Beton-House.com

Website about concrete: construction, characteristics, design. We combine the experience of professionals and private craftsmen in one place

DIY aerated concrete

When calculating the construction budget, many developers begin to look for savings options, one of which may be an attempt to independently produce building materials. However, home production is not always economically profitable, because to organize a mini-production, in any case, you need at least a minimum set of equipment and basic raw materials.

In this article we will understand how justified the manufacture of products intended for the construction of walls can be. So, do-it-yourself aerated concrete at home: is it possible, and how profitable is it?

- Required set of equipment and materials

What is aerated concrete

Aerated concrete building blocks can come in different sizes and shapes. But their composition is almost always the same. You can make aerated concrete blocks with your own hands from:

- high quality cement; lime; quartz sand; gypsum; aluminum powder; water.

The production technology of this material is quite simple.

You can produce aerated concrete in the yard of your home or directly at the construction site. Ready-made blocks are parallelepipeds made of a porous concrete mass containing many small air pores. They measure about 3 mm.

Pores are formed by adding aluminum paste or powder to the solution. Sometimes, in addition to the listed components, some other substances are added to the composition in very small quantities. They are needed to change some parameters of the building material.

According to the production method, aerated concrete can be made using autoclave and non-autoclave methods. The first method is not suitable for home use.

It requires expensive equipment. The non-autoclave method is simpler; it allows you to set up the production of aerated concrete yourself at home. During production, a reaction of water with aluminum powder is used, as a result of which a huge amount of carbon dioxide is released, which forms pores inside the blocks.

The mass hardens after some time. This happens in natural conditions. The body of the block receives many pores from 1 to 3 mm in diameter.

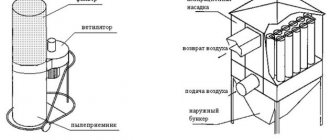

Mini-plant for the production of non-autoclaved aerated concrete

The porous structure is the main advantage of the gas block.

Pores make the material light and give it high thermal insulation properties. The density for aerated concrete is kept at the level of 300-1200 kg/m³. In order for the pores to hold firmly in concrete, it must be placed in a strong form, which determines the size of the future block.

The mass hardens in 2 hours. After this, the blocks can be removed from the mold and placed on racks to completely harden. The final strength is formed only on the 28th day of natural drying of the blocks.

Pros and cons of producing aerated concrete at home

The advantages of creating gas blocks with your own hands are the following:

- Low costs for purchasing materials. Tools and equipment can always be rented for the required period.

- Flexible work schedule and independence from suppliers.

- Creation of an environmentally friendly block of the desired shape, density and strength, in accordance with the plan.

- Independent control over the work process.

The disadvantages of own production are:

- It is time-consuming, so you will need to be personally present from the beginning of the process to the end.

- Labor intensive - you need to do everything yourself (purchase of materials, preparation, mixing the solution, temperature control, laying out the pour, loading finished products).

Non-autoclave blocks will be less durable than professional autoclave ones , but they will have material characteristics no worse than those made on an industrial belt, differing only in strength (for conveyor ones it is much higher).

Making aerated concrete with your own hands

Producing aerated concrete at home requires some tools. You need to prepare:

- a grinder with a disk; a hacksaw for wood; an electric drill; a plane; a hacksaw for working on metal; a sharp knife; a plumber's hammer; a shovel for mortar; a mixer for mixing the mixture; a ruler; a hair dryer; a trowel, a steel string for cutting blocks; a spatula; scales ;chisel and chisel;measuring bucket.

Using a measuring bucket and scales, the necessary components for the solution are measured. The production of gas blocks is carried out from the following components:

- Portland cement grade M400-M500 - 50-70%; sifted quartz sand - from 20 to 40%; lime as a plasticizer - 1-5%; aluminum powder or paste - 0.04-0.09%; water - 0.25 -0.8%.

Collapsible metal form Pouring lightweight concrete Removing excess concrete mortar Blocks after stripping

The mixture is thoroughly mixed and laid out in forms, which come in different shapes. This can be a pretty durable box. Its height is equal to the height of the blocks.

The total volume is 4-9 gas blocks. The molds can be made of wood or metal. It is advisable to make the structure collapsible.

A more complex option is a box with cells, which can be made of wood 30-40 mm thick, or metal 4-6 mm thick. Internal partitions can be made of plywood. Its thickness should be 12-15 mm.

