- Posted by Anastasia Mikitalo

- Date: October 11, 2017

The developments of past centuries are taken as the basis for new building materials. Thus, shingles were used by our ancestors for many years as the main roofing covering that met the requirements of the standard of that time. Such a roof not only looked beautiful, but also provided reliable protection of residential premises from various kinds of negative factors. Modern developers classify shingles as refined, expensive materials that require special skills to perform flawless installation. Despite the lack of craftsmen who are well versed in the technology of work, as well as the high cost, you should pay attention to a shingle roof that will last for many decades.

- 2 Features of manufacturing roofing shingles

2.1 Instructions for preparing roofing shingles with your own hands2.1.1 Video: how to make shingles with your own hands

- 3.1 Video: laying shingles on the roof with your own hands

- 4.1 Service life of roofing shingles

Basic principles of plastering work

The quality of plaster application depends on the preparation of the base and the prepared mixture. It is necessary to follow the manufacturer’s recommendations and be guided by SNIP. The human factor is also important: the qualifications of the master.

As a result of treating walls with plaster, the surface should be smooth and free of cracks. The mixture recipe largely depends on the base material: brick, wood, concrete. An important factor is the operating conditions of the structures: the exterior decoration or the interior of the room. Plastering various surfaces involves applying the mixture in several ways:

- By throwing method.

- Spreading method.

General information

Difference between wood chips and shingles

The “chip” variety is more textured and rough, while shingles are considered a well-processed material. For this reason, the appearance of shingle and chip siding panels, despite many similarities, is different. In shingles, each “scale” is usually either the same or similar in size, while in chips it is specially made in relief and different to imitate untreated wood.

Manufacturers of shingles

T-siding, TZK Tekhosnastka LLC

Despite the fact that you can buy shingled siding in Russia, no one complained that the material was from a domestic manufacturer. There are no complaints about the quality, and this is pleasing, especially since the plant has been operating since 2009. The T-siding collection with imitation wood chips is called “Chip Oak”, and as the name implies, it imitates oak chips.

A house that is covered with such material will be 100% different from neighboring houses with a unique appearance. And one more interesting property: you can install “Chip Oak” panels on the roof as a roofing material. In this case, you will get an interesting house that is different from the rest. Naturally, when finishing a roof with this type of siding, you should very well prepare the base on which it will be installed, and the installation method will differ from the standard installation of a siding panel on the walls. T-siding is precisely the material that has been tested by time, so that you can safely recommend it to customers when covering a house.

Nailite facade panels (USA)

This type of panel was the very first to appear in Russia. Most often they were installed on the base during the process of covering the house with siding. They are quite expensive, and not every person can afford such finishing of the basement, not to mention the entire house. Now, due to the fact that the dollar exchange rate has become higher, the panels have become even less affordable, but it is still possible to buy them and even save a little (but we will talk about this at the end of the article). Nailite produces shingle siding in as many as three collections:

All photos were taken from the official website of the production nailite-siding.ru. If you want to order siding with imitation shingles or wood chips from this company in St. Petersburg, then there is a high probability that it will be made to order and you will have to wait from 1 to 1.5 months. Take this into account when upholstering your house.

Facade panels Foundry (USA)

Oddly enough, information about these panels was found by accident. They were used already in 2012, in particular for the construction of frame houses. Such panels can imitate cedar chips, and are quite realistic in both appearance and touch. The interesting thing is that even to the touch the panels give the impression of wood - warm and rough, like real wood, although they are completely made of artificial material.

Surface of panels under shingles

As a rule, all manufacturing companies that produce facade panels make material with imitation shingles or wood chips, which are as similar as possible to real wood. For this reason, most often you will feel that the surface of the material is rough, and even more so than that of standard siding panels. In the case of shingles, the roughness is not so great, but the chips will always be rough.

