixing the corners.

The miter connection with a flat tenon through is strong and easy to manufacture. The decorative appearance is spoiled by the spike visible on both sides (edges).

A miter joint without spikes using glue and staples is easy to make, but fragile. It is used for simple and complex profile parts in operating conditions of the product without loads, for example, decorative frames.

With a short tenon length (up to 20 mm), the strength of the connection decreases, and when the tenon length increases beyond 49 mm, the strength does not increase. Therefore, the length of the tenon should be between 20 and 40 mm.

For a single-tenon connection, it is recommended to take the bevel angle α = (12 – 15)0. With a multi-pin connection, the bevel angle depends on the step size t. To ensure the durability of the cutting tool, the pitch t of the tenon should be taken in the range from 8 to 10 mm.

The Hoffmann dovetail joint is durable and easy to manufacture. The connection element can be on the face side and on the corner side. No open ends. Can be used for any profile parts with a thickness of 8 mm or more (Fig. 4, 5).

Hoffmann dovetail keys can be used efficiently and practically without problems both for creating individual connections and for entire blocks.

“Swallow” Hoffmann has a set of unique properties:

- The geometric shape is carefully thought out; in cross section it represents a double wedge. The angular parameters of the wedges are such that the Hoffmann “swallow” works like a clamp, pulling the two parts being connected tightly and firmly;

- The material from which the “swallow” is made is a synthetic polymer that does not dry out, does not swell, and is highly resistant to impact loads. It can withstand both low and fairly high ambient temperatures;

- High precision manufacturing of the Hoffmann “swallow” and the dimensions of the keyway guarantees ideal strength and tightness of the joint.

Rice. 5. Options for design solutions with Hoffmann dovetail key

When performing joinery and carpentry work, they resort to joining, splicing, extending and knitting (angular connection) of parts.

Bonding is the joining of bars and boards into shields. Otherwise, such a connection is called a width connection. The boards and bars that form the shield are called plots (lamellas).

Joining can be done on a smooth fugue, in a quarter, on a lath, in a groove and a rectangular comb, in a groove and a triangular ridge, in a dovetail (Fig. 6).

Quartering assumes that quarters have been pre-selected on each plot. Quartering is very uneconomical and leads to unnecessary waste of wood.

Racking onto a rail is more economical. When joining to a lath, grooves are selected in both plots (lamellas), and their connection is carried out using a lath, which is inserted into adjacent grooves on the edges. The tire of the groove and the rail should be approximately 2/3 of the thickness of the plot.

The tongue-and-groove joint and the rectangular, trapezoidal or triangular tongue are similar types of tenon joints. Their difference is in the shape of the spike. With such consolidation, a tongue and groove is selected at one edge of the plot, and a ridge (spike) is made at the edge of the other. The groove should be about a third of the thickness of the plot, the tenon should be a little thinner.

Tongue-and-groove joining is somewhat inferior in strength to adhesive joining to a smooth joint. The reason for this lies in the fact that the shape of the tongue and tongue inevitably has inaccuracies, as a result of which it is impossible to ensure the necessary density of contact of the mating parts.

Rice. 6. Cohesion: 1 – smooth fugue; 2 – in a quarter; 3 – on the insert rail; 4 – in a rectangular groove and ridge; 5 – in a triangular groove and ridge; 6 – on the dovetail tenon

Tongue and groove joints are used in the manufacture of panels, flooring and carpentry partitions.

The dovetail joint is a tenon joint, the peculiarity of which is that the tenon has the opposite shape of a trapezoid.

Bonding is done using glue. When joining shields, other types of connections are also used. They use dowels, lugs in grooves and tongues, straight and triangular slats glued into the end.

A dowel (like a lath) is a long, flat tenon that runs along the entire length of the part. The key is driven into the groove using a hammer. You can first apply glue to it to increase its strength, but this is not a prerequisite.

Groove and tongue ends are attached to the lower or upper end of the shield. A groove is usually made in the tip itself, and the ridge is selected on the shield. Solid groove and tongue can be replaced with dowels.

The choice between adhesive joints and other types of joints should be made based on the purpose of the board, since the advantage of the latter is that they protect the boards from warping.

Splicing is the joining of lengthwise segments. It is used in cases where it is necessary to make a longer part or workpiece from smaller elements. Several types of splicing are used: end-to-end, on the “mustache”, in half a tree, with an oblique cut, in a straight and oblique patch lock, in a straight and tension lock, etc. (Fig. 7).

Rice. 7. Tenon joints along the length

Butt splicing is a joining of parts lengthwise along a plane with the formation of right angles. It is advisable to resort to this method of splicing only in cases where it is not necessary for the product to be strong enough and able to withstand heavy loads. In carpentry, butt splicing is used only when both parts being joined are supported. They are usually connected using staples.

Miter splicing is a connection in which the mating planes form an acute angle with the longitudinal planes of the workpieces. The part spliced in this way is secured using dowels. Mustache splicing can be done with or without a protrusion against which another part rests; the presence of a protrusion prevents the parts from moving relative to each other.

Splicing in half a tree resembles splicing in a quarter. The depth of the wood cut should be exactly half the thickness of the mating beams, and the length should be at least 2.5 times greater than the thickness. The connection is secured with dowels. This connection is very strong, can withstand quite large loads and is most often used when splicing bent workpieces. Depending on the angle of the surface in relation to the end, such a connection is called a splice with a straight or oblique patch lock.

The most durable connection method for splicing is an adhesive toothed connection. It is desirable that with such a connection the length of the tenon should be approximately four times greater than the pitch (width at the base).