Before you begin building a country house from edged timber, you must clearly understand the scope of work, the order in which it will be carried out, and the list of necessary consumables and tools. This will allow you to correctly calculate the forces and resources and create cost estimates. Treating the outside of the house will require significant labor costs; the treatment of external walls is divided into the following stages:

- After the construction of the log house. The purpose of the work is to protect against mold and rot during the shrinkage stage. The log house is built from timber with natural moisture, which is susceptible to fungus. At this stage, it is imperative to protect the timber from biological pests; protective treatment is carried out inside and outside,

- After shrinkage of the log house. At this stage, the timber, which has reached air-dry moisture, is prepared for long-term use. The log house is impregnated with moisture-protective compounds, fire retardants and antiseptics,

- Depending on the operating conditions and the effectiveness of protective equipment, the treatment of the outside of a wooden house is periodically repeated.

How to treat a log house at the shrinkage stage

Lumber is supplied to the retail chain of varying quality, it depends on the type of wood and the moisture content of the material; in any case, at the shrinkage stage, the log house must be treated with an antiseptic. For this, compositions are used that do not disrupt the drying process of the wood; the pores of the wood must remain open and ensure natural evaporation of moisture. The best antiseptics are potent poisons; when using antiseptics, you must take precautions and use protective equipment. While the house is not occupied, the same compositions can be used to impregnate the walls inside and outside the building.

Craftsmen recommend starting construction in winter; in the cold, mold and rot fungus spores do not develop. The log house can be treated with antiseptics for the first time with the onset of a warm period at temperatures above 10 degrees. Be sure to treat the wooden parts of the foundation, the mortgage crown, attic structures and floor joists. For this purpose, solutions are used: sodium fluoride, copper and iron sulfate, boric acid; compositions containing chlorine have a detrimental effect on the microflora. These products do not clog wood capillaries.

Features of the harmful effects of the environment

It is recommended to paint wood due to the need to protect the surface from many harmful natural factors to which the façade of a house is constantly exposed. The following impacts can be identified:

- Water has a destructive effect on a wooden structure; over time, the material becomes covered with unsightly stains and stains appear. The result will be darkening and deterioration of integrity;

- Ultraviolet radiation also leads to a change in surface color;

- Insects and pests destroy the tree;

- Humidity can lead to biological formations.

You need to move on to coloring faster; usually you can wait no more than 3-4 months.

It is recommended to paint wood due to the need to protect the surface from many harmful natural factors to which the façade of a house is constantly exposed.

How to get rid of wood blue stains

An alarming “bell” is a change in the color of the wood and the appearance of bluish or blue-gray bald spots on the surface of the external walls; a log house under shrinkage is most often susceptible to this phenomenon. The appearance of blue discoloration is caused by the development of a fungus that feeds on wood starch and glucose. Blue appears actively in the first months after the construction of a log house; the cause of this phenomenon is most often the use of waterlogged timber.

It is believed that blue fungus does not destroy wood fibers, the tree retains its properties, but its appearance indicates that something is wrong with the wood material and measures must be taken. In recent studies, scientists have noted that blue damage does not go away without a trace; in the affected areas, an increase in pores is observed and hygroscopicity increases. This phenomenon reduces the service life of the structure.

The blue develops from the outside and penetrates deeply into the timber; sanding does not completely eliminate this defect; the façade of a house with blue-gray stains has an unpresentable appearance. Blue mold is easily eliminated with chlorine bleaches “Belizna”, “Iney”, “Sagus”. It is advisable to carry out the treatment immediately after the first signs of damage appear; if the timber is covered with blue in the stack, it is advisable to treat it before laying it in the log house and further dry it in a well-ventilated place.

Wood blue: 1-surface; 2-deep.

Useful tips:

- If your log house has been left untreated for a long time, the wood may darken in some places, and when a coloring agent is applied, this place will have a different tone. Solving this problem is quite simple - just coat the surface with a special bleach before treatment. After this procedure, you can safely cover the log house with paint.

