SHARE ON SOCIAL NETWORKS

FacebookTwitterOkGoogle+PinterestVk

Specialists who have repeatedly used metal cutters for a lathe in their practice to perform certain jobs clearly understand what types of these tools there are. For beginners who encounter these elements for the first time, it is difficult to understand what is the distinctive feature of each specific model and how to choose the right tool to perform certain tasks. This article will help you understand this important issue.

Turning cutters are the main working tool of metalworking machines, through which the processed workpieces are given the required shape and size

Lathe cutter design

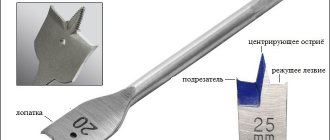

Different types of cutters for a lathe differ in shape, the presence of additional blades, and teeth. However, the overall design remains unchanged. The equipment consists of two main elements:

- Rod is another name for “holder”. A piece of equipment that is attached to equipment.

- Working part. The sharpened element of the cutter that comes into contact with the workpiece. Depending on the design features, the plate in contact with the workpiece may consist of many cutting edges and working planes.

When working with equipment for turning equipment, we must not forget about the importance of sharpening angles of the working part. There are three angles in total, changing which will affect the result.

Features of the design of a metal turning cutter

The design of the element consists of a cutter holder, thanks to which the tool is fixed on the machine, and a working head, which directly processes the surface of the workpiece. The holder may have a square or rectangular cross-section. The working part of the tool is formed from several adjacent planes and cutting edges. Their sharpening angle depends on the characteristics of the material being processed and the type of processing.

To achieve the specified parameters of the part, the cutter and workpiece fixed in the machine move relative to each other

The working head can be solid or with welded or soldered plates. New are metal cutters for lathes with replaceable inserts. The first option is presented as a one-piece element with a holder. Such a tool can be made of special high-carbon tool or high-speed steel. But such cutters are used extremely rarely.

Mostly for metalworking on a lathe, cutters with welded or soldered plates are used. The tool is made from high-speed steel or a hard alloy containing metals: titanium, tungsten and tantalum. It is distinguished by its high strength and pricing policy. This turning tool can be used for processing products made of non-ferrous metals, cast iron, any steel and non-metallic materials.

Important! When working with carbide inserts, you should adhere to safety rules, since the products are very fragile.

Very often, when processing materials, turning cutters with replaceable inserts are used. Unlike the previous version, the plate is attached to the head mechanically using special clamps or screws. The tool is convenient for further use if the plate is made of mineral ceramics, which significantly increases the cost of a cutter with replaceable plates.

A variety of metal turning cutters with replaceable inserts

The working part for a lathe cutter can be made of hard alloy (tantalum-tungsten-titanium, titanium-tungsten, tungsten), high-speed steel (high or normal efficiency), high-quality carbon steel. Cutters can be used for such types of lathes as planing, turning, slotting, turret and special.

Cutter geometry

There are different types of cutters, which differ in size, shape of the holder and the number of planes on the working head. For example, the rod for securing the equipment can be round, rectangular, or square. The working element of the device is a set of surfaces

— Incisors are divided into right-handed and left-handed. The difference lies in how the cutting edge is positioned relative to the holding part.

Types of planing cutters

Planing products differ from turning products by having a backward curved head and a top that does not coincide with the reference plane of the tool. This design is explained by the technological features of metal processing. If the cutter were not curved, it would break under the pressure of the removed layer of metal.

Image No. 3: types of planing cutters (diagram)

According to the type of work performed, tools are divided:

- on passages for horizontal planes;

- cutting for ledges;

- for cutting workpieces;

- shaped for working with complex surfaces.

Classification of cutters for turning

There are state standards that describe the classification of turning tools. One of the classifications is the division according to the type of processing of metal surfaces:

There is a division according to the type of material from which the working part of the equipment is made. A separate classification concerns the integrity of the equipment design:

- One-piece fixtures. They are accessories for lathes made from alloy steel. Models made of tool steel are rare.

- Devices with additional plates. They are made at the factory from different types of hard metals and alloys.

- Models with removable plates. They are fixed to the holder using screws. Rarely used during serial processing of metal parts.

The main classification is the division of devices into separate types according to shape and design. We need to talk about them separately.

The process of sharpening cutters for metal

To sharpen cutters, sharpening and grinding machines with a constant cooling function are used. The main surface of the product is first sharpened, then the back and additional surfaces. At the final stage, the original configuration of the front face is returned.

Photo No. 11: the process of sharpening the cutter

For the operation, two grinding wheels are used: silicon carbide and electrocorundum. Silicon carbide is suitable for machining high-speed steel products. Electrocorundum is made from carbide materials. To check the degree of sharpening, special templates are used.