Color palette

It is interesting that although there are not many manufacturers of shingle siding, there are more than enough colors. The problem is that most colors of panels for facades under shingles or wood chips are made only to order. Each manufacturer has panels that are painted in 2 or more colors, which makes it possible to give the panels the appearance of natural wood and avoid that unwanted “artificiality” for which ordinary siding is disliked.

T-shaped siding for wood chips is available in 5 colors. Nylight is 18 for shingles and 12 for chips, and Foundry is 9 (in the vintage collection) and 21 shades in the standard one. If you want to cover your house with “chip” façade panels, or vice versa, shingles, then no matter which manufacturer you choose, you will probably get the shade you wanted.

Dimensions

Most often, the sizes of shingle or chip siding panels are smaller than those of conventional siding panels.

Installation

As with other façade panels, installation of siding under wood chips and shingles is practically no different from installation of standard siding panels. It is required to make the same frame, ventilation gap and protection from wind and water. If you plan to insulate the house under the panels, be sure to install a vapor barrier film under the insulation layer.

T-shaped siding is a little easier to install, since the panels are not too long (they are 1.5 times shorter than those of Foundry and Nylight). If installation work is carried out by non-professionals, then such siding will help hide some of the mistakes. But it will still be better if you ask for help so that everything is completed on time, accurately and according to technology.

Modern methods of plastering wooden walls

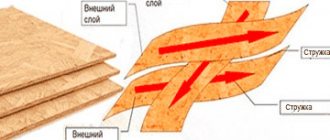

The plaster shingles are first filled across the entire width of the working surface - this is the beginning of the process. The name speaks for itself. The shingle is a kind of base on which the second layer of shingle is attached at an angle of 450 relative to the floor. In this case, you can use curved and narrow dies.

Note!

The thickness of the working dies should be less than 3 millimeters. Using a material of less thickness will not allow the shingles and mortar to bond well; we need adhesion.

The second layer is filled with the exit shingles at the same angle as in the first case. And in relation to each other, the location should be perpendicular: the contact angle is 900. The distance between the dies should be 450 mm. These indicators must be maintained in the second row. As a result of the work carried out, a mesh with cells of 450/450 mm should be obtained. This will give rigidity to the entire structure.

When arranging wooden buildings, thick, even dies up to 5 mm thick and 15 to 20 millimeters wide are selected for the second layer.

Take note!

It is important to observe the specified dimensions, since the use of material less than 10 millimeters wide may “fail” when driven in: it will simply crack.

If you use material more than 20 mm wide, this may cause the dies to bend and not have time to dry.

Benefits of use

Laying shingles is a long and labor-intensive process that requires professional skills and certain financial investments. At the same time, shingles have a number of advantages compared to many modern types of finishing:

- is a pure natural material that allows air to pass through, perfect for interior decor in any room, including bedrooms and children's rooms;

- simple and accessible, does not burden the structure of the house, installation does not require complex equipment or additional materials;

- resistant to winds, precipitation, ultraviolet radiation, provides sound and heat insulation;

- can be installed at any time of the year due to its resistance to temperature changes, suitable for unheated rooms.

Also worth adding:

- Versatility. Shingles can be used not only when cladding the roof, but also when decorating the façade of a building, walls and enclosing structures.

- Long operational period. Such a roof will last you from thirty to fifty years. If you treat the materials with a primer and varnish before use, this will extend their service life by another ten years.

- Light weight. Wooden plates are lightweight, so they can be mounted on any structure, regardless of the type of base.

Shingles look organic and natural in any application; the variety of shades and textures of wood allows you to create original compositions indoors and outdoors and give homes a unique look.

Author: A.N. Ivanova

What is shingles

Plastering on shingles involves the use of natural materials - wood. Shingles are a narrow plank 2-5 mm thick with a length of up to 1-2 meters. The most common material for covering a plastered ceiling and not only is coniferous trees. They contain large quantities of resin substances, which, as a natural antiseptic, resist the development of mold and bacteria.

