| Kind of work: | Essay |

| Date added: | 21.01.2020 |

- This type of work is not a scientific work, it is not a finished final qualifying work!

- This type of work is a finished result of processing, structuring and formatting collected information intended for use as a source of material for independent preparation of educational work.

If you have a hard time understanding this topic, write to me on WhatsApp, we’ll look into your topic, agree on a deadline, and I’ll help you!

If you want to learn how to correctly carry out and write abstracts on any subject, then on the page “what is an abstract and how to do it” I wrote in detail.

Introduction

Prospects for the development of the woodworking industry are usually associated with the development and widespread use of wood composite materials (WCM).

They have a complex of properties and properties that differ from traditional woodworking building materials (solid wood) and together open up wide opportunities for the development of new materials and technological processes.

The expansion of work on the creation of DCM has led to the need to streamline and improve terminology, as well as to highlight the main, essential features of these materials.

There is no clearly established, scientifically based nomenclature for DCM. The terminology of the woodworking industry dates back many centuries and was usually of a spontaneous and artisanal nature. For various reasons and conditions, synonymous terms, inaccurate names and names of concepts that do not reflect their essence have spread in the terminological field. In practice, instead of terms and definitions of concepts, descriptive expressions of arbitrary structure using foreign words and words of everyday vocabulary are often used. Terminology is inherently subjective because people define time. Therefore, their standardization is always controversial. To solve this problem, it is necessary to unite philologists and all wood specialists. Standardization is a step towards mutual understanding. By solving this problem, we will simplify the relationship both between specialists in related branches of the woodworking industry, and between specialists in different industries and, undoubtedly, simplify the learning process in educational institutions. The solution to this problem is associated with the development of a classification of DCM.

Development of the woodworking industry in Russia

One of the aging sectors of the Russian economy is the wood processing industry. The most common areas of this industry are:

Finished works on a similar topic

Coursework Woodworking industry 450 ₽ Abstract Woodworking industry 280 ₽ Test work Woodworking industry 240 ₽

Receive completed work or specialist advice on your educational project Find out the cost

- lumber production;

- production of slabs and furniture.

The history of the development of the woodworking industry began at the beginning of the 18th century, but reached intensity only in the middle of the 19th century. Combines and factories were created that were engaged not only in cutting material, but also in the production of furniture, matches and plywood. Production volumes were growing, but the industry was at a low level of technical development compared to foreign countries. Before the 1917 revolution, the main product of this industry was lumber. Before the First World War, large and equipped wood processing factories began to open in Arkhangelsk and Onega.

In the period from 1929 to 1940, there was an increase in capital construction, furniture and other production. Enterprises began to produce products for the mass consumer (windows, doors, etc.). Many mills and factories have automated their production processes.

The Second World War, financial and economic crises in the country had a negative impact on the development of the industry. Many businesses closed due to losses. Workers became unemployed and were forced to look for a new job, even outside their specialty. There was also a reduction in product exports, a decrease in production volumes and the accumulation of stocks of unclaimed products in warehouses.

Note 2

Currently, the woodworking industry is actively developing. Russia's share in the world's forest reserves is ¼. The state pays special attention to the introduction of innovative technologies and the use of the latest equipment, which allows for an integrated approach to the production process and minimizing costs.

The territory of Russia is rich in coniferous trees, which are more valuable for the wood processing industry than deciduous trees. Such forests are found in the Northern, Ural, Volga-Vyatka, Far Eastern and Siberian regions. The main enterprises of the industry are located in these areas.

General information about wood composite materials

As you know, materials made entirely or partially from wood are classified as wood materials. WCM (wood composite materials) are materials obtained by processing natural wood under pressure at elevated temperatures, impregnation with chemicals, gluing, etc. That is, these are materials made from wood, the processing of which changes its natural physical structure and chemical composition.

