Frame construction in our country is gaining unprecedented popularity. The construction of such houses is quite simple to implement. The cheapness of such a structure is also an important factor, and the warmth and comfort inside a room built using this technology speaks for itself. But due to its availability, a structure of this kind assumes fragility and the impossibility of long-term use. But the service life of a frame house directly depends on the quality of the raw materials from which it is made. In this article we will look at the operational life of such construction.

Reasons for the popularity of frame construction

Every year the demand for houses made using frame technology is growing and justifiably becoming more and more popular. The primary reason is the amazing low cost of such a structure. Due to the difficult situation in the country, not everyone can afford to rebuild a house from brick or logs, and having their own real estate is the desire of every adult citizen. It is for this reason that the choice often leans towards frames.

Secondly, the choice in favor of this technology is because the house can be rebuilt in the shortest possible time. After all, if you take the construction issue seriously and plan the progress of the work correctly, then you can get a finished house within a few months.

And, of course, thirdly, this is the environmental safety of such a structure. Houses using frame technology are made exclusively from environmentally friendly materials.

And for a city dweller this is an extremely important aspect, since modern people are tired of concrete and synthetics.

Possible service life

When deciding what the house will be constructed from, the owner relies not only on the external data of the future structure, but also on how many guaranteed years the frame house will last.

The construction of houses using frame technology has been used for at least 200 years. Initially, such houses were produced in Canada. All this time, disputes between specialists have not subsided: how long such a structure can be operated. Some say that such a house will not last even 30 years, while others cite the example of German half-timbered houses and American cottages, which have already stood for more than 100 years, and this is not the limit.

Official standards also provide for long service life, and the State Construction Committee indicates the possibility of using such housing for 75 years, after which they need to be disposed of. But, as practice shows, such houses are used much longer.

What does it depend on in Russia?

The Federal Ministry for the Construction of Housing and Communal Buildings has determined the service life of frame buildings at 75 years. In reality, these structures last much longer.

A house made of SIP panels sometimes costs more than 150 years;

several factors influence the period of use:

- builders' experience;

- quality of building materials;

- developed project.

An important role is played by how the house was built - with your own hands or with the help of experienced builders. For all building materials, GOST is provided, which determines their service life. But disruption of the construction process significantly reduces the service life of the material. Therefore, the work must be entrusted to professionals.

To calculate the period of use of a building, the following factors must be taken into account:

- compliance with the technological process;

- quality of material;

- reliable hydro, heat and wind insulation;

- quality of the building foundation;

- climate features in a particular region.

Frame house options

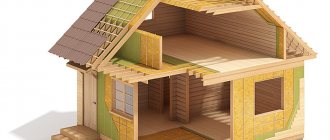

Frame construction has several options, but the main ones are two of them - construction using Canadian technology and panel board construction. Using Canadian technology, SIP panels are delivered to the construction site and, by installing them together in the established sequence, the structure is assembled. With the panel construction option, bars and sheet finishing materials are used when the structure is being erected.

Shelf life of houses using Canadian technology

The service life of a Canadian frame house is much longer than that of its panel-board counterpart. The SIP panel from which the house is assembled using Canadian technology consists of a sandwich of OSB boards with an expanded polystyrene layer. OSB is a multilayer board made from lumber waste. Thanks to the factory production of such panels, the service life of a house made from them can last up to 150 years. The only thing that matters most in this case is a high-quality, strong foundation.

According to standards and experience of use

The main feature, which is also an advantage of a frame house, is the speed of construction. There are several options for this building construction.

Made of wood

The timber is the basis of this frame, after which it is sheathed with various building materials. As a rule, particle boards are used.

The house is insulated using special thermal insulation. The best option is basalt insulation, which can retain its shape well. Mineral wool, after time, slides down, which causes cold bridges to appear. The builders assure that this house will last for 50-100 years.

On a note. It should be noted that half-timbered buildings, which are one of the types of frame structures, have been in regular use for more than 200 years. Therefore, taking into account the analogy, such a building will be able to last longer than the period guaranteed by the builders.

Made of metal

This design is based on a frame made of a special building material - a thermal profile. Its main advantages are high resistance to corrosion, mold and fire.

This house is faced with materials similar to wooden buildings, but in some cases glass-magnesite sheets are used.

This structure can last more than 100 years.

Reinforced concrete frame

In this case, the frame is made of reinforced concrete monolith. First, the foundation is poured, where columns are installed that support the weight of the building. The walls in these structures are constructed from aerated concrete blocks.

