Despite the modern abundance of various building materials, wooden houses remain traditional in almost all regions of Russia. From time immemorial, their log houses were erected in both urban and rural areas. Nowadays, the possibilities of using wood have expanded significantly - today, processed timber is widely used for the construction of residential buildings, frame structures made of lumber and plywood or chipboard (OSB) are used.

Painting a wooden house inside

Every home owner, when choosing natural wood or materials based on it to build a house, wants it to retain its original qualities for as long as possible. Therefore, painting a wooden house inside, as well as outside, is a mandatory process to create conditions for long-term operation of such buildings. In addition, this significantly expands the horizons in the possibilities of both external and interior design.

Reasons for the need to stain wood

Why is it generally necessary to treat wood with various paints and varnishes? It would seem that the natural texture of wood is attractive in itself, and in most cases there is no particular need to embellish it? And all this is due to the fact that impregnation and painting of wood is capable of preserving its physical and aesthetic properties for the longest possible time, such as integrity, strength, warmth, environmental friendliness of the material and the beauty of its textured pattern.

As you know, the first enemy of wood is moisture, which, when it penetrates the structure of the material, has a destructive effect on its fibers. As a result, they swell and deform, losing elasticity and strength. Inside a house with damp walls, various fumes that are unpleasant for the senses inevitably dominate, which easily permeate the structure of the wood. In addition, dampness always “kicks off” the biological decomposition of wood, causing the appearance of mold and blue stains, which, in turn, in addition to creating an unhealthy atmosphere in the premises, also weaken the strength of the building material.

Paint and varnish products, as well as special protective compounds, are primarily designed to protect wood from negative external influences and preserve its structure from destruction. And, of course, the task is always to preserve the aesthetic texture of the wood unchanged or to decorate it in accordance with the intended interior design.

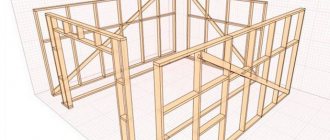

Profiled and laminated timber: differences in the process

Sanding allows you to improve the appearance of walls and prepare them for high-quality painting, waxing or varnishing. For profiled and glued material, the process is different:

Profiled timber. Usually processed in two steps. The first time is sanded with a coarse abrasive (a wheel with a grit size of No. 40), even at the construction stage. The second treatment (final polishing) of the walls is carried out after completion of the shrinkage process.

Glued laminated timber. This building material is carefully processed at the production stage, does not shrink strongly and therefore does not require preliminary deep grinding like its profiled counterpart. To process walls made of laminated veneer lumber, nozzles with a circle are used, starting from No. 80

Sanding must be done with care - excessive force may damage the outer lamella.

Materials for preparing and painting wood for interior decoration

Solutions for preparing wood for painting

The entire process of preparing wooden interior wall surfaces for painting consists of three stages - cleaning, sanding and treatment with protective agents.

Before moving on to the characteristics of paint and varnish decorative compositions, it is necessary to first consider solutions designed to protect wood from negative influences that destroy its structure, such as high humidity and ultraviolet rays, from damage to the material by various harmful insects, mold, fungus, moss and other parasites representatives of microflora. Some solutions include not only antiseptics, but also fire retardants, which are designed to significantly reduce the risk of wood fire in the event of emergency fire situations.

So, before painting, the wood must be treated with special antiseptic agents.

When purchasing a solution for primary wood treatment, be sure to pay attention to the permissible area of application of the composition

When purchasing one of the protective solutions available for sale in a fairly wide range, you need to pay attention to the packaging label (label). It must indicate the area of its application, that is, a specific composition is intended for internal or external work.

Protective compounds can be transparent, preserving the completely open texture of the wood or giving it a glossy brightness or soft matte finish. However, there are also tinting solutions that make the material one or more shades darker.

There are several types of different solutions that can be intended to protect against various negative influences on wood - these are conventional and biomoisture-protective antiseptics, fire retardants, bleaching and primer compounds. To understand how they differ, it is advisable to consider each of them. This will make it easier to make the right choice.

Prices for wood antiseptic

antiseptic

- Antiseptic solutions are designed to combat fungus and mold that have appeared on wooden surfaces, as well as to prevent the formation of new formations. These compositions, in turn, are also divided according to different criteria.

An example of a high-quality antiseptic with a tinting effect.

