Insulating the walls with caulk helps solve this problem. Each case uses its own material and technology.

We will describe them, and also consider how to check the quality of the craftsmen’s work, what prices exist in the Russian Federation today, and give an example of calculating the amount of jute fiber for caulking a timber house.

Why do you need to insulate the seams?

When building housing from wooden beams, insulation is laid on each crown. But over time, the house shrinks by 5-10 cm, the linen or jute tape moves, and gaps appear. This leads to the appearance of cold bridges.

To increase the thermal capacity of the building, be sure to caulk all joints and cracks. This procedure allows you to avoid the appearance of frost on wooden surfaces , which is fraught with cracking of the wood and the occurrence of high humidity.

Thanks to caulking, the microclimate of the house becomes more favorable, and heating costs are reduced.

If the humidity of the beams is high, mold may appear and rot may spread. This will affect the health of the people living in the house.

Lack of timely caulking will lead to the following problems::

the homeowner will be forced, figuratively speaking, to “flood the street”;- the wood will rot and turn black due to dampness;

- the performance characteristics of profiled or laminated timber (heat capacity, strength) will deteriorate;

- There will be a distortion of the walls due to the unevenness of the insulation between the crowns.

In addition, there will be sections of walls that are periodically subject to icing. Through them, the heat will quickly leave the house.

Even if the outside walls are finished with siding with a windproof membrane, the building still needs periodic caulking.

Beams for a country building can be selected from different batches, differing in operating conditions, shrinkage period and other characteristics. This will affect the deformation of the walls, lead to the appearance of cracks and, again, lead to the issue of insulation.

Why do you need to caulk a log house?

A wooden house is very favorable for living. Wood holds heat well. But in log houses, gaps inevitably remain between the crown logs. They need to be closed to prevent the cold from penetrating inside the house. This operation is called caulking. With careful caulking, the house will be reliably protected from the cold even in the most severe frosts.

In addition to performing the function of insulation, caulk also protects a wooden house from rotting.

What you need to know about log caulking.

How often is caulk needed?

Experts advise insulating inter-crown joints and corners of a timber building every 3 years , not counting the first three times:

- Initial. After completion of construction of the building, to reliably seal all seams. It is carried out with low density, since the house must still shrink.

- Second. One and a half to two years after the first procedure. During this period of time, the shrinkage of the house will be approximately 80%. Here caulking is carried out with a higher density to prevent sagging of the material.

- Third. It is carried out in the absence of external insulating cladding of the house. The duration of these works falls on the fourth or fifth year of operation of the building. In this case, the caulking is carried out even more tightly than the second time.

Video description

Caulking with rolled material: you will see how to do it correctly in the video:

The corners of the timber are caulked using the same technology:

- If the gaps are wide, a cord is formed from the insulation tape. Roll it into a ball.

- Unwind part of the cord and weave loops from it. Then each loop is pushed inside the seam.

- Hammer the loops with a spatula, first from above the joint, then from below.

- After sealing the seams, final caulking is carried out if necessary. It involves residual filling of joints and is carried out if necessary.

- The density of the caulk is checked with a kitchen knife. The knife blade should not extend into the joint more than 1.5 cm. If this condition is met, caulking is done correctly. If not, then additional caulking is required.

Checking the density of the caulk Source 24aul.ru

Caulking corners is done using the same technologies using roll insulation, for this they move along the seam from the bottom up. To ensure uniform laying of the material, it is constantly tensioned and straightened.

Requirements for insulation

There are many insulation materials on the market, but not all of them are suitable for log houses. Polyurethane foam and synthetic analogues lead to dampness in the building, rot, mold and other related problems.

The best option is to choose materials that have the following characteristics:

- Environmental friendliness. Since log houses are built with this property of wood in mind, the insulation materials must have the same quality.

- Hygroscopicity. The ability to accumulate and release moisture without loss of thermal characteristics is very important.

- Breathability. Do not interfere with the flow of warm air.

- Antiseptic properties. Such insulation does not harbor pests, mold and fungi.

- Low thermal conductivity. Materials for caulking should easily withstand temperature changes without losing physical properties and retain heat well inside the house.

- Elasticity. This property allows wood to change its size without harming the structure.

- Density. A characteristic that will allow the insulation to withstand the pressure of beams and wind flows.

The most important quality of a good material for caulking is low thermal conductivity. It should be less than that of wood. The lower this value, the longer the material retains heat.

For pine timber, the thermal conductivity will be 0.015 W/(m °C) across the fibers, and 0.004 W/(m °C) along the fibers. For comparison, the thermal conductivity of jute fiber is 0.036 W/(m °C), and that of flax tow is 0.034 W/(m °C).

Caulking rules

Caulking of a log house is carried out in two stages - immediately after construction and after some time, when shrinkage occurs. Primary (or rough) caulking can be carried out in two ways: with laying insulation during the process of assembling the walls or performing one-time work upon completion of construction.

Each log house requires high-quality caulking, which is performed in two stages

1 way

Lay the bottom row of logs on the base.

Layed logs of the log house and inter-crown insulation between them

Then the insulation is spread on top so that the ends of the material hang evenly on both sides. Next, lay the second crown, and again a layer of insulation. This is repeated until the very top of the log house. After all work on the construction of the log house is completed and the roof is installed, the protruding ends of the seal are driven into the gaps between the beams using caulking.