- It is also worth remembering that paint, when applied to wood (even one layer), will instantly destroy the smell of wood, but the material will not lose its properties.

Finishing the outside of the frame after shrinkage

Finishing treatment with protective impregnations is carried out after shrinking the frame and sanding the walls. Impregnating compositions for external walls are selected taking into account the climate, local conditions and design features of the structure; the goals of this work are:

- Long-term protection of wood from atmospheric and soil moisture,

- Preservation of wood, allowing to protect the surface from solar ultraviolet radiation, the appearance of microcracks and delamination of fibers,

- Creating an environment unsuitable for the development of harmful microorganisms and insects,

- Increasing the resistance of wooden structures to fire.

Correctly carried out treatment of the exterior walls of a log house ensures the durability of the building. To treat the exterior of residential buildings, complex industrial impregnations are used that have all the listed protective functions. Among the TOP 5 products for treating the outside of a wooden house:

- “Senezh” (Russia), a washout-resistant complex impregnation that provides protection against moisture and biological pests, prevents fire, and is used for treating residential and commercial buildings.

- “Pinotex” (Estonia), a polymer-based composition, has high adhesion, can be used in winter, provides protection against moisture, is an effective antiseptic, and contains anti-fizz additives.

- “Belinka” (Slovenia), a highly effective environmentally friendly composition, protects against solar ultraviolet radiation, moisture, biological pests and fire, and is suitable for treating any external elements of the house.

- "Tikkurila" (Finland), a moisture-resistant impregnation that forms a protective film, provides long-term bio- and fire protection.

- “Aquatex” (Russia), deep-penetrating impregnation, the composition protects against putrefactive fungus, moisture and UV rays, suitable for processing log houses for shrinkage.

To treat the outside walls of outbuildings, cheaper means called “folk” are used, including:

- A composition based on linseed oil with the addition of turpentine (ratio 2:1), up to 5% rosin is added to the mixture, applied to the exterior walls of the log house, the product protects against moisture and biological pests,

- Transformer oil or machine waste, the compositions penetrate deeply into wood pores and microcracks, are applied in a heated state with a brush, and are effective antiseptics,

- Coal tar and creosote oil, these products are coatings that are used to treat exterior flashings of outbuildings, wooden foundation elements and basement walls; the product must be applied in dry weather.

Replacement of the lower crowns of the bath

If things have reached such a state that it is urgently necessary to replace the lower rims of the bathhouse, then you will have to work hard:

- prepare the logs, fit them to each other. Or assemble the log house if 2-3 crowns will be replaced along the entire perimeter

- dismantle the sauna stove pipe

Nests are cut out in rotten logs for jacks

cut nests (holes) for jacks in those logs that will be replaced

- place four (or more, depending on the size of the log house) jacks in these sockets

- raise the frame using jacks

- place logs next to the jacks and lower the frame onto them, thereby removing the jacks

- Now you can remove the rotten logs completely

- if necessary, build support pillars from bricks

- you need to bring the new crown on one side, where there are no stops and which seems to hang in the air

- well, continue in the same spirit...

In each case, the entire process of replacing the lower crowns of the bathhouse will be individual. controversial argumentative essay topics

Protective treatment of critical structures

Application of protective compounds

Structural elements of the house that must be treated with special care include:

- Mortgage crown,

- Corner ends of the log walls,

- Attic structures,

- Floor joists on the first floor.

These elements are most susceptible to external negative factors and are most often affected by biopests; it is necessary to choose the right ways to protect them.

The best way to process the embedded crown

The frame is the lowest crown of the log house, the most vulnerable to putrefactive fungus, this is caused by its getting wet from moisture accumulating on the edge of the foundation. Conventional protective agents are ineffective in this case; experienced professionals recommend using “folk” remedies that provide more effective antiseptic protection. Among such means:

- A solution of copper or iron sulfate, the timber is placed in a bath with a 1.5 percent solution of vitriol for 2-3 hours, the composition is deeply absorbed into the wood, the timber is ready for use after drying for 3-4 hours,

- Finnish composition, which is prepared according to the following recipe: a homogeneous paste made from 750-800 g of any flour is poured with 10 liters of warm water, alternately adding 1.5 kg of copper sulfate, 400 g of salt, 1.5 kg of slaked lime and stirring thoroughly. The timber is treated on all sides in two layers, the composition is applied with a brush or roller, complete drying time is 12 hours.