Most modern DCM are compositions, products from which have a certain combination of performance properties, for example, chipboard, plywood, etc. In all cases, this is a system of different materials, each of which has its own specific purpose in the finished product. Neither veneer nor glue can perform their function independently, but in plywood they are used together and must be considered as a single composition. Consequently, the expression "composite material" includes in a new form the very old and simple idea that the joint work of dissimilar materials produces an effect that is tantamount to the creation of a new material whose properties are both quantitatively and qualitatively different from those of each of its components.

Consequently, DCM is characterized by the following features:

- are not found in nature, as they are created by man;

- unlike natural wood, they have improved performance and other properties;

Report No. 2

Wood is one of the cheapest and most common building materials. This material has been used for thousands of years, and is now often used for decorative purposes. Bridges, houses and even entire cities were built from wood. Thanks to the tree, Khokhloma painting was born and exists. In the modern age of machines and artificial intelligence, the demand for hand-made wooden products is growing. There is a demand not only for rolling pins, cutting boards and masher, but also for wooden toys such as nesting dolls. There is also a huge demand for cabinets, nightstands, window frames and many other carved wood products.

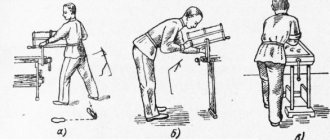

No sophisticated equipment is required for wood processing. The most important thing in the workshop is to have a bench and a basic set of carpentry tools. Very often, such workshops have a lathe, which greatly simplifies many operations. Since modern technologies do not stand still, in workshops you can already find 3D printers, laser engravings and 3D burners. This set of modern tools significantly increases efficiency. If your workshop does not have a bench, you can modify a regular table. To do this, you will only need a few clamps with which you can fix the workpiece on the table surface.

For artistic and decorative products, high quality wood is required, that is, it must be smooth, dry, free from defects and without knots. But crooked, cracked wood should not be rejected either, as it is ideal for products of a special style.

For all fakes, their own special wood is selected. The main parameters for this are the location of the fibers, density, viscosity and many other characteristics.

Wood for decorative work is harvested from early autumn to mid-winter, since at this time it has the least amount of water. Also, the workpieces must be dried for at least four months. The workpiece must be made long, since cracks will appear during drying; to avoid this, the ends of the workpiece are painted over with varnish or paint. If dry harvesting is required in a short time, then the wood must be soaked in boiling water for eight hours. After this, it will dry within three weeks.

5th, 6th grade

Classification of composite materials

DCM can be divided into two large groups: modified wood and wood composition. Modified wood is natural hardwood that has been subjected to a treatment that alters the natural structure of the wood. A wood composition is a combination of wood and a binder, a combination of wood and non-wood materials.

It is customary to select the composition of the components, the structure and arrangement of the components, the type of raw materials (filler and binder), the geometry of the filler, the production method, the main quality indicator (average density) and the scope of use of the materials as classification characteristics of DCM.

Based on the composition of components, DCMs are divided into:

- One-component.

- Two-component.

- Multicomponent.

A component is a filler, binder and other materials of various types and parameters included in the composition.

Based on the structure and arrangement of components, the DCM is divided into four groups:

- DKM with a frame structure (impregnated wood, laminated wood structures) In these DKM, the main component - solid wood - forms a frame that shapes the future appearance of the material.

- DCM with a layered structure is a material obtained by a set of sheets (layers) of components that alternate. This group includes plywood and wood-laminated plastics (chipboards).

- DCM with a matrix structure is a material in which the binder is a matrix. The role of the matrix is to give the product the desired shape and create a monolithic material. By combining particles or fibers into one whole, it gives the composite material the ability to withstand various loads. These DCMs include chipboard and fibreboard.

- DCM with a combined structure - materials containing combinations of the previous groups (laminated chipboard is a material that combines a matrix and layered structure, and a wood panel combines a frame and layered structure).

Depending on the type of filler, DCM can be divided into three groups:

- Wood-based materials (fabric, trees and shrubs).

- DCM based on bast and other plants (reed, straw, flaxseed, etc.).