The result of caulking a log house

Method 2

Caulking begins after installation of the roofing system on the log house. Insulation (preferably tape) is applied to the seam of the bottom row and, using a tool, is pushed into the gaps between the logs along the entire length, leaving hanging edges 5-7 cm wide. Then these edges are folded in, formed into a roller and hammered inside the seam. Repeat the procedure in the next row and so on until the top of the structure.

The second stage of caulking is carried out after shrinkage of the log house - after 1-2 years. The selected insulation is applied to the cracks between the crowns and driven tightly inside. You should always start work from the bottom row, and be sure to do it along the perimeter of the log house.

Insulation padding

You cannot caulk one wall first, then the second, and so on. In addition, each row is caulked both from the outside and from the inside to avoid distortions in the structure. The insulation raises the frame by 5-10 cm, and its uneven distribution contributes to the vertical deviation of the walls. In some cases, the log house is caulked for the third time - 5-6 years after construction. During this time, the wood completely shrinks and new gaps form.

Gaps between crowns

There are two ways of caulking - “set” and “stretched”. The first is used to eliminate wide gaps between logs, the second is usually used during primary caulking, when the gaps are still narrow.

To work, you need tools - a set of caulking tools, a road worker and a mallet. As a rule, metal caulks are used, although many craftsmen make them themselves from hardwood.

This is interesting: Why does the stove smoke in the bathhouse?

Types of materials

Although many natural materials are used for laying between the crowns of timber, not all of them are suitable for caulking.

Among the materials for caulking there are traditional and modern insulation materials :

- The first group includes: moss, flax tow and hemp.

- For the second - jute and linen felt.

Moss

Kukushkin flax or sphagnum is often used to insulate joints between crowns. Thermal conductivity coefficient is 0.04 W/(m °C). Caulking is carried out with slightly damp material. If the moss is overdried, it becomes unsuitable for this work.

Advantages:

- environmental friendliness;

- durability;

- antimicrobial properties.

It prevents the timber from rotting, which is a definite advantage over other insulation materials.

Flaws:

- before use, soak in a soap-oil solution and dry briefly;

- difficult to find on sale.

Flax tow

This insulation is a waste product from flax production. Its density is 160 g/cub.m. Thermal conductivity - 0.034 W/(m °C). The peculiarity of working with tow: it requires calm weather and compliance with fire safety, since it is a flammable material.

Advantages:

- environmentally friendly;

- has antiseptic properties.

Flaws:

- compared to moss, this type of insulation is less durable;

- used by birds for nests, which makes it less suitable for such work;

- it is difficult to place in inter-crown seams;

- skill required.

Tow absorbs a lot of moisture, which can lead to wood rotting.

Hemp hemp

The fibers of the plant of the same name are durable and hygroscopic. The fibers do not shrink even at temperatures of 300 degrees, which is an advantage for insulating wet areas in the house. Thermal conductivity - 0.036 W/(m °C).

Advantages:

- lightweight and easy-to-install material;

- environmentally friendly;

- durable and resistant to elevated temperatures.

Disadvantages : inaccessibility.

Jute

Another name is Calcutta hemp. Made from the wood of a southern tropical plant. Available in the form of ribbons, tow, fiber. Density - 400-800 g/sq.m. Thermal conductivity - 0.036 W/(m °C).

Advantages:

- extremely low ability to absorb moisture (30% at absolute 100% air humidity), which makes it an excellent material for timber;

- environmental friendliness;

- antimicrobial properties.

During operation it becomes even denser, which leads to tight joints. Easy to install between seams.

Flaws:

- the material is taken away by birds;

- rapid caking leads to the need for repeated caulking;

- its short service life - 2-3 years - makes it less suitable for insulation compared to moss.

Combination options are often sold under the guise of natural insulation: a mixture of jute and flax hemp. This option is also used for caulking, but has worse performance characteristics. You can distinguish it from natural jute by color: analogues are lighter than the original.

Linen felt

In terms of technological properties and price, it surpasses the same tow. Another name for felt is flax wool.

Advantages:

- low hygroscopicity;

- ease of installation between the crowns;

- long service life.

Flaws:

- inferior to natural jute in density;

- quickly loses its shape, which leads to the need for additional caulking;

- When exposed to moisture, it loses its performance properties.

Synthetic sealants

Insulating the seams of a log house using these materials does not always give the desired results. It is often used as an additional means for caulking with natural jute or tow. In this case, installation of the product should be carried out directly on the timber, and not on the insulation.

Advantages:

- long service life;

- plastic.

Flaws:

- does not allow pairs to pass through;

- not environmentally friendly due to its chemical composition.

Construction of houses

0 votes

+

Vote for!

—

Vote against!

Have you been told that it is not necessary to caulk a house made of timber, they say, everything fits perfectly there anyway? You can safely send such “woe” specialists home and invite real professionals in the construction of wooden houses. Like any other, the technology of building houses from timber has its own stages and design features, which invariably include caulking of a timber house, even if you are going to subsequently do external and internal finishing with insulation. You should not try to save time and money so as not to overpay in the future. If you don’t want there to be constant drafts in your house, curtains to flutter even in calm weather, and over time wet and rotten places in the wood to appear, it is better to complete all the caulking work at home on time.

- Is it necessary to caulk a log house and why?