Boring cutters for through holes

This is equipment for industrial equipment. It is used for boring holes created by drilling. The depth of machining of the holes depends on the length of the part fixed in the caliper. The element with the cutting edge has a bent head. The thickness of the material removed by the cutting edge is almost equal to the bend. The maximum length of the holding part is 300 mm.

Types of cutter wear

The cutting tool wears out during use.

- Wear on the rake edge occurs due to friction of the chips on the tool surface. As a result, a depression is formed on the edge, located behind the build-up of the stagnation zone (1–2 mm from the edge).

- Flank wear occurs due to its friction against the machined surface. As a result, a wear area appears on the edge.

Typically, the front edge wears during roughing, and the back edge wears during finishing.

There are several stages of tool wear:

- running-in;

- steady wear;

- critical wear.

We recommend not bringing the cutter to the last stage, as this leads to its destruction and shortening its service life. Sharpening will allow the tool to return to its original geometry.

Prefabricated cutters

Perform various technological operations. The design allows you to attach different carbide inserts to the holder. The presence of several working elements allows you to increase the versatility of the device. The cutters, which are assembled from different plates, are fixed in the spindles of equipment controlled by a CNC system. Using prefabricated devices, holes are machined, contours are made, and grooves are selected.

Prefabricated structures

Speaking about the types of devices for metal processing, it should be noted that cutters have a prefabricated structure. This instrument is considered universal because you can put almost any records in it. For example, by fixing different types of cutting blades in one holder, you can make a device for working with metal workpieces at different angles and with different levels of productivity.

In most cases, these types of cutters are used on machines equipped with CNC, or for boring through and blind holes, contour high-precision turning and other work.

Features of thrust, scoring and parting

The thrust tool may have a straight or bent working element. This tool can be used to machine cylindrical metal alloy workpieces. Many specialists often use this type of gear.

Scoring cutters on the outside have similar features to through cutters. Only the first tool has a triangular cutting insert. It contains a solid metal alloy.

The cutting type tool has become the most common. With the help of such gear you can cut material at right angles.

In addition, they are used for making all kinds of cuttings on metal parts.

The peculiarity of this type is that it has a thin leg with a carbide plate soldered onto it.

See also: The most expensive metals in the world

Turners use cutters and other varieties

- To cut external and internal threads;

- Treat through and blind holes.

Any type of turning tool has its own characteristics and purpose.

High-quality work with sharpened knives

To ensure quality work, you need to constantly sharpen your tools. In the mechanical engineering industry, specialized equipment with accessories is used.

Grinding machines use two abrasive wheels. White circles are used for turning steel parts. The second circle with a green tint is filled with a carbide plate.

Blades are sharpened in the following sequence:

- Main rear corner;

- Auxiliary back angle;

- Front corner;

- Make a rounding along the radius.

Coolant is used to sharpen blades. You can constantly feed it, just like during grinding. Replaceable inserts do not require re-sharpening.

Rating of the best turning tools for 2022

The product review was compiled based on customer reviews of online tool stores and the Yandex Market platform. There are three categories: according to cost - cheap, expensive, sets consisting of 6 or 12 tools.

Cheap (from 68 to 265 rubles)

5th place Boring through 25x25 VK8

Price: 265 rubles.

Manufacturer: Russian brand “INIGS”.

Type – boring through. Specifications (mm):

- holder 25*25;

- length 200;

- weight 980 g.

Alloy – VK8 (cobalt 8%, tungsten 92%). GOST standards – 18882-73.

Used when boring through holes (conical, cylindrical). Can be used on objects made of alloy steel, stainless steel (of varying hardness), cast iron, non-ferrous alloys, plastic, titanium.

Boring through 25x25 VK8

Advantages:

- wide application on different materials;

- durable composition;

- standard parameters.

Flaws:

- not identified.

4th place Straight through 20x12 T5K10

Price: 68 rubles.

Manufacturer – Kanashsky IZ (Russia).

Type – straight through.

Parameters (mm):

- length – 120;

- holder section – 20*12;

- weight – 0.2 kg.

Alloy – T5K10. Used for chamfering, turning parts from non-rigid materials, stepped shafts, protruding parts.

Straight through 20x12 T5K10

Advantages:

- easy to find in stores;

- performs many functions;

- compliance with GOST standards.

Flaws:

- not identified.

3rd place Trimming bent 16x10x100 T5K10 2112-0086

Cost: 102 rubles.

(Russia).

Type – bent scoring with soldered plates. Right feed direction.

Parameters (mm):

- length – 100;

- width – 16;

- weight – 400 g.

