Treatment of a wooden house after construction is an essential part of its operation. Without protection, the tree quickly darkens, deteriorates, rots, and insects appear inside. As a result, the appearance deteriorates and the service life is reduced. Proper treatment protects the walls from the sun, moisture and pests, and becomes an additional decoration of the cottage.

When processing a wooden house made of timber after construction, it is important to protect the surface, but preserve the natural properties of the materials. From the article you will learn when, how and with what to treat a wooden cottage so that it becomes beautiful, receives reliable protection and does not lose the pleasant aroma of a coniferous forest.

Tasks for painting walls from the inside:

- The coating protects the wall from dirt and abrasions. The sanded surface is easy to stain - the dirt eats into the wood, and sometimes you have to remove a layer of wood to remove it. It is much easier to wash off dirt from a painted wall.

- Paint is needed to protect against high humidity and direct ingress of water. If it is decided to leave exposed wood in the “wet zone,” then the walls are painted with a waterproof compound or covered with a moisture-resistant impregnation. This technology is used in bathrooms, swimming pools, and kitchen work areas.

- The right shade helps solve design problems. The color of the walls is chosen taking into account the purpose of the rooms: calm shades for bedrooms, neutral shades for common areas, bright shades for the kitchen and living room. It is important not to overdo it with saturation, otherwise the walls can visually reduce the volume of the room.

Bedroom in a house according to the SV-4 project

How to protect timber before construction?

If it is impossible to begin work on assembling a log house immediately after manufacturing a set of beams, it is necessary to ensure their proper storage, which for lumber consists of using moisture-proof packaging. To do this you should:

- stack the beams using wooden supports between each row,

- there should be a distance of 5 cm between adjacent bars in a row,

- the stacked stack is covered with tarpaulin or wrapping paper.

The ground in the storage area must be level to prevent puddles from accumulating under the beams. It is not recommended to use polyethylene film as packaging material, which does not provide protection against UV radiation from the sun. Fulfillment of these conditions will prevent the appearance of mold on stored wood from excess moisture.

Purposes of processing and painting walls outside:

- The coating prevents exposure to ultraviolet radiation. Direct sunlight discolors and dries out the outer part of the fibers, accelerating the destruction of wood. Unpainted areas quickly darken and become brittle.

- The paint coating film protects the walls from direct moisture. The paint does not absorb water - drops flow down the surface, the wood retains normal humidity. Without coating, the fibers swell, lose their shape, and cracks appear on the timber.

- The antiseptic protects the tree from insect pests, fungus, and mold. The wall is impregnated with an antiseptic before painting or multifunctional paints and varnishes are used.

- Paint affects the appearance of a building. When painting a wooden house, natural wood shades are often preserved, but there are houses made of timber in white, pink, blue and even black.

House according to project SP-4

Reasons why a log house should be treated with antiseptics. Expert opinion

Novice builders, building a wooden house for the first time, have probably heard advice regarding the antiseptic treatment of a log house. Some listen and carry it out, while others neglect the use of antiseptics, because... They don’t even suspect what problems can arise in the first year after construction with a wooden house not impregnated with antiseptics.

1 reason for antiseptic treatment of a log house

All untreated wood materials are exposed to biological agents. Mold and fungus spores usually appear on wood in the forest, before it is cut down. And as soon as suitable conditions for the development of biological pests are provided, they will immediately begin to develop. Initially, small multi-colored spots can be detected on the material. Over time, these stains will begin to grow, they will not only worsen the appearance of the wood, but also have a negative impact on the health of people around. Residents of a wooden house infected with mold may develop allergic diseases, problems with the upper respiratory tract, laryngitis is often observed, and asthma is possible.

In the future, these fungi will begin to develop into wood-destroying fungi, which will begin to destroy the wooden material. A tree under their influence can turn into dust in a short period. And then it will be impossible to return it to its previous appearance.

2 reasons for antiseptic treatment of a log house

Wood is a living material, which is why it is valued in the field of house construction. The same quality of wood is also valued by insects that settle in it and feed on its fibers. These beetles are pests that cause great harm to wooden materials. They settle under the bark, as deep as possible, and gnaw through many passages in it, which impair the strength of the material. Over time, the tree can fall apart even from slight mechanical stress.

