- Problems of framers

Frame construction dates back to the Middle Ages, when half-timbered houses began to be built in Germany and other European countries. In them, the gaps between the frame supporting structures were filled with brick, stone, coated with clay. The houses turned out to be strong and durable (many of them have survived to this day), but cold.

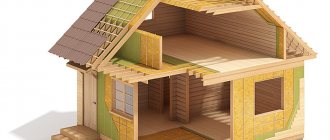

Today they no longer build like this, but use insulation, protected by external skins, to fill the frame, or hang multilayer panels. Such houses have long been considered the most thermally efficient - until cellular concrete appeared. Why it is better, and which house is cheaper to build: frame or aerated concrete, we will figure it out as the article progresses.

Comparisons of frame and aerated concrete houses from the point of view of construction technology

In order to understand everything about frame or aerated concrete - which is better from the point of view of labor-intensive construction and ease of use, you need to at least superficially familiarize yourself with the technologies. There are points that are equally important for both types of construction. For example, horizontal waterproofing between the base and the wall, because the service life of the house depends on it.

It is important that moisture does not get to the bottom trim of the frame, which, despite the antiseptic, can simply rot. In the case of aerated concrete, capillary suction of moisture will occur, and the walls can become damp all the way to the ceiling. Therefore, in both cases, two layers of waterproofing are mounted on the horizontal plane of the base, and its connection to the wall is protected by ebb. This is the only thing that a house made of aerated concrete and a frame have in common - otherwise the technologies are completely different. Judge for yourself.

Aerated concrete: features of material use

Trying to figure out whether a gas block or a frame house is better, we will try to briefly consider all the main aspects. The first question any customer asks concerns the choice of wall thickness. In stone houses it consists of several layers, since in most cases they have to be insulated.

- In this regard, aerated concrete compares favorably with other types of blocks and bricks, since a wall made of it can be single-layered and quite warm. Walls 200 mm thick made of aerated block with a density of D500 or 400 provide the same living comfort as brick walls of 380-520 mm.

- The need to insulate aerated block masonry does not always arise and must be confirmed by calculation. Thermal conductivity decreases in proportion to the density of the concrete stone, therefore, the lighter the cellular material, the thinner the walls made from it can be.

- For the construction of a country house that is not used in winter, there is no point in taking blocks thicker than 250 mm. But for a permanent home (in the middle zone of the country), it is better to take products with a width of 300 mm. Developers often make a “margin” of thickness by using 375 mm blocks, and for residential buildings this can be quite justified.

Expert opinion Vitaly Kudryashov builder, aspiring author

Ask a Question

Note: Considering that aerated concrete walls require external finishing, this reserve can be created using it. For example, you can plaster the insulation, cover the walls with lightweight bricks, or use hanging materials using a ventilation façade system. It is better to plaster aerated concrete on the inside, which reduces air permeability and eliminates the risk of blowing through the masonry.

How to deal with external influences

Temperature and humidity changes cause deformations in aerated concrete: expansion and contraction, swelling and shrinkage. These processes lead to the emergence of stresses in cellular concrete, which resists tension rather weakly. Hence the formation of cracks.

- The reason for their appearance can also be the weak rigidity of the support base, so it is best to pour the foundation in a monolith. The resulting cracks do not reduce the load-bearing capacity of the masonry, but can lead to increased air permeability of the walls, not to mention a damaged finish.

- To avoid the appearance of cracks, the masonry must either be divided into fragments separated by expansion joints, or reinforced, including in the finishing layers (with fiberglass mesh).

- When constructing load-bearing walls, reinforcement is most often used. It is carried out at the beginning of the masonry (in the first row), in every 4th row (if the wall is longer than 6 m), on the horizontal boundaries of openings, under the support of floors and rafter systems.

- When laying internal walls and partitions, instead of reinforcement, frequent expansion joints can be provided.

When figuring out which house is better - frame or aerated concrete, we will also consider the features of constructing a competitive option.

Frame construction technology

What is cheaper is frame or aerated concrete, it was clear from the comparative table. Due to the low cost of construction, frame houses have gained popularity all over the world. This is their main advantage, but if everything else was cloudless, then you must agree that no one would build stone houses.

- There are regions where they do not build using frame technologies at all. For example, in the south of Russia, where high summer temperatures can provoke a fire, and the lack of frost in winter leads to increased humidity.

- Plus, there are frequent strong winds, which make it quite difficult for a frame structure to withstand. At a minimum, you need a rigid cladding, either made of brick or fiber cement panels, the price of which may well equal the cost of a frame with aerated concrete.

- Another advantage of walls built using frame technology is their high resistance to heat transfer. But this is subject to proper filling with insulation. And developers often make mistakes when using bulk materials such as expanded clay, sawdust, and ecowool for this purpose.

Without special diaphragms that prevent their compaction and the formation of voids in the walls, the work on their construction is wasted. That is why building rules (352.1325800) recommend using only thermal insulation boards and mats with a thermal conductivity of no more than 0.10 W/m*C to fill wooden frames (clause 11.6.3).