- How to caulk a timber house

- When to caulk a log house

- Do-it-yourself caulking of a timber house

- How to caulk a timber house with jute

- Caulking a timber house: video - example

Is it necessary to caulk a log house and why?

In some sources you can find information that a log house does not need to be caulked. And the builders who are building your house can say the same thing. They explain this by the fact that, unlike timber houses, in log houses the shrinkage and displacement of wood occurs stronger and more intensely, cracks and leaks appear, so it is necessary to caulk the structure. But houses built from profiled timber practically do not shrink, since the wood is pre-treated. Let's figure out how it actually happens when building a house from timber with your own hands.

Timber with natural moisture is a relatively cheap building material, which is why it is popular in the construction of economy-class houses with subsequent insulation and finishing with siding. Even if you invite the best architect, he will not be able to build a house from such timber without gaps between the crowns and gaps. Moreover, when the timber begins to dry out, and this is inevitable, additional cracks will appear, wider ones, the timber will decrease in size, and it will begin to “twist”. As a result, cracks will appear, due to which the wooden wall will lose its thermal insulation abilities. To avoid such a sad end, the walls must be caulked at least 3 times and thoroughly insulated.

Profiled timber was invented precisely in order to reduce costs and time for building a wooden house. It undergoes special processing in production, due to which it practically does not dry out during operation, and its tongue-and-groove connections are perfectly aligned to the nearest millimeter. The beams fit together as closely as possible, and 5 mm insulation is placed between the crowns, which is located between the interlocking parts. Despite the seller’s assurances, the house made of profiled timber still shrinks, as the timber finally falls into place under the weight of the structure. In addition, the properties of wood greatly depend on the region of growth, climatic conditions and storage conditions. No one can guarantee that absolutely all the timber you purchased is of the same high quality. As a result of building movements, the timber may shift slightly and the insulation may become wrinkled. Even if no gaps appear after shrinkage, and this option is possible, still those gaps that are located in the inter-crown space outside and inside the house accumulate moisture, and since the place itself is very secluded and vulnerable, mold and rot can form in it.

Caulking a timber house is necessary in order to insulate wooden walls, completely filling them with natural insulation and sealing the gaps and cracks between the beams and in corner joints. This guarantees tightness, no heat leaks through the walls, drafts and icing of the timber outside the building, which occurs when warm steam escapes through the cracks and settles as wet frost on the surface.

How to caulk a timber house

To summarize, the material that can be used to caulk a house must meet the following requirements:

- Have low thermal conductivity.

- Be immune to temperature and humidity fluctuations, and easily withstand wind.

- So that insects and pathogenic fungi (mold) do not grow in it.

- Be an absolutely environmentally friendly material, otherwise the whole point of building a wooden house is lost.

- Be relatively durable (not lose properties for at least 20 years).

- Be breathable.

- Be hygroscopic, i.e. when you need to absorb moisture, when you need to give it away.

- And the most important thing is to be similar in its properties to wood.

Due to the fact that our ancestors caulked their houses hundreds of generations deep on their own, materials that have been tested and tested by thousands of years of successful practice have survived to this day. They can be called traditional materials.

Moss is the best material even today for caulking wooden buildings. This is sphagnum moss, a bog plant that can be red, white or brown. Subsequently, peat is formed from it. None of the modern materials can compare with moss, it is so durable and environmentally friendly. You can travel through old abandoned villages, look at the houses: the logs have almost rotted, and the moss is still in excellent condition. Moss is simply irreplaceable as an interventional sealant: it has antiseptic, antibacterial and healing properties. Sandwiched between wood, it suppresses the development of putrefactive bacteria and mold fungi, due to which the wood lasts longer. Moss easily allows air to pass through itself, which, passing through it, is saturated with healing vapors, so the atmosphere inside the house becomes healing. Moss is hygroscopic, which means it smoothes out changes in humidity. In general, moss has no drawbacks, except for one thing - it is not so easy for them to caulk, otherwise no one would invent or look for anything new.

Tow made from flax fibers is used as a sealant and sealant everywhere, but for caulking - mainly in regions where flax grows and where there are no swamps where moss could be stocked. No one produces tow specifically; it is waste from the production of ropes, cords and linen, or tweezing and stripping after cleaning flax fibers. Tow has some antiseptic and bactericidal properties, but to a lesser extent than moss. Therefore, in some cases, tow is treated with resins to increase resistance to high humidity. These resins can be natural, i.e. tree resins, then this material can still be called environmentally friendly, but petroleum products are also used for impregnation, then tow no longer has anything in common with natural materials. The tow contains a large amount of fire, which will be shaken out during the first years of operation of the house, so the caulk will need to be repeated several times.

Hemp hemp is very similar to tow, only its fibers are coarser, so they are sometimes confused. Hemp is not afraid of temperature changes and high humidity, so it can be used even in very humid regions. These properties are due to the high content of the polymer lignin, which is also found in any wood to bind cellulose fibers. Hemp does not lose its properties even after getting wet, therefore it is resistant to rotting.

Among the modern materials for caulking, the following can be distinguished:

Jute is a foreign product; it is imported to us from China, India, Egypt and other countries with a tropical climate or heavy rainfall. It is produced from the shoots of the jute plant of the Malvaceae family. Jute fiber is very durable, not affected by mold, putrefactive bacteria, not interesting to insects and birds, hygroscopic, i.e. easily accumulates and releases moisture, allows air to pass through. Jute contains about the same amount of lignin as wood, so their properties are similar and together they are a perfect pair.