Insects can also carry a fungal infection deep into the wood. Why will it begin to rot from the inside? The danger is that insect infestation of a material is difficult to detect at first, and in more severe situations it is impossible to restore the characteristics of the material.

3 reasons for antiseptic treatment of a log house

Wooden material is also negatively affected by the environment. Wood can crack and fade from sunlight. Constant rain and contact with moisture can lead to rotting of the wooden material. Fire is a great danger to a log house; under its influence a large house can burn out in just minutes.

All these pests and atmospheric conditions lead to damage to the wooden material, deterioration of its strength characteristics and overall appearance. Antiseptic impregnations can protect a home from many unpleasant influences; they prevent the occurrence of fungi and mold, insects, fire and reduce the severity of the consequences of weather conditions.

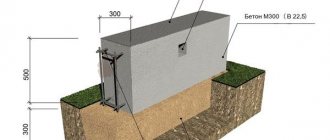

Why are the ends sealed?

A special sealant is applied to the ends of the beam, which completely blocks the ingress of water through the end cut, without interfering with natural moisture and air exchange. Without sealant, moisture quickly absorbs and evaporates through the cross section, the wood swells, cracks, and collapses. It is easier for pests to penetrate the tree through the end. The most correct option is to tightly seal the ends.

Choice of paint and varnish

See also

Decorative plaster lamb

Antiseptic and fire protection treatment of the outside of a log bathhouse is important. But it is equally important to then coat the wood with paint or varnish. And at least 2 layers.

A bathhouse is not quite the same as painting imitation timber, since the material, as well as the operating conditions, are somewhat different.

When thinking about how to paint a log bathhouse on the outside, you usually choose among the following options:

- Oil paints

. The most affordable. But they are not environmentally friendly. Plus the service life is insignificant. That’s why I don’t recommend taking it; - Alkyd varnishes and paints

. One of the best options for baths, as well as exterior wood finishing. There are no toxins or solvents in the composition. Durable, durable, vapor permeable. They also have a wide palette of shades. Color fading does not occur over time; - Scuba diving

. They contain acrylates, resins and dispersions. Eco-friendly and beautiful in appearance. But they are inferior in durability; - Oil waxes and clear varnishes

. The main advantage is the ability to preserve the original appearance of the material. But you can’t count on a high level of protection; - Acrylic paints.

Perhaps the best paint option for wood, which is ahead of even alkyd analogues. They are offered in a large assortment, are environmentally friendly, odorless, do not cause allergies and fit perfectly on a wooden surface. The disadvantage is the high price.

And then decide for yourself how to paint the outside of the timber bathhouse.

I don’t think it’s worth mentioning how to paint a bathhouse.

Technologies for processing a wooden house made of timber after construction

Antiseptic . Necessary to prevent the formation of fungus, mold, and insect damage. For antiseptic use, special impregnations are used that penetrate the wood and destroy pests.

It is especially important to use an antiseptic if the construction is carried out from ordinary timber or logs - beetles and microorganisms often grow in heartwood. Logs are often completely immersed in antiseptic baths directly on the construction site and further treated after construction.

Glued laminated timber is not so susceptible to rotting - the manufacturing technology includes several mandatory stages of testing and chamber drying. Glued laminated timber is treated with an antiseptic on the outside - this is enough.

Painting . This is the final stage of processing a wooden wall - the composition with colorant is applied to the wood in 2-3 layers, creating protection from ultraviolet radiation and moisture. When painting, the wood texture is preserved (glaze coating) or completely hidden (covering).

The paint is applied in 2 or 3 layers with preliminary and intermediate sanding. Painting technology depends on the manufacturer's recommendations.

Complex processing . To speed up and reduce the cost of processing, universal compositions are used: paint that contains an antiseptic. This approach speeds up construction and makes processing cheaper.

How to get rid of wood blue stains

An alarming “bell” is a change in the color of the wood and the appearance of bluish or blue-gray bald spots on the surface of the external walls; a log house under shrinkage is most often susceptible to this phenomenon. The appearance of blue discoloration is caused by the development of a fungus that feeds on wood starch and glucose. Blue appears actively in the first months after the construction of a log house; the cause of this phenomenon is most often the use of waterlogged timber.

