The range of lumber represents the main consumer characteristics of industrial wood. Considering the increasingly growing interest of the Russian population in the construction of their own suburban housing from profiled, rounded logs, the annual increase in their consumption becomes understandable.

Most developers want to build warm, cozy houses made of wood. To do this, millions of people are carefully studying all the advantages and disadvantages of this accessible, effective material.

Product grade

The grade of edged board directly depends on the quality of the element and its strength characteristics, this parameter is applicable only to edged elements and is intended to simplify the selection of a specific type of product for certain jobs, we will consider the main options, and the photo below shows all the defects that must be taken into account when determining the variety.

Experts identify all defects by eye, but even they have unique samples that show the characteristics of a particular defect

Top grade

This option is also called grade 0 board, and it is almost impossible to find it on the open market for the following reasons:

- The requirements for the material are high, and it has practically no flaws, since it is exported;

- The cost of this option is higher than any analogue, and the difference is very noticeable;

- The standard sizes of the products differ from ours, since they are produced for foreign markets; it is not for nothing that this option is called export.

Such products undergo the strictest control

First grade

If we consider the characteristics of the board - grade 1 will be the optimal solution in terms of reliability and durability, the basic requirements for geometric parameters are reflected in the chapter above, here we will consider other criteria:

- The moisture content of the material should be within 20-22% with a permissible deviation of 3%, this is a very important indicator, and you need to start checking the board with it. If the moisture content of the board is higher, the products are classified as so-called raw, and their cost is noticeably lower;

- There should not be any traces of rot on the surface; all sides must be healthy without signs of damage by putrefactive bacteria;

- Knots may be present, but they must be exclusively healthy; the presence of even one unhealthy knot on the entire element causes a decrease in grade;

Planed board grade 1 20x200 has an excellent appearance and can be used for finishing surfaces.

- End cracks may be present in the material, but their number cannot exceed 25%;

- It should be noted that grade 1 edged coniferous boards according to GOST 8486-86 must meet a number of criteria, but it will be difficult for a person far from this industry to understand all the defects and their features, so it is better to hire a specialist to help.

As for the use of lumber of this grade, it can be used in the most critical structures - in rafter systems, when creating load-bearing frames, finishing surfaces, and also for much more.

Second grade

Grade 2 edged board has softer tolerances, so it may have a much larger number of flaws:

- There may be knots on the surface, but their number should not exceed 2 pieces per linear meter;

- The presence of wane is allowed, which negatively affects the appearance, but has a slight effect on strength;

The difference between grade 1 and grade 2 edged boards mainly lies in less stringent processing requirements; in general, the technical indicators will be almost identical

Products may have resin pockets, and may also have color stains from fungi.

The scope of application of this option is very wide, since it represents the optimal price-quality ratio; it is used both in the construction of various frames for outbuildings and internal partitions in the building, and for the assembly of formwork, scaffolding and other structures.

Lower grade

The third, fourth and fifth types of boards are much cheaper, but they also have many more flaws, let’s consider each of them in order:

Grade 3 edged board has moisture restrictions in the same way as the first two options, while various defects may be present on the surface, and their number can be quite large

The most important thing to remember is that rot is not allowed on the surface, since many sellers claim the opposite and sell products with lesions under the guise of third grade;

Grade 3 is used for structures that do not bear high loads

- If you think that grade 3-4 edged boards are almost the same, then this is far from the case. The fourth grade has no moisture requirements, and up to 10% rot is allowed on its surface; such elements are used only for unimportant structures;

- The fifth grade is the lowest quality, which may resemble waste rather than material. This variety is used as fence boards in the construction of buildings and structures.

The lowest quality elements are rejected into the fifth grade

timber

The appearance of lumber, for obvious reasons, depends not only on the type of tree. The processing process leaves its mark on the characteristics of each product. One of the most common is timber. It is used in the construction of both cladding and independent structures and buildings.

There are several types of timber. The simple type (non-profile) looks like a log processed on 4 sides. But other types of similar products are also made. Profiled timber is produced in a clearly defined form. Most often it is a rectangle with a notch at the bottom. Good-quality houses and cottages are assembled from such lumber. They hold heat well and have a low percentage of deformation (if the timber is properly processed). The profile can be very different.

There is also glued laminated timber. It is assembled from lamellas and has improved characteristics. It practically does not shrink and does not crack. Today, rounded timber is also in demand. It has high aesthetic qualities.

Varieties

OSB boards: technical characteristics, types, sizes, painting

There are several types of lumber. The grade depends on the quality of deciduous or coniferous wood and its processing. Deciduous materials are divided into 4 grades, the coniferous classification consists of 5 (a selected grade is added).

Selected

Selected lumber is considered the best grade. High-grade wood (grade 0) is used in shipbuilding, automotive construction, and furniture production. It has no defects (knots, stepsons, through and deep cracks, remains of tree bark, rot, wane, roots). Foreign inclusions are excluded, the fiber inclination is 5%, the growth is one-sided. Minimal drying cracks are allowed.