Jute is produced both in fibers and in strips of different widths. Tape jute insulation is very convenient to use for laying between the crowns of a log house. In addition, pure jute compacts evenly. These advantages more than cover the price of this material.

In addition to materials made from fibers, felt insulation materials (inter-crown felt) are also used for caulking:

Jute inter-crown insulation consists of 90% jute and 10% flax. But it is better to follow this ratio, since there is jute felt that consists of 70% jute and 30% flax, which significantly worsens its properties.

Linen felt is also called eurolin or flax wool. It is a needle-punched material made from highly purified flax.

Flax-jute felt consists of jute and flax in a 1:1 ratio.

All-jute modern insulation materials are considered the best, since they interact perfectly with wood and shrink evenly, while other materials with the addition of flax worsen the properties of the insulation. The more flax, the worse the properties.

When to caulk a log house

Work on caulking a house is carried out in several stages, this is due to the fact that the timber dries out gradually, the house sinks under its own weight. The largest shrinkage occurs in the first year and a half after construction, and every year it is less and less. Experts say that after 5–6 years, shrinkage practically stops.

The first time a timber house is caulked immediately after construction. During the construction process, insulation is laid between the crowns, and after the entire house is erected, the gaps between the beams are filled with caulking material, but not too tightly.

The second caulking is done a year and a half after the completion of the house. The house will already have settled, so it is necessary to caulk tightly, leaving no gaps or hanging material.

The third time the caulking work will have to be done again after 5 - 6 years, carefully filling all the newly formed gaps and cracks and adding material where it accidentally spilled out or was pulled out by birds.

If it is planned to cover the outside of a timber house with siding, then the third caulking is not performed, but the first two must be completed. There is no need to rush and save on something for which you will later have to pay much more.

Do-it-yourself caulking of a timber house

Caulking is a very responsible and labor-intensive process, despite some monotony of the operations performed. Not many construction crews agree to do caulking work; they simply don’t know how to do it and are afraid of ruining it, which is why they recommend not caulking at all. We have already discussed why you should not listen to them.

But there are teams and entire organizations that deal with caulking professionally. The price for caulking a timber house depends on the stage of work and amounts to a certain amount per 1 linear meter of each crown. The average cost of caulking is 50 – 60 rubles. for 1 m.p. And caulking corner joints can cost up to 200 rubles. for 1 m.p. At a separate rate, caulking will be carried out with a decorative rope (rope), which decorates the appearance of the caulked walls and prevents birds from pulling out the material. By the way, it is customary to pay for the material separately. If you are offered to perform caulk work for 25 rubles. m.p., you should not agree, since the work will be done extremely poorly.

If you want to do all the work yourself, then stock up on patience, material, tools and subsequent information.

How to caulk a timber house with jute

Jute, as a material for insulating a log house, is gaining wild popularity. It is often used in the construction of the house itself.

Before caulking a timber house, you must first properly lay and secure the timber. Insulation is always laid in the inter-crown space with a layer of at least 5 mm. Even if the beam is profiled, jute must be laid between the tenon and groove. But its width depends on the shape of the tongue-and-groove system. The simplest option is when the lower beam has a surface convex with a crescent, and the upper one has the same notch (somewhat reminiscent of a joint of logs), in which case the space between the crowns is completely filled with insulation, and its edges remain hanging 4 - 5 cm on each side. A more complex version of profiled timber, when it is impossible to lay the insulation with a continuous carpet, then it is laid only in the middle, and the external and internal cracks are then caulked separately.

If the house is made of timber with natural humidity, then the thickness of the inter-crown insulation should be 10 - 15 mm.

Important! Caulking must be done from top to bottom. In this case, first one crown is caulked completely outside, then inside, and only then they move on to the second crown. It is better if the work is carried out by 4 people simultaneously on 4 walls. This is necessary to ensure that the house does not warp. After all, after caulking is completed, it will rise by several centimeters, from 5 to 15 cm.

Let's consider the option when the insulation hangs between the beams by 4 - 5 cm. The caulking technology is very well shown in the video example. Using a caulking tool (tool), the jute is tucked underneath and lightly pushed into the gap. Then it is gently, but more forcefully pushed in the upper part, and finally - in the middle. To push the material inside the crack, use a rubber or wooden hammer (mallet), which is gently hit on the caulk.

If, after the work has been completed, loose cracks are still observed, then additional caulking is performed.

Let's consider the option when the gaps between the crowns are not filled (the insulation is located somewhere in the middle of the beam). The work will be exactly the same as with additional caulking.

Usually the gaps between the beams are quite narrow, so this caulking method is used: a rope as thick as the gap is twisted from jute fiber and hammered into the gap with a mallet.

There is another way - “stretching”. Separately taken fibers of jute are laid in fibers across the beam and pushed inward with a spatula or caulk until the gap is completely filled. We leave the remaining ends of the material hanging, it should be about 5 - 6 cm. Next, take a little more jute, roll it into a ball (roller), which is wrapped in these hanging ends and pushed into the gap.

Important! How can you check whether it’s enough to push the insulation in or if you still need to add a little more? If a kitchen knife fits 15 mm or less into the gap between the crowns, then the caulking has been done successfully. If the knife goes further, then material should be added.

When large cracks are formed, use the “set” caulking method. Long strands of jute are twisted and rolled into a ball. Loops are then made from the ball and pushed into the cracks until they are filled.

