The tree itself has a very beautiful pattern and pleasant appearance. But, as they say, there is no limit to perfection, and over a long time we have been able to invent many ways to give wood interesting visual characteristics. One of the ways to give wood an unusual appearance is to roast it. It would seem that a tree is afraid of fire, and it is not very rational to subject it to this test. But, if you do everything correctly, the result is an extremely attractive surface, and the wooden product is not damaged and does not lose its performance characteristics, while acquiring many new qualities.

Yakisugi – Japanese wood burning technology

In fact, we are not talking about something new, since in Japan such wood processing has been known for a very long time - since the 18th century. Wood burned in this way not only becomes more interesting visually - changing color and showing texture, but also receives protection from fire, as well as insects, which are the scourge of wooden buildings and products. Finally, the service life of such wood is also greatly increased, and it can last up to 80 years. Add to this protection from fungus and rot, and you get one of the best ways to process wood, which also does not require any third-party chemical components and is completely environmentally friendly.

Wooden components burned in this way are used in various fields, but they are most actively used for cladding buildings.

Installing poles

I'm starting to install fence posts along the road. First I measure the distance, then I make calculations:

- The length of the two sections with space for pine between them is 9.80 m (4 1.8 4).

- I divide the length of my section along the road by the calculated value, I get the number of pillars and the distance between them. There are only 4 pillars per section - 2 central ones 1.7 m high, and 2 side ones 1.2 m high.

- Using a nylon thread, I mark the installation line by hammering in 2 pegs.

- I dig holes for pillars 0.9 m deep.

- I install the posts in the holes, level them along the cord and using a level, then fill the holes with large stones and rubble.

- I cut off the outer posts to make the fence multi-level.

How wood was burned before and how it is done now

As we said above, the process of burning wood has been known for a very long time. And not only in Japan, but also in other countries of the world. It appeared, most likely, by accident, since at one point people noticed that burnt boards had qualities that their ordinary counterparts simply could not boast of. This process was also known in Rus', where it was called “smoking.”

If earlier a fire was used to burn boards, which was very inconvenient, since the process was difficult to control, now, with the help of a conventional gas burner, the quality of the final product has become much higher. At the same time, we are not talking about some incredibly complex technology that is inaccessible to the vast majority of us. If you follow the rules, the process happens quite quickly, and the result is very interesting.

How wood is burned in industry

There is such a method as full firing. In this case, the boards are placed in an oven where the temperature reaches 400 degrees Celsius. In this case, temperature treatment occurs in vacuum conditions, which allows you to achieve the desired effect. This method is used for large volumes of products, and an ordinary person cannot have such equipment. And wood still loses a number of its qualities.

There is also deep processing, during which the wood burns up to 20 millimeters, but, surprisingly, does not lose its properties. However, for such an activity you still need a stove, and the wood itself becomes not very interesting in appearance due to too much charring.

Decorating the pillars

I didn't want the edges of the sections to look like an unfinished fence. Therefore, I came up with a frame for the outer columns using boards.

- 3 long section boards will be attached to each extreme post.

- I file their edges at an angle of 45 degrees.

- I cut out boards with a width equal to the width of the post, also sawing their edges at an angle of 45 degrees.

- I cover the side edges of the pillar with them.

- I nail a wooden square on top of the post.

Self-firing - basic rules

- When starting work in the direction of firing, it is better to practice on unnecessary wood scraps. This way you can properly dose the effort without causing excessive damage to the wood. This is especially important if furniture firing is being prepared. After all, if the same board is damaged in the process, then you can take another one for finishing. This move doesn’t work with furniture; you can simply ruin an expensive product;

- Pay attention to the burner itself. Clean it well from soot. Otherwise, you will not be able to get an even blue flame, since it will be changed by combustion products;

- When firing, the upper part of the flame is most effective. You may remember school lessons where you were told that the top of the fire has the highest temperature. It is she who needs to process the wood, otherwise the effect will be very far from ideal;

- The wood itself must be cleaned and properly sanded before processing. This is especially true for old boards, which have lost their original appearance over time, and the patterns on which have become dull. In this case, the top layer can even be removed, opening access to fresher wood, which, when pyrolyzed, will better reveal its design.