- Materials based on fillers of the two previous groups (based on a mixture of wood and plant raw materials).

According to the filler geometry (filler parameters), DCMs are divided into six groups:

- Materials based on solid wood.

- DKM based on veneer is a wood material in the form of thin sheets of wood obtained by peeling wood or planing planing.

- Materials based on discrete particles of various shapes and sizes. Wood particles are used as filler: industrial chips, wood wool, special shavings, machine shavings, sawdust, bark particles; plant particles: cereals, crushed plant stems, seed waste.

- DCM filled with wood or other plant fiber (cotton, jute, flax, etc.).

- DCM with powder filler (wood flour, processing and grinding powder).

- Materials based on fillers from the previous groups (based on a combination of different fillers).

DKM, depending on the nature of the binder, are divided into:

- DKM without the use of third-party binding. Materials based on natural adhesives (products of hydrolytic breakdown of the hydrocarbon complex of wood). Such materials include piezothermoplastics and lignocarbohydrate plastics. Thermo-mechanically, chemically, chemical-mechanically modified wood belongs to DCM without the use of binders.

- DCM using a binder. Content created using a third-party binder.

Based on the type of matrix, they are divided into 4 groups:

- Polymer DCM. Materials that use synthetic polymers. Such materials include polymer-modified wood; glued wooden structures consisting of boards and bars glued together; plywood, plywood boards, chipboard, fiberboard, fibreboard, MDP, etc.

- Inorganic DCM. Materials using minerals as a matrix: cement, gypsum, magnesium binder, liquid glass. Such materials include wood concrete, fibrolite, xylolite, corolite, thermoconcrete, cement concrete, GSP and hot water supply, slabs and products made from wood particles and liquid glass.

- Metallized DCM. These include metallized wood (impregnated with metals with a low melting point and wood impregnated with solutions of salts reduced to pure metals.

- The fourth group may include materials whose matrices are natural adhesives or products of hydrolytic decomposition of the hydrocarbon complex of wood. Such materials include piezothermoplastics and lignocarbohydrate plastics.

According to the method of obtaining DCM, they are divided into three groups:

- DKM impregnated, obtained by impregnation.

- DKM pressed, obtained by pressing. This pressing can be: flat pressing, extrusion, stamping, etc.

- DCM is impregnated and pressed, obtained by a combined method. These methods are based on the sequential or parallel application of several other methods.

Based on average density, they are divided into two groups:

- Light DCM - average density less than 1200 kg/m3. Modified wood, GSP, fibrolite, arbolite, corolit, DKK and other light ones.

- Heavy DCM - average density more than 1200 kg/m3. Heavy materials are piezothermoplastics and lignocarbohydrate plastics, construction beams, chipboards, MDP products and others.

The division on this basis is rather arbitrary, since it is not always possible to draw a clear boundary between groups.

Classification of DCMs by areas of their use.

Materials based on mineral binders are used in construction. Modified wood - in construction, furniture production, transport, mining and light industry. The products are used in mechanical engineering, the chemical industry and the radio industry. Chipboard and fibreboard are used in the production of furniture, packaging, instrumentation and radio equipment, construction, shipbuilding, automotive and automotive manufacturing.

Abstract on the topic: “Artistic wood processing”

Explanatory note to the additional educational program of the creative association “Artistic wood processing”

Among the artistic works in our country, the most widespread and beloved among the people has long been wood carving and mosaic.

Wood mosaic is one of the types of decorative and applied arts that has a strong aesthetic impact. The decorative qualities of wood make it possible to create a wide range of mosaics, from small souvenirs and decorations on furniture to monumental panels.

The art of wood carving is just as rich and varied in its capabilities. Carvings were used to decorate homes and ships, furniture, dishes, and tools - spinning wheels, seamstresses, rollers. Folk wooden toys are distinguished by the brightness of their images, keen observation, subtle humor and genuine beauty.