After all caulking work is completed, the house is loaded and, if possible, used for a whole year. In winter, it will be possible to check for the presence of cracks using the so-called “hares”. These are pockets of frost on the outside of the wall. If you find them, mark the place, this means that there is a leak of warm air from the house. A year to a year and a half after the first caulking, a second caulking is carried out, the house is carefully inspected, insulation is added to those places where it has spilled out or frayed, where the cracks have widened, where the timber has warped, and also in places where there are “hares”.

Only after re-caulking can you begin the exterior and interior decoration of the house. Even if it involves 100 mm of mineral wool and a ventilated façade.

You can caulk a timber house with other materials. But there are some exceptions. For example, only a house made of non-profiled timber can be caulked with moss, since this material is laid and completely fills the inter-crown space, which is absolutely impossible if the timber has a tongue-and-groove system. The work itself on caulking a house is complex and painstaking, although from the outside it seems painfully simple. If you are not confident in your abilities, invite a specialist.

Caulking a timber house: video - example

Which is better to choose?

- Moss is the most environmentally friendly and durable material, but it is very difficult to obtain, to ensure compliance with installation technology and the need to maintain optimal moisture content of the insulation, since it crumbles when it dries out. Requires skilled work. Therefore, using moss will be the best solution if you have good caulkers.

- Linen tow is less strong and durable, and has low performance characteristics. Not suitable for timber walls due to high hygroscopicity.

- Hemp hemp is the best option, but is difficult to obtain. Natural jute is a good material, but has a short shelf life. Its advantage is density - 300-400 g/sq.m. m.

- Jute is the best insulation for a house made of profiled timber. It has a high density, and a layer of 3-4 mm is enough to lay it. If jute is not suitable for some reason, linen felt 5-10 mm thick will be an excellent solution for insulation.

How to choose a jute ribbon

Jute insulation is selected according to density, thickness and width. A high-density jute tape is laid between the crowns; when shrinking, the low-density insulation cakes more; the width is chosen according to the size of the timber; for rounded logs - according to the size of the laying groove. Experts recommend:

- Lay the edged timber with jute tape 20-25 mm thick; under pressure its thickness will be no more than 4 mm;

- For dry planed timber, use a tape 10-12 mm thick, which shrinks to 2 mm.

Intervention seams are caulked with a material of lower density; to fill cracks, jute batting with a density of 500-600 grams per square meter is used.

Consumables and tools

For this procedure, special tools are purchased that make the work process easier.

These include:

- different types of caulking (stacked or straight, curved, broken);

- road worker;

- mallet.

Caulking is an item for laying insulation between the crowns. Depending on the type, it is used for “stretch” or “set” work.

Many experts advise using wooden caulks rather than metal ones.

Purpose of the tools:

- Curved caulk is used for corner seams; its blade has a width of 50-60 mm.

- The breaking variety of the tool has a width of 30-35 mm; it is used, as the name implies, to “break” grooves in order to facilitate the laying of insulating fibers between them.

- The road worker is used to form rolls of tow so that the seam is beautiful. Usually has a width of 170 mm.

- Mallet - a wooden hammer for hammering insulation into gaps.

These basic tools will allow you to make caulk quickly and efficiently. In addition to them, for the work you will need a stepladder, gloves and consumables - moss, as well as a container for soaking it with soap and oil.

Video description

Description of the “stretch” caulking technology in the video:

This technique is practiced both using natural traditional materials and modern insulation materials, and if the material is represented by a tape or roll, caulking is much easier and faster. When caulking, standard tools are used: a wooden spatula and a wooden hammer.

- “To set” method

This method is used if significant gaps larger than 5 mm in size have formed during the shrinkage of the house.

From the selected material, carefully twist the tourniquet and fold it into loops. The space between the logs is filled with rolled loops, filling wide gaps and minor cracks as tightly as possible. A special spatula and a wooden hammer are used.

Method “to set” Source galich-dom.ru

With this technique, it is recommended to use rolled tape materials, since twisting strands of fibrous materials with the subsequent set of loops is a complex matter. But in general, seams can be sealed with any materials.

Step-by-step instruction

When insulating, it is customary to use two caulking options :

"Stretch" .

This method eliminates gaps in the longitudinal rows of wood around the perimeter of the entire house. The principle of work is to gradually fill all the gaps between the crowns with two strands: regular and twisted.The insulation fibers must be laid perpendicular to the beams, the ends of the material must be twisted into a roller, pushing between the remaining gap.

- "To the set." The method is most often used for re-caulking after shrinkage. A strand of insulation is twisted into a bundle, wrapped in a loop, and pushed into the gap. The fibers also occupy a position perpendicular to the beams. Typically, this method is required to eliminate cracks larger than 5 mm in diameter.

Each material has its own caulking method.

Tow

Caulking instructions:

- A wide fiber of tow is carefully hung along the entire seam. The upper part of the strand is driven into the slot, and the rest awaits the master’s repeated penetration.

- After completing one crown around the entire perimeter of the building, the caulker returns back. Now almost the entire 1-2 cm wide strand is driven inside the wall.

- After this, the loose ends are rolled up and pushed into the remaining space.

- The end result should be neat and even seams.

Before use, the tow must be freed from debris and combed, if this has not been done before.