Before pouring the solution, the surfaces from the inside must be lubricated with technical oil and the entire structure must be heated with a hairdryer to 40˚. The mixture is poured to the level of half the height of the box. The remaining space will be filled as the composition expands and pores form.

The gas release reaction lasts 6-8 minutes. The solution first rises, then shrinks slightly. After shrinkage, you can cut off the upper part with the prepared string and remove the blocks from the mold.

Cooling of the blocks should occur under natural conditions. The use of fans is not recommended. It is recommended to install the mold on a flat horizontal surface.

It is better to prepare several boxes at once in order to mix a significant amount of solution. The work site must be sheltered from wind and precipitation. The block sizes can be chosen at your own discretion.

Possible difficulties and errors

Errors may occur during the production process, which it is advisable to avoid , since they affect the quality of the industrial product, especially when creating it at home:

- Incorrect grade of cement for mortar. The best brands for aerated concrete are considered to be M400 and M500. It is allowed to use M300 only for the production of products that will be used as thermal insulation material or partition walls.

- Purchasing low-quality components to create a dry mortar mixture. It is best to purchase materials from trusted suppliers, with a quality certificate for the product, a guarantee, instructions and mandatory labeling.

- Failure to follow the sequence of mixing the composition, which can adversely affect the formation of cellularity. According to the technology, all components except the gas generator are poured into heated water, mixing them continuously for a given time. Aluminum powder (dry paste) is added at the end, mixing it with the general mixture for 30 s.

- Carrying out work in a draft. The poured solution with gas-forming agents and plasticizers may sink in the mold, so internal ventilation should eliminate drafts.

- Failure to comply with the temperature regime in the room (below 20°C), during the process of heating water in the boiler (less than 40°C) and while maintaining the operation of the autoclave (the norm is 60°C), can lead to cracking of the product. A production conveyor or stationary line has temperature controls so that it is easy to maintain the temperature.

- Removing the form ahead of time. This can lead to deformation of the artificial stone and loss of the specified size (as well as the time spent creating the product). Regardless of the method of creating an aerated block (autoclaved, non-autoclaved), experienced specialists recommend removing the mold after 7-10 hours of hardening.

In the process of work, you need to follow the production technology , according to the list of GOSTs, and then the time and money spent will be as efficient as possible, and the resulting industrial product will fulfill its intended role in construction.

The main GOST used in the production of cellular concrete is 31357-2007, as well as CH 277-80.

Features of aerated concrete

Aerated concrete blocks are regular parallelepipeds made of porous concrete.

The material itself is a type of cement-based concrete in which air pores up to 3 mm in size are evenly distributed. Aluminum powder or paste is usually used as an additive to form pores. In general, the concrete mixture has the following composition: cement, sand, aluminum powder, water, and various additives.

Technology for the production of aerated concrete blocks.

According to the manufacturing method, aerated concrete is divided into autoclave and non-autoclave. The first type of material is obtained in an autoclave at elevated pressure and temperature, which is realized only in industrial conditions that ensure proper control of the process in extreme conditions.

The non-autoclave manufacturing method is implemented under natural conditions, which allows you to use it yourself.

The production technology is based on the fact that when aluminum powder comes into contact with water, a violent reaction occurs with the release of carbon dioxide. If this process occurs in a closed form inside a viscous mass, then the gases form pores in the volume of this material. Even after the gases leave the mixture, the pores remain in the thickness of the mixture.

After the mass hardens under normal atmospheric conditions, aerated concrete is obtained, i.e. concrete with closed pores in a shape close to round, with a diameter of 1-3 mm.

The porous structure provides the main advantages of the material, namely high thermal insulation properties combined with low specific gravity with sufficiently high compressive strength. Aerated concrete blocks have a density from 300 to 1200 kg/m³, depending on the amount of pore-forming substance introduced.

Return to contents

The technology for producing non-autoclaved aerated concrete includes several mandatory stages and conditions. The pore-forming component is added to the cement-sand mixture and distributed evenly throughout the volume. The process of pore formation occurs quite actively with the expansion of volume when the powder comes into contact with water.

Production of non-autoclaved aerated concrete.

To retain the pores inside the mass, the gas evolution reaction must occur in forms that have sufficient strength. The internal cavity of the mold determines the dimensions of the resulting aerated concrete block. For the initial hardening of the mass, at least 2 hours are required.

