Future home owners are increasingly choosing frame construction. There are many advantages to such buildings. Construction takes a minimum of time; wood is the most environmentally friendly material and provides comfortable living. The main task of builders is to carry out all work according to proven methods and use high-quality materials. The customer should know the basics of construction. For example, how to properly build a corner of a frame house and make it warm.

The warm corner of a frame house must be built taking into account all standards Source dom-steny.ru

Organization of external corners

The main task of the corner is to rigidly join adjacent wall structures and minimize cooling bridges.

There are several dozen schemes for constructing the outer corner of a frame house. For cold regions, only three methods are suitable. But two are the most popular.

The most common diagrams of the corners of a frame house, described below Source zen.yandex.ru

The simplest option

The “California” corner assembly is a leader among others. At the junction of wall structures, a board or narrow OSB panel is nailed on the inside. It firmly holds the walls together. In the future, the nailed strip serves as a support when installing the inner layer of the wall, allowing for high-quality interior finishing.

Second place

The so-called “Closed” corner ranks second in popularity. The point is to install an additional column in the inner corner between wall studs or bars, the result is a shelf on the side of the inner corner. The design retains heat. In this case, it is enough to insulate the building only from the outside, but do this before covering it with sheets.

The warmest option

The “Scandinavian” option is used quite rarely. Experts determine that this is the warmest corner in a frame house; this is achieved due to the maximum cutting off of cold bridges. The design maintains the necessary rigidity. The disadvantage is the complexity of the work.

When assembling the frame with your own hands, experts recommend choosing method 1 as the simplest.

The outer corner can also be made in the form of the letter “P”, and three short blocks can be fixed on the inside.

Details about warm coal in a frame house.

Frame houses are being built almost everywhere today, due to ease of installation, low construction costs and the ability to locate a house even on a small plot of land. At the same time, when starting the construction of their own home, any owner wants to end up with a durable, comfortable and warm home. Warm corner technology allows you to avoid freezing of corners and walls in a frame house, retain heat and rid the building of mold and dampness.

A new house is built to last for decades, and this is only possible if it is built in compliance with certain rules and regulations.

To achieve this, it is necessary to carefully study the technology for building such houses, carefully approach the choice of project, materials for construction and control the quality of the work performed at all stages. By entrusting the construction of a house to a non-professional team of builders, you can end up with many design errors, which during operation will reduce all the advantages of a frame house to zero.

Often, even the most minor mistakes during construction turn into big troubles for those living in a new house. One of the main tasks when constructing new housing is to maintain heat in the premises, reduce heating costs and create a comfortable microclimate in the rooms. To do this, you should pay attention not only to insulation, but also to the correct construction of walls.

If the corners are made incorrectly during construction, they will freeze even with a slight drop in temperature; in severe frosts, ice will form in the corners; in this case, dampness will be added to the obligatory cold, heating costs will increase significantly, and this combination is unlikely to please the owners.

Organization of internal corners

The angle between the outer and inner walls of a building is made in several ways.

Correctly organizing the corner from the inside is no less important than from the outside Source indeco.ru

The first option is the following:

- between 2 beams, one regular beam or three short ones are installed (in the top view the letter “P” is obtained);

- A wall element is attached to the middle beam.

Second option (especially heat-intensive):

- the outer wall at the junction with the internal stand is made up of horizontal bars 50x50, located between the vertical bars, with a pitch of 60 cm;

- A vertical post is installed to the horizontal bars, forming the edge of the inner wall.

The blocks are knocked together only with 90mm nails every 50-60 cm.

As practice shows, not all construction teams offering services to individuals are proficient in the technology for making corners.

Corner insulation options.

If, during the construction of a frame house, a closed or Scandinavian version of warm corners was chosen, then their additional insulation is carried out before the outer cladding of the house, since then this work will be impossible to perform.

The corner cavity from the outside is filled with penoplex, possible gaps are eliminated using polyurethane foam, or basalt or mineral wool is used as insulation. The use of basalt wool is preferable, although it is somewhat more expensive.

Ordinary mineral wool loses its insulating properties over time, it absorbs moisture much more strongly and, compared to basalt, has a shorter service life.