So, you can find two types of antiseptics on sale - impregnations and coatings:

— Impregnations are designed to penetrate deeply into the wood structure. When purchasing this version of the solution, you need to carefully study its composition, since some of these treatment agents are very toxic;

— Coating solutions create a film on the surface of the wood and protect it from moisture. They are especially relevant for covering walls in rooms with high humidity, for example, in a bathroom or bathhouse.

Antiseptic solutions are produced on different bases, and according to this criterion they are divided into the following:

— Water-soluble compounds are environmentally friendly, so they are excellent for treating indoor walls. They are usually used under paints that are also water-based. A significant disadvantage of such antiseptics is that over time their protective qualities decrease.

— antiseptics made on an organic basis have high protective properties. However, they are more suitable for the facades of wooden houses, since they contain toxic components and are also unsafe in terms of flammability during application and before drying.

— Oil solutions of antiseptics are most often used for facade surfaces, wooden cladding of a balcony or loggia, especially if the house is located in a region with a harsh climate.

— Combined solutions consisting of oil and high-carbon components are used to treat both external and internal wooden surfaces. Moreover, they are also suitable for rooms with high humidity, providing their surfaces with high-quality protection.

The last option of antiseptics is the most expensive, since, in fact, it becomes a universal remedy used in any areas of construction and finishing.

- Biomoisture-protective antiseptics are used as an effective measure of protection against fungal growths, mold and insects harmful to wood. This type of antiseptic creates a protective barrier on the surface of the wood and also serves as a decorative coating. Therefore, the biomoisture-proof solution can be called universal, since it performs two functions at once.

One of the means for effective bio-moisture protection of wood - but it is more suitable for outdoor work.

Thanks to these properties of the antiseptic, not only money will be saved, but also time for painting. It is these solutions that are in high demand among owners of wooden houses.

- Fire retardants are used to make wood more resistant to fire, that is, material treated with such a composition is able to withstand exposure to open fire for a long time without igniting.

The main disadvantage of wood is its low resistance to fire, and treatment with fire retardants helps reduce the risk of fire.

Fire retardants are divided into two groups according to their reaction to fire:

— One group of solutions contains salts, due to which, when wood is exposed to high temperatures, gases are released that can prevent rapid combustion.

— The second group of fire retardants blocks flames by foaming, which occurs when wood is heated to elevated temperatures and creates a protective coating on it.

More effective fire retardants, according to experts, are those that contain sodium salts, as well as orthophosphoric, pyrophosphoric and tripolyphosphoric acids.

- Biopyrenes are impregnations that combine the functions of both a fire retardant and an antiseptic. Similar solutions can be used to treat walls from the inside and facade.

Binary action impregnation - provides both biological and fire protection for wood.

Due to the fact that this product is a complex consisting of all the components necessary to protect wood, using it you can save some money, time on work and on waiting for several different layers to dry out. solutions. So the costs are likely to be justified.

Biopyrene prices

biopyrene

- primer is another effective protective agent used for preparatory work before painting. These solutions are not only designed to prevent various manifestations and effects destructive to wood - they also create good adhesion between the surface of the wooden wall and the applied decorative layer. Water-based wood primers can be transparent, translucent or opaque. According to this criterion, they are selected depending on what effect is planned to be obtained as a result.

The use of primers greatly simplifies the subsequent process of applying paints and varnishes.

For example, if you plan to paint primed walls with a thick layer of paint, then it does not matter what kind of transparency primer to cover the wood with. In this case, rather, you only need to take into account that an opaque version of the soil will give a smoother surface. Transparent compounds work like impregnation, penetrating the structure of the material and filling its pores, but they do not have the property of creating a protective layer on the surface of the wood.

However, whatever primer is used, it creates a good base for the wood and paint to adhere to.

- Wood bleaching products are used to remove various manifestations from its surface that spoil the appearance of the entire wall - these can be blue, streaks or dark spots. Simultaneously with the removal of the above-mentioned flaws, these compositions also perform a protective function.

When using bleach, you must strictly follow the instructions provided by the manufacturer.

Bleaching solutions can be one- or two-component. The second version of the compositions is combined and mixed immediately before applying them to the wood. The formulation of some of the products provides for them to be washed off after a certain period indicated on the packaging, while others remain on the wood for painting as an antiseptic. Therefore, before purchasing one or another type of bleach, you need to pay attention to the packaging, which contains instructions for using the solution.

Varnish as a protective and decorative agent

As a protective agent for wooden walls, in addition to the above mentioned products, varnish solutions are used, which can also be made on various bases. To know which of the existing varnishes are suitable for indoor use, you need to consider each of them in more detail:

Varnishes are one of the best means for protecting and at the same time decorative coating of natural wood.