Corner end protection

The corner ends of the log house absorb 10 times more moisture than the walls; the process of intense wetting and drying causes the appearance of deep cracks, which create a favorable environment for the development of putrefactive fungus. To reduce this process, the ends are “riveted” with a rubber or wooden mallet; deliberate destruction of the wood structure prevents the formation of deep cracks. After this operation, the ends are impregnated from the outside with deep-penetrating compounds such as “Aquatex”. When finishing the ends, a protective acrylic coating “TEKNOL JRM” (Finland) or a water-dispersion agent “Remmers SW-910” (Germany) is used; the compositions form a durable protective film resistant to low temperatures.

Treatment of attic structures

Fire statistics show: fires in wooden houses and bathhouses begin in the attic; chimneys and ventilation hoods are located in this space. From the outside, atmospheric moisture does not penetrate into this space; in summer the air temperature rises above 40 degrees, the racks and rafters are always dry, which increases the likelihood of fire. Rafters, roofing sheathing and counter beams are additionally impregnated with fire retardants, including: non-flammable paints and varnishes, fire-resistant pastes and mastics. A popular fire retardant is biopyrene “Pirilax” (Russia), which has antiseptic properties.

Protection of joists under the floor on the first floor of the house

Logs under the floor are classified as hard-to-reach structures, the periodic processing of which is difficult. The joists on the ground floor of the house are protected from atmospheric moisture, while at the same time, excess moisture accumulates in the basement due to soil evaporation. Such conditions are favorable for the development of harmful insects, rodents and fungi. To reduce air humidity in the underground space, natural ventilation is installed.

Floor joists are treated in various ways; one of the effective methods is burning the surface with a blowtorch. Wood capillaries are destroyed by fire, the process of natural moisture absorption is disrupted, and the ash layer is an antiseptic. After such treatment, the logs are impregnated with finishing compounds, including bitumen impregnations and mastics.

Expenses should be taken into account at the project stage

It is profitable to order a ready-made standard project for the construction of a cottage from timber with reference to the region. It is up to the designer to select from savings on the network and adapt the technical design to the request. What are the advantages of the project:

- Get a detailed cost estimate for materials, components, and work costs;

- Issues of material shortages or sale of remaining surplus will not arise;

- Detailed drawings and subassemblies will lead you out of the maze of errors;

- Transport costs are optimized;

- Laying pipes and cables will not cause any difficulties;

- The maximum cost of a standard project is 20 thousand rubles.

But the implementation of the idea depends on the need to hire a team of qualified carpenters. The level of responsibility, skill of specialists and the seriousness of hidden defects will become clear during the first wintering.

What should an ordinary person, inexperienced in construction, decide to build a warm house from profiled timber with his own hands? Order a house kit from a local house-building plant and save a significant amount of money with this step and speed up your move-in date.

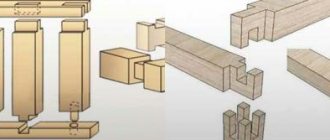

Essentially, a house kit is a kit for the builder. The profiled timber is cut to size, the dovetail type connecting locks are made without gaps using precise factory equipment, which eliminates the appearance of cold bridges.

In the attached video, craftsmen use a chainsaw for this purpose. But are they capable of reproducing the precision of a machine production line? It can be seen that the cuts were made approximately, with a margin. Will they definitely caulk or foam the inconsistencies in the cuts? Doubt encourages self-building. And the cost of the work will amount to no less than factory processing.

Video:

Do-it-yourself house made of profiled timber

The benefits of purchasing a house kit made from profiled timber

A technological worker has replaced a carpenter - that’s what machining means.