It is believed that blue fungus does not destroy wood fibers, the tree retains its properties, but its appearance indicates that something is wrong with the wood material and measures must be taken. In recent studies, scientists have noted that blue damage does not go away without a trace; in the affected areas, an increase in pores is observed and hygroscopicity increases. This phenomenon reduces the service life of the structure.

The blue develops from the outside and penetrates deeply into the timber; sanding does not completely eliminate this defect; the façade of a house with blue-gray stains has an unpresentable appearance. Blue mold is easily eliminated with chlorine bleaches “Belizna”, “Iney”, “Sagus”. It is advisable to carry out the treatment immediately after the first signs of damage appear; if the timber is covered with blue in the stack, it is advisable to treat it before laying it in the log house and further dry it in a well-ventilated place.

Wood blue: 1-surface; 2-deep.

Basic stages of processing a wooden house after construction

- Checking humidity. For high-quality painting, the wall humidity should be within 12-15%.

- Primary grinding. Wood is sanded not only for leveling - mechanical processing opens the pores and ensures deep penetration of the antiseptic.

- Antiseptic. Pre-impregnation with an antiseptic is necessary when using regular wood paint. If the composition contains an antiseptic, the item is skipped.

- Padding. The primer penetrates the fibers and ensures a strong bond between the paint and varnish coating and the wall. When priming an external wall made of laminated veneer lumber, a thin layer of paint is usually used, which already contains an antiseptic.

- Intermediate sanding. Soft mechanical processing removes possible irregularities - when priming, the “pile” on the fibers rises.

- Application of intermediate and final coating. Three-layer painting creates the most saturated color and reliably protects the wood from precipitation, sun, and pests.

- End sealing. The sealant is applied according to the manufacturer's recommendations.

How often is treatment required?

The first application of protective and decorative agents is carried out immediately after completion of construction - it is best to do this after the construction of the roof. This primary treatment will become the basis for the longevity of the structure and the preservation of its aesthetic appearance.

It is advisable to carry out repeated and subsequent treatment of external surfaces annually, but at least once every 3-4 years.

For the first time, internal processing is carried out simultaneously with external processing. Repeated is done with the same frequency as the external one. Its main task is fire and antiseptic protection.

How to treat a wooden house after construction

To prevent protection from spoiling the feeling of a new wooden house, you need to choose a neutral composition of paints and varnishes. GOOD WOOD uses SEDIPAN products, a water-based acrylic paint. The coating applies smoothly, dries quickly, and leaves no odor.

For exterior painting, we use the WACT 640 line as a primer - the products contain a large amount of antiseptic and colorant, which additionally protects the wall from ultraviolet radiation. For interior decoration, it is enough to use WACT 650 - a paint with a lower antiseptic content. We seal the ends with a special compound WV 024, which completely blocks the sap-conducting channels, without disrupting the moisture and air exchange of the wood.

Is it necessary to prime the surface?

Wood protection consists of three main stages, after which you can begin to prime the surface.

A primer is necessary so that further finishing work can be carried out. In addition to the fact that the primer significantly increases adhesion between materials, it closes all pores from negative effects.

Priming is necessary to improve adhesion between layers of paints and varnishes

At the final stage, the outside of the timber is treated with a special bleaching agent. With its help, wood acquires a magnificent appearance. The final processing depends on what kind of finishing will follow. It is also possible to coat the wood with a special wax.

High-quality processing guarantees the preservation of the attractive appearance of a wooden house. But most importantly, the house will last much longer in this case. The environmental impact in this case will not be so destructive.

When performing all work, it is imperative to strictly follow all instructions from the manufacturers that are indicated on the packaging. It is also recommended to take the advice of experienced craftsmen who know all the intricacies of performing such work. And only in this case can you get a high-quality result for a long time, without the need to carry out repair work in the near future.

Processing results

- Long-lasting barrier against pests, insects, fungus. The sealant protects the end, the antiseptic impregnates the outer part, and the paint prevents the protection from being washed away.

- Ultraviolet light does not cause wood to darken. The house retains its “fresh” color. If the color is chosen correctly, then there is no resin release or burnout on the surface.

- Moisture protection. The film covers the entire wall, even after a serious rainfall the walls do not get wet.

- The house corresponds to the design project. The cottage is beautiful inside and out.

