Modern plastic windows are not only durable and practical in everyday use, but also universal - they can be installed even in a wooden house. However, the choice of window design, site preparation and the installation procedure itself have many important features. Let's look at what the correct installation of double-glazed windows in a wooden house should be, what the specifics of the procedure are and what important nuances need to be taken into account, what are the general pros and cons of using plastic windows in a wall made of logs, timber or boards, what types of them are used, and also what are the main stages of the installation procedure.

Installation of a plastic window in a wooden house Source ytimg.com

Specifics of installing plastic windows in a wooden house

Plastic windows look quite attractive in a wooden wall. However, when installing them, it is necessary to take into account at least 3 important features:

- Shrinkage of wall material.

- Problems that arise when installation technology is not followed.

- Accumulation of dampness in the window environment.

Let's look at the specifics of each aspect in more detail.

Tree shrinkage - what needs to be taken into account, important nuances

Due to its specific structure - the ability to retain moisture in the fibers - wood is distinguished by pulsating dimensions. Even well-dried pieces dry out and decrease in size over time. Therefore, the opening in a wall made of timber, logs or boards will become smaller after a certain time.

On average, a one-story structure decreases by 2-6 cm in the first 2-3 years after construction. In addition, seasonal changes in air humidity can to some extent restore the original size of the structure. This property must be taken into account when installing plastic windows in a wooden house.

To compensate for shrinkage forces, a gap is left above the window Source stroyfora.ru

Otherwise, the window frame will be subject to bending, torsion and skew loads, which will significantly shorten its service life and subsequently require repair or complete replacement. This problem can be avoided by using a special installation technology, the main element of which is the casing system.

Problems with incorrect installation

In order for the installed window to operate normally, it is necessary to avoid the following series of errors during the installation procedure:

- Installation of the frame without preliminary manufacturing of the casing. As a result, the window becomes deformed and jams due to the pressure of the wall material during the natural shrinkage of the wood.

- Filling horizontal seams between the box and the wall with construction foam. When frozen, the filler is characterized by sufficient rigidity. Therefore, deformation forces will be completely transmitted to the window and destroy it - even if there is a properly equipped casing system.

Attaching a PVC window to foam is allowed only to the casing, and not to the wall of the house itself Source jurnalstroy.ru

- Incorrect ratio of frame dimensions and window opening. If there is no installation gap, the opening will have to be widened, and if it is excessive, the slopes will freeze, so additional insulation will be required with the installation of an expansion profile.

- Application of foam without protection from the street. When exposed to water and light, the material will degrade over time. This can be avoided by installing a protective strip of the PSUL type on the outside.

- Incorrect arrangement of hydro-vapor barrier of the gap or its complete absence. As a result, the material and parts of the wall adjacent to it will become damp and collapse.

- Installation of the frame is not level. The rules for installing plastic windows in a wooden, brick or concrete house are the same - horizontal and vertical elements must lie strictly in the corresponding planes. Otherwise, the fittings will be constantly overloaded and quickly deteriorate.

- Placing the frame in the area where negative temperatures penetrate the wall. As a result, condensation will always accumulate on the inside.

Freezing of a plastic window is the result of improper installation Source stroi.tv

Note! There is a widespread belief that when replacing old windows with new ones in a house that has been in use for a long time, there is no need to leave an installation gap and make a siege. In fact, even well-dried wood easily swells and then dries out again, constantly changing its size and putting pressure on the frame, under favorable conditions for this, for example, seasonal or absolute changes in air humidity.

Pitfalls - moisture accumulation

Tightness, high-quality heat and sound insulation – these are the main parameters that PVC window manufacturing companies often use to advertise their products. However, these positive properties have a downside - the lack of natural ventilation, characteristic of wooden unsealed frames.

This contributes to the accumulation of excess dampness, if not in the entire room, then at least near the window. The problem is solved in two ways:

- The operation of general ventilation systems in the house. However, if it is not there, then its installation will cost the owner an additional round sum.

- Arrangement of supply channels. Ventilation is formed after replacing the standard seal with special profiles.

The formation of condensation is a negative consequence of the tightness of a plastic window Source mirnadivane.ru

Important! Almost no installation company gives a standard guarantee for the installation of windows in a timber or log house. This is explained by the unpredictability of the behavior of wood, and, as a consequence, the impossibility of 100% compliance with the correct operating conditions of the window.

See also: Catalog of companies that specialize in doors, windows and related work

Cutting methods

To cut a doorway with your own hands, you will need a tool, but you can choose it correctly after determining the method of work being carried out. The method depends on the wall material. It is not advisable to chisel and sledgehammer, as the integrity of the entire partition will be compromised. You can carefully cut the opening using diamond, laser, waterjet or oxygen cutting.

Diamond cutting

For concrete partitions, the method of diamond cutting of a doorway using a grinder or circular saw is used. The cutting element of the tool is a metal disk coated with diamond.