1

First-class lumber is used in construction and the furniture industry. This is the most popular product with a minimum of defects (knots, cracks). It does not have dry, loose, fallen knots, healthy branches, cracks with a width and depth of more than 1 cm. The total length of cracks should not exceed 1⁄4 of the length of the workpiece.

It has no rot, through cracks or growth, mold or other elements. Sapwood is excluded, first grade timber has no blue discoloration, rottenness, traces of parasites, or dark spots.

2

Second-grade lumber used in furniture production has more defects than its selected counterpart. They are subject to less stringent requirements, so their quality is lower. These blanks may have cracks with a total length of up to 1/3 of the length of the board, as well as knots with a small diameter of knots. It is allowed to have 2-3 traces of wormholes per 1 m of length (or 1 large one).

Second grade timber should not have mold, mildew, traces of rot, through cracks and crevices. Its differences with first-class products are small. Falling out, rotting knots are excluded, the size of healthy ones should not exceed 2 cm. Rottenness is not allowed, mechanical damage, as well as foreign inclusions are excluded.

3

Third grade lumber is used for the manufacture of transport packaging and containers (including disposable boxes, decking, pallets). Essentially, these are trimmings from grade 1 and 2 lumber. The amount of defects here is even greater; this is low quality wood with low cost.

The main requirement for such material is the absence of large fused knots and deep end cracks. A sharp angle of inclination of the fibers, mechanical damage to the wood layer, mold, and wormholes are allowed. There may be internal sapwood and browning.

4

Lumber of the fourth grade may have almost all the defects specified in GOST, including waviness and warping. In this case, the length of cracks and the size of knots can be any. The number of wormholes should not exceed 6 per 1 m of the workpiece. This material is used for the production of fences, formwork, pallets, outbuildings, cabins, sheds, and gazebos.

It may experience a change in color, as well as mechanical damage. Both wane of the top layer and winging are allowed. The presence of rot and foreign inclusions is excluded. The integrity of the base must be maintained. The surface may be rough, there may be fused knots.

Purpose of lumber

Various types of lumber have found application in almost all spheres of human activity. But the majority of all wood produced is used in the construction and furniture industries, as well as for interior and exterior finishing work. Moreover, lumber is often further processed before final use; it is sanded, polished, painted or varnished, and grooves, patterns and holes are cut out. In some areas, additional processing is required; the wood is treated with chemicals against rodents, high moisture, or fire-fighting liquid.

How to choose lumber

When making furniture, it is often necessary to bend wood to obtain unusual shapes and patterns. Curved products are the most expensive, since their production technology is very resource-intensive, requires a lot of time, certain knowledge and special equipment.

It is noteworthy that an already curved product can be bent again, changing its shape. To do this, you just need to wet and heat the wood; often steam under pressure is used for such purposes.

How to choose boards? What should you consider and what should you pay attention to when choosing boards?

1st grade board, truth and deception

Edged board. Varieties. Types of deception.

Wood quality

Technical characteristics of Monterrey and Supermonterrey metal tiles: length and width, lathing pitch and special installation technology

Deciduous wood is divided into 4 grades. Coniferous edged lumber - 5 (plus - selected). The best variety is recognized as selected and is designated “O” or a horizontal stripe. The rest of the quality range is indicated by numbers or the corresponding number of strips. It is typical that a particular piece of lumber is assessed by the worst of the cut sides or edges. And grades are determined due to the absence or presence of cracks, chips, deformations, knots, possible rot and moisture. The type of sawn wood also depends on the precision of processing.

Typically, first grade lumber can be used for a variety of building structures - permanent and temporary. And also for the final finishing of walls and floors of standard thickness. Second-grade lumber is suitable for the construction of decking, formwork, and sheathing. Third-class - for load-bearing structures of the third category. But the fourth grade is used for the manufacture of small pieces or for containers. It is characteristic that the moisture parameter for the latter variety is not standardized. But for the previous ones, the humidity parameter should not be higher than 22 percent. When it exceeds, the material is called “raw”. At the same time, it significantly loses its strength.

Defects of lumber from the inside

GOST 8486 86

This regulation was introduced in January 1988. GOST 8486 86 “Softwood lumber” is intended for the classification and sorting of sawn materials according to the degree of distribution of defects on the surface . The text provides definitions of materials, nominal dimensions for width, thickness, length and permissible deviations.

Based on the quality of wood and processing, lumber is divided into several grades :

- selective;

- first;

- second;

- third;

- fourth.

There are technical requirements for humidity and antiseptic treatment. Recommendations for choosing the type of wood for each type of lumber are provided. There is a special table in the appendix with recommendations for the purpose of the products.

Types of timber

Technical characteristics of vinyl siding

The trunks of deciduous or coniferous trees, with branches and knots removed and sawn across, are round lumber. The bark on them can be removed. The thickness varies. Also, their purpose may be different. There are 4 groups of round timber.

- Materials for peeling and planing.

- Materials for sawing.

- Materials for processing and producing wood pulp and cellulose.

- Materials for use without sawing, i.e. in round form.

The production of round timber is carried out with the aim of obtaining lumber. Softwood roundwood is primarily a raw material for lumber production.

