Sapwood is the outer layer of tree species. It is a physiologically active layer, which differs from the core in a light shade. Thanks to it, the plant receives nutrients and liquid to the crown. In conifers, it contains resin and resin, which help protect the wood from pests. Sapwood is also called subbark or sapwood. In the article we will consider the description and distinctive properties of sapwood, as well as the classification of tree species by sapwood and heartwood.

What is a tree trunk made of?

Before you can study sapwood, you need to understand exactly how the tree works.

Without proper preparation, it will be difficult for you to understand the essence of the subcore.

- The core is the first and most basic thing the tree consists of. It is formed after the process of cell death. Has a dark brown tint.

- Obolon (or sapwood) is one of the most important elements of a tree, since thanks to it, useful substances, water and all the necessary elements flow to the crown.

- The cambium is a layer of living cells; it is because of its presence and functioning that the trunk has the ability to grow in width. Thanks to this layer, experts determine how old the tree is.

- Bast - this part is responsible for the reverse process, since the organic substances produced by the leaves go through the bast part to the rhizome. In this way the tree functions as a living organism.

- Bark is considered the protective layer of the trunk and all its systems. Usually it is a rather dense growth of a dark color.

Now, knowing what the barrel consists of, you can easily figure it out and find the part you need.

Four-edge and straight-edged timber

Lumber can vary in price and quality. The cheapest include four-edged timber, which is produced in large quantities without requiring large, costly capacities.

The production of timber is carried out by sawing or hewing solid wood, but the quality of the surface will differ significantly. For example, when hewing, the sides end up torn, which is not always acceptable. When sawing, the edges and ends are more accurate; such timber is suitable for work where the appearance of the materials is important.

Clean-cut timber is a square-section material, planed on all sides. Its length is usually 4 m, thickness - from 100 mm, depending on the purpose. Such timber is usually made from pine.

It is processed from all sides, including the end parts. It is most often used for the construction of house walls, beams, ceilings, and subfloors. It has high strength properties.

What beneficial properties does it have?

It's no secret that useful substances are transported through it, along with water to the crown. Besides this, it has many other properties:

- The water content in this part of the tree is much higher than in the rest.

- This element has a higher density than others.

- Quite a fragile material in case of mechanical stress, like all the others.

The very first one is susceptible to pest damage:

- Fungus - it is capable of destroying first the top layer of wood, and then the inner one.

- Mold - if wood is infected with this infection, you may forever lose your favorite piece of furniture or raw materials for the construction process.

- If mold growth is not stopped in time, it can cost you money.

Woodworm - you've probably observed how a healthy tree acquires eaten holes and rot next to them. They are the ones who turn the wooden surface into dust.

The wood is saturated with moisture quite quickly. No moisture is retained.

Main cuts

The main sections are shown in the figure below. They have different properties and structure.

The main cuts of a tree trunk: 1 - transverse (end), 2 - radial, 3 - tangential

Cross section

A cut perpendicular to the axis of the trunk and the direction of the fibers forms the end, or, as it is called, the transverse secant plane of the trunk. In this section, the structure of the wood is clearly visible, namely concentric annual rings, pith, medullary rays, bark section and bast. The cross section is shown in the figure:

Radial section

A cut passing through the middle of the trunk along the direction of the wood grain forms a radial secant plane. With this section, the growth rings are also visible, but not in the form of concentric rings, but in the form of parallel stripes.

Tangential cut

The tangential cut, like the radial one, is directed along the fibers, but does not pass through the axis of the trunk, but at some distance from it. In other words, this section is constructed along the chord of the cross section. In a tangential section, the growth rings have the appearance of elongated parabolas, since the trunk with the growth rings narrows upward.

How wood is distinguished depending on the sapwood

Wood varies by grade. Let's take a look at the classification:

- According to the core, these are dead microelements in the core of the trunk. Most often they are dark in color. Varieties: larch, oak, pine, juniper, apple, ash.