- Acrylic varnish consists of polyacrylates and is organic or water based. The solution is an environmentally friendly product without a pungent odor, and therefore it is often used to cover the surfaces of not only wooden walls from the inside, but also furniture.

Acrylic varnish - fits perfectly on the surface of wood, but, unfortunately, is not resistant to abrasive loads.

However, it must be taken into account that the layer formed by this type of varnish is not highly resistant to abrasion. This means that the coating will have to be updated quite often, and this is especially true for furniture accessories.

- Polyurethane varnish is made on a water basis, but despite this, it has high strength characteristics, including abrasion resistance. The composition of this protective agent is environmentally friendly and almost completely odorless after drying, so it is perfect for application to wooden walls inside the house.

Polyurethane varnish is highly resistant to abrasion - it is suitable even for wooden floors.

Some experienced craftsmen recommend adding hardening agents to the polyurethane solution to extend the life of the finish. Due to its high strength characteristics, this varnish is often used to cover wooden floors and parquet, so it is also fully suitable for walls. However, the price of these products is quite high, and this factor is the main disadvantage of this material.

- Alcohol varnishes and polishes can create a durable glossy layer on the surface of wood. However, despite their high strength, compositions based on this basis are not resistant to moisture, so they cannot be used to cover walls in bathhouses, loggias and balconies, as the coating layer will begin to peel off.

Varnishes are made based on natural resins, so their prices are quite high. This circumstance, coupled with low moisture resistance, determines that such compositions are not in high demand.

- Nitrocellulose varnishes consist of organic solvents and cellulose nitrate with the addition of synthetic resins to the solution.

Nitrocellulose varnishes are durable and quick-drying, but extremely flammable and have a strong odor until completely cured.

This type of varnish is divided into two varieties:

— One of them is intended for preparatory work, that is, it creates the basis for the outer layers.

— The second one is itself a decorative coating.

They are distinguished by the digital markings applied to the packaging. Typically, preparatory solutions have the property of drying quickly - this quality is provided by the manufacturer to avoid delays in the work. Therefore, when purchasing this composition, you need to pay attention to the instructions printed on the packaging with varnish.

Nitrocellulose solutions create a fairly durable coating layer on the surface of wooden walls, which is transparent and therefore does not change the natural color of the wood. Therefore, if you intend to preserve the beautiful textured pattern of the internal surfaces of wooden walls, then this type of varnish is well suited for this purpose. True, it is necessary to work with such compositions with special caution - they are extremely flammable in their uncured form (before the nitro solvent evaporates), and will emit a pungent odor before drying.

- Oil varnishes are made on the basis of artificial or natural resins; in addition, they also contain modified natural oil, driers and solvents. Varnishes of this type penetrate well into the wood and form a durable protective layer on its surface, giving the wood a warm ocher tint.

The solutions are well suited for interior finishing work; they cover wooden walls, floors, and furniture.

- Alkyd varnish is made on the basis of glyphthalic or pentaphthalic resins, to which driers are added. Since this type of varnish contains oils used as solvents, they are also often called oil-based. However, the alkyd version of varnish differs from oil varnish in its higher physical, technical and operational characteristics, so it is successfully used not only for interior but also for exterior decoration.

Some of the most popular and affordable varnishes are pentaphthalic-based alkyd varnishes.

In addition to alkyd varnishes, alkyd-urea solutions consisting of alkyd and amyl-formaldehyde resins are also available for sale. This type of varnish can be called two-component, since its drying is only possible when acidic hardeners are added to the mixture. This varnish is mixed immediately before applying it to the surface of the wood, since after preparation the solution remains suitable for a very limited time, and after it has hardened it will no longer be possible to dilute it.

This type of varnish is easy to apply and, after hardening, forms a durable protective layer on the surface that is highly wear-resistant. Thanks to this property of alkyd-urea varnish, it can be used not only for covering walls indoors, but also for covering parquet.

Paints for finishing wooden walls

In order to paint the inside of a wooden house, paints made on any base are suitable. Nowadays, various types of this material are presented in specialized stores in a very wide assortment. And one of the most important criteria when choosing a composition should be its safety, that is, the paint should not emit harmful toxic substances both during its application and during use of the premises.

Therefore, when purchasing any paint and varnish material, you need to pay attention to its characteristics, which should be presented on the packaging. In addition, it is recommended to obtain information from a sales consultant.

