To build a private house from wood, many people choose profile timber. Manufacturers produce this popular building material in several types. They offer timber with two types of profiles - tongue and tongue and groove. Each option has its own advantages and features. Therefore, before purchasing lumber for the construction of a wooden house, it is worth finding out which profile of the house is better and more practical.

Comb profile

This profile got its name due to the appearance of its locking connection. The second name of the comb is the German profile. Depending on the width of the beam, it can have from 4 to 6 grooves. The comb lock ensures high reliability and immobility of the connection of adjacent elements. Therefore, houses built from timber with this profile are durable and safe.

The peculiarity of the lock connection is the absence of gaps between the beams. The comb ensures their tight fit to each other. This allows you to avoid laying flax-jute fiber between the crowns. Due to the absence of gaps, cold will not penetrate into the building. Therefore, caulking of the walls is not required. This reduces building construction costs and increases the speed of work. To increase heat saving in a building, it is recommended to use 3-4 pieces of timber with grooves for the construction of a residential building.

When choosing timber with a German profile, you need to know that the lumber must be made from dried wood. If it is made from wood with natural moisture, then during shrinkage the grooves may change their geometry and dimensions.

Manufacturer is different

It is possible to make a complex locking connection only on a specialized four-sided milling machine with special cutters. Inexpensive machines are not suitable for such work.

After manufacturing the profile, responsible manufacturers clean the lock from sawdust and treat it with special antiseptic compounds. Small companies miss this stage, and it is not uncommon to find inexpensive lumber on the market that is susceptible to rot and mold. It’s not worth buying this one, as its quality characteristics have been lost.

It is difficult to dry a large section, so you should only buy chamber lumber from a trusted company. You can distinguish a good-quality manufacturer by a number of signs:

- have been working in this industry for more than 5 years.

- have their own warehouses where finished lumber is stored in a certain humidity and cleanliness.

- The goods will be delivered to the construction site packed in sealed film.

- They provide a guarantee on their lumber.

- treat the material with antiseptics, since it will be difficult to process a complex lock in the future.

Positive feedback from customers is important. Moreover, you should be wary if there are no negative reviews among them. Only those who do nothing make no mistakes. Moreover, one should not exclude the human factor when producing complex profiled comb material. You can see more details on how a complex lock is made in the video:

Let's look at several large companies that produce profiled timber combs in the form of a table:

| Manufacturing company | Contact details | Types of profiles produced |

| “LesStroy” | Moscow, st. Kommunisticheskaya 123-23 b, office 14. | Comb, simple profile, plain and laminated timber. |

| “PiloProm” | St. Petersburg, Lenin Avenue 41, office 2b | Finnish, comb, simple. |

| “LesSnab” | Kirov, st. Yarovaya 21, section 2. | Any type of profile, glued and profiled timber. |

Any major manufacturer offers customers high-quality comb lumber at an affordable price with a flexible system of discounts. Since most companies producing timber offer ready-made houses from the material, we recommend buying one for DIY construction. Whichever manufacturer is closer to your construction site and has more positive reviews is better.

Tongue and groove profile

The locking connection has two tenons located at the edges of the beam and a groove between them. The profile ensures a tight fit of adjacent crowns, which helps prevent the walls from blowing even when gaps form after shrinkage of the wood.

Unlike the German profile, timber with a tongue-and-groove connection requires insulation. It provides protection from blowing if, when the building shrinks, gaps appear between the crowns.

The advantages of the tongue-and-groove connection are the ease of assembly of the timber. Moreover, if necessary, the erected structure can be easily disassembled.

Price analysis

The price depends on the type of wood, cross-section and distance from the manufacturer. The price of gasoline and seasonality are also important. So in winter you can buy lumber at a lower price and of high quality. Let's look at the average price for comb material in the table:

| View | Price of different sections, mm, rub./cube | |||

| 100x100 | 150x150 | 150x200 | 200x200 | |

| Natural humidity | From 9 000 | From 11 000 | From 11 500 | From 14 000 |

| Chamber drying | From 11 000 | From 13 000 | From 13 500 | From 17 000 |

| Glued | From 12 000 | From 14 000 | From 17 000 | From 25 000 |

It’s too early to talk about quality in full, since we got the material not so long ago. It is impossible to say in monosyllables which profile is better, a comb beam from the manufacturer or a simple one. Its use in Europe and other countries is not an indicator, since our climate is different.