Neomid Thor Plus

Neomidator Plus has an aqueous composition, which includes synthetic copolymers and various auxiliary substances. It is intended to provide protection for the ends of logs, beams and other dimensional materials, both individually and in ready-made structures, such as bathhouses, houses, gazebos, etc. This composition prevents the occurrence of rotting and cracking of wood during drying of the material. After treatment with Neomid Tor Plus, a thin elastic coating is formed on the surface of the log structure, which will provide good water resistance and vapor permeability. Thus, the wood will not accumulate excess moisture. The structure of the wood will not change after processing.

When to treat a wooden house

It is recommended not to delay with protective coatings and to paint the house in the first 3-6 months after construction. Before painting, be sure to check the humidity of the walls - manufacturers of paints and varnishes usually indicate 12-15% in the instructions.

Question to a specialist: - Is it possible to paint a house in winter? — Most paints and varnishes are applied at a temperature not lower than 15 °C. If you need to paint a house in winter, we build greenhouses and heat it with heat guns. If the technology is followed, the paint will not dry for long.

How to use Neomid Thor Plus?

This composition is available in ready-to-use form, so it does not need to be diluted with anything. But it is recommended to stir before application. It is necessary to work with Neomid Thor Plus only at temperatures exceeding 10 degrees Celsius. Do not apply the product to frozen products or at low temperatures. It is necessary to carefully prepare the surface before applying the protective composition, check for dirt and dust. If mold or mildew has appeared on the log house, then before applying Thor Plus it is necessary to eliminate them and remove stains using bleach.

The composition must be applied in an even layer. You can use various tools, spray devices, rollers or brushes. For best effectiveness, it is better to apply 2 layers. When working, you must also remember about safety. Contact with skin or eyes can cause severe irritation and an allergic reaction. Therefore, it is recommended to wear special protective clothing, and do not forget about gloves and goggles. If the product does get on the skin or mucous membranes, it is necessary to rinse thoroughly with water and if the burning sensation does not go away and the redness does not go away, then you should contact a medical facility.

Where to order treatment at home

It doesn’t matter who paints the cottage - a construction company or a third-party team. The main thing is that painters know how to work with wood. GOOD WOOD has its own painting department, where you can order professional finishing of a laminated timber home. All work is controlled by a technical supervision engineer.

Checking the thickness of the paint coating is an important point in the painting phase. Want to know more about painting? Call GOOD WOOD and schedule an appointment with a painting representative. If necessary, a specialist visits the site, assesses the condition of the walls, helps you choose the color and treatment option.

How to choose the right antiseptic for profiled material

The offer of impregnations for houses made of profiled timber is wide. The price category is similar to any product. The more popular the brand, the more expensive the product. But cheap antiseptics are not always less effective. There are professional products that do not reach the buyer at all, since the manufacturer works directly with companies that produce profiled material. You can choose the right composition for impregnating a log house yourself, the main thing is to take into account some factors:

- Class and degree of protection (medium, high, low). Professional products only have a high degree of protection. For exterior treatment, it is better to take these; for interior, medium and low are suitable.

- Non-toxic to animals and humans.

- Resistance to external influences (resistance to mechanical stress, ultraviolet radiation, precipitation, temperature changes, etc.)

- Effective period of one or two coatings (from 1 year to 15 years)

- Penetration depth.

- Impregnation consumption per 1m2.

- Temperature conditions at which you can work with an antiseptic (from -20 to +50 degrees).

- Price-quality ratio".

Based on these factors, you can choose a suitable coating at a low price. Let's look at some of these in more detail.

Inexpensive but effective antiseptic agents

Among the complex drugs, I would like to highlight Phenylax and Senezh Ognebio.

Senezh Ognebio is a deep-acting impregnation that can protect timber from mold, rot and fire. Due to its deep action, house impregnation creates a thick protective layer. The price of Snezh Ognebio ranges from 70-100 rubles/l. It is also used after the construction of a house made of laminated veneer lumber.

Phenylax is a medium penetration impregnation. Treating a house made of profiled timber with this composition can protect the material from fire, rot and mold. Also, Phenylax is not liked by wood-eating bugs. The price for impregnation is from 60-90 rubles/l.

Inexpensive but high-quality antiseptics include Neomid 440 and Aquatex.