For additional protection, you can use liquid insulation. It can be applied with a regular brush in several layers. This composition not only provides reliable insulation, it also has fire-fighting and waterproofing properties. Can be used:

- "Corundum";

- "Astratex";

- "Akterm"

- "Armor".

When purchasing such compounds, carefully read the instructions and scope of application, and be sure to pay attention to the weight of the purchased heat-insulating mixture. 1 liter weighs no more than 600-650 grams, only in this case the heat-insulating composition can be considered high-quality. After insulation, such a corner is hidden under the elements of the external cladding.

In the case of a “California” warm corner, insulation is carried out from the inside of the house.

To insulate vertical surfaces, rigid insulation boards are used, for example, polystyrene foam or expanded polystyrene, which have low thermal conductivity, since loose and loose types of insulation quickly fall down or crumple, ceasing to perform their functions. In this case, the cost of heating the home soon increases significantly.

The disadvantage of such stoves is toxicity when burning. If insulation is carried out with various types of mineral or stone wool, the rows of slabs are additionally strengthened with spacers; it is not practical to lay mats of similar insulation on top of each other.

Additionally, such spacers increase the rigidity of the frame and make it easier to install the interior cladding of the house. The distance between the vertical posts should be 59-60 cm. In this case, there will be no gaps between the insulation mats. For year-round use, the thickness of the mineral insulation must be at least 150 mm.

Warm corner technology

It is often believed that it is enough to install three racks, and the corner will be sufficiently protected from freezing. In severe frosts, ice and frost form in such corners.

Corners are insulated from the inside for thermal insulation Source stroychik.ru

According to advanced technologies, the corner of three racks gives off heat perfectly, so it is covered with insulation:

- a beam 50 mm thick is stuffed on the inside and a layer of insulation is laid;

- on the outside there is also one layer of insulation.

As a result, the thickness of the laid insulation increases to 25 cm, resulting in the correct warm corner of the frame house.

See also: Catalog of companies that specialize in designing country frame houses.

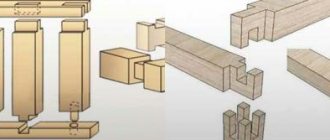

Methods for tying corners

The following schemes for tying corners are trusted by builders:

- The simplest and most popular option among builders. A right angle is formed from 2 beams (one beam is placed on the edge of the other), the assembly unit is installed on the rough surface of the floor, and its top should be directed towards the corner posts.

- "One-sided groove." Initially, grooves are cut out in one block, then counter grooves are cut out in another block so that when installing the bars to each other, a right angle is obtained. The ends of the beams should extend 10-15 cm from the top of the corner; the top view should resemble a cross.

- The connection principle is similar to the first method. In one block, the end is 4-5 cm high. In the other block, a counter groove is cut out, its size is slightly smaller than the “tenon”. Next, the bars are tapped to each other at 900 so that the “tenon” fits tightly into the groove.

- "The Secret Thorn" The method resembles the previous option. Only the shape of the groove and the “tenon” changes, in which one bar is installed to another along a vertical plane. There should also be a right angle between the bars.

One of the options for tying a corner Source stroystory.ru

Vertical posts in corner joints are secured using corners and wood screws. The stability of the structure is guaranteed by reinforced galvanized corners; this is the best option.

Corner trim

There are several ways to sheathe the corners of a frame house:

- Nails, 150 mm long. 4 nails will allow you to securely fix the angle. There must be at least 2 cm from the place where the nail is installed to the edge of the beam. These are mandatory conditions for proper assembly.

- Anchor fastening guarantees the necessary reliability and strength of the result.

- Dry oak is most suitable for using wood pins. Dowels with a diameter of 20 mm are cut out. The holes are made, their length should exceed the length of the dowel by 1.5-2 cm, and the diameter should be made slightly smaller. The dowel is not driven into the hole completely; it is left approximately 10 cm above the surface. This part will be needed for the next step when forming the corner.

Anchor fasteners are available and reliable Source olestnicah.ru

Some tips

The outer cladding is made of OSB boards, boards, DSP boards, lining; any option strengthens the frame structure, but this does not mean that the strength of the frame house depends solely on the outer cladding.

If a frame house is being built for permanent residence, it is better to insulate it both outside and inside the building. This will prevent possible freezing of the walls, rid the room of humidity, and make it warm and comfortable. Particular attention should be paid to corners, door and window openings and the roof. High-quality installation of windows and doors will keep your home warm.