DIMENSIONS

Moscow Standardinform 2007

INTERSTATE STANDARD

| SOFTWOOD TIMBER | GOST 24454-80 |

Date of introduction 01/01/81

1. This standard applies to edged and unedged softwood lumber and establishes requirements for the size of lumber used for the needs of the national economy and export.

The standard does not apply to resonant and aviation lumber, as well as black sea sorted softwood lumber.

The standard fully complies with ST SEV 1264-78, ST SEV 1265-78, ST SEV 1147-78, ST SEV 1266-78 and takes into account ISO 3179-74 and ISO 738-81.

Terms and definitions of lumber - according to GOST 18288;

(Changed edition, Amendment No. 1).

2. The nominal dimensions of the thickness and width of edged lumber with parallel edges and the thickness of unedged and edged lumber with non-parallel edges must correspond to those indicated in the table.

Nominal dimensions of thickness and width

mm

| Thickness | Width | ||||||||

| 16 | 75 | 100 | 125 | 150 | — | — | — | — | — |

| 19 | 75 | 100 | 125 | 150 | 175 | — | — | — | — |

| 22 | 75 | 100 | 125 | 150 | 175 | 200 | 225 | — | — |

| 25 | 75 | 100 | 125 | 150 | 175 | 200 | 225 | 250 | 275 |

| 32 | 75 | 100 | 125 | 150 | 175 | 200 | 225 | 250 | 275 |

| 40 | 75 | 100 | 125 | 150 | 175 | 200 | 225 | 250 | 275 |

| 44 | 75 | 100 | 125 | 150 | 175 | 200 | 225 | 250 | 275 |

| 50 | 75 | 100 | 125 | 150 | 175 | 200 | 225 | 250 | 275 |

| 60 | 75 | 100 | 125 | 150 | 175 | 200 | 225 | 250 | 275 |

| 75 | 75 | 100 | 125 | 150 | 175 | 200 | 225 | 250 | 275 |

| 100 | — | 100 | 125 | 150 | 175 | 200 | 225 | 250 | 275 |

| 125 | — | — | 125 | 150 | 175 | 200 | 225 | 250 | — |

| 150 | — | — | — | 150 | 175 | 200 | 225 | 250 | — |

| 175 | — | — | — | — | 175 | 200 | 225 | 250 | — |

| 200 | — | — | — | — | — | 200 | 225 | 250 | — |

| 250 | — | — | — | — | — | — | — | 250 |

Note. At the request of the consumer, it is allowed to produce lumber with dimensions not indicated in the table.

3. The width of the narrow face, measured anywhere along the length of unedged lumber, should be for thicknesses:

| from 16 to 50 mm……………………………………… | not less than 50 mm; |

| from 60 to 100 mm…………………………………….. | not less than 60 mm; |

| from 125 to 300 mm…………………………………… | not less than 0.6 thickness. |

The width of the face of edged lumber with non-parallel edges at the narrow end should be for thicknesses:

| from 16 to 50 mm………………………………………. | not less than 50 mm |

| from 60 to 100 mm…………………………………………… | not less than 60 mm |

| from 125 to 300 mm……………………………………. | not less than 0.7 thickness |

(Changed edition, Amendment No. 1).

4 Lumber must also be manufactured with the following cross-sectional dimensions:

For export - 63 ´ 160; 90 ´ 90; 90 ´ 125; 50 ´ 300; 63 ´ 300; 75 ´ 300; 100 ´ 300 mm. By agreement with the consumer, lumber of the specified cross sections can be produced for the domestic market:

for truck platforms - 40 ´ 180; 70 ´ 150 mm;

for oil rig beams - 400 ´ 400; 360´360; 200 ´ 400; 180 ´ 350; 150 ´ 300; 300 ´ 300 mm;

for bridge beams - 200 ´ 240; 220 ´ 260;

for automobile and carriage building - 110 and 130 mm wide.

5. The nominal dimensions of lumber in terms of thickness and width are established for wood with a moisture content of 20%. When the wood moisture content is more or less than 20%, the actual dimensions of thickness and width should be more or less than the nominal dimensions for the corresponding shrinkage value according to GOST 6782.1.

6. The nominal length dimensions of lumber are established:

for the domestic market and export - from 1.0 to 6.5 m with a gradation of 0.25 m;

for the manufacture of containers - from 0.5 m with a gradation of 0.1 m;

for bridge beams - 3.25 m;

for export - from 0.9 to 6.3 with a gradation of 0.3 m.

7. Maximum deviations from the nominal dimensions of lumber are established, mm:

| by lenght…………………………………………….. | + 50 and - 25; |

| by thickness | |

| for sizes up to 32 mm inclusive……………………… | ± 1,0; |

| from 40 to 100 mm inclusive……………………………… | ± 2,0; |

| more than 100 mm…………………………………………………… | ± 3,0; |

| in width for edged lumber | |

| for sizes up to 100 mm inclusive. | ± 2,0; |

| more than 100 mm | ± 3,0; |

For lumber less than 1.5 m long, maximum length deviations are not established.

7a. By agreement with the consumer, lumber with a gradation in length of 0.3 m and maximum deviations in thickness and width in accordance with GOST 26002 are allowed for the domestic market.