Neomid 440 is a water-based composition that has antiseptic fungicidal properties. It is resistant to external influences and has a service life of up to 15 years. Antiseptic costs from 90 rubles/l.

Aquatex is an antiseptic with decorative and protective properties. According to user reviews, this is the most suitable product that can disguise inexpensive pine, for example, as oak. Antiseptic costs from 120 rubles/l.

Among fire retardant impregnations, according to reviews, Neomid 530 is considered the most effective and inexpensive. The composition is water-based, so it is popular for use both inside and outside the house.

Among synthetic ones, users highlight KSD. Produced on the basis of fire retardants, antiseptic and biocidal elements. Costs from 70 rub./l.

A large assortment of impregnations for profiled timber has pushed into second place traditional methods, which include treatment with copper sulfate or chlorhexine. But do not forget that copper sulfate is a poison, and chlorhexine is a strong oxidizing agent. Reagents are available and sold in many hardware stores, but you need to work with them wearing a respirator and thick rubber gloves.

Traditional methods of processing profiled lumber

Let's look at the most popular home treatment methods using the simplest reagents: sulfur, copper sulfate and chlorhexine.

Antiseptic sulfur

Sulfur is taken at the rate of 200 g per 100 cubic meters of room. This treatment is suitable for the basement of a house made of timber, basements and underground spaces. The sulfur is placed on a ceramic container and set on fire. The main danger of such treatment is sulfur dioxide, which is released from the reagent during combustion.

It kills all microorganisms, but if you do not leave the room quickly, it can kill a person. The fumigated room is tightly closed and left for 6-9 hours. Care must be taken to ensure that animals do not get inside. After this, quicklime is brought into the room. It is most convenient to do this in a box or larger basin; it will absorb the poisonous gas and draw out excess moisture.

Antiseptic treatment with copper sulfate

Copper sulfate or copper sulfate can be purchased at a hardware store in the form of blue crystals (reminiscent of potassium permanganate) and used for the construction of a house made of profiled timber. Copper sulfate is a poison, so it should be treated only on the outside, or soak the floor beams.

The solution is prepared in the ratio: 1 part to 10 parts hot (50-60 degrees) water. The resulting mixture is applied to the timber using a brush or spray. The easiest way is to soak the timber before construction. To do this, it is immersed in the composition for 2-3 hours and dried well.

But copper sulfate is also a very strong corrosive reagent, so areas with metal fasteners cannot be treated with it.

Antiseptic treatment with chlorhexine

Chlorhexine is essentially the same as bleach. The powder is mixed with other components in the following proportions: 1 part chlorhexine, 2 parts water, 2 parts quicklime, 1 part ash. Mix well and apply the resulting mixture to the timber using veneer or a brush. This composition can cause serious burns to the skin, so you should only work with thick rubber gloves. One can only guess what the walls will look like after such antiseptic treatment.

Traditional methods are time-tested, but not safe. Using modern ready-made compounds, you can antisepticize your home yourself without harm.

Protective impregnation options

When choosing how to cover the outside of a log house, you have to take into account several aspects: the protective layer must preserve the natural qualities of the wood so that the house has a pleasant atmosphere and there are no problems with air exchange. The coating for a log house must perform several functions: it must create reliable bioprotection from microbes and pests, protect the wood from fire, in addition, the finishing has an important decorative value.

To provide your home with comprehensive protection, you will need to purchase the following types of products:

- Antiseptics of domestic or imported origin. These are substances that can be deeply absorbed into wood, increasing its resistance to pathogenic microbes.

There are quite a lot of such products offered today: the most common are “Senezh”, “Belinka”, “Pinotex”, “Neomid 500”, impregnation from Finnish has also proven itself well. Many people trust Finnish antiseptics, since this country has a centuries-old culture of building wooden houses.

- Fire retardants are substances that prevent the spread of fire. They are absorbed into the wood, and when the temperature rises significantly, they come out, forming a film that prevents combustion. Fire retardant treatment must be carried out, since fire is always a very significant threat to a wooden structure.

- The tree must also be protected from street humidity, snow and wind, so you can choose the right product from a wide range of paints and varnishes. Alkyd and acrylic paints for exterior use are now popular; they can be either “dull” or translucent. The second option is chosen by those who appreciate the natural beauty of wood and want to maintain maximum environmental friendliness of the building.