The diamond cutting method has many advantages:

- low level of vibration eliminates the appearance of cracks even on loose partitions;

- during the cutting process, an accurate thin cut is entrusted along the marked contour and at the desired angle;

- the noise level of a working tool does not exceed the permissible threshold specified in sanitary standards;

- a small amount of debris due to the absence of chips, which is impossible to achieve when using a hammer drill.

Among the shortcomings

highlight the costs of purchasing expensive diamond blades. During work, the concrete wall is moistened with water, but fine dust still spreads into the room.

Laser cutting

Expensive equipment is used for laser cutting of openings. Previously, it was bulky and was used only in production. Modern laser cutting equipment is compact, but its high cost and specific purpose have made it popular only among specialized repair teams. The cutting of a concrete wall is made with a laser cutter due to the gas-discharge action.

Before starting work, the parameters of the wall

:

- thickness;

- the presence of a reinforcing frame;

- passage of communications inside the partition;

- grade of reinforced concrete wall.

Additionally, the floor of the apartment building where cutting is planned is taken into account, as well as the admissibility of wetting the concrete structure with water.

Waterjet cutting

Cold cutting of an opening in a wall refers to the waterjet method. A special installation is used for work. It creates a strong stream of water at a speed of 1 thousand m/s. The liquid in the tank is mixed with abrasive particles with a diameter of about 0.4 mm. The prepared mixture is fed through a nozzle onto the reinforced concrete structure and destroys it at the point of contact. The cutting force depends on the pressure. At the maximum power of the equipment, a reinforcing frame made of steel rods is cut along with the concrete.

The waterjet cutting method has the following advantages:

- precise cutting of concrete according to markings;

- the environment is not polluted due to the absence of chemical impurities and harmful gases;

- the concrete partition is not subject to mechanical and thermal stress;

- no wall vibration;

- low noise level;

- The method allows you to cut out a section of the partition at any angle, as well as make a doorway of complex shape.

Disadvantage

is the formation of dirt, the high cost of consumables, and the large dimensions of the equipment. Waterjet cutting is used on construction sites that have not been put into operation.

Oxygen cutting

The oxygen cutting method is also called spear drilling. To cut out a doorway, a machine with a metal tube is used. Oxygen is supplied through the spear under high pressure. At the same time, the jet is heated inside the tube to a temperature of 1400°C using a gas burner. After the spear has ignited, the external heating source is turned off. When the temperature reaches 2000°C, the tube is leaned against the concrete surface and turned slightly. During cutting, you cannot move the spear away from the concrete, as it cools quickly.

The disadvantage of this method is considered to be a fire hazard, as well as the possibility of getting burned. During cutting, hot slag particles scatter throughout the room.

Advantages and disadvantages

The use of plastic windows in a wooden house has the following number of advantages:

- Minimal care procedures.

- There is no need to periodically update the surface - painting and applying special protection.

- Long service life.

- Low susceptibility or complete absence of influence on the material from destruction factors - thermal changes, high humidity, sunlight, corrosion, rotting, etc.

- High mechanical resistance.

- Fire safety.

- No deformation - cracking, drying out, swelling, warping.

At the same time, PVC windows also have a number of specific disadvantages:

- Impossibility of repair and the need to completely replace parts and elements if damaged.

- The inability of the window system to fully exchange moisture between the room and the street.

Installing radiators under a window in a wooden house - as a measure to prevent the accumulation of dampness Source enter-city.ru

- Collection of dust by the surface due to the static-electric properties of plastic.

- A high coefficient of thermal expansion in the absence of a gap contributes to the destruction of the wall material upon contact with the plastic frame.

- Sound and heat insulation values are lower than those of a solid wooden structure.

On a note! Often, plastic windows in both old and new wooden houses are fastened directly to the mounting foam without casing. However, in addition to maintaining pressure and stress from the walls through the hardened foam material to the frame, this approach has another obvious drawback - insufficient thermal insulation. Without additional insulation in winter, the window will become a place for heat leakage and the formation of dampness.

Types of windows

According to their design, structure, operating features and purpose, PVC windows used for installation in wooden walls differ into the following types:

- Single leaf. They are characterized by minimal dimensions and light transmittance. Suitable for installation in small areas - in the hallway, kitchen, corridor, landing.

Single-leaf plastic windows in a wooden house Source multiok.by

- Bivalve. They have a standard design. Designed for any medium-sized rooms. As a rule, one of the doors is capable of opening in two planes.

- Tricuspid. Due to the high light transmission capacity, they are ideal for spacious rooms - living rooms, halls, halls, bedrooms. At least two doors can open.

- Deaf. Characterized by small sizes. Installed in utility rooms, bathrooms, boiler rooms, basements, attics.

Regardless of the design, a high-quality plastic window is easy to use and retains its original properties for a long time in any climatic conditions, but in terms of aesthetics it does not always harmonize with the facade of a house made of timber or logs.

Installation steps

Installation of a plastic window into the wall of a wooden house is carried out in three main stages:

- Preparing the opening.

- Arrangement of the casing.

- Installation, assembly and checking the window for serviceability.

Let's look at the features of each stage in more detail.