You can make plaster slats yourself, but this is not cost-effective: it’s a lot of hassle. The cost of slats, which are made from third-grade wood in finished form, is small. Therefore, it is better to buy a ready-made mesh with cells in the form of diagonal diamonds. They are always on sale and sold in packs of 50 or 100 pieces. The use of shingles in plastering work facilitates the process and allows us to talk about reducing the cost of surface treatment.

Features of care

Facade shingles, as this material is also called, does not require complex maintenance if it is made of larch. But pine products are not so durable and require periodic treatment with protective compounds. At the same time, it is possible to refine the shade of wood using stain or special paint.

Sawn dies, unlike chipped ones, have a rough texture and absorb moisture more strongly. Therefore, to increase their service life, they are treated with protective compounds. And they do this before attaching them to the facade.

PDF - top 10 mistakes when choosing a contractor

Take

Loading a timer

How to choose material for shingles

To fasten the mortar of the walls of a wooden house, thin plaster shingles with a thickness of 3-5 mm and a length of 1.5-2 meters are used. Experts recommend these particular material parameters, since it is convenient to attach a narrow strip in several layers. They are usually used on small work areas.

When finishing large areas, it is better to use a shingle panel. This is a ready-made structure of large dimensions, which, after fastening it to the work surface, is ready for use.

There is one inconvenience: transporting the assembled shield is problematic.

In addition to wood, thermal insulation materials are needed for work. It can be felt, matting or burlap. The material must be laid out under the structure and treated with an antiseptic.

Performance characteristics

The plates have a thickness from 3 to 8 mm. Their width varies from 8 to 16 cm, and the length can be either the classic 30–50 cm or the extended 80–100 cm. They are distinguished by noticeable flexibility, due to which the installation of a special sheathing is required for durability.

Shingles are free-breathing materials. Periodically, it swells and dries out under the influence of the external environment, which allows air to penetrate through the product. Even sudden changes in humidity and temperature will not have a negative impact on the appearance or basic properties of the coating.

Light weight is one of the most important properties of shingles. Thanks to it, the overall load on the foundation and rafter frame is reduced. This ensures reliability and safety for the entire building, not just its roof.

This type of roof prevents heat loss during the cold season. Therefore, the house will always be comfortable. And in the summer heat, overheating will be excluded, which is no less important for the well-being of all residents.

Interesting! The sound insulation of shingles is so high that people inside the house will not hear the impact of raindrops on the roof.

Preparation for plastering

Working with wood involves the use of certain fasteners. Experts recommend abandoning self-tapping screws and using ordinary nails.

Their length can vary from 25 to 40 millimeters. It all depends on how many layers of shingles are used. Usually this is two layers, although it can be more. The diameter of the products is 1.5-2 mm.

Those who want the thermal insulation functions of a wooden house to be at a high level should use the simplest thermal insulator, which is felt.

It is rolled out along the entire perimeter of the wall, nailed, after which the felt must be treated with antiseptic compounds. Before putting shingles on it, the felt is allowed to dry a little.

About the work order:

- Forgive is stuffed onto the prepared wooden surface. The first layer of planks is mounted at an angle of 450 relative to the floor. The distance from plank to plank (step) should be 45 mm. At the initial stage, you can use curved and narrow dies. It is important that the hollow of the element does not exceed 3 mm.

- The stuffing of the sheet shingles is the base on which the second layer is stuffed. Higher quality wood is used here. The design should be in the shape of a diamond with cells of 45/45 mm.

- Stuffing the output shingles completes the job. The thickness of the narrow exit shingles should be within 4-5 mm. Now you can apply the prepared solution and perform finishing work.

To plaster shingles correctly, you need to use a special tool, which you can read about below.

Installation

The technology for installing wooden planks is carried out according to the principle of manufacturing ventilated facades. It's necessary:

- for natural ventilation of wood;

- moisture removal;

- maintaining the thermal insulation properties of the material;

- to maintain a healthy indoor microclimate.