Types of frame houses

We continue our research on the topic: which house is cheaper - frame or aerated concrete. The difference in price may not be so great, depending on the type of frame technology. There are four options in total:

- Frame (sheathing). The walls are completely structured on site.

- Frame-panel. The walls are assembled from enlarged factory-assembled external panels.

- Frame-panel. A frame is assembled onto which ready-made three-layer panels (SIPs) are hung.

- Frame-frame. Here the frame is assembled not from individual elements, but from volumetric frames.

These four types combine many European technologies, used both in pure form and in combination. Their prices vary greatly, so comparing a frame and aerated concrete house by this criterion is not always appropriate.

In our country, modifications are often used, since there are no normal standards for such construction. There was a document from 2002, which was updated only in 2017. But it also provides only two types of frames: with through (uncut) and with floor (composite) racks. It says nothing about frame and panel options - however, these technologies are also used.

In fact, many contractors work according to their own rules, interpreting Finnish, American, and German technologies in a way that is convenient for them. If this person is not a legal entity and works without a contract, no one will give you a guarantee on the final result. By mixing together the concepts of different technologies and calling the project a beautiful, catchy name, a house can be built from substandard material and in violation of installation rules.

As a result, the customer is unlikely to be happy that the frame is cheaper than aerated concrete. So the most important thing in the case of frame framing is control over the work. And to do this, you at least need to be familiar with the technology yourself.

Insulation of sheathed frames

The thermal efficiency of frame walls is ensured not by the structural material, but by the insulation. The main task of structuring frame-type enclosing structures is to prevent it from getting wet and blown by the wind.

The thickness of the installed insulation is determined by calculation, depending on the duration of the winter season and average temperatures. To protect against circulating air flows, the thermal insulation layer is protected by vapor and waterproofing membranes.

Apart from the finishing layers, the structuring of the wall core is carried out according to two schemes.

- Scheme 1:

Insulation boards are laid only between the load-bearing posts - that is, the thickness of the filler is equal to the height of the cross-section of the frame element. Accordingly, the sheathing layer is attached directly to the racks. - Scheme 2:

It is provided when the main layer of insulation is not enough to ensure normal thermal efficiency of the walls. In this case, additional insulation is carried out on the outside by installing spacer sheathing.

Expert opinion Vitaly Kudryashov builder, aspiring author

Ask a Question

Note: When figuring out which is cheaper: frame or aerated concrete, pay attention to the thickness of the insulation. If it is necessary to perform a second layer, the cost of the walls increases sharply - and not only due to the increase in the volume of thermal insulation, but also the cost of lumber for the counter-lattice.

In this case, you can save money if you use rigid boards with a foil surface for the second layer. In this case, there is no need to install the sheathing and windproofing membrane, and you can immediately hang the façade material. The main thing is to leave the joints of the slabs uncovered so that steam can escape through them without hindrance.

The most crucial moment when assembling frame walls is to lay the insulation in such a way as to prevent air convection. To do this, the slabs or mats must sit very tightly in the frame cell, and the vapor barrier layer must fit tightly to their surface from the inside.

From the outside, the structure is covered with rigid sheet material. It could be:

- Moisture-proof plywood 8 mm thick;

- Flat slate 6 mm thick;

- Cement particle boards (CPB) thickness 8-10 mm;

- Wood polymer (OSB) boards;

- Plastering can be done directly over the insulation, with the layer reinforced with fiberglass mesh.

When used for finishing sealed coatings such as brick or ceramic siding, the sheet material may not be installed.

The interior cladding is most often made with plasterboard, as the most environmentally friendly material, creating a smooth white base for finishing.

Nuances of block construction

In the construction of houses, aerated concrete is often used in the form of blocks.

They are divided according to density and thermal conductivity:

- Thermal insulation;

- Structural and thermal insulation;

- Structural.

For the construction of wall structures, structural, thermal insulation and structural blocks are used.

The attractiveness of aerated concrete technology

Lightweight and porous products have many advantages:

- The light weight of the blocks does not require a powerful base. This significantly saves financial and material resources.

- The porous structure of aerated concrete has excellent thermal characteristics. The buildings turn out to be very warm.

- The strength of wall structures is sufficient for the construction of small buildings.

- Aerated concrete is an excellent soundproofing material.

- It has excellent vapor permeability.

- The variety of shapes and sizes of elements allows the construction of buildings of the most complex configuration.

- The clarity of the geometric shapes makes it possible to install them not using mortar, but using mounting adhesive. Wall structures are lightweight.

- Large-format elements are quickly installed. There is no need to use special equipment and complex tools. Correct laying is ensured by a special block joining system.

- Aerated concrete does not rot and is not damaged by insects and rodents.

- The material is non-flammable and fireproof.

- All components included in aerated concrete are environmentally friendly.