After this, the concrete can be removed from the mold, but must remain stationary on racks until completely cured. The final strength value is achieved only after 28 days of drying the blocks. To make aerated concrete with your own hands, it is necessary to ensure that the basic conditions are met and a number of necessary works are carried out.

Return to contents

To make aerated concrete blocks with your own hands, you will need the following tools:

- grinder; hacksaw; plane; electric drill; hacksaw for metal; knife; hammer; shovel; mixer; ruler; hair dryer; trowel; spatula; steel string; chisel; chisel; scales; measuring bucket.

Return to contents

Composition of aerated concrete.

The standard mixture for aerated concrete contains cement, sand, water and lime.

Aluminum powder is used as a pore-forming substance. Slaked lime acts as a plasticizer. To improve the properties, it is recommended to use additional additives: sodium sulfate (no more than 0.5%) and caustic soda (no more than 1.5% by weight).

The basis of aerated concrete is cement. It is recommended to use Portland cement grade M400 or M500. The filler is taken in the form of quartz sand.

It should be thoroughly sifted to remove large fractions. Clay in sand can only be in the form of small traces and amount to no more than 7% of the weight of the sand. The following composition and ratio of concrete mix ingredients are recommended:

- cement - 50-70%; sand - 20-40%; lime, caustic soda, sodium sulfate - 1-5%; aluminum powder - 0.04-0.09%; water - 0.25-0.8%.

The mixture must be thoroughly mixed. By changing the cement content and pore-forming composition, it is possible to regulate the volume of pores in concrete, that is, change the density of the material.

Return to contents

Types of aerated concrete blocks.

In order to solve the question of how to make aerated concrete, it is necessary to ensure the production of a mold for pouring the concrete mixture.

Such forms can be of two types. The first type (the simplest) is a rectangular box with a height equal to the height of the block. The area of the box must contain the volume of mass from which several (4-9 pieces) aerated concrete elements can be made.

If a significant volume of production of gas blocks is planned, then it is better to make the mold from a steel strip 4-5 mm thick. The structure must be collapsible to facilitate the removal of the concrete blank. A removable cover must be provided on top.

It is advisable to provide for its fastening to the sides of the box using bolts (screws) or other clamps. A simplified version of the form can be made from wood. For the sides of the box you should use a board 30-40 mm thick.

The second type of shape is a lattice system.

In this design, the cavity of the box is divided by partitions into cells, in which one gas block is formed. This form can also be made of steel strip or wood. For internal partitions, plywood with a thickness of 12-15 mm can be used.

Return to contents

Before starting work, the inner surface of the mold must be thoroughly lubricated with machine oil to prevent the mass from sticking. It is recommended to heat the mold to a temperature of about 40º C. Aluminum powder is added to the uniformly mixed concrete solution and it is poured into the mold.

Do-it-yourself aerated concrete block production table.

It is necessary to pour to a height approximately equal to half the height of the side of the box, which takes into account the expansion of the mass during a chemical reaction with the formation of pores.

A violent reaction with the release of gas occurs within 6-8 minutes.

At this time, there is an active increase in the level of mass in the form. At the end of the reaction, the expansion of the composition stops, and then a slight shrinkage of the solution occurs. After stopping the vertical movement of the level, using a strong steel string, all irregularities (bumps, sagging) are cut off from the surface of the workpiece.

A heat-insulating material is placed on top of the calmed block blank: asbestos, foam plastic, etc. The mold is closed on top with a lid.

Natural drying of aerated concrete blocks is carried out.

Minimum drying time is 2 hours. After this, the monolith can be cut into blocks of the desired size. The recommended time before transportation to the storage site is 24 hours.

During the work, it is necessary to prevent the occurrence of drafts. Fan operation is not recommended. Cooling of the mass should be slow and uniform.

Return to contents

Before preparing the concrete mixture, it is necessary to check the quality of the cement: the integrity of the packaging, the production time, the presence of sticky lumps, etc. Only high-quality ingredients should be used.

The mold for making blocks must be placed on a horizontal, flat surface (preferably metal).

It is recommended to use several forms at the same time so that the solution can be mixed in large quantities at once. The manufacturing process itself should be carried out in a warm room. If the molding of blocks is carried out outdoors, then warm weather should be chosen, and the area should be closed from the wind.