Features of profiled timber

The main advantage of profiled timber is that it is made from dried wood. This is done in order to prevent strong shrinkage of the lumber and a noticeable change in the geometry of its grooves and tenons. Manufacturers use natural or kiln-dried lumber. At the same time, they ensure that the moisture content of the timber before cutting the profiles does not exceed 22%.

The construction of buildings made of timber with interlocking connections does not take much time. Profiles are cut at the stage of lumber production. Therefore, the timber is delivered to the site ready for assembly. Builders only need to fold it in the order determined by the project plan.

It is difficult to say which type of profile is better. Each of them has its own advantages and disadvantages. The comb allows you to speed up the construction of a residential building, but it ensures a permanent connection. Therefore, dismantling lumber will be difficult to perform. The tongue and groove, on the contrary, makes it easy to disassemble the constructed wall, but the construction time will be longer due to the need to install insulation. What to choose - everyone who wants to build a house from timber decides for themselves. If you compare prices, they are almost the same for lumber with different profiles. Therefore, when selecting a building material, you first need to look at the ease of its installation and performance characteristics, and not at the cost.

Pros and cons of comb timber

When planning permanent residence in your own wooden house, you will need to take care in advance about insulating the walls of the building. You should choose products only from large manufacturers. When deciding which timber to choose, you should take into account other advantages of multi-tenon corrugated timber:

- Accelerated pace of construction work in compliance with the technology of laying tongue-and-groove products.

- The high quality of raw materials for the production of corrugated timber ensures a reduction in heat losses in finished houses.

- Insulation or sealing tape is not used when constructing walls made of corrugated timber.

If comb-profiled beams are laid in rainy weather, their humidity begins to increase. The construction of a wooden house from high-quality timber occurs quickly if all work is carried out by experienced craftsmen. The concept of a high-quality profile means a dry building material that was stored in acceptable conditions before use. In general, the type of profile does not play a big role in the process of speeding up the assembly of walls, since the result always depends on the professionalism of the builders.

Since insulation of the walls of a house made of German timber is excluded, finishing work will not be required. This significantly reduces the cost of construction work. Living in a new wooden house will be comfortable, since the comb beam ideally retains heat and does not allow moisture to pass between the crowns.

After the work related to laying thermal insulation, the facade of the house requires a suitable finish. This type of work is carried out not only after the walls are insulated, but also when various damage to the wood appears. It is worth remembering the torsion of the timber due to strong drying, which causes the formation of cracks between individual structural elements.

Shrinkage of a house made of profiled timber with natural humidity

Wooden building materials are characterized by their ability to respond to changes in humidity. It is impossible to accurately predict the consequences of the influence of factors on wood. Since the likelihood of cracks and gaps occurring between the crowns is high, assembling a house from profiled timber requires the use of special devices: dowels, pins, etc. They are necessary for a complete interlocking connection of the beams. In practice, gaps and cracks of completely different sizes can appear in any type of timber.

Appearance

This timber may differ in its appearance on the front side. There are types:

- Straight outer side.

- D – Shaped front side.

The straight outer side of profiled lumber is the standard option. By using this type, you will get smooth and straight external walls.

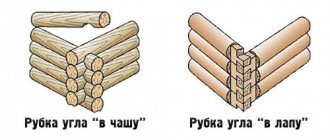

D – The shaped front side is used for Block House buildings. This type of timber is suitable for those who want to have an aesthetic house reminiscent of a Russian log hut. The rounded outer side of such a profiled beam will make it possible to create such a structure. In this case, the internal walls will be smooth.

Professional services

We employ specialists who have both experience and skills in working with any finishing materials. Cladding of wooden houses is one of the main specializations of our company.

Wood is a building material that we know everything about; we have been working with wood for more than ten years, so we have studied all the nuances of its behavior. We will carry out any type of cladding efficiently, professionally and in compliance with contractual deadlines.

To contact us, go to the “Contacts” section, where you can find all our coordinates.

Benefits and advantages of the material

The main reasons why preference is given to profiled “comb” timber when building wooden houses is speed, quality and ease of wall construction. The use of such material allows us to reduce labor costs and the impact of the human factor on the construction result.