- Long service life of buildings - at least 60 years.

Aerated concrete blocks are in great demand in the modern market.

Construction from aerated concrete.

Arguments against using blocks

But all materials, in addition to their pros, also have their cons:

- The degree of thermal conductivity of aerated concrete is inversely related to their strength and density. A light and warm block - low strength, a heavy and durable option - low thermal insulation values.

- Fragility of products - aerated concrete blocks are easy to process, but they are also easy to paint.

- Porous gas blocks require mandatory external protection from atmospheric influences. They easily absorb moisture. The simplest solution is plastering. But cladding would be a more reliable option. This leads to an increase in the total weight of wall structures and the need for a powerful foundation. Accordingly, construction costs increase.

The disadvantages are not particularly significant for many.

The main disadvantages of frames

And yet, frame or aerated concrete - which is better? To confirm your choice, you will have to pay attention to the negative aspects, the main one of which is considered to be insufficient strength - walls are easily destroyed by a chainsaw. In addition, there are certain other points:

- Many modern building materials used in the construction of a frame house are harmful to the human body.

- Load-bearing walls and floors of frame objects, unlike houses made of other materials, do not have sufficient thermal mass to create the required temperature stability.

- A frame house, if it does not have a double volumetric base and without external facade insulation, creates “cold bridges”, which cause deformation.

- The entire structure is considered a fire hazard.

- The classic version of the frame is distinguished by rectangular shapes, which do not create normal strength during lateral deformations.

- Such a house is poorly protected from vandalism and intruders.

- Low vapor permeability of the house using mineralized wool as insulation and membranes.

- There is always a high level of humidity in the house; it should be constantly ventilated.

Safety and ease of use

A solid building made of stone always has the advantage: it lasts a long time, since it does not burn, does not rot, and is not damaged by rodents. As for aerated concrete, it differs from brick or blocks made from other types of concrete by its higher level of environmental friendliness. It does not contain clay or granite crushed stone, which has a high natural radiation background.

- If a successful picture deteriorates, it is only due to polymer insulation, which the owner decides to install from the inside. In general, proper thermal insulation is located on the outside of the walls, and in this case it not only protects them from freezing as much as possible, but also cannot create problems for the people living in the house. In frame houses, the insulation is separated from the interior only by a thin sheet of gypsum board or plywood, or even just decorative sheathing.

- Aerated concrete has its own problems, which can be successfully solved through proper design. If they do occur, they occur mainly in houses built without a design, with incorrectly chosen wall thickness, foundation depth, and excessive weight of floors that is not comparable to the density of aerated concrete.

- In any case, there are official standards and recommendations for aerated concrete construction, compliance with which guarantees a high-quality result. With frames, the situation is worse due to the lack of a regulatory framework, as was already mentioned at the beginning of the article. Everyone builds according to their own understanding, and hence numerous problems. The reasons can be legion - from loosely fitted insulation to a membrane laid on the wrong side.

- Thermal insulation materials have low heat capacity - that is, they cannot accumulate heat like stone. The rooms heat up quickly, but as soon as you turn off the heating, they cool down just as quickly. But this can still be survived if there are no interruptions in heating, but the danger of fire worries people much more.

- It is clear that all wooden elements must be treated with fire-retardant compounds (fire retardants). However, this protection is not enough for the entire life of the house, and it is impossible to re-treat it after 5-10 years. All that remains is to trust in God, try to use only non-flammable materials in finishing and observe fire safety rules to the maximum.

- Now let’s look at what is better: a frame or aerated concrete house from the point of view of wind resistance. The impact of wind is a lateral load, which can be so strong that it sometimes destroys permanent buildings. What can we say about the flimsy wooden frame, which in the “economy” version is assembled from 45*145 mm boards?

- How resistant frames are to wind can often be seen in the news about America and other countries located on the ocean coasts. Spectators are impressed when frame houses, which are very popular because of their cheapness, fall into pieces like doll houses, but hardly anyone would want to be their owner. An aerated concrete house has a much better chance of surviving in such conditions - the most that can be damaged in a hurricane is the roof.

- Everything is clear with safety, now about ease of use. Most often, mineral wool is used to fill spans in frames, since it does not burn and has high vapor permeability. However, it is impossible to use this property for good in a frame house, since the cotton wool has to be protected from moisture by films.

- In fact, the effect of a thermos is obtained, due to which all the steam remains in the room. Therefore, in the absence of forced ventilation or the impossibility of keeping the vents constantly open, moisture begins to accumulate on the structures and mold forms.

This can also happen in an aerated concrete house, but at least there is an opportunity to avoid this as a result of the correct structuring of the finishing layers. Many problems of aerated concrete walls (excessive vapor permeability, airflow) are solved with the help of internal plastering or adhesive plasterboard cladding. These layers do not seal the walls tightly, but simply slow down the process of steam passage, and if nothing interferes with its exit outside (for example, a ventilated facade is installed), there will be no problems at all.