It is recommended to keep aerated concrete blocks on the storage site until they reach full strength (28 days).

The mold must be heated evenly (over its entire volume). If several molds are used, then they all need to be provided with the same temperature conditions.

When choosing the size of forms, it is best to proceed not from standard block sizes, but from the sizes that are most suitable for your structure, so that in the future you do not have to frequently cut elements. It is possible to produce some elements of a different configuration by inserting into the form.

The technology for manufacturing non-autoclaved aerated concrete blocks is quite simple. With proper organization of work, the required number of building elements can be made with your own hands at home.

Home|Types of concrete|How to make aerated concrete with your own hands?

Date: November 29, 2016

Comments:0

At the beginning of construction work, the question arises: what material is the most durable, reliable and financially beneficial?

We offer an alternative solution - to set up the production of aerated concrete with your own hands. At the very beginning, it is important to understand what aerated concrete is, what properties such blocks have, as well as the scope of application. So, let's study the questions in order before making a choice.

Equipment and selection of materials

To prepare aerated concrete material, the following tools are used:

- electric drill;

- Bulgarian;

- scales;

- knife;

- shovel;

- plane;

- gloves for hand safety;

- chisel;

- hammer;

- mixer;

- hacksaw for metal;

- putty knife;

- chisel;

- bucket.

If you plan to produce aerated concrete yourself, then you cannot do without a unit for mixing the concrete mixture, which will help to qualitatively combine the components in the required proportions. You also cannot do without forms that will give the concrete its intended dimensions. After pouring the solution, remove its excess from the top of the mold; metal strings are used for this. It is impossible to make aerated concrete without using the following materials:

- aluminum powder;

- cement;

- sand;

- lime (quicklime).

If you produce aerated concrete yourself, the starting material will be small, but this will be enough for a small volume of construction. The cost of preparing a solution made with your own hands is less than if you purchase ready-made aerated concrete in construction stores. And if you follow the manufacturing technology and use only high-quality materials, the product will be of good quality, no worse than the finished product.

If financial situation allows, purchase mixers for preparing the solution yourself. Their use simplifies and reduces the time for preparing blocks. The mobility of the unit reduces the cost of additional transport due to the ability to locate it at the place of work. Prices for these machines depend on the volume of the mixing tank and the quantity of initial products.

Return to contents

Description, types and characteristics

Aerated concrete block is an artificial building material obtained by mixing various natural components. High strength and porous structure with excellent thermal insulation properties allow the material to be used for the construction of residential premises.

Organizing the production of aerated concrete at home allows you to produce artificial stone with any required geometry

Compared to other building materials for building walls, it is lightweight and is used for laying external, load-bearing walls of a building, as well as interior partitions. It is used in monolithic construction to fill openings.

Aerated concrete blocks are divided into three types:

- structural; thermal insulation, used for internal partitions; structural and thermal insulation.

According to the shape of the product, they are distinguished:

- rectangular blocks - for load-bearing and external walls; floor blocks, or reinforced aerated concrete beams - for ceilings; for installation of window and door openings, T-shaped or U-shaped product.

Features of manufacturing U-shaped aerated concrete blocks

The U-shape is considered multifunctional, since it is advisable to use it for arranging various lintels, including above windows and doors, installing a monolithic frame (stiffening belt) under the roof.

Blocks of this shape are available in different sizes. The shape of the block is determined by the cut in the wall of the structure being built.

At home, the nuances of creating this product are as follows::

- the future size range is determined, the mold is prepared and the solution is mixed;

- the poured mixture is left to dry, excess residue on the sides of the mold is removed;

- removing the product using a mason's hammer, making cuts and processing the internal walls (adjusting to the standard size).

If it was not possible to find a form for a Y-shaped block, then it is possible to make cuts according to the given dimensions in a regular, rectangular gas block obtained during the production process, but this will result in a loss of material (and money spent). If you only need a few such blocks, then the losses are not so costly. Therefore, it is better to take care of purchasing the necessary forms in advance, not forgetting about the cuts in the walls.

Important ! Some enterprising people use the remains of aerated blocks in landscape design, or break them down to a small state and use them in construction, as a basis for backfilling a monolith, in combination with other bulk materials (they make granulated slag).

Main components

Let's consider the composition, as well as equipment for carrying out work on the production of aerated concrete.