The color can be added directly to the antiseptic impregnation, in which case you can save on purchasing paint. Antiseptics often have a faint green tint: this allows you to better track which areas of the wall have been treated to prevent skips and uneven coverage.

What happens if you don’t treat the log house? Opinions are often expressed that wood can do without impregnation, because old wooden houses in the north last 100 years.

However, we must not forget that only winter forest with dense wood was used for them, and in cold climates the process of decay is slower. In addition, we must not forget about the aesthetic side: the logs will darken very quickly, and blue mold spots will very soon appear on the untreated timber.

When should you treat wood?

When choosing what to cover a log bathhouse with, it is important to correctly determine the processing time. The wood is subjected to the first impregnation during the initial processing, but it does not last long. Its purpose is only to ensure that the wood is delivered intact to the site, and then the owner himself must take care of the future home.

The log house is treated with an antiseptic for the first time immediately after assembly. Wood has natural moisture, and it will take a long time to dry. After assembly, be sure to treat the ends of the log with special means: this will ensure uniform drying along the length of the log, so the end will crack much less.

A layer of antiseptic is applied, after which the log house is left for at least six months for final drying. This is usually done in the fall in order to begin full finishing in the spring.

When the tree dries, a full multi-layer treatment is carried out, which will provide it with comprehensive protection.

Bioprotection of wood

Fungal spores cause a change in the color of the tree, followed by rotting. Antiseptic compounds penetrate deeply into the pores of wood and disinfect it without increasing hygroscopicity.

Antiseptic treatments can be:

- short-term action, for the period of transportation and pre-sale storage;

- preventive, in construction conditions;

- long-term, to restore protection;

- medicinal, for infected wood.

Before purchasing a composition, carefully study the properties of the preparations: purchasing a complex-action composition that protects against all types of damage (rot, mold, woodworms, etc.), imparts fire-retardant properties and at the same time tinting will reduce processing efforts, time and money. It is also necessary to distinguish between compositions for internal and external treatment.

Fire protection of wood

It is easier to carry out primary treatment with deep penetration fire retardants in a factory environment, where there are special baths for this purpose. After building a house, initial treatment can only be applied to visible surfaces, which significantly reduces the effectiveness of the compositions. After the guaranteed period of action of the protective drug has expired, periodic renewal of fire protection is required.

Load-bearing structural elements (beams, rafters) require fire protection group 1. When purchasing a fire retardant, you must read the product data sheet and instructions for use, since not all compositions are able to provide the required level of fire protection.

For fire protection of baths and saunas, there are profile compounds that ensure the safety of wood in conditions of high temperature and humidity (Pirilax-Terma, etc.).

IMPORTANT: To control the quality of application of the drug, choose formulations with a tinting effect in shades natural to wood.

In what order are the compounds applied?

If the wood is in good condition, you need to start with fire retardants, then treat it with an antiseptic, and use preservatives before applying the finishing coat. If the tree is damaged by bark beetles or mold, then first a primer with active fungicides (Neomid, Pufas) is applied, then fire retardants (although some prefer to do without them altogether).

If the tree is already infected with insects and there are probably bark beetle larvae in the depths, this scourge must be dealt with radically. It is not enough to simply apply an antiseptic with a brush. Firstly, a separate product is required (Antizhuk, Lignofix concentrates), and secondly, the application methods are different - injecting or intensive spraying.

Of course, we did not include tinting, putty and other products responsible for decorative design in the list. Their use is dictated only by the taste and needs of the home owners.

Types of materials

To protect the timber inside the home, several preparations with different properties are applied sequentially.

Fire retardants

Chemicals once applied to the surface of wood significantly reduce its flammability. Fire retardants according to their mechanism of action are divided into two groups:

- Products that release non-flammable gases that block the access of oxygen to the surface of the wood. The base is ammonium sulfate or ammonia.

- Compositions containing low-melting salts of boric, orthophosphoric or silicic acid. They increase the combustion temperature and cover the wood with a fire-resistant film.

Fire protection products are available in the form of paints, varnishes or impregnations. Preparations of the first group of effectiveness best resist fire.