Ribbon

Work with tape insulation is more labor-intensive due to the straightness of the timber. Because when you hammer in the material, it starts to come out on the other side.

Caulking instructions:

- First you need to hammer in the edge of the first tape, under which you place the second tape.

- The remaining ends will need to be placed so that the second layer of insulation is between the first.

If the seam width is large and the perimeter of the walls of the house is large, you will need a larger roll, since it is undesirable for the material to break.

To avoid distortions of the building, you will need to go through one crown at a time , and so gradually the entire timber house. Laying is carried out along the inside and outside of the building simultaneously in the absence of external finishing.

It’s worth starting from the corner of the house, so it’s better to control the work process. The material should be trimmed along the edge of the timber.

The nuances of caulking corners

For wide gaps, the twisted insulation is squeezed perpendicular to the wall using “set” loops. First push through the top part of the felt, then the bottom. In fact, caulking joints in corners is no different from the same technology for wall insulation .

Caulk or sealant for a log house - which is better?

Synthetic caulk works well for sealing gaps between crown timbers. It leaves no cracks or gaps, tightly filling all gaps. It is convenient to apply. In aesthetic terms, the sealant is also good, since it has different colors and can be matched to any type of wood, while fulfilling an aesthetic role.

The sealant itself does not serve as insulation and allows cold to pass through. Therefore, it is used only as an additional material that tightly covers all cracks. The composition of sealants is:

- silicone,

- acrylic,

- polyurethane.

The sealant has an impressive cost, so it is also combined with other, cheaper materials - jute, linen. This combined seam will hold heat perfectly.

The sealant is durable. When using it, you will not need to re-seal the seams. It also prevents insects from getting into the porous insulation.

To insulate a log house with sealant, you need to proceed as follows:

- Place insulation cord into the cracks.

- Fill the cracks with sealant. Start working from the bottom log, from the corner, from the outside of the log house. Move along the entire perimeter of the log house, and then higher.

- Carefully remove all excess sealant with a spatula.

- Treat the inside surface of the frame in the same way.

To answer the question: Caulking or warm seam - which is better for a log house? — it’s worth remembering the many advantages that a warm or heat-insulating joint made with wood sealant has:

- The sealant easily penetrates into all hard-to-reach cracks and seals them tightly. As a result, all cold bridges are blocked. The premises are reliably protected from drafts.

- Considerable strength. It does not crumble or fall out of cracks for a long time, and birds do not peck at it.

- The ability to preserve the walls of the house. Traditional insulation gets wet in wet weather and dampens the wood. As a result, the walls begin to rot. Acrylic sealant is moisture resistant.

- The ability to improve the microclimate in the house due to durable protection from moisture.

- Durability. The service life is 20 years or more.

- The sealant also protects the wood from insect pests, such as wood-boring beetles.

- The sealant tolerates any high and low temperatures, as well as their changes.

- Environmental friendliness. The sealant does not release any harmful substances into the air and is in perfect harmony with the wooden structure.

- Elasticity. The “Warm Seam” sealant is flexible and can change its shape following the expansion of cracks between the logs due to shrinkage of the house. In this case, no cracks are formed.

- The sealant is much easier to work with than traditional caulk. The process takes less time.

Although caulk is more expensive than tow, the caulking job is even more expensive.

Therefore, many owners of log houses prefer a modern method of insulating a log house, namely, using sealant instead of tow, moss and flax.

To make the seams look aesthetically pleasing, they are trimmed with decorative jute. In this case, all traces of sealant are covered.

The use of sealant for insulating a log or log house is called a breakthrough in modern construction.

Caulking a log house with sealant is done quickly and looks very neat.

Some owners of log houses use construction foam to insulate the seams between logs. This is not suitable insulation. Very quickly, within a year or two, it dries out, falls into pieces and falls out of the seams. After this, the caulking must be done again.

In addition, foam does not retain heat and cannot act as insulation.

To caulk a log house, you need to choose a special sealant for wood that retains its plasticity for a long time, does not dry out and does not fall out of the cracks. This sealant must be used in conjunction with insulation.

Construction foam is not suitable as insulation for log caulking. It quickly dries out and falls out of the seams.

Owner reviews

The traditional method of caulking a log house with tow or moss requires special skills from craftsmen. Nowadays such craftsmen are difficult to find. Therefore, hired workers do not always perform high-quality work, charging a lot of money for it. This is what Igor M. from Moscow says about his experience in insulating a bathhouse.

After building a bathhouse on the site, I hired a team and caulked the entire frame with tow. The work turned out to be expensive and long. But the guys were good, they didn’t drink, they worked every day. The job was completed in 3 weeks.

After 5 years of use, some of the logs cracked and gaps appeared between them. The question about caulking came up again. I no longer wanted to spend a lot of money on a team, and I couldn’t find good workers. And then I decided to do the work myself. I chose sealant as the insulation material. Everything turned out great, even better than the specialists.

The bathhouse has stood for 15 years and there are no cracks. Therefore, I advise everyone to choose new materials, namely, wood sealants.

Quality checking

Many owners of log houses hire construction crews to carry out such work. In this case, you need to know how to check the quality of the seams between the crowns.

You can use two methods:

You should try pushing a regular awl or knife into the seams. If it barely penetrates to a length of 15 cm and is not visible from the opposite side, the caulk is made with high quality.- You can also try pushing the caulk between the seams yourself using a mallet. Usually it rests on a dense layer of insulation.