Sometimes a metal frame is installed between the columns, filled with basalt slabs, and then sheathed with glass-magnesite or particle boards.

Note! The lifespan of the building is approximately 120 years, and with proper care and repair - up to 150.

About the shelf life of panel houses

The durability of a frame house directly depends on the quality of the material from which it was made. Thus, it is recommended to use bars only of the highest quality, fully dried and properly treated with antiseptics. Subsequently, these bars are sheathed with OSB boards or plywood with a thickness of more than 10 mm.

After a couple of decades, it is strongly recommended to change the thermal insulation material, but even in this case it is necessary to purchase a high-quality one. For this, it is better to use mineral wool or high-quality polystyrene foam.

To extend the life of walls, it is necessary to use reliable hydro- and vapor barrier materials. To extend the service life, it is necessary to install high-quality ventilation in the house, this will avoid diaper rash and dampness indoors.

If all technological processes and construction conditions are observed, the service life of a high-quality frame wooden house becomes almost unlimited, well, in any case, no less than 150 years.

Bridges of cold

Even in very insulated frame houses, the appearance of so-called cold bridges is possible. Because of them, condensation appears on the walls, which leads to mold and destruction of the wooden structure. The effect of cold bridges is the difference in thermal conductivity between the insulation and the frame elements.

This problem can be solved quite simply. To do this, it is necessary to build a house using two cellular frames (double frame), which are positioned by moving one relative to the other. This is a very simple technology that has proven its effectiveness in practice.

The second option to combat cold bridges is to install a reliable heat, hydro and vapor barrier system.

Whose frames are more durable: Western or domestic?

It has long been noted that frames made in Russia are not distinguished by the same quality for which their American, Canadian or Finnish counterparts are famous. The service life of houses manufactured by us is 2 times lower than that of foreign ones. This happens for the following reasons:

Saving on materials by irresponsible developers. For frame construction, only high-quality material should be used;

Due to inexperience, the work is not performed at the proper level. Our consumer and developer are trying in every possible way to save money, but doing this is highly not recommended;

Abroad, construction is treated much more responsibly; the angle of the roof, additional insulation of the leeward wall, as well as all utilities are taken into account.

For this reason, the service life of houses made by our manufacturers is much lower. Recommendation - under no circumstances should you skimp on material.

Thermal conductivity of house walls and its impact on service life

As mentioned earlier, the walls themselves in a frame house without insulation actually have high thermal conductivity (this is terrible, since it will immediately evaporate to the street). Naturally, if you build an entire wooden house without insulating material, the service life will become 3 times shorter! but this can only be done in equatorial and tropical countries, where there are no winters, much less severe ones. But in Russia there is such a problem, and this problem was relevant during the USSR, when frames just began to be built, because at that time there were no high-quality insulation materials.

As for modern building materials, the best in terms of ensuring durability are slabs that are made on the basis of basalt fibers. Naturally, such material for thermal insulation is very expensive, but its performance qualities are at the highest level. Bulk insulation is not used in the external walls of buildings (sandwich panels). It is also better not to use expanded polystyrene, even in slab form. We invite you to watch a video that tells about the service life of the frame.

We choose quality material

The service life of frame houses directly depends on the quality of the material: the higher the quality, the longer the service life of this structure. The most suitable wood for a frame house is pine. Pine lumber is quite affordable, durable and excellently resistant to rot.

Having chosen pine raw materials, you need to know the harvesting time of lumber. Raw materials harvested in winter are of much higher quality; at this time, there is minimal sap flow in the trees, due to which the wood dries much faster. The moisture content of pine raw materials should not exceed 20%.

In addition, you need to pay attention to the presence of knots and the quality of the wood. The grade of material for the frame must be of the highest quality and treated with all necessary impregnations; all reasons must be eliminated to reduce operational life, which will significantly increase the service life of the frame house.

How to extend this period?

To increase the service life of a building, you need to follow the technology of constructing a frame house , and do not ignore the installation of a durable frame, reliable formwork, and ventilation system.

In some cases, it is worth using metal rather than wood when installing the frame. The steel frame lasts much longer, but it also needs to be treated, reducing the possibility of the development of corrosion processes.

The service life of foam plastic is approximately 50 years, membrane film is 100 years, timber is 75 years, mineral wool is 40 years. Choose thermal insulation of the desired thickness and density.

Remember that in the process of contact between metal and wood products, both materials are destroyed. Wood rots and metal rusts, so the joints need to be covered with a septic tank.