So, in specialized stores today you can find the following paints for finishing wooden surfaces:

- Water-based compositions are quite popular, since with their help you can cover the wood with a thick layer of paint, or you can make it translucent, thereby preserving the textured pattern of the wood. If the latter option is chosen, the paint must be diluted with water to the required consistency.

Water-based paints are attractive due to their low price and versatility, but are not durable - they cannot withstand abrasive loads.

Water-based solutions are distinguished by the absence of a sharp unpleasant odor and the fact that they do not emit toxic fumes harmful to humans. Therefore, they can be safely called an environmentally friendly material. The layers applied to the prepared surface set well and dry quickly, but are inferior to varnishes in their strength and wear resistance.

Prices for silicone paint

silicone paint

- Silicone paints are a solution of silicone resins, and thanks to them, they create a reliable and durable coating on the surface of wood. The paint composition has excellent technical characteristics, it is inert to mechanical stress and has good vapor permeability, that is, it allows wooden walls to “breathe”.

Some of the most durable and practical to use are silicone paints.

Moisture-resistant silicone film is resistant to abrasion and ultraviolet radiation. The applied coating is distinguished by enviable durability and is not only protection for the wood, but also a way to hide some flaws on its surface. The coating does not crack when the walls shrink, as it has good ductility.

- Silicate paint compositions are made from “liquid glass”, and therefore have a large number of positive characteristics. They are highly resistant to ultraviolet rays, high humidity, low and high temperatures, as well as open fire.

Silicate paints have a very beneficial effect on the atmosphere in the house, due to their environmental friendliness and high vapor permeability.

Silicate paint is an environmentally friendly product, since it does not contain substances harmful to humans and does not emit toxic fumes. Therefore, this type of material is excellent for covering internal surfaces, not only wooden ones, but also those made of other materials. Considering all the characteristics of this finishing material, we can conclude that it is well suited for rooms where conditions may arise that increase humidity, for example, an unheated balcony or veranda.

True, silicate compositions are completely incompatible with finishing solutions made on a different basis. That is, in case of repainting, it is necessary either to use silicate paint again, or to clean the surface to the very base.

- Acrylic paints are water-based, but have characteristics that exceed those of oil-based compositions, and therefore are able to provide reliable protection to wood and preserve its natural color. Due to their elasticity, paints have excellent adhesion to surfaces; they do not deform or crack.

High-quality acrylic paints are an excellent solution for interior decoration.

Paint can be used to paint both internal and external surfaces of a building.

- Alkyd enamel is used for painting both facades and interior wall surfaces. It creates a protective glossy or matte layer on the wood, making it smooth and aesthetically pleasing.

However, this composition also has its drawback - over time, alkyd white enamel turns yellow, and paint that has color fades, so to paint walls, for example, a balcony located on the sunny side, or that constantly receive a “portion” of sunlight, use it is not recommended.

- Oil paints have a considerable number of advantages over other compositions and are suitable for both internal and external coating of wooden surfaces. High-quality solutions are highly resistant to external mechanical influences and high humidity.

The obvious disadvantages of oil-based paint compositions include their long drying period, low resistance to ultraviolet radiation (over time, the coating begins to crack and peel) and air tightness. This type of paint is most often used to cover facade surfaces, but even then - with fairly frequent updating of the finish.

- Natural wax paints or liquid wax are made on a linen base and have been used to coat wood for decades, so they can be called a traditional material. Wax is well absorbed into the wood structure, making it waterproof.

Wax paints - create a pleasant matte wood surface, well protected from moisture penetration.

The solution can be transparent or tinted. If you plan to preserve the original color of the wood, then choose a transparent wax option, and if you need to darken the wooden walls, then you should use a tinted solution. Wax paint is easily applied to the surface, but acquires the chosen shade only after complete drying. Therefore, it is recommended to first apply a similar composition to a small area of the wall and wait for it to dry to make sure that the optimal paint tone is chosen.

Advantages of log sanding

Sanding timber is a rather labor-intensive and time-consuming process, but, as they say, “If you’re afraid of the wolf, don’t go into the forest.”

Before you start work, you need to realize the importance of the matter so that the mosquito does not undermine your nose

Sanding logs:

- perfectly levels the surface;

- ideally cleans raw materials;

- helps maintain the original shade;

- provides high adhesion to paints and varnishes;

- reduces the cost of finishing materials;

- allows antiseptic impregnation to be evenly distributed over the surface without the formation of pigment spots;

- prevents wood aging;

- protects the material from rotting, mold and insects;

- increases resistance to the negative effects of climatic, thermal, mechanical, and chemical factors.