Since a frame house is built from wood, proper waterproofing of all components of the building is a guarantee of excellent preservation of the structure. Rotting of frame or ceiling elements will lead to the need to rebuild the house, and this is a labor-intensive and expensive process. When laying membrane waterproofing, it is necessary to install the film correctly, in strict accordance with the manufacturer's instructions.

In order for the frame of a new house to be strong and not “sag” over time, it is necessary to properly arrange window and door openings; for additional strength of the frame, it is necessary to install jibs, and they are installed not only in load-bearing walls, but also in partitions, especially if it is planned to build 2-storey house or building of complex configuration.

Common mistakes

During the assembly of his future country cottage, the owner needs to keep under his own control the important stages of the construction process.

Wrong choice of materials

Do not use wood materials with natural moisture. For example, untreated softwood has a moisture content of approximately 40%. The humidity of the “working” material is 14%. As the tree dries out, it shrinks in size and becomes deformed. What happens to the house when the wood in the corners dries out? Firstly, the necessary rigidity of the frame will be lost. Secondly, cracks and additional cold bridges will appear.

Selecting materials with insufficient cross-section. According to GOSTs of the Russian Federation, in the construction of frame houses, bars with a thickness of at least 40 mm and a width of 150 mm are used. A frame built from bars less than 35 mm thick does not have the necessary strength reserves.

Angles must be made in accordance with GOST. Source hochu-stroitsya.ru

Errors with fasteners

The correct choice of fasteners is an important point.

Experienced builders, when constructing corners in a frame house, never simultaneously use perforated corners and black self-tapping screws, intended exclusively for fixing drywall. These fasteners are easily installed in wood, their cost is not high, but together they cannot provide the necessary safety margin.

The correct choice of fasteners should not be underestimated Source giropark.ru

It is permissible to use yellowish or silver self-tapping screws; their thickness should not be less than 5 mm. In this case, the use of a perforated corner is permitted.

The frame itself is fastened only with nails no less than 90 mm long.

Required tools and materials

Beam with a section of 50x150 mm for installing a warm corner

To build a warm frame corner, you will need the same materials and tools as for building the house itself:

- 3 or 4 boards for arranging a corner element with a cross-section of at least 50*150 mm.

- Galvanized nails 150 mm long. You can use anchors and “silver” dowels, but not black ones.

- The use of wooden fasteners – dowels – is allowed. It is better to take oak ones, as they are much stronger. Diameter – 20 mm. For dowels, you must first make holes in the boards.

- Insulation – mineral or basalt wool.

Before use, boards should be treated with fire retardants and antiseptic impregnations.

General recommendations for choosing specialists

Not all builders know the design features of a frame building. When forming angles, mistakes are often made:

- use timber;

- They simply nail three boards to each other without forming warm bridges.

When choosing a construction team, it is worth learning more about the work schemes and asking questions that arise. If a clear and concise explanation is not forthcoming, the competence of the workers should be questioned.

Only professionals can guarantee high-quality results Source stroyizbrusa.ru

External wall cladding

Taking on a large load, the outer cladding of the wall frame ensures the rigidity of the structure and its stability during operation. Properly selected building materials for cladding will allow the walls to maintain their shape for many years and withstand negative external factors.

Application of OSB-3 boards in frame construction

OSB-3 boards (OSP-3) are moisture-resistant oriented strand boards of increased rigidity. They are made by pressing and gluing three to four layers of wood chips. In each layer it has a different direction, which gives the material increased rigidity.

Advantages of OSB-3 boards:

- The optimum ratio of price and quality.

- Easy to process - cutting, drilling, grinding.

- Suitable for using various fastening elements - nails, screws, dowels, etc.

- Resistant to splitting even when fasteners are used close to the edge of the slab.

- Do not deform due to temperature changes and various atmospheric conditions.

The main disadvantage is the low vapor permeability. Walls made of OSB boards do not “breathe”.

Of no small importance is the fact that synthetic resins are used for gluing chips. This means that the cladding material can release formaldehyde and phenol into the air.

However, stoves made according to European standards are safe for humans.

Note! The most environmentally friendly material is the one marked E0 and E1

Cement particle boards (CSP)

DSP is a material based on a mixture of wood chips and high-grade cement. To improve its performance properties, special additives are included in the composition.