It is also necessary to lay waterproofing between wood and concrete, since wood deteriorates over time, and temperature fluctuations speed up this process.

Exterior decoration can also significantly increase the life of the building. Until recently, structures were lined with brick, but now there are more inexpensive ways to protect walls - these are plastic panels.

Mistakes of frame house construction installers

The first mistakes appear already at the design stage. Some, saving on an architect, begin construction without a project or turn to people who do not have the necessary qualifications. Errors include the following:

- Unreasonable replacement of parts. Often, manufacturers or private teams use low-quality material that is not sufficiently dried or dried out. To avoid this, it is worth monitoring the entire construction process;

- The next mistake is that the owners, in order to save money, do not pay for geological work. This happens because many people mistakenly assume that since a frame house is light enough, it does not require a powerful and high-quality foundation. The service life of a frame house depends on a well-made foundation and the presence of floats in the ground. If there is still a floater, then you will have to either change the building site or use a foundation suitable for such soil.

The developer usually offers turnkey construction, or simply the construction of a house without communications. In this case, saving is also not recommended, since in the second case all communications will have to be carried out independently, and the developer is unlikely to prepare the necessary place for this.

An incorrect estimate is also a common mistake. This document must contain information about all estimated construction costs. The lack of detailed information may lead to delays in work due to the fact that some minor detail may be missing.

All these errors can occur at the initial stage, while during the construction itself there can be many times more errors. Most often, unqualified specialists make mistakes; problems can be of the following nature:

- Unsystematic installation of frame posts can significantly reduce the shelf life of a standard frame house. This will be especially noticeable when laying insulation, since proper installation requires a strut pitch of 600 mm;

- Installation of the top trim after installing the first wall. This binding is made exactly along the lower binding;

- Building a house at the wrong time of year. To ensure that the wood does not become saturated with excess moisture, construction must be carried out in the spring or summer, and in no case in the fall or winter;

- It is necessary to build a blind area under the foundation, this will prevent the accumulation of moisture under it;

- Neglect or use of low-quality vapor and waterproofing materials. This is the stage where you should not skimp;

- Installation of double-glazed windows in close proximity to the studs, since when exposed to temperature or moisture, the wood can change in size, which, in turn, can damage the window, thereby reducing the service life of the frame house;

- When installing, use only self-tapping screws. This is also a significant mistake, since they can burst under load, for this reason it is recommended to strengthen these places using nails;

- Installing the roof up to the gables and overhangs will make it extremely difficult to install these elements later;

- The beams must correspond to the given cross-section and not be thicker, since with increased humidity the deformation of the beam may increase;

- Neglecting floor insulation will also lead to the formation of dampness inside the room.

Here, of course, not all possible mistakes that can be made by unscrupulous developers are indicated, saving on time and material. It is recommended to contact trusted contractors and even in this situation it is better to control the work of the team.

Finnish house - the most important structural elements

Based on the type of manufacturing, frame houses can be divided into frame-panel and frame-frame. The first are common in the north, most often one-story, have a gable roof. For the construction of a frame house, parts are produced in different variations - from individual elements (frame, panels, windows, doors) to fully assembled wall panels, with ceilings, and roofs. Factory production with strict adherence to all dimensions allows you to install the box in place in a week.

Finnish houses are most often one-story and have a gable roof.

If the construction of a frame-panel house requires equipment, then a frame-frame house can be built without it. Any design can be used, even your own; DIY construction is possible. First, the foundation is made, the lower frame of the frame house is attached to it, on which the frame is installed, it is strengthened, and the roof is mounted. Only after this they begin covering the frame and thermal insulation. The rest of the work does not differ from the construction of a frame-panel house. You can erect such a building yourself in six months.

Strapping elements ensure the structural strength of structures, reliability and durability. Without the bottom frame, which attaches the frame to the foundation, it is impossible to build a house. In addition to the strengthening and connecting function, it plays a vital role in redistributing the load of the walls of the house to the foundation. It is important to choose the right material for the bottom trim. Coniferous wood is preferable, which is durable and less susceptible to deformation and cracking. The high resin content protects the material from moisture.

The top frame of a frame house combines the internal and external walls into a single, durable structure. It also transfers the load of the floors located above the walls to the roof and distributes it evenly. For the top trim, use a material similar to that used in the bottom, with the same dimensions, so that the cross-section of both straps coincides. If this condition is met, further installation and insulation will be simplified. The upper trim is attached to the racks, which are installed strictly vertically, without the slightest deviation.