The reliability and strength of a frame building largely depends on the lower and upper trim. They must be carried out in full accordance with technology, otherwise the house will not last as long as its owner would like. The bottom frame of a frame house is a support for the walls, so it is securely fixed to the foundation of the building. Of course, only piping made of high-quality materials will ensure reliable attachment of the building to the foundation, strong support for the joists of the floor and walls - all together this is the key to the long life of the house.

Only high-quality wood is selected for strapping Source lestorg32.ru

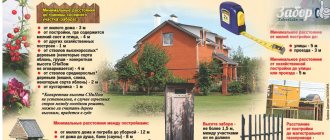

Basic requirements and purpose of framing a frame house

The roof and foundation are tied to strengthen the frame, its strength and reliability. The lower and upper play different roles, but their design is basically the same.

The bottom frame helps strengthen the building structure below. It distributes the load equally around the perimeter of the house. The upper one is intended to combine the walls of the house outside and inside into a single whole. It provides the load between the walls and ceilings, which is also distributed evenly. Before the work process, the foundation must be ready.

All details of the frame building meet certain requirements:

- The boards used are standard, even boards with dimensions: 38x100 or 38x140 mm. When using timber, its dimensions are: 150x150, 120x120, 100x100 mm.

- It is preferable to use materials made from coniferous wood, since their performance characteristics are most suitable for these purposes.

- Materials should last a long time. To do this, they must be coated with an antiseptic to prevent rotting, otherwise the elements will need to be replaced.

Additional processing of the strapping bars will never be superfluous Source stroyfora.ru

- Racks and other parts must be highly durable.

The layer of piping must follow the contours of the foundation. If there are discrepancies in width, moisture will accumulate, which will lead to destruction of the wood.

Recommendations from experts

Experienced builders recommend not only waterproofing the piping, but also thermal insulation. This determines how protected the interior space of the house will be from blowing.

If cold air moves freely under the floor, this will significantly increase heat loss, which means energy costs will increase. If you make a so-called false base and insulate the intake, then cold air will not be able to penetrate into this area.

For insulation, you can use polystyrene boards, penoplex or EPS. These materials have low thermal conductivity and are quite cheap.

To further protect the sheathing and the entire house as a whole from water pouring from the roof, it is recommended to make a concrete blind area around the perimeter of the building .

Requirements for materials for the bottom trim

In addition to boards, logs or beams, to install the strapping you will need materials to create a waterproofing layer (roofing felt is most suitable), and accessories for fastening: nails (50, 100, 150 mm), self-tapping screws (50, 100 mm).

When choosing materials for strapping, you should consider the following requirements:

- must withstand the highest loads that are possible during operation;

- have high resistance to mechanical stress;

- resistance to external and internal influences;

You also need to take into account the weight and density of the materials used.

See also: Catalog of frame house projects presented at the Low-Rise Country exhibition.

The highest quality material is required, for example, for a pile foundation, since in this case the piping will always be practically “in sight”. But with austerity, some go to make frames from boards, although in essence this is the same lottery as using a columnar foundation.

Columnar foundation and frame made of boards fastened together. This combination is like a real powder keg for a residential building - sometimes it doesn’t even explode Source deltodom.ru

It is important to know! According to its characteristics, a columnar foundation is unacceptable for residential buildings, but it is permitted and quite often used as an economical option for outbuildings.

Subfloor and floor joists

From under the base the house can have a negative impact due to its proximity to the soil, high humidity, etc. Therefore, when the lower floor in a frame house is close to the foundation or to the ground, the wood is isolated from concrete, brick or soil. This reduces the likelihood of condensation and also prevents wood decomposition.

Useful: Design and application of sandwich panels

The materials used in the construction of the coating must undergo similar treatment. Waterproofing work is quite simple, you can do it yourself. The waterproofing layer must be laid before installing the insulation to prevent it from becoming damp and destroyed.

Laying and securing the bottom trim

Each type of foundation (pile-grillage, strip, screw, monolithic) consists of several constituent elements that are located at intervals. The piping of a columnar foundation serves to combine its fractional elements, making them a single element. There are various methods for laying the strapping: threaded, welded, using clamps.