The centuries-old culture of artistic wood carving has national traditions that are passed on from generation to generation when decorating wooden houses with carvings and creating household decorative products. The best examples of such products, created by folk carvers, are carefully preserved in museums of our country.

The art of artistic woodworking, which has deep traditions in our country, is widely developed in the regions and regions. Studying a course in artistic woodworking allows young people to acquire general and partially specialized knowledge, and will also provide them with intellectual, ethical and aesthetic development. These goals can be achieved if the necessary attention is paid to the quality of work and readiness for self-education, restoration and preservation of family, national and regional traditions and universal values.

The program is directly related to the integrative educational area “Technology” of the secondary school.

The program is the author’s; in its compilation, educational and methodological literature on the declared profile was used, as well as the personal experience of the teacher S. A. Peresypkin.

The program studies three different areas of artistic wood processing: saw carving, marquetry, geometric carving. The outcome of the training is the completion of the project. A project is understood as a creative, completed work that corresponds to the student’s abilities and capabilities.

Main goals of the program

Teaching wood carving in the system of additional education for children involves the following goals:

- developing in students the qualities of a creatively thinking, actively acting and easily adaptable personality, which are necessary for activities in new social conditions, starting from identifying the needs for the production of artistic products to their implementation;

- preparing students for conscious professional self-determination and achieving life goals through self-realization;

- formation of an aesthetic attitude towards the surrounding world;

- formation of a creative attitude towards the quality of work;

- the formation of artistic culture among students as an integral part of material and spiritual culture, artistic and creative activity, to help them master the figurative language of decorative and applied art. The proposed program is structured to give schoolchildren an idea of the various types of arts and crafts and their importance in the life of every person.

Main objectives of the program

Educational:

- formation of polytechnic knowledge and environmental culture;

- development of cognitive interest in work and artistic crafts;

- acquisition of serious knowledge and skills in handling hand tools and machine equipment;

- mastering technological techniques;

- solving problems aimed at creating a complete product that meets both functional and aesthetic requirements,

- ability to build interdisciplinary connections.

Educational:

- instilling in students, through program material, a careful attitude towards natural resources, hard work, humanity, and decency;

- formation of an aesthetic attitude towards work;

- formation of social activity and social roles in students (employee, producer, consumer);

- acquiring healthy lifestyle skills (familiarity with design developments, an atmosphere of harmony, working with environmentally friendly materials);

- education of patriotism through studying the history of traditional folk crafts.

Educational:

- development of such business qualities as independence, enterprise, accuracy, hard work;

- formation of the need for self-development;

- development of interest, imagination, fantasy and creative potential of schoolchildren,

- development of aesthetic taste.

Features of the program

Decorations on furniture and other wood products have a long history. The most common types of decoration in the past were carving, turning, wood mosaics and painting.

Wood mosaic is one of the types of decorative and applied arts that has a strong aesthetic impact. The decorative qualities of wood make it possible to create a wide range of mosaics, from small souvenirs and decorations on furniture to monumental panels. The art of wood carving, which was the most widespread and beloved artistic work among the people, is also rich and varied in its capabilities. Carvings decorated homes and ships, furniture, dishes, and tools.

The centuries-old culture of artistic wood carving has national traditions that are passed on from generation to generation when decorating wooden houses with carvings and creating decorative household products. The best examples of such products, created by folk carvers, are carefully preserved in museums of our country.

Artistic wood processing provides a unique opportunity to combine labor training with aesthetic education, without which it is impossible to achieve a high work culture.

Analyzing the “PROGRAMS of general education institutions on “technology” recommended by the Ministry of Education of the Russian Federation, I come across the fact that in the module “Artistic processing of materials” (B.I. Orlov, K.A. Skvortsov, O.A. Kozhina)

The 3rd quarter in VIII grade for boys and the 3rd quarter in VIII grade for girls are allocated to study the program.