Cement particle boards have the following advantages:

- Resistant to moisture and, accordingly, to mold formation.

- They are not afraid of rodents.

- Environmentally friendly. They do not release harmful substances into the air.

- Fireproof, belong to the category of low-flammable materials.

- Retains heat well.

- They have good vapor permeability and are breathable.

- When covering the frame, a flat surface is formed.

In contrast to the advantages of DSPs, they also have disadvantages:

- Heavy weight.

- Difficulty in processing the material. Drilling and cutting require a lot of physical effort. At the same time, a lot of dust is generated during the work.

- High price.

The recommended thickness of cement particle boards for frame construction is 12-18 mm.

Fiberboard for external cladding

Fiberboard is wood fibers pressed into a board. As in the production of OSB, they are laid in several layers, in each of which the fibers have their own direction. No adhesives are used. Enough pressure, exposure to high temperatures and resins contained in coniferous wood.

What characterizes this material on the positive side?

- It provides good heat and sound insulation of rooms.

- Environmentally friendly.

- The slabs are light in weight.

- Good vapor permeability.

The main disadvantage of fiberboard is its low stiffness index. When using this material, it is necessary to install jibs and select rigid internal lining.

Note! The recommended thickness of fibreboards for cladding the walls of a frame house is at least 25 mm

Covering the frame with plywood

Plywood is a sheet material made from several layers of veneer that are glued together. In frame houses, regular walls made of moisture-resistant plywood have a thickness of at least 12 mm.

Advantages of plywood:

- not afraid of low temperatures;

- easy to process;

- high compressive strength;

- affordable price.

The disadvantages of plywood include its flammability, the presence of synthetic resins, and its tendency to chip.

Attaching the outer skin to the frame

Attaching the outer skin to the frame is done according to general rules.

- The presence of a temperature gap of 3-5 mm between the plates (sheets) is mandatory.

- Their joints should be in the middle of the frame beam.

- To fasten the sheathing, self-tapping screws 55-70 cm long are used. At the same time, they must go into the frame stud to a depth of at least 40 mm.

- Self-tapping screws are screwed in at a distance of at least 10 mm from the edge of the slab.

- Fixation of sheets or slabs is carried out in increments of 15 cm - along the edge, in 30 cm - in the center.

Since you will be using a huge number of fasteners, stock up on high-quality power tools in advance.

Timber for construction

The basis of any frame structure (as the name suggests) is the frame. It is made from timber and boards. The amount of timber and the sizes of individual parts completely depend on the chosen construction technology and the design of the house. Thus, to save money at this stage, you should carefully choose an ergonomic design and method of constructing the house.

Materials for constructing the frame

To build the frame of a house, you can choose different materials. Depending on this choice, the construction technology depends, and therefore the performance indicators of the finished home and the volume of the budget.

Unprofiled planed timber. This material is most often used for the construction of a frame house. Non-profiled planed timber is a rectangular or square shaped timber that has undergone forced drying.

The dimensions of the sides of the bar are 100*100 mm. The beams are connected together using a board. As a rule, the buyer receives a house kit with ready-made timber. To facilitate the assembly of the frame, all bars, boards and components are marked at the factory.

Profiled timber. This type of timber has one distinctive detail - grooves and tenons located on both sides. The other two sides remain planed. Thanks to this feature, the installation speed increases noticeably.

This type of building material is also worth choosing for those who want to save a lot. The timber acts here both as a supporting structure and as walls. Additional interior finishing is also optional - the planed sides of the timber create an aesthetic and reliable canvas.

Glued laminated timber. Bars of this type are made up of pieces of timber (boards) glued together. All elements differ in the direction of the fibers. This option provides high assembly speed and greater deflection strength.

Materials for frame cladding

The plywood is waterproof. The finished frame can be sheathed with waterproof plywood. At the same time, when choosing a material, you should not confuse it with moisture-resistant plywood. The latter has a certain sensitivity to moisture (unlike water resistant). Waterproof plywood is made from coniferous or birch veneer. The veneer is held together with a special adhesive.

OSB (often called oriented strand board). The main raw materials for the production of this building material are wood chips glued together with a special glue. The top pillar of the slab consists of chips in the longitudinal direction, and in the inner layer the chips are glued together in the transverse direction. Due to its increased moisture resistance, this material can be used for cladding both internal and external walls.