- If you want to achieve deeper burning of wood, before work you need to soak it in copper sulfate and wait for the latter to dry completely. In soft types of wood, vitriol will be absorbed more deeply, and therefore they will burn deeper;

- After finishing the procedure, go over the wood with a wire brush, and then soak it with a dark antiseptic. The next stage will be grinding followed by impregnation with a light antiseptic composition. As you scrape away the soot layer, a distinct woody structure will be revealed;

- You should not fire wood that has previously been treated with drying oil or putty. In this case, these materials will appear in the form of unsightly spots, which will completely cancel out the positive visual effect of such processing;

- You can also reveal the wood pattern after firing by painting the surface and then removing the paint. Thus, the latter will remain only in the depressions previously expressed by pyrolysis. The main thing here is to choose the right colors. The ideal solution would be ivory paint. In this case, it is better to select acrylic paint, and it must be applied to a surface that has been previously cleaned of combustion products. Other visual effects can be achieved using varnish and technical wax.

The essence of the method

Classic approach

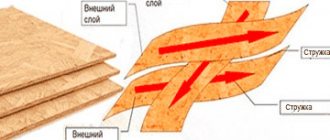

In the traditional version of the Shou sugi ban technology, the process of charring wood looked like this: 1. We connect three boards (10-15 mm thick) so that a triangle is formed. 2. Tie them tightly together with rope or wire. 3. Install the triangle in a vertical position, while ensuring that it has access to oxygen from below and at the joints. 4. We stuff a bunch of straw or paper into the lower part of the structure, and then set it on fire. 5. The firing process, as a rule, takes no more than three minutes, after which the burned boards are cooled and washed with water.

Initially, the Japanese used the charring technique only on cedar boards, but later they began to use it on ash, oak, maple and other types of wood.

Modern approach

Nowadays, a gas burner and, in rare cases, a blowtorch are used to burn boards.

The most suitable material for implementing the Shou sugi ban technique is coniferous wood:

- To create a facade, pine boards with a thickness of 20 mm and a width of 140 mm are ideal.

- The most commonly used wood for interior decoration is larch, acacia, ash or alder.

The duration of thermal exposure depends on the type of wood, its moisture level, thickness and what structure and shade of the material you want to achieve. The firing process is as follows:

1. Before you start directly firing the boards, you need to practice on several test samples. This will determine the amount of firing time needed to achieve the desired result. The burner should be kept at a distance of 30-40 cm from the charred board.

2. Having achieved the development of the required pattern, let the wood cool completely.

3. As soon as the wood has cooled, we clean the top layer and completely remove the soot. To do this, we use a stiff brush or special brass wire.

4. After this, thoroughly rinse the product with running water and leave to dry. If you plan to paint the boards in any color, then this should be done at this stage.

5. Treat the dried wood with tung oil (a natural, non-toxic product without adding any solvents). It has a high impregnation ability and does not leave a film on the surface. If the boards are intended for outdoor use, they can be additionally varnished to further increase their service life.

If you strictly follow all the above instructions, you can char the existing wood yourself and use it to create your own, original house façade or room interior.

Where else is wood burning used?

In addition to giving an interesting appearance and a host of new qualities to façade elements, interior decoration and furniture, firing is often used for various wood elements that will be in the ground.

A striking example in this case is a wooden fence or posts. Of course, you can treat them with special compounds, which are currently available in abundance on the market. However, the ability to resist moisture, insects and not rot can be achieved by simply placing it in a fire. In this case, a better effect can be achieved if the firing is carried out slightly above the level that will be in the ground.

Application

Burnt wood is used in the finishing of external and internal surfaces of walls in the form of facade or decorative panels and half-timbers, which meet high requirements for wear resistance and durability. In the interior, burnt wood products are found as exclusive furniture and luxury items.

Fire-treated wood is a durable and reliable material that retains its elegance and nobility. This material will make any home cozy and add a special chic.