This amounts to only 20 hours for the entire “technology” course in the core curriculum. Moreover, artistic wood processing and artistic metal processing are available to choose from. That is, the material is presented in an overview, introductory form. In the variable part of the curriculum, artistic processing of materials can

be studied in grades IX-XI. But it is possible to truly interest and captivate a child in any activity in early adolescence, i.e. at 12-13 years old.

In my opinion, the existing program pays unforgivably little attention to the artistic processing of wood, which has deep traditions in our country.

In the existing bank of educational programs of the Center for Education and Science of the Moscow Region for 2007, ten programs in this area are presented. Let's list them:

- Vinokurova N.I. Program “Wood Carving”, 1997.

- Glozman E.S., Glozman A.E. Sample program “Artistic wood carving”, 2001.

- Karpov Yu.V. Program “Teaching Wood Carving”, 2001.

- Program “Wood Carving” (for secondary educational institutions), 1997.

- Slipak V.P. Program of the “Wood Carving” circle, 1994.

- Woodcarving program, 1997.

- Khvorostov A.S., Khvorostov D.A. Woodcarving program, 1997.

- Program “Arts and Applied Wood Processing” (program for general education institutions, grades 5-7), 1993.

- Program “Making artistic products from wood” (programs for secondary educational institutions), 1992.

- Ryazanov L.V., Kosogorova L.V. Program "Artistic processing of wood", 2005.

Of the above programs, seven are focused on additional education.

The listed shortcomings of programs for general education institutions and the analysis of additional educational programs prompted me to create an additional educational program for the creative association “Artistic Woodworking,” which provides great opportunities for studying the subject.

The main differences from the listed programs are:

- The outlined program has a implementation period of one year and is an introduction to activity course. Pupils of creative associations are provided with three areas of artistic wood processing for familiarization. The result of the annual training is the child’s choice of the direction he likes.

- In parallel with practical training, students receive theoretical information about professions related to woodworking, which can help them take the first step in choosing a future profession.

- The introduction of project activities into the additional education program is also new, and the project is carried out in the direction chosen by the student.

Making beautiful and functional objects with your own hands arouses increased interest in work and brings satisfaction with the results of work, arouses the desire for subsequent activities.

To further develop the artistic abilities of students, further classes in a creative association are recommended in subsequent years of study. Programs for these classes are currently being developed by me.

Wood remains a favorite material for artists today. It is used to create sculptures, carved decorative and utilitarian-decorative objects. Folk craftsmen and professional artists work in the field of artistic woodworking, and personnel training is organized in an organized manner. And even if not every child studying in creative associations of additional education in artistic woodworking will become a professional, but he will receive not only work skills, but also a readiness to make an informed choice of profession.

Elements of the author’s program of additional education can be used in “Technology” lessons in a secondary school, when studying the section “Artistic processing of materials”.

Age of students and characteristics of the group:

- the program is designed for students aged 12-13 years, which corresponds to grades VI – VII of general education institutions (it is not recommended to start classes at an earlier age due to the increased danger of cutting tools and the child’s not yet fully formed coordination of movements);

- The composition of the group is recommended to be constant;

- Enrollment of students is free.

Age-related psychological characteristics

Adolescence is an acute transition from childhood to adulthood, when contradictory tendencies are clearly intertwined. On the one hand, this difficult period is indicative of negative manifestations, disharmony in the personality structure, the collapse of the previously established system of interests of the child, and the defiant nature of his behavior towards adults. On the other hand, adolescence is also distinguished by many positive factors: the child’s independence increases, relationships with other children and adults become more diverse and meaningful, the scope of his activities expands significantly, etc. Most importantly, this period is distinguished by the child’s emergence into a qualitatively new social position , in which his conscious attitude towards himself as a member of society is formed.

Adolescents have a desire to understand themselves more deeply, to understand their feelings, moods, opinions, and relationships. The life of a teenager should be filled with some meaningful relationships, interests, and experiences. In adolescence, a certain range of interests begins to be established, which gradually acquires a certain stability. The range of interests is the psychological basis of a teenager’s value orientations. During this period, there is a switching of interests from the particular and concrete to the abstract and general, and there is an increase in interest in issues of worldview, religion, morality and aesthetics.