(Introduced additionally, Amendment No. 2).

8. Measuring the dimensions of lumber - according to GOST 6564.

(Introduced additionally, Amendment No. 1).

INFORMATION DATA

1. DEVELOPED AND INTRODUCED by the Ministry of Forestry, Pulp and Paper and Woodworking Industry of the USSR

2. APPROVED AND ENTERED INTO EFFECT by Resolution of the USSR State Committee on Standards dated November 10, 1980 No. 5731

3. The standard corresponds to ST SEV 1264-78, ST SEV 1265-78, ST SEV 1147-78, ST SEV 1266-78

4. Instead of GOST 8486-66, section. 1 in terms of size

5. REFERENCE REGULATIVE AND TECHNICAL DOCUMENTS

| Designation of the referenced technical documentation | Item number |

| GOST 6564-84 | 8 |

| GOST 6782.1-75 | 5 |

| GOST 18288-87 | 1 |

| GOST 26002-83 | 7a |

6. The validity period was lifted according to Protocol No. 4-93 of the Interstate Council for Standardization, Metrology and Certification (IUS 4-94)

7th edition (September 2007) with Amendments No. 1, 2, approved in December 1986, November 1987 (IUS 2-87, 2-88)

What does GOST regulate for lumber?

According to GOST 24454-80, a clear classification of species is established for all lumber. They are divided according to dimensions, weight, and permissible humidity values. The entire forest, that is, industrial wood, is used by the construction industry as logs or lumber. The round log can be used unprocessed.

GOST for lumber sizes

However, most often it is dissolved into slats, lining, and various other parts, in order to then produce carpentry and semi-finished products:

- tongue and groove products;

- door frames;

- skirting boards;

- fillets;

- door frames;

- window blocks;

- balcony frames;

- timber of various assortments.

Each of the parameters for the listed products is regulated by GOST. Main technical characteristics - thickness, length, width, weight, permissible humidity. If the first three parameters are regulated by setting up woodworking equipment, then the regulation of humidity and weight must be carried out by long-term drying of the wood in special gas drying chambers. Significant differences in the assortment of lumber are made by the type of blanks.

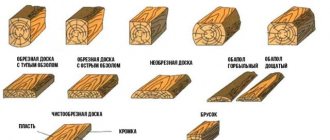

Types of lumber depending on size, shape, structure

board

Board

- This is lumber up to 100 mm thick and more than twice the width. The main material for making boards is coniferous trees, such as larch, spruce and pine, but boards are also made from deciduous trees. The choice of one material or another depends on the purpose for which you intend to use the board.

Construction boards are divided into unedged and edged. An unedged board is lumber from which the tree bark has not been removed or has been partially removed. They are used for minor work: to create formwork, install scaffolding. This type of board usually has uneven edges.

Edged boards are lumber from which tree bark has been completely removed from all surfaces. Used for external and internal finishing of surfaces, floors, roof elements.

Board size chart

Thickness Width

| 16 | 75 | 100 | 125 | 150 | – | – | – | – | – |

| 19 | 75 | 100 | 125 | 150 | 175 | – | – | – | – |

| 22 | 75 | 100 | 125 | 150 | 175 | 200 | 225 | – | – |

| 25 | 75 | 100 | 125 | 150 | 175 | 200 | 225 | 250 | 275 |

| 32 | 75 | 100 | 125 | 150 | 175 | 200 | 225 | 250 | 275 |

| 40 | – | 100 | 125 | 150 | 175 | 200 | 225 | 250 | 275 |

| 44 | – | 100 | 125 | 150 | 175 | 200 | 225 | 250 | 275 |

| 50 | – | – | 125 | 150 | 175 | 200 | 225 | 250 | 275 |

| 60 | – | – | 125 | 150 | 175 | 200 | 225 | 250 | 275 |

timber

laminated veneer lumber

– this is lumber with a thickness of 100 mm or more, rectangular or square cross-section and a length many times greater than the width.

Timber is a natural, environmentally friendly and durable material. The timber is made mainly from coniferous trees. It is used for the construction of cottages, building frames, foundations, dachas, houses, furniture, and ships. The most used timber sizes are 100x100 and 150x150 mm. The small cross-section of this lumber allows us to guarantee high quality construction. It is also good as a wall material for wooden houses.

The timber is divided into regular unplaned, profiled, rounded and glued. We will talk about these types of timber in a separate article.

Bar

– this is lumber up to 100 mm thick and no more than double the thickness. They are made from boards. The bars are used in carpentry, construction, and repairs. in the furniture industry. For coniferous trees, the thickness of the bars is from 16 to 75 mm, the length is from 1 to 6.5 m. Dimensions of the bars from deciduous wood: thickness from 19 to 100 mm, and length from 0.5 to 2 m.