This is achieved through the following components:

- precision of factory production - eliminates the need for significant fitting operations;

- ready-cut bowls on all four sides – provides a reliable “labyrinth lock”, which makes the structure practically windproof;

- marking of cut elements - allows you to quickly and correctly erect a structure in full accordance with the assembly map.

High thermal insulation properties

The shape of the comb prevents the walls from being blown through and moisture from flowing in. Spruce and pine - materials for the production of timber - are characterized by a low thermal conductivity coefficient, which is 4 times less than that of ceramic bricks. This means that a wall made of 20 cm wide timber has the same thermal insulation properties as 80 cm thick brickwork!

Rigidity and strength of the structure

The walls are an almost monolithic compound. After drying, the timber does not crack or deform. Due to the use of a profiled shape, there is no need to use a seal.

Finished facade finishing

Assembling a house from profiled timber does not require external finishing with various panels. This is the case when installing popular siding will only do harm. After all, during the assembly process, the house immediately acquires the beautiful and expensive appearance of real wood.

Environmental friendliness and comfort

Wood absorbs various odors. Natural material does not contain harmful additives. The house is provided with constant humidity, natural ventilation and freshness. Residents of such a building fully enjoy the comfort of a cozy microclimate.

Wall insulation

Houses made of laminated veneer lumber with a wall thickness of 200 mm or more can withstand the most severe frosts and do not require additional insulation, even when built in the north of Russia. But for houses with thinner walls - for example, country houses - heating can become the most expensive service in the field of housing communications, because in cold weather the walls transmit 40% of the heat. Therefore, by properly insulating the walls of your country house, you will solve both thermal and financial issues.

Common insulation materials in order of decreasing thermal conductivity

The key characteristic of insulation is thermal conductivity. It shows the amount of heat that passes through a sample of material 1 m thick, with an area of 1 m2, in 1 second. The lower the thermal conductivity, the more effectively the insulation retains temperature and the less thickness you will need to thermally protect your home.

Fiberboard, 0.08 - 0.1 W/m*S

- Not susceptible to rotting, insects and rodents when dry;

- Does not deform from frost and prolonged exposure to moisture.

- Susceptible to fungus at humidity levels greater than 35%, which is why it should not be used in damp areas.

Foam plastic, 0.037 - 0.047 W/m*S

- Fungus and mold do not form on the surface of the foam;

- Easy to process and install.

- It is fragile and therefore requires additional protection from mechanical damage;

- Easily destroyed under the influence of nitro paints or paints and their vapors. This means you are limited in your choice of finishes.

Sprayed ecowool, 0.04 W/m*S

A loose material that is 81% cellulose and 19% additives.

- Creates a uniform layer without cracks and gaps;

- Does not require a frame for application;

- Protected from fungus and rodents.

- Shrinks up to 20%;

- Price.

Cork material, 0.04 W/m*S

It consists of slabs of crushed cork oak bark and binding additives of organic origin.

- Hard and durable;

- Resistant to rotting and mold formation when exposed to moisture;

- Not afraid of rodents;

- Does not change volume with humidity fluctuations.

Stone wool, 0.035 - 0.039 W/m*S

It is also mineral wool and basalt insulation. Often, buyers believe that these are different insulation materials - in fact, these are varieties of the same material.

- It fits well due to its elasticity, softness and lightness;

- Not attractive to rodents and microorganisms.

- Absorbs moisture and, as it gets wet, loses its thermal insulation properties. Therefore, it provides for the installation of vapor and moisture insulation;

- Fibers that separate from the cotton wool and enter the lungs cause irritation;

- It compacts and clumps.

Sprayed polyurethane, 0.03 W/m*S

- Creates a uniform layer without cracks and gaps;

- Does not require the creation of a frame for application;

- Not susceptible to chemicals.

- Price;

- Rapid aging.

Liquid ceramic insulation, 0.002 - 0.005 W/m*S

Do-it-yourself finishing caulk

After the log house has been subjected to shrinkage, finishing caulking is carried out at home. During the shrinkage process, the previously laid layer of insulation is deformed, voids can form in the inter-crown cracks, and vertical cracks can form in the corners of the frame. The operation is performed from the outside and inside. Caulking is a labor-intensive process that requires diligence and attention; the main tool is a wide wooden chisel or rubber mallet. To avoid damaging the integrity of the fibers, it is better to blunt the chisel. The operation begins with the lower crown along the entire perimeter, after caulking of the first crown is completed, they move on to the second, etc.