Purchasing ready-made blocks, including delivery to the site, will cost much more

Material or ingredients for aerated concrete:

- water; lime; quartz sand; cement; aluminum powder.

All materials used in the production of aerated concrete do not emit toxic substances. Thanks to this, the building material is safe for human health and can be used to build residential premises. High-quality equipment and affordable components make the process of producing aerated concrete quick and convenient.

In recent years, such products have been in increased demand with increasing percentages of sales. Often, equipment for the production of aerated concrete becomes a start - the start of your own business with a stable income.

Making aerated concrete with your own hands is an alternative solution for those who have a lot of free time and want to save on material to build a house.

Profitability of production

The economic feasibility and profitability of production depends on a number of factors.

Some of them:

- Investments related to the purchase of equipment;

- Cost of raw materials. Agree, the price may vary;

- Production waste and defective products can lead to unplanned expenses;

- Desired volume and purpose of production (for yourself or a mini-business)

Now let's proceed directly to the calculations.

- 1 m3 of blocks costs an average of 3,200 rubles.

- Let's assume that we need to purchase 90 m3 of products to build a house.

- We will need 90*3200=288,000 rubles to purchase finished aerated concrete products.

- The most budget option of equipment (possibly used) will cost 50,000 rubles. Costs for raw materials, water and electricity will be about 2000 for 1 m3 of blocks.

- 2000*90+50000=230000. The same 90 m3 of self-made blocks will cost this amount.

- The result is savings of 58,000.

- But non-autoclaved aerated concrete is cheaper, about 3,000 rubles per m3. Then we count again: 3000*90=270000. And it still ends up being more expensive.

If you imagine that you decide to start a mini-business, then the income can be quite good. If you manage to sell the manufactured products in a short time, the equipment will pay for itself in several months.

If you decide to make the blocks yourself, be prepared to spend time and effort.

Studying technology

Production begins with the preparatory stages:

- We assemble and install the mold, the inner walls of which must be treated with lubricant to avoid the mass sticking to the mold. The material from which the molds are made is wood or metal;

Plus - hardening occurs naturally

We prepare the main components for aerated concrete.

According to the proportions, we prepare the mass, pour it into the mold, and send it to the so-called maturation zone. First, the mass increases in volume. At this stage, aerated concrete becomes porous.

A chemical reaction occurs between aluminum powder and lime. The filling mass is evenly saturated with hydrogen bubbles, up to 2 mm in size; the cutting stage consists of sawing a large array (6160 mm x 1580 mm x 690 mm) into smaller parts. The top is removed and the surface is leveled with wire strings; we send the formed blocks for further drying and hardening in a natural way.

Cost of equipment

The final price depends on the power of the equipment and its specific configuration. Everything is expensive: a mixer, the main part of the price of which consists of the dispensers and the mold. A mini line will cost around 400,000 rubles. If we talk about the conveyor line, then the total minimum price will be around two million.

Despite the fact that aerated concrete blocks are a proven building material that has been used for a long time, it does not lose its relevance. The production is characterized by significant simplicity of the process, and the use of natural materials for the mixture gives the finished blocks many advantages.

What should you pay attention to?

Criteria that serve as a guide when choosing aerated concrete blocks in construction:

low cost of the finished product. The ability to make aerated concrete blocks with your own hands or buy equipment for the average consumer will not be a problem; high strength with low weight. The size of the building material allows for high-quality masonry in a short time.

Bricks in the amount of 20 pieces = 1 aerated concrete block; are not subject to aging and rotting processes. They consist of natural materials, have the ability to pass air; a high heat transfer coefficient contributes to productive heat conservation during the heating period. Reduces the level of thermal insulation work of the finished structure; low load on the foundation, does not shrink;

This stage is always the most difficult.

And it’s not the quality of mixing, but the proportion of ingredients that are easy to process. The need to trim, thin and drill will not be a problem. A hand saw will be a tool that can easily cope with such a task; they are highly resistant to direct fire; aerated concrete can withstand frost and thawing for up to 100 cycles - twice as much as brick. high level of sound insulation when using interior partitions and load-bearing walls; level of water absorption compared to brick 1:1.

Additional recommendations

In order for aerated concrete structures to last for more than one year, the recommendations for their manufacture are followed. Before starting to mix the solution, check the quality of the components of which it consists. Also pay attention to the packaging and the absence of damage on it. When choosing a material, look at the production time.