Sleepers

Sleeper

- This is a support for rails in the form of bars. The width of the wooden sleeper is 23 - 25cm, depth 18 - 20cm, length - 275m. Houses made from sleepers are very heat-intensive; such construction is durable, as they are made from coniferous wood such as spruce, pine and fir. Sleepers are used for the construction of fencing structures, outbuildings, and as construction beams for the construction of residential buildings. This is an economical option. Due to the treatment of sleepers with creosote, they are not susceptible to rotting, damage by insects and fungus. But there is also a disadvantage of this treatment, since creosote contains toxic substances such as phenols and their esters, naphthalene and anthracene, which can contribute to the development of serious diseases. Creosote affects the nervous system and can cause headaches, weakness, and liver pain. That is why sleepers are very dangerous to use as construction timber for the construction of houses. However, they are still used in an attempt to use old materials, where the level of creosote is much lower.

Gorbyl

Gorbyl

- it is also called obapol, this is the side part of the log, having one sawn surface and the other not sawn or not sawn to the full length.

This is waste, part of a tree trunk that remains when sawing logs. On one side, the slab retains the natural surface of the wood, and on the other side it is flat. Used for the construction of fences, auxiliary rough structures, rough floors, formwork, pallets, and for kindling a stove. The main advantage of slab over other lumber is its low cost.

Wood and business croaker.

Wood slabs are only suitable for lighting stoves; they are no longer valuable as a building material.

Slab fence

The business one differs from the wood-burning one in that its sawn side is processed and polished. It can also be used to kindle stoves, but its condition allows it to be used in the construction of non-residential buildings, fences and enclosures.

Thus, all of the above types of wood can be used in different areas of construction, production, and life. It is virtually waste-free, environmentally friendly and relatively inexpensive. self-healing material.

Lumber range: features, scope

Various types of lumber are increasingly in demand and popularity today. What causes this? Since the number of people wishing to build their own housing is growing year by year, and environmentally friendly materials, such as wood, are most in demand, the need for lumber is increasing. Everything is very simple and logical. Lumber in modern construction is represented by products made from logs, which have standard sizes, shapes, and so on.

Wood is widely used for construction. It is environmentally friendly, durable and useful.

The range of lumber is quite diverse and affordable.

This type of product is produced by cutting logs using special machines and saw frames.

According to the type of cut used, all lumber is classified into the following categories: radial type, tangential and combined (mixed). The cross-section of lumber can be either round or square. Each side has its own name. For example, the narrower side of the workpiece is called the edge, the wider side is called the edge.

Quality and scope of lumber

Diagram of wood defects.

As for the quality indicator of lumber, it is determined by such a property as uniformity. After all, the strength of the workpieces, and, therefore, the structure as a whole, depends on it. To determine the uniformity of wood, it is necessary to find out how many areas and what size there are damages that lead to a violation of this quality. Such defects are called defects.

As noted above, lumber is most often used for housing construction; in addition, such areas as railway construction and industrial construction cannot do without it. Lumber is used as materials for various purposes, for example, as finishing, cladding or blanks for roofing. In addition, various joinery parts and sleepers are made from lumber.

Most often, modern lumber is made from high quality wood, which has good strength and environmental safety.

Pine is an expensive, but very reliable and durable material.

This category includes pine, birch, and oak. These tree species are especially popular in the construction of private dwellings, such as a summer house or cottage.

The construction area in which lumber is used is simply enormous. This is a roof or attic ceiling or interior finishing material, or maybe both. The most significant advantage of a material such as wood is its thermal conductivity. Wooden structures are impervious to either winter cold or summer heat, which allows you to maintain an optimal microclimate in the room.

For each type of lumber, there are special tables that indicate their essential characteristics, such as name, grade, size, and so on. These parameters are regulated by GOST.

Return to contents

Lumber of softwood and hardwood analogues

Classification of wood species.

Lumber is also classified depending on the type of wood. As is already clear from the title - for coniferous and deciduous species.

The softwood lumber category includes trees such as spruce, cedar, pine, fir and larch. Their positive characteristics include high quality, the presence of a straight trunk, and the smallest number of knots. The price of these lumber is considered relatively affordable.

They can also be described as hard but easy to work with, durable and resistant to wet environments. But due to the fact that their resin content is higher than that of other tree species, there is a danger of spontaneous combustion when exposed to high temperatures. Their use is most appropriate for the construction of load-bearing structures.

Now a little about hardwood lumber. Hard varieties include maple, oak, ash and birch, while softer varieties include aspen, beech, linden and poplar. Compared to conifers, they are less durable and have more irregularities in their uniformity. This wood is used to produce blanks such as dowels, dowels, and so on. They are also successfully used for finishing.

Return to contents

Assortment and its features

The range of lumber is quite diverse. So let's take a closer look at the options that represent it.

Lumber assortment diagram.

- Plates. This type of workpiece is obtained by longitudinally cutting a log, dividing it into two identical parts, which can be considered halves. It turns out that the plates have only one processed side. Their size depends on what kind of log they were made from. This lumber is used in the production of sleepers, bars, joinery parts and boards. Other options are also possible.

- Quarters. This type of lumber is produced by cutting logs longitudinally, but into four parts. The size also depends on the dimensions of the log. Used in carpentry, mainly for the manufacture of small parts.

- Bar. This lumber has a width not exceeding two thickness sizes, with the thickness corresponding to a value not exceeding 100 mm. The use of these blanks is possible in the carpentry field, for example, for the manufacture of lining, for the production of furniture, finishing floors, and so on.