Materials: plate – T5K10, holder – steel 45. Compliance with GOST – 2112-0086.

Functionality: ledges (at right, sharp angles), turning along the axis, processing of end parts.

Bent trim 16x10x100 T5K10 2112-0086

Advantages:

- compliance with the requirements;

- universal alloy;

- wide application;

- you can work at higher modes.

Flaws:

- not identified.

2nd place Bent 25x16x140 T5K10 2102-0005

Price: 235 rubles.

Manufacturer – Russia.

Type – bent through.

Specifications (mm):

- length – 140;

- width – 16;

- weight – 400 g.

T5K10 alloy is used. The product is made according to GOST parameters.

Functions: roughing and finishing, cutting ends and sides, stepped parts.

Bent 25x16x140 T5K10 2102-0005

Advantages:

- hard alloy;

- compliance with GOST;

- performs many functions;

- easy to find on sale.

Flaws:

- not identified.

1 place Straight through 16x10x100 T5K10 2100-0401

Cost: 99 rubles.

Product from a Russian manufacturer. Refers to the type of straight line.

Parameters (mm):

- length (L) – 100;

- width – 20;

- weight – 380 g.

Material – T5K10. Manufactured according to GOST 18878-73, designated 2100-0013.

It is used when processing various shapes and materials.

Straight through 16x10x100 T5K10 2100-0401

Advantages:

- universal application;

- quality composition;

- Russian manufacturer;

- low price.

Flaws:

- not identified.

Expensive

They differ in structure - they have threaded plates, functionality - processing of wooden and metal objects.

5th place HSS Line Profi 16 mm Narex 819316

Cost: 7,230 rubles.

(Czech Republic).

Purpose – processing of wooden blanks. Consists of a handle (elongated shape, material – light natural beech), a brass cap. There is a steel blade and a hard alloy roller.

Dimensions (mm):

- total length – 395;

- plate diameter – 16;

- blade – 150;

- handle – 315.

Product weight (packed) – 360 g.

The product is made of HSS steel with hardness HRC 64 (blade), natural beech (handle). The surface is ground and polished.

HSS Line Profi 16 mm Narex 819316

Advantages:

- high quality steel;

- blade strength;

- for wooden elements;

- comfortable handle shape made of natural wood.

Flaws:

- high price.

4th place Cutting groove for replaceable inserts MGEHR1010-1.5

Price: 903 rubles.

Manufacturer – . Designed for processing metal elements. Features: Replaceable plates (MGMN150).

Dimensions (mm):

- length – 100;

- width – 10;

- height – 10.

Weight – 100 g. Made in right-hand version (R).

Functions: processing of external grooves, cutting of the required size.

Cutting groove for replaceable inserts MGEHR1010-1.5

Advantages:

- replaceable plates;

- GOST standards;

- available for sale.

Flaws:

- plates must be purchased separately.

3rd place Cutting tool for replaceable inserts ZQ2525R-4

Cost: 1,283 rubles.

The product is manufactured.

Purpose: cutting grooves, cutting metal elements. Features: replaceable inserts with one cutting side, rigid structure, low deformation.

Parameters (cm):

- length – 15;

- width – 2.5;

- height – 2.5;

- plate width – 0.4.

Weight – 720 g. Depth of the resulting groove – 2 cm.

Correct execution of the product. Plate type – SP400.

Cutting machine for replaceable inserts ZQ2525R-4

Advantages:

- processing of metal parts;

- high-quality element designs;

- long-term use;

- one functional side of the plate.

Flaws:

- not identified.

2nd place For replacement inserts for external turning 25mm WWLNR2525M08

Price: 1,283 rubles.

.

Features: W-trigonal shape of the plate, angle – 95⁰, fastening W-clamp with a wedge clamp on a pin.

Dimensions (cm):

- total length – 15;

- holder section – 2.5*2.5;

- width – 7.

Weight – 850 g.

Product brand – WWLNR, plate – WN-0804.

Functions: chamfering, trimming, external turning.

For indexable inserts for external turning 25mm WWLNR2525M08

Advantages:

- reliable fastening;

- plate shape;

- functional;

- durability of materials.

Flaws:

- plates are not included.

1 place Thrust and contour pass-through for replaceable inserts MDJNR1616H11

Cost: 1,074 rubles.

The product is manufactured (Russia).

It differs: fastening system – M (combined clamp), main angle 93⁰, right-hand feeding direction.

Characteristics (cm):

- length – 10;

- width, height – 1.6;

- cutter length (working part) – 3.15.

Weight – 230 g. Suitable plates DN-1104.

Functions: contouring, longitudinal, transverse turning.