Antiseptic drugs

Compositions with antiseptics prevent the proliferation of fungal spores and mold, which cause allergies and bronchial asthma. They are created based on water, oil or organic solvent. For interior work, water-soluble products and products based on natural oil (linseed, hemp) are allowed. Depending on the type of action, there are two types of drugs:

- Impregnations - penetrate several centimeters deep into the wood, destroy existing microorganisms and prevent their further appearance.

- Film-forming compounds form a protective coating on the surface that does not allow moisture and biological pests to pass through.

Compositions for internal use are transparent (glaze) and covering. They give the wood the desired color. To change the tone of the timber while maintaining the structure of the wood, use a tinting antiseptic (stain).

Biopyrenes

Complex action preparations have antiseptic and fire retardant properties. They are approved for use in residential premises, children's and medical institutions. The compositions destroy fungi and insects and prevent their appearance. They are designed for processing hardwood and softwood timber.

Primer

Products with an antiseptic effect are used as a preliminary coating for surfaces before painting or applying varnish. They penetrate deeply into the wood structure and reduce the consumption of paints and varnishes.

Whitening products

Blue spots often form on timber and logs. This is one type of fungus that is difficult to remove. The damage is removed by sanding, but bleaching compounds completely eliminate it. Based on the main component they are distinguished:

- Chlorine-containing preparations are effective, but they are harmful to health and are used for external treatment.

- Based on active oxygen, the composition is safe, perfectly brightens and disinfects wood.

- Oxalic acid is a less effective remedy recommended for soft wood.

Bleaching agents are applied according to the instructions, left for the specified time and washed off if required by the manufacturer. To prevent subsequent infection, a deep penetration antiseptic is applied.

Recommendations for selection

The service life of protective equipment is no more than 5 years.

If they write more, we are talking about industrial application. Treatment of logs inside and outside the house is aimed at protecting against many different factors. At the same time, there is not a single protective agent that could simultaneously protect a wooden structure from all negative influences.

There are general rules that allow you to choose a truly effective material that protects a wooden house:

- The service life of any protective coating is from 2 to 5 years. If such a period is indicated on the packaging, the manufacturer is most likely not lying. If a period of 20-40 years is indicated, most likely it is written somewhere in small print that such a period of validity of the product is possible if this product is applied industrially.

- The consumption of the protective agent is important when choosing the brand of material. It often happens that increased material consumption negates the economic effect of low cost. The optimal consumption of any protective agent (except fire retardant) is 200-250 g/m².

- You should not chase universal drugs whose manufacturers promise combined protection against various negative effects. Experts argue that the individual substances included in such products do not enhance each other’s effects, but, on the contrary, worsen them.

- When purchasing a protective product, request a certificate of conformity, which confirms the safety of the material during application and operation.

Protection of a wooden house should be carried out regularly throughout its entire service life.

Wood defects

Before the advent of industrial sawmills, when wood materials were harvested using an axe, there were fewer problems with the durability of the tree: when cutting with an axe, the internal pores were reliably sealed. Now, when wood is sawed, the pores remain open, and this speeds up the process of wood destruction.

The most common defects:

- Rotting of the ends of logs due to different evaporation rates along and across the grain of the wood.

- Fungal infection leads to the appearance of mold and causes discoloration; mold is dangerous for asthma patients and allergy sufferers.

- Infestation by woodworms, termites or ants leads to the gradual destruction of structures.

- UV radiation causes photoaging, which is when wood appears shabby due to a gray tint.

- Rotting of wood due to high humidity also leads to the loss of the structure's load-bearing capacity and the destruction of the house.

- In the event of a fire, charring occurs; in the event of a fire, well-dried wood burns out completely.

These and other defects can be avoided with the help of modern protective equipment.

Protecting the ends of the logs

In production, the ends of the logs are subjected to primary processing, which must be renewed every 5–7 years. Since the process of absorption and release of water vapor through the ends occurs an order of magnitude more intensely than across the wood fibers, the end cracks and deforms much faster than the longitudinal surface of the log.

Protective agents form coatings that are impenetrable to air, which normalizes the rate of moisture evaporation. When choosing the best way to protect the ends, give preference to compounds that hydrophobize wood to a greater depth, for example, the preparation PU-Holzverfestigung. The ends of the log house inside the building also need protection.

ATTENTION: Wood preservatives must be compatible with compounds for subsequent decorative finishing. It is better if they are from the same manufacturer.