- Beam. Such lumber is represented by a range of sizes in which the width and thickness exceed 100 mm. The shape of the lumber is parallelepiped. It is used to construct the floor, roof, ceiling, etc.

- Sleepers. As many people know, their main use is in railway construction. The dimensions of the sleepers are large in width and also thick, but the length of these products is not very long.

- Gorbyl. This lumber is a side part of a log. It represents the waste resulting from cutting a whole log into planks. The croaker has one flat side, the second is rounded. The most appropriate direction for its use is the construction of temporary and commercial buildings.

The sizes of lumber are usually indicated by three indicators. These are: length, width and thickness. For length, the measurement is meters, for width - centimeters, for thickness - millimeters. For example, 5X15X25. Sizing occurs at a humidity reading of 15%. This is a mandatory standard condition.

masterbrusa.ru

Wood requirements and grade

The grade of a board or its grade is a classification that indicates the permissible defects of wood and their number. Boards and bars can be of five grades - selected, 1st, 2nd, 3rd and 4th. The timber is not selected, so it has only four grades, designated by numbers.

Sawn timber of selected, first, second and third grades is produced:

- from dry wood with a moisture content of no more than 22%;

- from raw;

- raw, treated with antiseptics.

Wood for the fourth grade is not regulated. The grade is determined by the worst face or edge. That is, find the worst part, and determine the grade based on the presence and number of defects and flaws. All of them are shown in tables, and the possible defects themselves are shown in pictures.

How to determine the grade of a board

Do you know how the grade of boards is determined in production? Approximately. No one counts knots, cracks and other defects. And the difference between, say, the first and second grade is very small. And not all manufacturers try to really sort it correctly. So it’s better to control everything yourself. But the tables are so large, and there are so many defects - it’s impossible to remember everything. But there are certain criteria that can help you determine whether the quality corresponds to what is declared.

Selected and first-class edged boards cannot have such damage

If there is at least one fallen twig, this is definitely not the best and not the first grade. At least second, or even lower. First grade boards and timber should be free of rot, fungi and core. These are all the places that are destroyed first

So there shouldn't be any. When choosing timber, pay attention to the number of annual rings. The more there are, the higher the quality of the wood.

It’s also worth looking at the storage conditions. In general, high-grade boards should be stored at least under a canopy. It should be placed in ventilated stacks and not lying in bulk. Ventilated stacks are those with spacers that separate one row from another and allow the wood to dry evenly.

Regulatory Requirements

In relation to lumber, the requirements are quite stringent, and they relate not only to size, but also to the level of humidity, number and types of defects. GOST for lumber contains similar information.

As for the regulatory framework, we can highlight such documents as GOST 2695-83, GOST 26002-83, GOST 8486-86, GOST 9302-83, GOST 8486-86, GOST 24454-80, among the more modern ones we can note GOST R 1.0 - 2007. In order not to retell the contents of each of the standards, we will limit ourselves to only the main information.

The types of coniferous wood, or rather the requirements for them, are specified in GOST 8486-86. The following features of dividing wood into classes can be identified:

- It is recommended that manufacturers divide bars and boards into 5 grades (classes or groups may be mentioned). The bars are divided only into 4 classes;

- roughness (that is, the maximum amount of irregularities on the surface of the wood) should not exceed 1250 microns for grades no lower than 3, but for grade 4 the tolerance is increased and is already 1600 microns;

- As for humidity, up to the 3rd inclusive it should not exceed 22%. For the 4th, this indicator is not standardized at all;

In production, as a rule, wood is dried

Wood varieties 1 2 3 4 differ not only in the listed characteristics; special emphasis is placed on the number and type of defects. In GOST this classification is given in tabular form.

Here are some excerpts from the standard:

for example, a defect such as knots is classified into healthy, partially fused and rotten. For selected wood class, the number of knots is limited to 1 (edge knot) and 2 (face knots);

- For selected wood, even such an indicator as the inclination of the fibers is standardized. If this indicator exceeds 5%, then the grade is not selected, but 1st;

- defects such as sprouting, rot, and discoloration due to infection by various fungi are also not allowed for selected wood.

Photos of some types of defects

Based on the norms given in the standard for the compliance of wood with a certain grade, it is possible to fairly accurately determine the type of wood.

Kinds

The name of timber in the classifier and other documents depends on the possibilities of their further use:

- the trunk after removing the roots and branches is usually called a tree whip;

- the process of dividing a trunk into fragments is called “bucking”, and these fragments themselves are called ridges;

- depending on the cross-section, the ridges are additionally divided into subtovarnik, log and pole (their sizes are respectively: 80-110, from 120 or more, 30-70 mm).

Unprocessed timber is the same tree that has been cut down, cleaned and cut into pieces. It is also common to call them round timber, round timber or round timber. Such products are in demand by match factories, pulp and paper mills, and plywood manufacturers.

Processed timber is divided into:

- lumber;

- chipped products;

- wood veneer;

- some other products.