See also: Façade construction

The planks are fastened over the lathing in 2 layers, and care must be taken that the rows on adjacent walls coincide. The dies are attached to nails or staples, which are covered with elements of the outer layer.

When installing sawn planks, the planks are shifted strictly by half their width relative to the bottom row. The installation step varies depending on the length of the strip.

| Length of the bar, mm | Mounting pitch, mm |

| 120 | 50 |

| 150 | 65 |

| 200 | 90 |

| 300 | 140 |

| 400 | 180 |

| 600 | 280 |

| 800 | 375 |

How to apply the solution

To get a high-quality surface, it is important to work with good plaster and primer. The process involves applying three layers of solution.

- At the initial stage, you should slightly wet the felt.

- Next, mark using a marker. Determine the irregularities of the sheathing. Apply the first layer of mortar no more than 1.2 centimeters thick. Experts recommend keeping the thickness of the rough layer to no more than 9 millimeters.

- Spray is the first layer of clay mixture. It must dry and only after that a layer of soil is applied. If gypsum-based compositions are used in the work, then the layer should be within 7 mm. When using cement-sand mortars, the working layer is up to 5 mm.

- When applying the spray, it is important to fill all voids. At this stage it is not necessary to level the work surface. Approximately the same level of applied solution is sufficient.

- Next, it takes some time for the primer to dry a little: the second layer is applied.

- The third layer is applied using the same technology. Here it is important to pass the solution through a sieve with small cells and prevent the appearance of lumps. The finishing layer is applied to the ground. The work uses a rule and a grater. The working area must be rubbed with a plastic float. The movements are circular and measured.

At this point the work can be considered completed, and the plaster on the shingles needs to settle: time is needed to dry the finishing layer.

Request a call

Search for "shingles" : Google Yandex

Comments

0 RE: Shingled roofing, wooden tiles, shindle and shingles. Finishing with shingles. — Alexander 05/04/2021 08:19 I quote Ivan:

Tell me, you have written that shingles can be used for the facade. But she will probably turn black later? Or is there a special technology here?

It won't turn black.

There is a special treatment of wood, after which it does not turn black for many years. We can advise you in more detail by phone. Quote 0 Shingles for the facade - Ivan 04/26/2021 08:11 Tell me, you write that shingles can be used for the facade. But she will probably turn black later? Or is there a special technology here?

Quote

Update list of comments RSS feed of comments for this entry

Kinds

The options are:

- shingle: a triangular wooden profile, one edge is thinner and the other has a longitudinal groove for a strong joint. To make it, the material is cut in the radial direction; shingle roofing is considered one of the most practical and durable;

- shindel: a Western European version of dies made only from thick larch logs. They are first divided into quarters, then into thin blocks, then each is planed, giving the required length and thickness. Then the ends are trimmed.

The edges of the dies can be cut straight, obliquely, diamond-shaped, rounded, or at various angles. Curly cuts provide the most decorative appearance of the finished roof.

Cost in St. Petersburg

As you guessed, the façade panels described above are not the cheapest. As a rule, such materials are bought by those people who do not intend to save money, do not chase after the cheapest, but value high quality, beautiful appearance and uniqueness. For this reason, the cost of panels with imitation shingles and wood chips is quite high.

The cost of T-siding under shingles in St. Petersburg in 2022 from different suppliers ranged from 450 to 500 rubles per panel. Foundry and Nylight cost approximately 490 rubles per panel. If you have already decided for yourself what types of panels you want to buy, then remember that many colors need to be ordered in advance and you will have to wait a certain time (1-1.5 months).

Source

Raw materials

Coniferous species with smooth fibers that split well are excellent as raw materials: larch or pine. Soft deciduous wood is also used: aspen or linden. But the strongest and most practical are considered to be dies made of durable wood - oak or beech. To ensure water-repellent properties, increase resistance to rotting, and exposure to adverse weather conditions, the finished plates are coated with natural impregnations or soaked in drying oil.