The block mold is fixed on a straight metal surface with a smooth and even structure.

To avoid “downtime” of the prepared solution, it is poured into several containers at once. This will also allow you to mix a large volume of consistency at one time. The mixture is prepared in a warm room; if it happens during the cold season, the room is heated to the optimal temperature. If it is not possible to prepare the solution indoors, it is sold outdoors, while the area is protected from drafts and precipitation.

You should not use poured aerated concrete before it reaches its maximum strength. The solution is kept for 28 days. Before pouring the mixture, heat the entire container. When using several containers, they are heated to the same temperature.

To determine the size of the forms, non-standard sizes are taken into account, and those that fit their structures.

How to make the right choice?

So, the decision has been made - the walls of the planned structure will be made of aerated concrete, we determine what is more profitable:

- We calculate the total cost of the material and make a purchase. We make an informed decision to purchase everything you need and set up the production of aerated concrete with your own hands.

You can find a reliable partner who will offer a quality product by using the services of our website.

You can purchase the appropriate materials and equipment to start work within one day, without unnecessary fussy running around the shops. The correct composition and maintenance of the technological process will bring long-awaited results. Setting up a mini-business for the production of aerated concrete or your own needs is a pleasant job with an obvious result.

- Date: 03/02/2015 Comments: Rating: 58

Aerated concrete, as a man-made building material, has become widespread in the construction of low-rise buildings.

Many builders, familiar with its excellent advantages, appreciated its low cost and practicality. These blocks are among the top ten materials that allow installation in record time. Self-made aerated concrete allows you to produce raw materials of excellent quality, and you can also save your own budget.

Scheme of aerated concrete production.

The main attractiveness of blocks is due to the fact that they can be made not only in industrial production conditions, but also in any environment. The technological process is so simple that this material can be made on your own, and there are no restrictions on size and shape. And this creates conditions for maximum convenience.

Preparing the mixture

Composition of aerated concrete.

The standard mixture for aerated concrete contains cement, sand, water and lime. Aluminum powder is used as a pore-forming substance. Slaked lime acts as a plasticizer. To improve the properties, it is recommended to use additional additives: sodium sulfate (no more than 0.5%) and caustic soda (no more than 1.5% by weight).

The basis of aerated concrete is cement. It is recommended to use Portland cement grade M400 or M500. The filler is taken in the form of quartz sand. It should be thoroughly sifted to remove large fractions. Clay in sand can only be in the form of small traces and amount to no more than 7% of the weight of the sand. The following composition and ratio of concrete mix ingredients are recommended:

- cement - 50-70%;

- sand - 20-40%;

- lime, caustic soda, sodium sulfate - 1-5%;

- aluminum powder - 0.04-0.09%;

- water - 0.25-0.8%.

The mixture must be thoroughly mixed. By changing the cement content and pore-forming composition, it is possible to regulate the volume of pores in concrete, that is, change the density of the material.

Step-by-step process instructions

Aerated concrete blocks are made in two main ways - autoclave and non-autoclave.

The first method is used for industrial production, and the second is suitable for home work, since the material poured into the mold dries under natural conditions.

The general technology for preparing aerated concrete products consists of the following steps:

- Acquisition and preparation of materials, tools and equipment.

- Formation of the composition (mixing the future filling).

- Distributing the concrete mixture into molds lubricated with a special product.

- Steam treatment (if drying is carried out using the autoclave method).

- Drying the composition in a natural environment (non-autoclave method).

- Removing aerated concrete from a removable mold.

- Laying for ventilation on a prepared surface.

- Packing in polyethylene for further transportation.

Comparison of self-produced and factory-produced products

To compare factory- and home-made gas blocks and understand which option is more profitable and better, you need to consider all the pros and cons.

When buying ready-made material, it is very difficult to accurately calculate the number of blanks. The masonry is done almost in a checkerboard pattern, so you have to cut the products, very often unused parts of them remain. This is an additional unnecessary expense.

Ready-made blocks are produced in several standard sizes, which does not always coincide with the wishes of the owner of the building. Self-production allows you to make blanks of individual sizes, even complex configurations (for example, arched).

Anyone can figure out how aerated concrete is made. This requires desire and patience. The process is very simple and much more economical than buying ready-made products.