It is at this age that a serious passion for arts and crafts can develop and the task of the additional education teacher is to provide the child with various types of folk crafts and crafts in all their beauty to choose from.

Class organization mode:

- the time allocated for training is 144 hours per academic year;

- 2 classes of 2 hours are held per week;

- The form of study under the program is full-time;

- Practical exercises make up a large part of the program.

Expected results.

Students should know:

- general information about folk crafts;

- principles of shaping and composition;

- basics of carpentry (manual and mechanical) preparation of wood surfaces for finishing;

- Features of finishing wood with paints and varnishes (staining, waxing, varnishing, polishing).

- types of mosaics (intarsia, inlay, marquetry)

- types of wood carving (carved, flat-notched, flat-relief, relief, sculptural, house).

- tools and materials for artistic wood processing;

- design stages and procedures;

- project evaluation criteria.

Students should be able to:

- choose and independently develop drawings for artistic processing of the product;

- prepare the surface of the product for artistic processing;

- carry out artistic finishing of the surface of the product (carved, geometric carving, marquetry, painting);

- plan, organize and execute the project taking into account all evaluation criteria;

- protect the completed project.

Students must have the competencies:

- on the general principles of artistic design;

- cabinetmaker by profession;

- woodcarver by profession;

- for the implementation of the project.

As a result of training, it is expected that children will develop independence, accuracy, hard work, and the need for self-development; developed imagination, fantasy, awareness of one’s creative capabilities.

The result of the year of study is independent creative work (project) from the concept and development of design, ornament, to the complete production and finishing of a complete product, both functional and meeting aesthetic requirements, as well as economic and marketing criteria.

Main types of DCM

OSB boards

Oriented strand boards appeared in the 1980s in the USA. For Russia this is a relatively new and promising material. They are based on wood chips obtained by peeling - cutting trunks in a spiral. Like many other composites, OSB is hot-pressed using water-resistant adhesive resins. Before pressing the raw material, the chips are oriented so that adjacent layers have a mutually perpendicular orientation, which makes it possible to obtain high bending resistance of the material in all directions.

DPK

Wood-polymer composite DKM consists of polymer, wood filler and various additives. The polymers used are polyvinyl chloride, polypropylene or polyethylene. Wood filler can be in the form of wood flour or fine shavings. Wood waste is used in large quantities. DCM is sometimes called liquid wood, thermoplastic or wood-plastic composite. In appearance, the wood-polymer composite is similar to MDF and fiberboard.

Chipboard

Wood-laminated plastics are obtained through a high-pressure heat treatment process from veneer sheets glued together with synthetic glue. Depending on the purpose of chipboard, 11 brands are produced with different types of veneer laying. Most brands of chipboard have a technical purpose: they are used in electrical engineering, shipbuilding and mechanical engineering, as a structural self-lubricating anti-friction material.

Bent glued parts

Bent-glued parts are obtained by gluing veneer or plywood with simultaneous bending. To do this, veneer sheets of the required size are glued together with urea-formaldehyde glue, placed in molds, where they are treated with steam and subjected to bending. By bending the bars, bent sawn parts are obtained, since at the bend the beam is sawed through, and veneer soaked in glue is placed in the cut. Bent parts of chairs, tables, backs, etc. are made from bent-laminated and bent-propyl timber.

Carpentry boards

Joiner's boards are panels glued together from slats of coniferous, soft hardwood and birch, covered on both sides with two layers of peeled veneer - an outer layer and an underlayer. All layers must have the same grain direction and be perpendicular to the slats. The slabs are made without coating and are lined with sliced veneer on one or both sides. The slabs are used for the manufacture of furniture panel parts: sides, doors, table tops. Joinery products are characterized by increased weight and specific surface waviness.