The best option not to make a mistake is to choose a knowledgeable person who will take responsibility for monitoring the work.

Then we can hope that the builders will not “crash” and the caulking will be carried out according to all the rules.

Features of caulking an old log house

Often old houses lose heat because the insulation has crumbled and does not retain heat. This situation is especially typical for log houses caulked with moss: over time, it dries out, crumbles, and falls out of the cracks. In doing so, proceed as follows:

- Using a stiff brush, remove as much moss as possible from inside the house.

- Caulk the vacated cracks with a jute cloth using the stretch method, driving the cracks to half the thickness of the wall.

- From the outside of the building, clean off any remaining moss with a brush.

- Caulk the remaining part of the cracks outside.

Difficulties and errors

Errors may occur when working independently:

- Caulking is carried out only on one wall. In this case, distortion of the house is inevitable.

- Work begins with the upper crowns of a timber house or with the central ones, although according to the technology it is necessary to caulk the lower elements.

- Caulking is carried out only inside the building without external walls. In this case, distortions or insufficient thermal insulation are possible.

- The insulation between the crowns was laid too tightly after the construction of the log house was completed. This will prevent it from “settling” evenly. According to the rules, light caulking is required at this time, taking into account the deformation of the beams.

Since the seams of a log house are straight, without indentations, unlike the logs of a log house, it is difficult to install insulation, since it sticks out on the other side.

Self-help errors

Making caulk yourself is not easy. Lack of experience and lack of caulking skills lead to the fact that the work is of insufficient quality.

Typical mistakes that inexperienced professionals make:

- Using low quality insulation.

- Incorrect preparation of material for work.

- Violation of the sequence of work.

- Caulking the house on only one side, internal or external.

- The caulking is not around the perimeter of the building, but along the walls.

- Loose fit of the insulation and its protrusion from the seams.

The caulk will turn out to be of poor quality even if only one mistake is made. It is not easy to become a specialist caulker. Experience in caulking is acquired over years, so it is not surprising that inexperienced craftsmen often make mistakes, which then have to be corrected by professionals.

Material calculation

How to determine the amount of flax felt or jute fiber for work? First of all, you need to find out the required density of the material for a particular log house.

Insulation that is too thin will be displaced by heavier beams. Therefore, the density of the fibers and the thickness of the walls are related to each other.

So, with a beam diameter of 200-300 mm, the density of the linen tape should be at least 300 g/sq. m. With a standard wall thickness of 150 mm, the density is 200 g/sq. m. will be enough. This value has a 15 mm layer of linen insulation or 6-8 mm of jute insulation.

Once the density is determined, the volume of material required can be calculated. You will need to find out the perimeter of a wooden house made of timber on the outside. After this, you need to multiply the resulting number by the number of seams in one wall - corresponding to the crowns. This will be the total linear meters that need to be caulked.

Based on this number, the volume of purchased material is calculated.

There is no need to skimp on the amount of insulation. If the calculated number is 1 cubic meter of jute fiber, it is better to take a little extra, taking into account corner joints, door and window openings.

Caulking technology and methods

Two classic ways to fill inter-crown seams – caulk “set” and caulk “stretched”

Wide seams are caulked using the “set” method. The insulation is formed in the form of flat loops and the inter-crown cracks are filled with them tightly, completely, until the insulation enters.

With the “stretch” method, insulating materials are slightly stretched along the fiber in the form of a sheet, and a special tool called a caulk is pushed into the gaps between the crowns. The insulation sheet remaining outside the gap is rolled up with a roller and driven tightly into the gap.

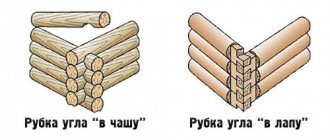

The most difficult thing to caulk is the corners of the house, due to cramped conditions and inconvenience of work. But it is in the corners that you should caulk especially carefully, since the corners are the main cold bridge of a wooden house, and are blown even more than window openings.

The technology is simple, but the work is very long and painstaking. It’s not difficult to master caulking; the point is to fill the seams with insulation as evenly and densely as possible, and the skill, as usual, comes along the way. Caulking is carried out using heat. They start working from the lower crowns, from the very bottom. Fill the seam, passing it around the entire perimeter, first from the inside and then from the outside. After passing the perimeter of one crown twice, you can proceed to the next crown, and so on for the entire frame. Under no circumstances should you caulk walls and corners in sections, or one wall or partition at a time. This can distort the entire frame. The shrinkage of the frame is uniform, but caulking can create uneven rises of the crowns, ultimately leading to a general uneven deformation.

If tape insulation is used, then before caulking, carefully straighten it and lay it out along the entire length of the crown or wall. They start from the corner joint, hammering the end of the tape insulation into it, and then evenly pass along the entire perimeter of the crown, laying and hammering the tape into the gap, and thoroughly compacting it. Caulking requires great care and does not like to be rushed. The insulation strips should not be twisted, but should be wrapped in a tight, tight roller.

It is necessary to caulk a log house regardless of whether it will be finished inside or along the façade. Caulking will not only insulate the log house, but will also not prevent infection and rotting of the logs. It is unacceptable to caulk the log house only from the inside or only from the outside, for the reasons given above - this can cause distortion and deformation of the log house.

Approximate costs

The cost of the work of craftsmen, regardless of the type of insulation material, is on average in the Russian Federation - 45 rubles per 1 sq. m. m, there are prices for 1 linear meter in the Moscow region - 65–70 rubles.