After pouring any type of foundation, strapping work begins:

- The first and important step is to check for the presence of unevenness on the base. If they are present, you need to get rid of them using cement mortar. If the irregularities are up to 3 cm, then they can be left.

- The waterproofing layer is laid using roofing felt and mastic.

- Tying should begin from the corners of the base. First, the structure is assembled for the first corner, which is the beginning of the tying. The construction triangle will help determine whether the work is being done correctly.

Frame house framing angle Source stroystory.ru

- Laying boards. The placement of joints in the corners is done in two options: in the “paw” or “in the floor”. Before fixing the main components of the structure, the diagonal and angular sides are drawn out very evenly. They are strengthened with nails (at least 150 mm).

- Before fixing the main components of the structure, the diagonal and angular sides are drawn out very evenly. They are secured with nails (at least 150 mm). The gap from the edge is 2 cm or more.

Before tying, waterproofing of the foundation is necessary.

Use of bulk aggregates

Bulk insulation of frame houses is very popular, because with the help of various substances (slag, sawdust, perlite, expanded clay) you can fill the entire space between the beams. Such flooring can withstand even increased loads.

Loose aggregates are typically used to fill the basement of a frame house when the subfloor is installed on joists. It is enough to install cranial bars 50x50 mm, as well as OSB 15-20 mm thick, and this design will be enough to withstand large expanded clay or other thermal insulation materials.

This type of insulation is convenient in that it is carefully distributed over the base until the desired thickness is achieved. You can fill it yourself, which allows you to save a lot at this stage.

It is better to use heavy filling materials only on the basement floor, so as not to load the building structure with additional weight.

Instead of expanded clay, you can also use ecowool. This insulation is of organic origin, it is very light, so it does not overload the frame. As for other fillers (sawdust, perlite), they are either very expensive and rarely used, or are considered an outdated option.

Connection of strapping beam

The framing of a frame house is done by ensuring that the grillage is firmly attached at the corners, where the internal and external walls adjoin each other. Usually the standard size of the material is not enough for the entire length of the building, so it needs to be increased. Connections are made using various methods:

- “in the wood floor” and “in the paw” to increase the length;

- “dovetail” is excellent for connecting internal to external walls (it is very difficult, but airtight);

- “butt” – a simple connection, but not very reliable;

- “root tenon” – used for corners.

Types of joints between strapping beams and floor joists Source teplye-doma.ru

Depending on the cross-section of the lumber, the length of the joints “to the floor” or “to the foot” is selected. The connection size is 2-3 beam heights. For the most durable fixation, dowels are used.

Possible problems

At the stage of installing a foundation on pillars or piles, you may encounter a problem when the foundation elements are not located on the same line. This may lead to the fact that during the tying process, not all walls will rest on the piles.

Fixing this error will be very difficult and expensive. Therefore, at the stage of installing the foundation of a frame house, it is necessary to take into account all the geometric features of the future object. Markings on the construction site must be applied with the greatest possible accuracy.

You need to drill the bars very carefully. The slightest wrong movement will lead to cracking of the timber. This may affect the quality of the entire structure.

Installation of the upper frame of a frame house

The top trim is made from boards, the width of which should not be less than 100 mm. Unplaned boards can be used as material. The strapping serves to evenly distribute the weight of the roof and any amount of snow that is transferred by the rafters to the walls. To make work easier, the lower and upper trims are made from the same material with a similar cross-section.

It is best when the harnesses are identical to each other Source m.2gis.ru

If the future building has several floors, then it is necessary to make two rows of lining at the top. It is needed only on the outside, but to avoid differences in height, it is also produced on the inside, although it is not as strong. You need to splice the harness directly above the stand. Both layers are attached to each other after approximately 20 cm; there should be no more gap.

Removal of load-bearing walls beyond the pile foundation

Sometimes private developers try to find solutions that allow them to save on the purchase of building materials and the work of screwing in additional piles. At the same time, they forget about the strength of the building structure, which can be broken very recklessly.

Here is an example of a gross violation of construction technology; the photo shows the removal of the outer wall beyond the boundaries of the pile row.