The developer is limited in time, looking for an opportunity to reduce the cost of building a timber house. Let’s look point by point at whether the costs of cutting and sampling are reasonable:

- You receive chamber-dried wood with 10–16% humidity in sealed bags;

- End processing with film-forming stabilizer INDULINE. This means that the main channel for moisture absorption is blocked, the web of cracks will not disfigure the cut;

- Each part is numbered, the instructions indicate the location of assembly;

- Adjustments and modifications are excluded, time is spent only on the process of assembling the house;

- Check prices at wholesale stores per cubic meter of long profiled timber. It turns out that the cost of a similar unit of a house kit is the same or up to 10% more expensive - this is where the benefit is hidden;

- A set of timber for a house with an area of 120 m2 will cost approximately 650,000 rubles, for 190 m2 – approximately 950,000 rubles;

- The average assembly cost will be 25% of the cost of the timber. Manage the reserve fund at your own discretion;

- The thickness of the log house will be offered according to the climatic zone: the common size of timber 150 x 150 mm is suitable for Voronezh. In Siberia, wall thicknesses less than 220–250 mm are unacceptable;

- Installation will speed up twice;

- The material is 100% treated with antiseptic and fire retardant.

100% complete from base to ridge, this is the construction service

Video:

Ready-made house kits from the manufacturer

Why are external walls treated with bleach?

Bleaching compounds contain chlorine or hydrogen peroxide, which have a detrimental effect on microflora; these products are used to treat the outside of buildings. The operation has a dual purpose:

- Affects spores of all types of fungus,

- Cleans the surface of the timber and the pores of the wood from contaminants.

Before and after applying bleach

Bleaching of the outside of a log house is carried out for preventive purposes and to update the facade; during the period of operation of the building, this operation is repeated periodically. Experts recommend treating walls in this way every time before applying protective impregnations. The most popular products include: “CEDAR (Bleach)”, “Nortex-Bleach” and “Bioshield-2”; a sprayer can be used to apply these solutions.

Types of paints

It is necessary to choose a specific type of paint and varnish product based on several factors:

- degree of resistance to atmospheric conditions and mechanical influences;

- guaranteed service life;

- vapor permeability level.

Otherwise, you can focus on taste preferences regarding color (or lack thereof)

It is important to pay attention to the climatic conditions in the region where the house is located

Opaque formulations

Preference is given to this type of composition if there is no desire to preserve the natural texture of the wood. Each type of paint and varnish material has a characteristic color; it is possible to choose the one most suitable for the overall design of the building. Of the entire available range of paints containing color pigments, the following varieties are distinguished:

- oil. Despite the fact that the compositions are considered the most affordable, their quality does not always reach the desired level. They are characterized by a low level of resistance to the relative influence of UV rays. For finishing work on the facade, it is very expensive to use such paint, since it requires re-processing after two to three years, otherwise the imitation timber will begin to fade and form cracks. These paints are also distinguished by the longest period required for the composition to dry and an unpleasant odor that appears only after several days;

- alkyd. They are considered the most modern products. They have a very large selection of colors and the highest level of protective functions. The duration of preservation of color in its original form is long. As for their processing of imitation timber on the facade, they are not very reliable.

- acrylic. This variety has proven itself to be ideal for woodworking. Their range is varied and allows you to choose the option that suits you best. This type of paint is characterized by practicality and durability in comparison with other types of paint. A separate advantage is the absence of pungent odors when working with the composition. The level of adhesion of simulated timber surfaces with paint is very high. Regarding the disadvantage, there is only one – the cost of materials is slightly higher than the previous ones.

Transparent compounds

There is a term for this type of paint - glaze. These compositions are distinguished by their ability to emphasize and accentuate the natural beauty of wood, highlighting their texture. The only thing worth considering when choosing a transparent type of paint is the presence of defects, cracking or dark inclusions on the surface of the imitation timber. They will not disappear after treatment with the composition.