- The sapwood contains living organisms. Part of the raw material acquires a light shade, quite different from all other parts.

- According to freshly sawn wood - in this case, the color of the sapwood matches the core. This is quite an expensive and reliable material. Varieties: beech. In addition, they can form false nuclei. How to determine this? It's simple - when cut, the wood does not have a uniform color and shade.

Receipt

The process of material procurement occurs in accordance with GOST. It is quite labor intensive. It all starts with the fact that it is necessary to determine from all the lumber exactly the one that meets the above requirements in terms of quality and characteristics. Those that are below third grade in terms of parameters cannot be used for the production of commercial lumber.

Industrial wood is obtained from the main part of the tree - the trunk. Wooden logs are cut lengthwise using special equipment and formed into assortments. Next, the material is also cleaned, trimmed, polished on special machines and, if necessary, coated with special paints and varnishes.

The process of processing a material is largely determined by its further use.

How much industrial wood will come out of a cubic meter of forest depends on many factors, mainly, of course, on the type of tree. Today, the following species are used to produce this type of lumber.

- Oak. This is the most expensive and valuable type of wood in the whole world. Furniture and structures for renovation are made exclusively from oak.

- Beech. An excellent material is obtained from its trunk, which is later used for the production of flooring.

Pine and spruce, as you know, are resinous trees that, even after being cut down, can secrete resin for many years. The scope of application of lumber made from them is quite narrow.

The leaders in industrial timber production today are the United States, which owns 18% of the total global lumber production, Russia – 11%, China – 9%, Brazil – 8%. Of course, only those countries that have enough forests on their territory harvest, process and supply such raw materials to the market.

Classes of processed raw materials

Sapwood can also be processed, so you should also be familiar with these classes. There are three classes of processed surface.

Let's take a closer look at them:

- When processing the first class, the temperature is quite low - up to 190℃. Considered to be quite weak. As for the color, it practically does not change.

- During processing of second class wood, the temperature reaches 210℃. Resistance to rotting appears and the properties of the material increase.

- In the third class of treatment, the temperature reaches 240℃. The color changes to dark saturated. All properties reach their maximum limit.

Most often, the processing class is determined by the customer. Each class has its own cost.

Semi-edged board and slab

The semi-edged board has uneven planes; traces of bark may remain at the ends. This board is used for technical work. Walkways are made from it; it can be used for technical and subfloors, as a basis for other products.

In appearance, the slab is very similar to the side of a log; part of it is sawn on one side, but not on the other. Such lumber is considered lump-type waste; it remains after cutting the base material.

But the dimensions of the slab are standardized; it has the same width at the ends and along the entire length. Today, two types of croaker are used - wood and business material. It is used for various purposes, as blanks for other products and building elements.

Lumber is blanks made from natural wood.

They all differ in shape, individual characteristics, size, appearance, and degree of processing. Lumber is used for construction and repair work of various types; it is often used in assembling furniture, fencing, and in the construction of subfloors. When choosing, you should focus on those properties that are necessary for specific conditions.

Review Types of wood and characteristics of lumber.

@@=

None of the building materials available on the market today have such unique qualities as natural wood.

It is very convenient and easy to process, so that you can make anything, even a spoon, even an airplane fuselage. The wood has excellent strength, it is light and has a pleasant smell. Working with wood is a real pleasure if you understand the types of wood and the characteristics of lumber.

Wood building materials

If you look closely at any block of wood, you can see on it a textured pattern formed by growth rings. Its appearance depends on the direction in which the tree trunk was sawn. It is customary to saw it in three directions: along and across the grain, as well as at an angle of 45 degrees. If the cut is made at an angle, then it is called tangential.

It forms a texture similar to cone-shaped lines. Three different types of cuts depending on the direction. If the cut is made along the fibers, then it is called radial. The parallel lines formed by the fibers are clearly visible on it. A cross section shows us the annual rings of a tree trunk in all its glory. The pattern is important for the external beauty of wood products, therefore, before making a wooden blank, you need to clearly imagine yourself in which direction we want the patterns.