Sawn timber is produced by further longitudinal division of logs. They are further divided into general and special categories. The first category includes, for example, lumber used for the construction of wooden structures (fences, private houses), as well as for the production of ready-made building blocks. The second group includes things that can withstand the highest possible loads and severe tests (for example, blanks for musical instruments, parts of carriages and aircraft).

According to the type of diameter, lumber is divided into the following products:

- beam;

- board;

- lagging;

- sleeper;

- bar.

1st grade

The issue of assortment is closely related to the quality characteristics of the finished product

Important: even if the timber is marked with a certain varietal group, the batch may contain individual inclusions (up to 10%) of both higher and lower quality products. When each beam or board is shipped, no one examines it “under a microscope”

That is why personal incoming control of incoming goods is so important.

Before moving on to a further description of the varieties, it should be noted that all products are divided into business and firewood categories. They are used respectively for construction and subsequent processing. All this information is very important for a deeper understanding of what each variety is and what their main characteristics are.

First-class wood is a high-quality and widespread product. It may contain only a limited number of knots and other defects.

2nd grade

This includes products that contain minor deviations from grade 1 standards that do not negatively affect the visual characteristics of the surface. There cannot be a single deepened crack, not a single rotten knot. Tobacco knots, of course, are also prohibited. But loose knots are acceptable. This material is used mainly for shields.

3rd grade

This is already considered low quality wood. However, cheapness still determines a stable demand for it. This material is commonly used in the packaging industry

Important: despite the bad reputation, this includes products that meet the requirements of the standards. Large intergrown knots and cracks extending to the full depth and affecting the end should not be allowed

4th grade

It is the lowest of the officially permitted categories. There may be any imperfections and deviations. It is allowed to include even trimmings from any higher quality timber here. This type of wood is used to make:

- pallets;

- handles for utility construction tools;

- temporary forests;

- formwork;

- secondary sheds.

Edged boards. Dimensions. Weight. Tables

Interstate standard. See GOST for softwood lumber here >>>

- Length 1 - 6.5 m with gradation every 0.25 m. Today, increasingly, consumers are offered lumber exactly 6 m long, which has already become a standard.

- Size a (width) of the edged board: 75, 100, 125, 150, 175, 200, 225, 250, 275 mm.

- b (thickness) 16, 19, 22, 25, 32, 40, 44, 50,60, 75 mm.

Table how many boards are in 1 cube (pieces/meters)

| Board dimensions | Volume of 1st board | Boards in one cube (pieces) |

| 25x100x6000 | 0.015 m3 | 66.6 pcs |

| 25x130x6000 | 0.019 m3 | 51.2 pcs |

| 25x150x6000 | 0.022 m3 | 44.4 pcs |

| 25x200x6000 | 0.030 m3 | 33.3 pcs. |

| 30x200x6000 | 0.036 m3 | 27.7 pcs |

| 40x100x6000 | 0.024 m3 | 41.6 pcs |

| 40x200x6000 | 0.048 m3 | 20.8 pcs |

| 40x150x6000 | 0.036 m3 | 27.7 pcs |

| 50x100x6000 | 0.030 m3 | 33.3 pcs |

| 50x150x6000 | 0.045 m3 | 22.2 pcs |

| 50x200x6000 | 0.060 m3 | 16.6 pcs |

Finding out the number of meters of edged boards in 1 cube is very simple. If we multiply the number of boards in a cube (third column of the table) by the length of the board (in table 6m), we will find out how many usual linear meters of board are in 1m3.

How much does a cube of board weigh?

M - weight.

V - volume

P - wood density depends on the type of wood, its humidity, place of growth, and the specific part of the trunk from which the board is cut.

Did you know?

The weight of 1m3 of freshly sawn edged lumber (pine) depends on many factors.

- If a beam 18*18 will be lighter than a board 0.025*0.18, because the core of the trunk itself is looser and the board that is usually cut from the edges of the trunk is denser.

- Sometimes the forest (pine) comes across “cut”, i.e. This is the forest from which resin was once collected (there was an organization called “Khimles”), the lumber is not rotten, not blue, and can be almost twice as light.

- Timber (pine) harvested in winter after January will be approximately 10-20% lighter

- Lumber always has an exact length, for example, if a timber is considered to be 6 meters long, then as a rule it has a length from 6.05 to 6.25 and maybe more, depending mainly on the sobriety of the “gooseberry”

- On the number of knots on the lumber.

- From many different standards for measuring the mass of 1m3 of lumber.