The following types of transparent compositions are distinguished:

- water-based compositions. They are considered the safest and most convenient to use; the main component is water;

- polymer type varnishes. Polyurethane-based materials are mainly used for external processing of imitation timber. They are characterized by the highest level of strength and wear resistance. The price of such materials is slightly higher than the previous ones;

- impregnation. The most common of this type of transparent paint is drying oil. Despite its ease of use and good protective properties, there are the most modern compositions that have better performance characteristics;

- glaze. Such compositions are used not only to provide protective functions to the tree, but also to give it a lighter or darker tone as needed. Wood is painted with it if there is a desire to create a “antique” effect.

Decorative treatment of the house outside

Decorative treatment of the house emphasizes its architectural features and gives the building an individual look. Homeowners choose their own decoration methods and style or use ready-made solutions. The main methods of decorating the outside of a house include: painting, oiling, waxing and decorative tinting.

Painting a timber house

The price lists of leading manufacturers often note that decorative treatments provide reliable bio- and fire protection, but this does not mean that special protective impregnations can be abandoned. The protective functions of decorative treatments are less effective; they do not provide full protection of wooden buildings from the outside and can be considered as additional protective agents.

General provisions

Many people believe that correct installation of all building elements, proper ventilation and the use of only high-quality tree species can prevent adverse effects on the walls of the steam room. And this is better than treating the walls in the bathhouse with some kind of antiseptic, since there will be no danger of the enzymes in the solution evaporating into the air at high temperatures.

Do-it-yourself ventilation arrangement

Absolutely right. Good air movement can overcome dampness in the bathhouse and prevent mold and fungi from developing from the inside. But this is not the only problem.

- The effect of “warping” of boards due to constant exposure to high temperatures. The most vulnerable finishes are on the ceiling and near the stove.

- Darkening and contamination of the wood surface with frequent use, making the interior look like the inside of a “black” bathhouse. This is especially true for shelves.

Type of “black” bath

- Pest attack. External timber walls are also susceptible to this.

- Stagnation of dampness in the absence of ventilation or an error in its design.

Thus, we can come to the conclusion that processing is still necessary in most cases. It will definitely be able to extend the life not only of the interior lining of the bathhouse, but also of the wooden walls outside the building.

Moreover, current solutions:

- Environmentally friendly even at very high temperatures.

- Heat resistant.

- Excellent protection from dirt.

- Drive away possible pests.

- Increases the strength of the material.

Let's consider the recommended compositions for various elements of baths and saunas.

Painting a house made of profiled or laminated timber

Glued and profiled timber has a higher cost. The grinding stage will be easier to carry out, and the base will be of better quality. It is advisable to apply antiseptic impregnation to the timber itself, before construction. Priming is necessary; it is better to paint the surface with oil, acrylic paints or varnishes.

It is prohibited to use water-based dyes due to the poor resistance of the material to moisture.

It is advisable to apply antiseptic impregnation to the timber itself, before construction.

Painting the timber is necessary to obtain reliable protection from natural influences. It is better to choose high-quality compositions; saving will lead to the paint peeling off quickly. And the material will last less. Painting can only be done after preparing the base.

The problem of excessive timber moisture

Wood is a living material, and even after cutting down the tree itself, biological processes in it do not stop . Unfortunately, one of these processes is rotting.

Professional builders know very well that a log house requires wood that has been dried to the required moisture content. However, the main problem is that the house is not built in one or two days. However, lumber, logs and other lumber are usually stored in an area where they can be exposed to the environment: rain, hail, wind or simply heat and humidity.

All these conditions increase the level of moisture in the wood, and rotting processes begin to develop there. Because of this, it is urgently to treat the materials with anti-rot agents, because the fungi that cause this process feed on substances contained in the wood and gradually destroy its structure.

There are a lot of products that protect wooden materials from rot and mold, all of them can be divided into 3 types :

- impregnations that contain antiseptics;

- bleaches;

- preservatives

What is their difference? In methods of exposure and methods of application.