Disadvantages of the material

Such construction can cost the owner several times more than when using conventional timber with natural moisture. But this is offset by a large number of advantages, which are discussed above.

Houses made of such material require higher heating costs compared to buildings for the construction of which insulated profiled timber was used. But it should be noted that the cost of insulated products is higher than that of simple ones.

For greater durability of any wooden house, it is treated with antiseptic compounds. Such a structure is more demanding to maintain than a brick structure.

Errors in doing the work yourself

At first glance, it seems that covering a log house is not particularly difficult. Therefore, many, without particularly delving into the process, undertake to decorate the house on their own, which does not have the best effect on the final result. Self-finishing leads to a poor appearance, poor-quality thermal insulation and has a direct impact on the comfort of living in the house.

Among the typical mistakes that non-professional craftsmen often make are the following:

- Out of a desire to save on material, many home-grown builders increase the pitch between the beams when installing the sheathing. The recommended distance between the frame elements is 40-50 cm, the maximum step length is 60 cm. Even a slight increase in the distance will lead to sagging of the skin, which will reduce its service life.

- When installing a ventilated frame, it is necessary to install a counter-lattice, but not everyone does this. As a result, the mineral wool slabs used as insulation are artificially pressed against the waterproofing, which causes a quilt effect. This leads to unevenness and depressions when installing the sheathing, which will also sag, as in the first case.

- When installing siding or lining, not everyone uses a building level and a cord to properly install the planks. As a result, the skin is uneven and looks skewed over the entire surface.

We have listed only the most common mistakes made by home craftsmen that have to be corrected by professionals. In fact, there are much more of them. We strongly recommend that you do not start decorating a house or bathhouse without experience and work skills. Our specialists will do the cladding quickly and professionally, without making a single mistake.

A little about sizes

As mentioned earlier, not all sizes are suitable for the construction of one or another part of the house. Many companies and firms provide services for individual production of lumber. The standard dimensions and thickness remain common, which is 100, 150 and 200 mm.

Small wooden structures do not need material with a thick cross-section. This could be a gazebo, veranda or small summer kitchen. A thickness of 100 mm is ideal here; a full-fledged residential building cannot be built from such material, but for a house that is used only in the summer, this is an excellent choice.

A thickness of 150 mm is already suitable for a large house. It is thicker than the timber that is used for the roof rafter system with a section of 100-150 mm, but at the same time it is cheaper than a section of 200-200. The standard here is a form with a comb look. In winter, such houses do not freeze.

Cottages, mansions or simply large residential buildings - all these buildings have in common a size of 200 mm or even 220 mm. A cross section of 200-150 and 200-200 mm is used here. The walls of such buildings are highly resistant and do not let the cold inside.

How to save money on timber construction

The budget deficit for building a house does not always allow you to choose expensive and high-quality materials. But, if you know how to choose the right timber - ordinary, not subjected to special treatment, and how to prepare it for work, you can save a lot and get a good-quality and beautiful structure. Our tips will help you with this.

So, what to look for when buying?

- Evenness of timber. Determined visually and practically. The product must be placed on a flat surface with all its edges in turn and make sure that it is not bent or twisted by a “propeller”.

- The distances between the annual rings, visible at the end of the beam, should be the same. If they narrow or widen on one side, this indicates that over time the beam will “lead” and it will bend.

- The surface of the wood must be uniform in color everywhere. A visually noticeable color contrast at the ends or side edges indicates the presence of layers with different internal stresses, which will also lead to deformation.

It is much more difficult to determine the moisture content of the material. But even if you see that the timber is completely fresh, but of good quality, you can independently bring it to the desired condition. True, this will take time.

Place the purchased material in stacks, placing even veins under each layer every 1-1.5 meters. Leave a distance of 2-3 cm between the beams in a row so that they are blown with air from all sides. Also place veins on top and cover the top of the stack.

Storing timber for drying

To avoid drying too quickly, which is accompanied by the appearance of cracks, position the timber so that the sun's rays are not directed at the ends. And whiten the ends themselves.

Construction can begin when the moisture content of the material is less than 20%. In this case, you can count on uniform shrinkage and the absence of deep cracks. And it will be easier to work with him.

Advice. Before choosing a groove in a beam for its corner or longitudinal connection, study the relevant articles on our website.