Removing old tow will cost about 30 rubles. for 1 m.

At the same time, the average prices for insulation materials in the Russian Federation:

- Jute tape - 9–16 rubles/1 linear line. m.

- Linen wool - 5–7 rubles/linear. m.

- Jute tow - 135 rubles/kg.

- Hemp hemp - 100 rubles/kg.

- Linen tow - 75 rubles/kg.

- Moss - 300 rubles/45 liter bag.

Insulation technology for log walls

From ancient times to this day, two main technologies have been used to insulate wooden walls.

Stretching - used mainly for caulking narrow cracks:

- a strand is formed from the selected insulation, placed in the slot and pushed through with a spatula, leaving an edge of the material about 5 cm long outside;

- then a thin roll is rolled out of the insulation, which is wrapped into the left free edge of the insulation and carefully, using a chisel, hammered into the groove.

Included in the set - used for caulking large grooves and cracks between logs:

- the sealant is twisted into long strands up to 15 mm thick and wound into balls;

- then it is carefully unwound, while simultaneously hammering the material into the cracks using a caulking chisel;

- if the gaps have different sizes, then for larger ones the required thickness of the insulation is gained by twisting it into loops.

Tools for work:

- caulks (they are different: type-setting, curved, broken);

- wooden mallet or rubber mallet with a wide head.

Caulking tools have a steel blade that must be soft and smooth, otherwise it may damage the seal.

Work order:

- The caulking process itself begins from the bottom, from the very bottom crown and continues upward. It must be taken into account that caulking the seams changes the height of the log house.

- One seam must be caulked along the entire perimeter of the log house, first from the outside, then from the inside. This will avoid distortions in the walls of the house.

- Then the next highest seam is processed. And so on until the very top.

It is forbidden to caulk individual walls; this may cause the wall to deviate from the vertical.

As you can see, the process of caulking a log house is not that complicated, but it requires great care and careful execution of all operations. Then your home will be protected from atmospheric influences for many years, and the facades of the house will take on a finished look.

(Visited 868 times, 1 visits today)

Moss

A very convenient material for applying before fitting the next timber - pieces of it are soaked in water before laying. The material itself remains dry after a long period of use. Durable, environmentally friendly, but...

!!! You won't be able to use it in gaps because it doesn't curl. After time, it dries out in the heat, turning into dust. Small particles will be carried away by the wind in the first year of use of the house.

Is it necessary to caulk a log house and why?

Wood, like any natural material, is subject to various natural processes under the influence of the external environment. Therefore, when purchasing a structure made of timber, a person should expect that after some time it may gain moisture or dry out. Then the house shrinks - on average by 10-12 cm per year. Under its own weight, the timber, which at the beginning of construction was almost perfectly fitted to each other, cracks and begins to form cracks. All the insulation laid between the crowns does not help matters. It can also lose its shape, and the house begins to “glow.”

Considering that the main goal of building a wooden house is comfort and its heat-saving properties, the timber is caulked. It prevents:

- accumulation of excess moisture, which contributes to the appearance of dampness on the walls and rotting of the surface;

- penetration of cold air from outside;

- heat loss;

- icing of walls.

Caulking also allows you to level a wooden structure after it has been deformed during shrinkage.

The process of filling gaps between logs

If the gap between the logs is even and approximately the same, you can push the insulation into the recesses with a special wide spatula - a road builder. This allows you to speed up your work. If the recesses are uneven, with narrow gaps, it is better to use a tool with a sharp tip. If the cracks are crooked and you have to drive the sealant into them at an angle, then it is better to use an oblique metal caulk.

You can process seams and gaps with jute in different ways. The choice of method depends on the size of the cracks and the desired aesthetics. There are 2 main approaches to laying the seal:

- Stretch. The compaction material is taken in individual strands and pushed with a thin tool along the gap between the logs. A roll is formed from the hanging remains of jute and forcefully compacted into the groove using a thin tool and a hammer. This method is suitable for processing small cracks and allows you to create good thermal insulation. But the wall does not look entirely aesthetically pleasing due to the remnants of insulation peeking out from under the logs.

- Into the set. This method allows you to process even the largest gaps. To do this, jute fibers of the required length are taken, which are then wound into balls. The larger the gap, the larger the ball you need to form. Then the formed balls are filled tightly into the cracks using a chisel and hammer. When using this method, the edges of the insulation do not protrude from the gaps between the logs, making the treated walls look more aesthetically pleasing.

Caulking should be done evenly, in a circle, level by level. You should move from bottom to top. If you treat each wall separately, the entire structure may become warped due to uneven distribution of gravity. One should take into account the fact that after caulking, the structure can grow in height by almost 15 cm.

How to make a log house correctly

Unfortunately, without this additional procedure it is impossible to achieve a normal microclimate in a wooden house.

Our ancestors came up with an effective way to deal with uninvited “fickle” guests. To do this, write down the rope with your own hands: after the trailer structure in the house, the room is tightly packed with insulating material on a natural basis (for example, moss, hemp, yarn).

Then the wooden cottage was completely protected from the weather, and the thermally insulated seams adequately played the role of a protective “jacket”.

Until now, the ancient technology is still in process, only the tools and materials for the work have been improved.

Builders systematized this process by developing two algorithms for constructing poles.