The result of the work is walls, as in advertising photographs of presentable construction companies.

Useful recommendations for purchasing paint and painting

When choosing and purchasing paint for the interior decoration of wooden walls, it is very important to pay attention to the date of manufacture of the composition and the availability of certificates confirming its quality and sanitary compliance. If the seller cannot provide documents for the product, and the production date is not stamped on the packaging, but is written on paper and pasted on top, so to speak, interrupted, then it is recommended to immediately refuse to purchase such paint, especially if a fairly expensive version is purchased.

The fact is that if the paint is expired or frozen, then it may simply not lie on the surface, even if it is well prepared, and you can determine the quality of the composition only by opening the package and trying to apply it to the wood. For example, it will not be possible to paint anything with a frozen solution, since the paint will most likely curdle and have the consistency of liquid cottage cheese.

High-quality paint should spread easily over the surface of the wood, while having high hiding power

If the paint is of high quality, it will be easily applied to the surface, which means that painting the walls can be done by a person who has never even performed such repair work before.

Next, it is worth considering those factors that will directly affect the final finishing result.

- First thing to note. It is a common phenomenon that many homeowners, when doing their own renovations in a house or apartment, are careless about the preparatory stage of work, since they consider it unnecessary. However, if the base for the decorative coating is uneven and untreated with protective agents, you should not expect the desired result. In addition, after a short time, even defects that are invisible immediately after completion of the work will begin to appear, for example, such as blue discoloration, blackness of the wood, or “resin pockets” near knots. Therefore, the preparatory process must be considered mandatory and carried out as efficiently as possible.

- When treating wood with one of the protective compounds, it is necessary to very carefully process the end parts of logs or beams if they face the rooms. If the walls of the house are covered with clapboard, then its side surfaces should also be carefully treated with antiseptic solutions.

- All protective and coloring compounds are applied to wooden surfaces in thin layers along the grain, otherwise their absorption into the wood will be uneven, which will negatively affect the overall appearance.

This simple “improvement” from ordinary rubber rings will greatly simplify the process of applying paint with a brush from a can.

- To ensure that there is no excess paint on the brush, and that it does not flow, but lies flat, it is recommended to use a simple device consisting of two stationery or ordinary rubber bands. One of the rubber bands is put on the bottom and top of the can, and the second along its diameter. The second elastic band will hold the first one, preventing it from sliding to the side.

After dipping the brush into the paint, press it against the stretched rubber band, leaving excess solution in the container.

- When applying paint to the surface of wood, do not try to cover it with a thick layer at once, as the painting will turn out sloppy. If you plan to get an opaque surface, then you should apply the paint in several thin layers, each of which should be applied after the previous one has completely dried.

- When painting walls covered with wooden clapboards, it is best to apply the final top coat starting at the top and gradually moving down - this method will help make the surface of the wall smooth.

- Paint can look different in a can and on the wall, so it is recommended to do a test paint job, that is, apply the solution to a small section of the wall in an inconspicuous area. It is best to choose the lower corner part of the surface.

- In order for the decorative layer to lie evenly on the surface, experts recommend adding a color to the primer that is one or two tones darker or lighter than the base color.

- The optimal temperature for painting surfaces is 22÷25 degrees. You should not carry out this process in hot weather, as the paint will dry too quickly and therefore unevenly. If the temperature is too low, the fluidity and hiding power of the compositions deteriorate, and the drying period increases.

When to grind

Opinions are divided on whether to sand the walls of the log house immediately or wait for it to completely shrink and dry. Some believe that waiting until the log house shrinks and the wood shrinks is too long, because the process is quite long, depending on many external factors such as:

- Log cutting season;

- Log manufacturing technologies;

- Type of wood, its density and humidity;

- Type of insulation used between the crowns;

- Climatic data of the region.

In addition, during this period the wood can become infected with fungus and change its color.

Others believe that this matter should not be rushed. The darkened color of the wood will disappear after sanding, and the fungus can be easily removed using biological impregnation. It is necessary to fully comply with all the necessary conditions for an effective and high-quality result.

To do this, the roof must be covered, the structure must completely shrink, but most importantly, the moisture content of the wood should not exceed 20%.

Despite the divergence of opinions, experts still recommend making your choice in favor of the second option. Premature processing and painting of damp walls can result in big troubles for the owner.