What can you recommend to people who prioritize questionable savings? The most important thing is to avoid self-indulgence, and then everything will work out for you. If building regulations provide for the installation of piles under each corner or wall of the future room, then so be it. There is no need to make any overhangs or indentations that are not supported in the form of a pile firmly screwed into the ground. This will not lead to a reduction in the cost of construction, but it will provide additional problems for the developer.

Guffych FORUMHOUSE user

If you make an overhang or indentation, then this structure will hang on the logs. In this case, you will have to make a double strapping from the inside and connect it somehow with the external overhang (so that the structure does not completely fall apart). It won’t be cheaper (due to savings on piles), since you will have to spend money on strengthening the lower floor, but this will add problems.

If you plan to add additional architectural elements to the house (a veranda or, for example, a porch), their corners should also be supported by metal piles.

Land user FORUMHOUSE user

In general, according to the technology of constructing a pile-screw foundation, piles must be placed under all cuts, corners and load-bearing walls. This is the most important rule.

Attaching the top harness

Fastening can be done using three methods:

- To the end of the rack, which is located in a vertical position, with nails or screws. The method is suitable when making a structure from a single board.

- To the end of the rack through notches. With this option, a notch is made in the harness, the depth of which should be one third or half the thickness of the wood. The top edge of the rack fits into this recess.

- Fastening with steel corners. A very reliable method that strengthens the fastening using the first method.

Additional fastening with steel corners increases the strength of the structure Source initechno.ru

The advantage of the first and second methods is that it is possible to position and secure the vertical posts one after another. To fix it using a notch, mandatory calculations and absolutely accurate markings are required. If there are violations, then there will be a defect in the vertical placement of the racks, as a result of which the structure will begin to collapse.

Grooves are made in the strapping beam or board for all the posts, which must coincide with the same grooves that are on the fastenings for the posts of the lower trim. In addition, the structure is secured with nails. Fastenings using corners are secured with self-tapping screws.

What is a subfloor

This is a plank covering that is located in the space between the joists and provides a level surface for the installation of the finished floor covering. The construction of the subfloor involves the use of insulation, which makes it possible to additionally heat and sound insulate the building from below. And only in the attic is the rough flooring made the main one, since there is no need to spend extra money on parquet, laminate or floor boards.

When choosing a material for a subfloor, only minor attention is paid to quality, so you can purchase inexpensive types of wood.

The subfloor experiences almost no load. On top of it there can only be a layer of insulation (it is very light), as well as a front covering. After all the installation work is completed, it itself will be completely hidden, so its appearance is also unimportant.

Turnkey price

The price per harness varies based on several factors. Among them:

- wood - an example would be larch, which is more expensive;

- availability of additional work;

- region.

According to the standards, the cost is calculated based on linear footage. Average prices in major cities:

| City | Average price for 1 linear meter in rubles |

| Moscow | 1100-1200 |

| Saint Petersburg | 1000-1100 |

| Kazan | 900-1050 |

| Novosibirsk | 800 |

| Ekaterinburg | 800 |

Additionally, take into account that a number of companies can provide discounts when applying. An example would be a large volume of work or similar situations.

Pie designs

First, a subfloor is made, which is also the ceiling for a frame house. Floor beams are secured to the foundation frame. At the same time, make sure that there is a layer of waterproofing between the foundation and the wood so that the wood does not begin to decompose due to natural humidity. To do this, lay a double layer of roofing felt or waterproofing material.

Next, they make the load-bearing base of the floor, using either only the main beams, or both the main and secondary beams.

Secondary beams or logs in a frame house are used to ensure that the pitch of the main beams is large. But at the same time, the consumption of materials increases, the thickness of the floor increases, and more work needs to be done.

If there are no secondary beams, the main beams can also be used as joists. Then the floor pie looks like this (from bottom to top):

- cranial bars with a section size of 50x50 mm, fixed to the load-bearing floor beams;

- layer of boards - filing;

- protective elements from wind and moisture;

- load-bearing beams, between which there is insulation inside;

- vapor barrier layer;

- rough flooring made of boards or thick chipboard.