Wood Density

| Breed | Density, kg/m3 |

| Lightweight | |

| Balsa | 150 |

| Siberian fir | 390 |

| Spruce | 450 |

| Willow | 460 |

| Willow | 470 |

| Alder | 460-640 |

| Aspen | 510 |

| Pine | 520 |

| Linden | 530 |

| Poplar gray | 550 |

| Average density | |

| horse chestnut | 560 |

| Cherry | 580 |

| Common yew | 600 |

| Teak | 620-750 |

| Walnut | 640 |

| Pear | 650 |

| White maple (sycamore) | 650 |

| Virginia maple (bird-eyed) | 650 |

| Birch | 650 |

| Cherry | 660 |

| Larch | 660 |

| Teak | 670 |

| Beech | 680 |

| Oak | 690 |

| Switenia (mahogany) | 700 |

| Sycamore (plane tree) | 700 |

| Dense rocks | |

| Ash | 750 |

| Plum | 800 |

| Hornbeam | 800 |

| Pecan (cariah) | 830 |

| Olive tree (olive) | 850-950 |

| Apple tree | 900 |

| Boxwood | 960 |

| Ceylon ebony (ebony) | 1080 |

Calculation example:

For example, we need to find out the weight of one cube of pine board:

m= 1m3*520kg/m3= 520kg at a humidity of 12% (physical and mechanical properties of wood are determined by this indicator)

For absolutely dry wood, the density will be lower (equilibrium humidity of wood for indoor use is 6-8%), and for natural humidity it will be higher.

Natural humidity is not standardized and can range from 30% to 80%. When using wood in contact with the external environment (any external wooden elements of the house, wooden window frames, exterior cladding, etc.), we exactly fall into 12% humidity for which the table above is given.

Materials

But the classification by variety is incomplete - it is still necessary to understand what is the difference between coniferous and deciduous species, and also which ones are better. Coniferous wood usually has straight trunks and is of decent quality. It is relatively easy to process. However, such “gifts of the forest” can be distinguished by their high strength. From them you can safely build even load-bearing structures of one-story and two-story houses.

Pine is very popular. It has relatively low moisture absorption. Larch has a greater absorption capacity, but upon contact with water it becomes harder. In favor of deciduous lumber (aspen, linden, birch, poplar) they say:

- fairly high density;

- grace of texture;

- Quite a long service life.

What are edged boards, beams and whetstones?

It is not so easy for an ignorant person to understand construction terminology. If you start a construction project, you will have to do this. First, let's figure out what a board is and how it differs from timber and timber. All definitions of lumber are given in GOST 18288-87. They rely on size. According to this document:

What is the difference between timber and timber? The cross-section of the beam has the shape of a square with a side of more than 100 mm. The block can be square, but the side must be less than 100 mm, but most often the block has the shape of a rectangle

- A board is lumber having a thickness of no more than 100 mm and a width greater than twice the thickness.

- Beam - more than 100 mm wide and thick. The maximum size of timber is not standardized. Only minimal.

- Bar - up to 100 mm thick and no more than twice the thickness.

So, if you look at the beam from the end, all its sides should be equal. The cross section of the beam will give us a square. The board and the block are rectangles. It’s just that the width of the board is more than twice the thickness, and the width of the block is less. For example, 25*75 mm is a board, and 25*45 mm is a block. And, by the way, 50*50 mm and 75*75 mm are also a bar, not a beam, because according to the standard a bar is considered to be a product with a side of 100 mm or more. We seem to have sorted out these names.

What is a croaker and a plank croaker is clear from the photo

A croaker is sometimes used for rough work. What it is? According to the same standard, this is a side part of a log, one side of which is sawn, the other is not. There is also a plank slab - this is when the outer part of the slab is partially sawn through.

Edged and unedged boards

It’s also worth deciding what a face and an edge are. This is either of the two wider surfaces in a board or block, and either of the surfaces in a block. The edge, accordingly, is the narrower part of the lumber.

The face of a board or block is a wide surface

Now you can find out what an edged board is and how it differs from an unedged one. The edged board has edges sawn perpendicular to the faces. There may be wane (remnants of bark) on the edge, but no more than is acceptable for the grade. An unedged board, accordingly, has uncut or partially cut edges. Edged lumber in which the wane exceeds the permissible limits falls into the same category.

There is also a semi-edged board. This is when only one edge is smooth, and the second may have wane. The timber, by the way, can also be with wane. The two-edged one has two opposite sides processed, the three-edged one has three, and the four-edged one has all four.

Edged and unedged boards. The difference is in the shape of the edges. The edged ones are smooth; In low varieties, a small amount of wane is allowed. An unedged board has edges that are not cut at all or only partially

You may also need such a concept as calibrated lumber. There are calibrated boards, bars and beams. This is lumber that has been dried and processed (on a thicknesser or planer) to the required size. It must be understood that an uncalibrated one may have deviations in size (the limits of deviation are normalized), while a calibrated one should not differ in size. Or rather, the permissible deviations are very small.

There is also a planed board. It differs from the edged one in that it has smoother sides, as it is subject to additional processing. The edged board is dried and then sent for additional processing on a planing machine. There the roughness left by the saw is removed. Calibration may occur at the same time, but is not required. The planed board may not be calibrated.

Business and construction board: what is the difference

Also in the price lists there is a board with the same dimensions, of the same grade, but one is for construction, and the other is for business. The difference is that the business one is made from non-dead trunks. It is dried, does not have fungal or bacteriological lesions, or wormholes, even if they are allowed by the standards. Therefore it costs significantly more.

Business board is used for roofing. Goes to the logs, rafters. It is also used in frame housing construction. The business board can be treated directly at the enterprise with the necessary compounds, but this is discussed specifically before delivery.

To understand whether the lumber in front of you is construction or commercial, look at the knots. A business board or beam can only contain healthy (light) fused knots