Step-by-step instructions for painting a wooden wall indoors

By adopting all the little tricks listed above, it will be easier to cope with the preliminary stage and painting the walls. Having prepared all the tools and workplace necessary for the process, you can proceed to the finishing itself.

The “lion’s share” of the total amount of work in the process of painting wooden walls is always occupied by the preparatory stage

The main part of the work is preparing the surface for painting, which is why they require a more detailed description.

| Illustration | Brief description of the operation performed |

| For preparation and painting, you need to have at your disposal some of the tools shown in the illustration. In addition to them, you will need a grinder with replaceable abrasive paper blades and, possibly, a grinder with an iron brush. If the wooden wall has an old coating, you can use a hair dryer and a scraper (trowel) to remove it. | |

| The first step is to clean the surface of the old paint coating (if there was any). To do this, the paint layer is heated until it softens and peels off from the wood, and then is removed with a scraper or spatula. This work is quite time-consuming and labor-intensive, but it must be done efficiently, otherwise the remaining paint will appear through the new decorative layer as unaesthetic irregularities. | |

| If the wall does not have an old coating in the form of a paint layer, but has acquired an unrespectable appearance during use, or wallpaper has previously been glued to it, its surface must be thoroughly cleaned by removing the top thin layer of wood. | |

| Restoration of such a surface is carried out using a grinder, on which a brush with soft metal bristles is installed, and then a grinding machine with first coarse-grained (P80÷P120) and then fine-grained (P150÷P180) sandpaper attached to it. In addition, cleaning the wall or its individual areas protruding above the general surface can be done using an electric plane. | |

| When the wood is cleaned, its surface should be sanded with a fine bristle brush or sandpaper. In the case where a wall made of new wood is being prepared for painting, it also needs to be sanded smooth. Cleaning and polishing difficult places, for example, between two logs of a log house, can cause a lot of difficulties. But here, as they say, there’s nothing you can do—you’ll have to “sweat” if you want to get a high-quality result. | |

| If you don’t have a sanding machine, you will have to sand the walls manually - this is a very difficult and time-consuming process, so it’s still better to purchase a specialized tool, since it will come in handy more than once in a wooden house. The sanded surface must be cleaned with a vacuum cleaner to remove any dust generated during the sanding process. | |

| The dust-free wooden surface is then coated with one of the selected protective agents - it can be an antiseptic and fire retardant, or one of the compositions described above. This operation can be carried out using a roller, a wide brush or a spray gun, depending on the topography of the wall and its area. If it is log, then the work will go faster if you carry out this process using a sprayer. At the same time, we must not forget about the need for increased precautions - many protective primers are very toxic before absorption and drying. | |

| As a preparatory, and sometimes even the main decorative layer, one of the types of varnish is used, which is applied with a wide soft brush. | |

| If, after the primer has dried, you plan to apply paint or a dark tinting varnish to the surface, then you should protect the ceiling from contact with the solution. To do this, it is recommended to stick masking tape onto the ceiling along the upper edge of the wooden wall, which can be easily removed upon completion of the work and will not damage the plastered or painted ceiling surface. | |

| To paint wooden walls, you will definitely need a soft brush and roller. The roller will significantly speed up the work, as it covers a large area of the wall at once and evenly distributes the paint solution over it. True, this is only possible on flat surfaces - when painting a log wall, a roller will not be a great help. | |

| A brush is needed for painting hard-to-reach places, for example, corner areas or horizontal joints between logs. It is recommended to paint in two or three approaches, but each layer must cover the entire area of the wall, otherwise the paint will lie unevenly. Each subsequent layer is applied only after the previous one has completely dried. |

So, the process of painting wooden surfaces in a house is a very labor-intensive, large-scale task, which, however, any owner must cope with. And for successful work, in addition to your own desire, you must:

- Have the necessary tools of good quality.

- Select and purchase high-quality primers and paints for preparing and painting surfaces.

- Carefully, without simplification, carry out all the preparatory processes, without convincing yourself that “it will do.”

- Do the painting without rushing and without trying to complete it in one go, that is, do not apply the paint in one thick layer - this approach will result in nothing but drips, overuse of paint and a sloppy surface.

If you strictly adhere to all these conditions, the coloring will definitely turn out the way it was originally intended, that is, neat and uniform, and the finish will last as long as possible.

And at the end of the publication, we invite you to watch an informative video in which the master tells and shows how to properly paint the inside of the walls of a house made of natural wooden beams.