Pass-through thrust and contour for replaceable inserts MDJNR1616H11

Advantages:

- performs many tasks;

- suitable for roughing;

- combined fastening.

Flaws:

- not found.

Sets

They consist of several items (from 5 to 12 pieces) and have different functionality (working on metal, wood).

5th place Woodworking set Enkor 10430, 8 items

Price: 7,440 rubles.

Manufactured (Russia, Voronezh) in China.

The set consists of 8 tools. Sold in a light-colored wooden box with a hinged lid. Contents - instructions for use.

The tools consist of a blade, a handle, and a ferrule.

Materials: blades - high-speed steel, handle - wood with a multi-layer cherry varnish coating.

Case parameters (cm):

- length – 44.5;

- width – 31.5;

- height – 4.5.

The weight of the box with tools is 2.6 kg.

Functionality: roughing, cutting off excess parts, facing, turning rounded shapes.

Woodworking set Enkor 10430, 8 items

Advantages:

- the number of different blade shapes in one set;

- comfortable handle;

- easy to store and transport;

- suitable as a gift for a beginner;

- attractive tool design.

Flaws:

- sharpening required.

4th place Set METALMASTER 18978, 5 pieces, wood

Cost: 11,499 rubles.

Manufacturer – (Russia).

Consists of 5 tools, wooden box with lid. There is a company logo sticker on the top of the lid. Bottom sides - the inscription “Made in Russia”, compliance with GOST.

Specifications (mm):

- blade length – 150;

- handle length – 330;

- blade width – 24.

Material: blade – steel R6M5 (hardness HRC 64), wooden handle – birch.

The set includes cutters:

- Cut-off.

- Right oblique.

- Rip-off.

- Section 30 mm.

- Section 12 mm.

The tools are manufactured according to GOST 19265-73 standards and are intended for working with wooden products.

Set METALMASTER 18978, 5 pieces, wood

Advantages:

- quality steel;

- high hardness;

- comfortable handle;

- popular assortment;

- beautiful wooden case.

Flaws:

- only 5 items.

3rd place Set Proma (25330808), 11 pcs

Price: 4.020-4.455 rubles.

Manufactured (Czech Republic).

Consists of 11 items, with a soldered VK8 plate. Suitable for Proma SM-300,350 lathes, mini-machines from other companies.

Dimensions (cm):

- length – 8 (9 pieces), 12.5 (2 pieces);

- cross section – 0.8*0.8.

Weight (with packaging) – 0.600 kg.

Packaging – cardboard box (length – 16 cm, width – 6 cm). Each tool is packaged in an individual zip bag.

Equipment:

- Passing straight.

- Passing bent right.

- Boring passage.

- Boring persistent.

- Shaped.

- Threaded (external thread).

- Grooved.

- Passing bent left.

- Cut-off.

- Tortsovy.

Functions: longitudinal grinding, trimming, cutting, external threading, chamfering.

Proma set (25330808), 11 pcs.

Advantages:

- a large set of items;

- performs basic types of work on the machine;

- simple packaging;

- affordable price.

Flaws:

- needs sharpening;

- no internal thread cutting.

2nd place Cutters for lathe FD 150/E, 6 x 6 x 60 mm, 6 pcs. Proxxon (24524)

Cost: 6,072 rubles.

Manufacturer: German.

It is used when processing metal and plastic elements.

Consists of 6 tools, packaged in a wooden box with a retractable lid.

Product parameters (cm):

- length – 6;

- cross section – 0.6*0.6.

Material: cobalt high-speed steel (HSS), case-hardened.

Suitable for the tool holder of the FD 150/E lathe.

Cutters for lathe FD 150/E, 6 x 6 x 60 mm, 6 pcs. Proxxon (24524)

Advantages:

- common types of incisors;

- quality work;

- durability of products;

- convenient packaging.

Flaws:

- recommended only for a specific machine.

1 piece Set of turning tools for metal 10x10 VK8 12 pcs

Price: 5.627 rubles.

The set consists of 12 pieces with soldered plates and a wooden box. retractable cover.

Equipment:

- Passage bent.

- Passing straight.

- Grooved internal.

- Left trim.

- Cut-off.

- Passing persistent straight double-sided right.

- Passing persistent straight double-sided left.

- Boring (blind holes).

- Boring (through holes).

- Trimming.

- Passing bent left.

- Threaded (external thread).

Material – hard alloy VK8.

Compliance with GOST standards. Suitable for household machines.

Weight (packed) – 1.3 kg.

Set of turning tools for metal 10x10 VK8 12pcs

Advantages:

- a large number of tools;

- high-quality alloy;

- multifunctional;

- convenient storage, carrying;

- Suitable for most machine models.

Flaws:

- not identified.