Application of sapwood

In a tree that has been cut down, it performs an insulating function. It is saved for felled materials due to its reliability and durability. It protects lumber from external pests, such as parasites that eat trees, ultraviolet rays, temperature changes, and high humidity.

Sapwood has increased absorbency, so the treated materials can easily be treated with an antiseptic and bleach. It is from this material that traditional huts and wooden houses are built. Wide sapwood is found in trees such as aspen, pine, and cherry.

It is important not to forget that in construction they are not used during the construction process due to unreliability. If you need to create a rounded log, you will have to remove the entire underbark.

This part is quite easy to recognize. For example, in parquet it is indicated by light stripes of different lengths and widths.

- This is considered acceptable for economical purposes, but their presence should not exceed thirty percent. But there are other parquets without its content.

- Sometimes it is added to decorate oak, ash and cherry parquet. Trees of exotic origin will certainly contain sapwood in order to give the final result brightness and originality.

- Properly selected wood can preserve your product for a long time, because wood is quite a durable material. You can choose the material that you want.

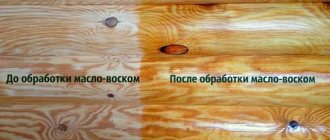

You can make your choice from a wide range of products at a fairly reasonable price. It is worth saying that you can process wood. After such an operation, the raw materials are not afraid of moisture, temperature fluctuations and parasites.

Don’t worry that the material will lose its natural properties - this is not true. Wood still remains a good heat conductor and still smells, while having all the properties of high-quality species.

Birch

Birch is a wood obtained from two types of trees: silver birch and downy birch.

Properties

The density of birch wood is about 650 kg/m³ (with a relative wood humidity of 12-15%). Elastic and viscous, has average bending strength, and is difficult to split. At high humidity, without special protection, it is easily attacked by fungi and quickly rots.

Birch is relatively well processed with hand tools or using machines: it can be planed and milled; turning or carved parts can be made from it; holds fasteners (nails, screws) well and sticks together.

Application

Furniture, plywood, laminate, wood slabs, tools, fittings, turning products, veneer, etc. are made from birch wood.

Photo of sapwood (base layer)

Lumber and its varieties

Mostly dry wood is sold at the lumberyard and in the store. Raw is rarely sold. If you decide to build something or make a piece of furniture, then you will come across the names of types of lumber, the meaning of which is worth understanding:

- The ridge is essentially solid tree trunks without bark or pieces of them of sufficiently long length. It is important that their diameter exceeds 25 cm. A ridge is the same ridge, but with a diameter less than 25 cm. A pole is a solid trunk without bark with a diameter of less than 9 cm. A plate is half a ridge, which is sawn along the fibers. A quarter is half a plate, sawed along fibres. A log, or in other words a timber with a wane, is a log hewn on both sides, which can be placed on one of two planes. A beam is a log that is hewn on four sides with a cross-section of at least 100x100 mm. If it is smaller, then the product is called a block. The board can be very different depending on the method of its processing and size: unedged, edged, slab, planed on four sides, tongue-and-groove, folded.

Cross sections of boards depending on processing.

All lumber that is commonly used in construction has its own specific name. They differ in the thickness of the product, as well as the ratio of width to this thickness.

For boards, this ratio should never be more than 2. The maximum permissible board thickness is 100 mm. The length of any hardwood material does not exceed 5 m, and that of coniferous trees does not exceed 6.5 m.

Main types of lumber

After reading this article, you have become familiar with the basic concepts and characteristics of wood. Therefore, with such knowledge, you can safely purchase lumber, using terms no worse than sellers. Today, almost no major construction or renovation can be done without the use of wood to one degree or another, so such knowledge will be very useful.

Similar articles

For lumber, not only the quality of workmanship is important. Their strength, aesthetic characteristics, durability and a number of other properties largely depend on the type of wood.