Do-it-yourself sanding of walls and ends of a timber frame

The photo at the beginning of the article is a real shot from the wall of the log house of my future bathhouse, in order to begin to discuss whether sanding of the walls and ends of the log house is necessary. Needed! - the question disappears immediately.

Definitely sand the walls! According to most paint manufacturers, sanding begins after the log house has dried sufficiently and “settled”. Dry wood is easy to sand, but I doubt it about waiting for shrinkage. So I sanded it right away.

If you paint raw wood without sanding, then after painting there is a high probability of cracking the timber and thus exposing areas of the wood. Many Internet sites recommend painting a dry frame.

Protecting the wood in the log house comes first! Despite the fact that when sanding walls made of raw timber, the pile lifts up and it becomes “shaggy”, I would not tolerate the sanding work. The primary task in building a log house is to install the box, cover it with a roof and preserve the walls. Drying will be more uniform, etc.

What does grinding do?

- after a week or two weeks of exposure to the sun, the surface of the wood acquires a yellowish color and sanding returns the original, attractive appearance of the log house;

- the surface of the timber acquires the ability to evenly absorb paint, varnishes and antiseptics, reducing the number of pigment spots on the surface;

- sanding together with a millimeter-thick top layer completely removes all defects and mold and fungal lesions of wood;

- During installation, some parts are used as scaffolding and simply get dirty when walked on. Sanding removes traces of dirt, etc.;

- Under some circumstances, such defects in timber processing may occur as in the main photo of the article. With special processing methods, even such a complex flaw can be eliminated.

Tools and attachments for grinding logs

Sanding the walls and ends of a log house is done with one tool and may include the following tools and devices:

- at the manufacturer - a grinding machine that processes the entire part (rarely used);

- belt hand sander (used often);

- angle grinder (grinder with a disk attachment) (used often);

- drill with a grinding attachment (used often).

A drill and an angle grinder are the most common tools for grinding, as they are in the arsenal of any home craftsman or just a good owner. All other devices are used mainly by professional workers and not everyone has them in their garage.

I would like to add a couple more “tools” that are very necessary. They cannot be classified as tools, but the need for them is great - a respirator and glasses. Oh, how I missed them in windless weather, when dust flew into my mouth and eyes! In windy weather the situation was better - the dust blew away on its own.

Regardless of what tools you use, the quality of sanding will depend on the parameters of the sandpaper and the hardness of the attachments. I used 80 and 120 grit sandpaper wheels. Larger ones (No. 80) were used for the ends and rough defects of the timber. 120 - for cleaning dirt and aesthetically finishing walls.

My experienced grinder did not go through the entire cycle of grinding work, so I finished sanding the frame with a drill (watch the video).

Loghouse wall grinding technology

I’ll start this point with the fact that first of all it is necessary to examine the log house for the presence of defects in the “radial structure of the wood” which, when planed, produces such pile as in the title photo of the article - entire petals of the tree structure peel off.

Before grinding, you need to treat such areas of the timber with adhesive (grease generously) and let it dry for 24 hours to protect yourself from further ruffling of the surface during sanding.

This technology allows you to save the tool and grinding wheels in subsequent operations.

Any grinding should be completed by treating the surface of the log house with antiseptics.

What should you pay attention to? Grinding the ends. The ends are the weakest point in a log house; they are more susceptible to cracking, getting wet, and exposed to sunlight to a greater extent than the walls.

Preparing the house for painting

By the time of treatment, the wall surface should be clean and smooth. A set of appropriate measures can achieve this. First, you should wash the surfaces using soft abrasives. For example, a brush with plastic bristles can remove the most severe dirt, dust deposits, etc.

Next is washing. At this stage, it is advisable to use special sprayers and washers with high pressure, or use a regular garden hose. In extreme cases, wet cleaning with a rag is performed.

Next, the technological process of preparing the log house for painting involves cleaning it using a hard abrasive. If at the first stage the brush eliminated foreign bodies, then this time the purpose of the mechanical action will be to refine the structure of the tree itself. Use hand sanders or brushes with metal fibers to polish the wood.

Then the washing operation is repeated again, which will complete the preparation for painting.

Advantages and disadvantages of oil processing

The oil has the following valuable properties:

- is a natural antiseptic, penetrates deeply into the layers of wood, protecting it from exposure to bad weather and pests;

- very easy to apply and also easy to remove from the surface;

- environmentally friendly product;

- has good adhesion;

- hides scratches, chips and other surface defects

- oil treatment is relatively cheap.