SIP panels

The most convenient and economical option. In this case, the calculation of materials for the construction of a frame house takes place entirely at the manufacturer’s factory. The sip panel has the shape of a “pie”, where calibrated timber (for the frame) and polystyrene foam (for insulation) are located between two OSB boards.

The use of sip panels significantly reduces construction time and also helps to save on frame construction. The rigidity of the panels allows you to build a house without a frame at all.

Video: independent calculation of building materials

The easiest way to calculate the required amount of materials for walls is using programs. How to do this, watch the video.

Use of bulk aggregates

Bulk insulation of frame houses is very popular, because with the help of various substances (slag, sawdust, perlite, expanded clay) you can fill the entire space between the beams. Such flooring can withstand even increased loads.

Loose aggregates are typically used to fill the basement of a frame house when the subfloor is installed on joists. It is enough to install cranial bars 50x50 mm, as well as OSB 15-20 mm thick, and this design will be enough to withstand large expanded clay or other thermal insulation materials.

This type of insulation is convenient in that it is carefully distributed over the base until the desired thickness is achieved. You can fill it yourself, which allows you to save a lot at this stage.

It is better to use heavy filling materials only on the basement floor, so as not to load the building structure with additional weight.

Instead of expanded clay, you can also use ecowool. This insulation is of organic origin, it is very light, so it does not overload the frame. As for other fillers (sawdust, perlite), they are either very expensive and rarely used, or are considered an outdated option.

What requirements must the harness meet?

- To create it, you need to choose identical, even boards. We will connect them with bolts or staples. For greater structural strength, such boards should be doubled or stacked.

- The thickness, diameter and other features of the boards for lining are selected depending on the walls of the future building.

- Coniferous logs are ideal as materials for strapping. They have the qualities of strength, durability and resistance to adverse weather conditions. The resin contained in such rocks will protect the boards from rotting and increase moisture resistance. Such structures are less susceptible to deformation and are more economical.

- To protect wood from rotting and other adverse effects, they should be treated with an antiseptic and fire-retardant compound. These actions are carried out before the installation of the structure begins.

- The beams must be made from trees with a straight trunk.

Types of fasteners for frame house construction

To combine individual frame elements into a single structure of the required configuration and dimensions, a wide range of connecting fasteners is used:

- nails;

- mounting plates;

- connectors;

- mounting angles;

- supports and beam holders.

The main structural material of connecting fastening hardware is cold-rolled steel (sheets, wire), which is characterized by high strength and long service life. To protect the metal from negative atmospheric influences, zinc or oxidized coating is used.

What is a subfloor

This is a plank covering that is located in the space between the joists and provides a level surface for the installation of the finished floor covering. The construction of the subfloor involves the use of insulation, which makes it possible to additionally heat and sound insulate the building from below. And only in the attic is the rough flooring made the main one, since there is no need to spend extra money on parquet, laminate or floor boards.

When choosing a material for a subfloor, only minor attention is paid to quality, so you can purchase inexpensive types of wood. The subfloor experiences almost no load

On top of it there can only be a layer of insulation (it is very light), as well as a front covering. After completing all installation work, it itself will be completely hidden, so its appearance is also unimportant

The subfloor experiences almost no load. On top of it there can only be a layer of insulation (it is very light), as well as a front covering. After all the installation work is completed, it itself will be completely hidden, so its appearance is also unimportant.

Hydro-wind protection of the external walls of the house

The insulation in the “pie” of the wall of a frame house must be reliably protected from moisture. Only under this condition will it be able to perform its direct function without deteriorating its performance properties.

On the outside of the walls, superdiffusion membranes are used for these purposes. Their complex structure makes it possible to remove steam from the insulation and at the same time prevent moisture from penetrating into it from the street. Low breathability makes this material windproof.

Note! Superdiffusion membranes are not a vapor barrier material, but a vapor-permeable waterproofing material. This must be understood, since the vapor barrier completely eliminates the penetration of steam through itself

The membrane is laid without gaps on the sheathing and secured with staples using a construction stapler. When laying rolled material, overlap adjacent strips by 10-15 cm on all sides. Then all seams are taped with special tape.