Diagram of a plastic window in a wooden wall Source mosokna.ru

Video description

Video instructions for installing a plastic window in a wooden house:

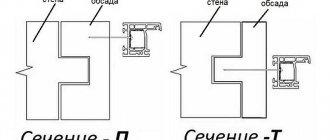

Most often, the casing is made using the tongue-and-groove technology according to the following algorithm:

- The groove markings are applied along the ends of the opening.

- A groove 5 cm deep and wide is cut out in the center of the side edges.

- The grooves are lined with jute tape.

- A board with insulation is installed on the lower edge of the opening.

- Bars of similar size, pre-wrapped with tape insulation, are inserted into the side groove recesses.

- Next, boards of suitable width and 5 cm thick are screwed to them in the center.

- After this, the top board is installed.

- The upper shrinkage gap is filled with insulation.

- Finally, the box is fastened and the remaining cracks are sealed.

Important! The casing is assembled according to the principle of a designer, after which it is fastened with self-tapping screws. At the same time, the structure itself is held in the walls of the house solely by means of a tongue-and-groove or monolithic connection. It should not be screwed, otherwise compression forces from shrinkage will be transferred to the window.

Interior doors

For a long time, a classic interior door for a dacha was considered to be a product made of solid pine/spruce with a paneled panel design. Such models are inexpensive (an unfinished canvas with a box costs from 4 thousand rubles), they are easy to repair with minor damage. Ryad, "BIS art" and Balwald, produce premium-segment doors made of oak and larch, including those with "high" varnish; the price starts from 40 thousand rubles.

You can also purchase serial panel boards with solid wood frame and MDF sheathing - they do not dry out, almost do not change their geometric dimensions when humidity increases, and they rarely warp. At the same time, the cladding - be it veneer or laminated paper - does not peel off or delaminate. The materials and adhesives used by leading manufacturers are moisture and heat resistant.

Practical advice

The best option for a summer veranda in terms of price and quality ratio is windows made of “cold” solid-drawn aluminum profiles with single-chamber double-glazed windows or single-glazed windows. Frame parts are usually powder coated in white and brown. Unfortunately, finishing using sublimation technology, which allows you to imitate the texture of wood, will greatly increase the price of the structures.

Useful tips

In order to correctly install plastic windows in a wooden house made of timber or logs, you must follow the following series of useful recommendations:

- It is necessary to install windows in walls made of wood after the completion of the main shrinkage processes. Even a well-made casing system will not fully guarantee the protection of the frame from the compressive forces of wood in the early stages after the construction of the house.

- The fastening of the frame to the structure must be sliding. Only this method ensures its protection from deformation under the influence of shrinkage forces.

- Finishing work should be carried out only after the installation and assembly of the window is completed.

- The successful completion of installation work is facilitated by careful organization of the work - correctly selected tools, materials, drawings, diagrams, instructions.

Recommendation! If it is necessary to replace a window in a wooden house with plastic ones, but of a smaller size than those previously installed, in order to reduce the window opening, a casing should be made with a larger thickness of the slats than in the standard case.

How a pigtail is made

The casing elements are made from hardwood: cedar, larch, ash or high-quality pine. The combined use of different types of wood is possible. The wood of the blanks should not have rotten knots, chips or other defects. The optimal wood moisture content should be at least 10%. In workpieces that are too dry, chips and cracks may form, and destruction may occur under load. For the manufacture of casing elements, it is recommended to use massive timber with a thickness of at least 50 mm. The width of the timber for the frame should be no less than the thickness of the log house, but the maximum size should be no more than 250-260 mm. A wider box may also be susceptible to cracking.

Briefly about the main thing

When installing PVC windows in a wooden house, three important features must be taken into account - the impact of wood shrinkage, possible problems due to technology violations and the accumulation of dampness at the point of contact of the frame with the wall. The advantages of using plastic windows in a wooden house are expressed in minimal maintenance, durability, strength and preservation of the original properties of the structure.

Disadvantages - the need to completely replace parts when they fail, insufficient air exchange, attracting dust to the surface, minimal heat and sound insulation properties compared to wood. In this case, the following types of windows are most often installed in a wooden house:

- Single leaf.

- Bivalve.

- Tricuspid.

- Deaf.

Each variety has its own characteristics in design, operation and purpose. Plastic windows are installed in a wooden house in 3 main stages - preparation of the opening, creation of a casing and direct installation and performance testing.

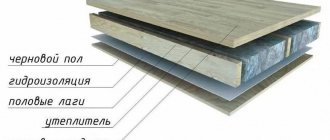

Metering

To correctly install the plastic structure, it is important to accurately measure the opening.

First you need to measure the width. Width is measured at 3 points: bottom, top and middle. The smallest indicator is taken and 5 cm is subtracted from it for the installation gap.

Next, the height of the window is measured in three places and 5 cm is also subtracted. When measuring the height of the window, it is important to take into account what the window sill will be. If it is thicker than the old structure, then the difference between the thickness of the new and old window sill is subtracted from the window height measurement.