It should be noted that only natural oils have beneficial properties. Therefore, when impregnating wood, it is better to choose natural oils that do not contain hazardous components and are harmless to humans.

However, oil processing has some disadvantages:

- Wood treated with oil loses its original appearance after some time. The procedure must be repeated regularly at intervals of several years.

- Grease stains are very noticeable on an oiled surface. Therefore, if grease gets in, it is necessary to re-soak the wood with oil.

Advantages of log sanding

Sanding timber is a rather labor-intensive and time-consuming process, but, as they say, “If you’re afraid of the wolf, don’t go into the forest.”

Before you start work, you need to realize the importance of the matter so that the mosquito does not undermine your nose

- perfectly levels the surface;

- ideally cleans raw materials;

- helps maintain the original shade;

- provides high adhesion to paints and varnishes;

- reduces the cost of finishing materials;

- allows antiseptic impregnation to be evenly distributed over the surface without the formation of pigment spots;

- prevents wood aging;

- protects the material from rotting, mold and insects;

- increases resistance to the negative effects of climatic, thermal, mechanical, and chemical factors.

The result of the work is walls, as in advertising photographs of presentable construction companies.

What tools are best to equip yourself for polishing a log house?

Sanding wood with a grinder is the most common and affordable way to sand a wooden house. Typically, an angle grinder is used for grinding a frame made of planed logs. Using a grinder is also convenient for sanding grooves and ends of logs. Actually, with this tool, if you have the skills, you can process any lumber.

Model selection

There are both household and professional models that differ in power and performance. You shouldn’t buy the cheapest grinder; its power is unlikely to be enough to polish the entire frame. Expensive professional models are also not the best choice for home use. They operate at high speeds and are distinguished by considerable weight and power. A non-specialist, without the knowledge of working with such a tool, can simply ruin the surface being sanded, leaving dents on it.

It is best to opt for:

semi-professional models with power from 800 to 1000 W

This will be quite enough to polish the frame. It is advisable to buy a tool with a rear air intake rather than a side one, so it will become less clogged with dust

You should also pay attention to the cable length. The cord is too short and inconvenient to use

Nozzles for an angle grinder

To work, you will have to stock up on attachments on which the abrasive is fixed. There are two types of nozzles:

- Rubber

- Plastic.

Abrasive wheels

For grinding use regular

or flap grinding wheels. Sanding a log frame is a very dusty job. A lot of dust is released, which, together with tree resin, gets clogged into the disc, the abrasive quickly wears off, so the grinding wheels quickly become unusable.

During rough processing, one disk is enough for about 3-5 meters of log, then it has to be changed. Consumption depends on the condition of the wood and the type of surface. How many fine grinding discs are needed depends on how thoroughly the initial processing was carried out.

The alpha disk, which is a metal disk with pobedite chips soldered onto its body, has a longer service life. Grinding timber with an alpha disc allows you to significantly save on consumables. A disk clogged with sawdust can simply be cleaned with a wire brush and you can continue to work calmly.

Today it is not difficult to acquire the necessary tools for carrying out the procedure. You should arm yourself with:

- grinding machine;

- cutting machine;

- chisel.

Important! When choosing tools, you should pay attention to weight, so as not to put too much strain on your hands and power. Tools with low power will heat up, significantly reducing productivity. High-quality tools are produced by Makita, Bosh, DeWalt, and the domestic Interskol is also worthy of attention.

High-quality tools are produced by Makita, Bosh, DeWalt, and the domestic Interskol is also worthy of attention.

High quality, durable equipment

High-quality tools are produced by Makita, Bosh, DeWalt, and the domestic Interskol is also worthy of attention. The equipment is high quality and durable.

For a timber frame you need a belt sander; its use will ensure a smooth surface. Equipped with a special dust collection bag, the machine will make subsequent cleaning of the room easier. I'll round the surface of the logs with a belt machine, it's difficult, a grinder and special attachments will come in handy here.

The correct power of the cutting machine is 600-900 W. Nozzles with different degrees of grain. Initially, use a coarse-grained nozzle (40), then take a nozzle 80-100. Disc 125mm, speed 10-12 thousand, preference should be given to a machine with a rear air intake and a long cord that provides freedom of action.

Important! For work, it is more convenient to use two machines, so as not to overheat and not change attachments; first work with the attachment with large grains, then with fine ones. Using plastic attachments; flexible plastic with an abrasive layer is more convenient, leaves no marks and lasts longer.