Piezothermoplasty (PTP)

Piezothermoplastics are obtained from crushed or solid wood or other plant materials without the addition of a binder by piezothermal processing of the compressed material in a confined space at a temperature of 160 ° C and a pressure of 15 MPa. This material is called PTP for short. Physical and mechanical properties of RTA: density not less than 1350 kg/m3; static bending strength of at least 25-40 MPa; compressive strength of at least 60-80 MPa; impact strength - 6.3-14.5 kg/cm2; Brinell hardness 15-19 kg/mm2; specific volume resistivity - 1x1012 - 1x1013 Ohm / cm; heat resistance - 50-90 ° C; abrasion - 40-64 g/cm2. Tiles are available in the form of squares, rectangles and hexagons.

Lignocarbon wood plastics

Plastics are produced in the form of sheet material based on wood particles without the addition of binders. The technology for producing these plastics is based on the ability of wood particles to be plasticized by taking advantage of the reaction properties of certain wood components. The technological process for the production of lignocarbohydrate wood plastics consists of the following operations: preparation of wood particles; drying wood particles; dosage of wood particles; carpet covering; cold pre-pressing; hot pressing; cutting finished slabs; air conditioning plates. Sawdust, as well as crushed waste from wood processing and logging, can serve as raw materials for the production of plastic. An admixture of bark is allowed in the raw materials.

Arbolit

Arbolite belongs to the group of lightweight concrete and is made on the basis of wood filler, binders and a mineralizer. Wood concrete products produced in the form of panels, blocks or slabs are divided into:

- by purpose - for heat-insulating and structural-thermal insulation;

- for reinforcement - for unreinforced and reinforced;

- according to the external profile - into smooth (flat) and complex profiles;

- for finishing surfaces - textured and non-textured.

Fibrolite

Fiberboard is a building material made from wood wool, Portland cement, chemical additives and water. Fiberboard will be used to make boards that are used as thermal insulation, structural and acoustic materials for walls, ceilings, partitions and building coverings.

Corolite

Corolite is made from mineral binders and particles from tree bark obtained by burning wood. Portland cement, high-strength gypsum, and phosphogypsum are used as binders. Corolite is used as a heat and sound insulating material in the construction of partitions and ceilings.

Xylolite

Xylolite (from the Greek Lnthos - stone), an artificial building material from a mixture of magnesium binder, sawdust and wood flour with the addition of fine minerals (talc, asbestos, marble flour) and alkali-resistant pigments. Xylolite is used mainly for installing floor screeds in residential and public buildings, as well as in industrial premises with dry operation.

Cement particle boards

CBPB is made by pressing wood particles mixed with cement binder and chemical additives. They belong to the group of non-combustible materials with increased water resistance and are used for the construction of wall panels, floor slabs, and floors.

GPS

GSP is a type of DSP made from gypsum. They are used for interior decoration of walls, ceilings, and floors.

Innovative composite material

In the laboratory conditions of the Department of Mechanical Engineering at UGFTU, a recipe for a carpentry adhesive composition was developed and the amount of filler was determined to provide sufficient protective properties, as well as an approximate technology for the production of a composite material, which is not fundamentally different from the technology for the production of chipboard.

Laboratory samples were tested to determine the basic physical, mechanical and protective properties. In terms of physical and mechanical properties, boards based on composite materials are not inferior to the properties of existing particle boards.

The degree of protection of the resulting material from X-ray radiation can be adjusted depending on customer requirements. The results of assessing the protective properties of the resulting material were carried out under hard (beam) radiation and give positive results.

The conducted exploratory experiments show that the developed composite material with protective properties against X-ray radiation, its structure and production technology show promise for the production of this material. The developed composite material can be used as a protective material against X-ray radiation; Woodworking waste can be used for its production. The material is recommended for use in equipping X-ray rooms, for cladding walls, floors, ceilings, making screens, door blocks, etc. The manufactured products will compete with existing building materials for furnishing premises that require protection. from x-ray radiation.