The foundation is the foundation of the house. The heavier the house, the more solid the foundation should be. Since a wooden house is relatively light, there may be several options for its foundation. But this does not mean that the choice should be approached carelessly - here it is doubly important to choose the right option, taking into account the complexities of the natural material, because organic matter can begin to deteriorate at the point of exposure to moisture, air and soil three times faster. Plus, the financial issue often comes first. As a result, which foundation is best for a wooden house has to be chosen based on the landscape of the site and the available budget.

The foundation for a wooden house can be made from different materials Source stroy-dom-pravilno.ru

Online foundation calculator

To find out the approximate cost of various types of foundations, use the following calculator:

Concrete strip

The strip foundation for a wooden house is one of the most beloved by our compatriots and, perhaps, the most reliable. Its width is the same around the entire perimeter, and leaves 50 cm “plus” to the width of the walls.

It is divided into three subspecies: deep, shallow and non-buried. Deeply buried is designed for “difficult” conditions: in the presence of basement premises (garage, basement), multi-story buildings, heaving soil on the site, large freezing depth. It is designed to hold the building stably even when weather conditions change and the ground moves. It is believed that such a base should be buried at least 200 mm lower than the freezing depth (the values for a certain latitude are known and can be easily recognized from the reference book).

Classic strip foundation for a wooden house Source tr.decorexpro.com

If the soil allows, then for the construction of low-rise wooden houses, a shallow foundation is most often used - it is buried to a depth of about 500-700 mm, which, although less than the freezing depth, is quite enough to support a light-weight house. And, of course, it will cost much less than a deep-seated belt one.

In the case of very light buildings (sheds or utility rooms), you can get by with a shallow foundation. This type of foundation can be made of concrete or brick, stone or blocks.

A relative novelty on the construction market is a foundation made of permanent formwork, which consists of ready-made elements that are combined into blocks, and then concrete is poured into them.

A non-buried foundation is essentially a plinth on a sand cushion. Source postroim-svoi-dom.ru

The production time for any strip foundation is about a month, since after pouring it is necessary to wait a certain time until the concrete reaches its design strength.

Slab concrete monolithic

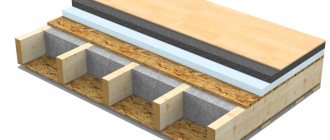

A slab foundation is simply a large concrete slab. This is a good choice for heaving and mobile soils, since the slab base has the ability to move along with the soil when it shifts. You should not think that the house will move around the site - moving soil means displacements of a couple of centimeters per year, but even such values can cause cracks to appear on the walls when using a strip base.

Making a monolithic foundation cannot be called an easy task - in terms of installation time, they are approximately equal to those of a strip foundation. It also requires clearing the site, deepening it, pouring concrete - and, given the harsh conditions, some experts ask for a grade no lower than M400, in principle, given the cost, you can get by with M150, but these are very minimal requirements. A big problem is also the uniform drying of the slab surface (a large area dries poorly, and it will take a long time to dry completely and begin the next stage of work). It will also be necessary to arrange a sand cushion for cement, a blind area on the finished foundation and waterproofing (as a means of protecting concrete from water - film or special compounds).

Ready slab foundation Source stroidom-shop.ru

Pile: steel screw or concrete driven

A pile foundation for a wooden house is a good choice for a site where there are problems with groundwater, and, in addition, the site itself has unevenness, the leveling of which will require significant effort. Proper calculation of the pile field makes such a foundation reliable and stable. In addition, the cost of a pile foundation is significantly lower than a concrete one, and installation is carried out in one day.

The main disadvantage is that with a pile foundation it will not be possible to create a basement or ground floor in the house. Auxiliary buildings on the same foundation as the piles are undesirable - due to the elevation above the ground. Entering a garage, for example, will not be very practical.

Block foundation

Block foundation

The construction of a block foundation for a log house will not take much time. The use of ready-made blocks gives the advantage of not having to wait for the foundation to dry out. This process usually takes two or more weeks. These types of bases are applicable on almost any type of soil. The finished blocks are equipped with correctly selected fittings.

Advantages of a block foundation:

- Frost resistance. The blocks can be used in regions with large temperature fluctuations due to the fact that special additives are mixed into the concrete.

- Good resistance to acidic soils. This allows them to be used on problem soils. For this purpose, the blocks contain crushed granite stone, which ensures this property.

- Large selection of product sizes. The manufacturer provides a wide selection of block sizes. There are large blocks for high-rise buildings and small products weighing 30 kg, which can be installed without the use of special equipment.

Foundation construction process:

- First, you should dig a pit for laying the foundation. To do this, you should make markings with pegs and tape, and hire equipment.

- Prepare the bottom of the pit. If there are soils of unknown quality at the bottom of the pit, it is better to make a sand cushion of about 15 cm and then compact it.

- Both columnar and strip foundations are built using the same masonry technique.

- The solution is prepared just before work. The strength of the foundation directly depends on its quality. Water should not be added to the solution, as this will worsen the adhesion of the structural elements.

- The masonry is made according to the type of brickwork. You should fill the seams with mortar very carefully, leaving no gaps. The thickness of the seams should be 10-15 mm.

Video description

What are the pros and cons of a pile screw foundation? Is it possible to make a high-quality foundation for little money? Watch in this video:

Pile foundation - screw and concrete Source stroy-dom-pravilno.ru

See also: Catalog of wooden house projects presented at the Low-Rise Country exhibition.

Log house

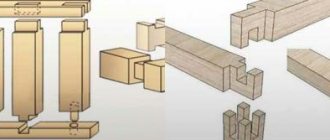

A log house is the walls of a house made of solid logs. In the corners of a wooden house, logs are connected into so-called crowns. At the bottom of the log, a piece of wood is cut out the width of the transverse diameter of the log. Wooden elements in the corners of the house form locking systems that do not require additional strengthening. This confirms the popular expression - to build a house without a single nail.

Such houses are most often built in areas where timber is available to consumers at a low price. Such places include Central, Eastern Siberia and the Far East. Although it is worth noting that the popularity of building private houses from solid wooden elements has increased widely in all regions of our country.

The low specific gravity, excellent thermal insulation qualities, durability and environmental friendliness of wood are an undeniable advantage over other building materials.

Video description

What are the features of concrete driven piles? We'll talk about pile foundations in our video:

Columnar: brick, block or concrete

Columnar foundations do exist as a separate type of foundation, but it must be noted right away that they cannot be used for the construction of a residential building.

In general, this is an inexpensive and easily erected foundation, which is a hole 50-70 cm deep, at the bottom of which sand and crushed stone cushions are laid, on top of which the pillar itself is built.

The methods for making “pillars” are completely different - bricks, pouring concrete into formwork, asbestos pipes, ready-made blocks. As with any technology that uses concrete, care should be taken to ensure that sand cushions, formwork and reinforcement are installed when making the bases on site.

Columnar foundation poured and made of blocks Source nauka-i-religia.ru

The distance between the pillars, regardless of unevenness, should not be more than 1.5-2 m; in addition, pillars must be present at the corners of the building and at the intersections and junctions of walls. Columnar foundations are installed almost everywhere, with the exception of floating areas (areas completely unsuitable for construction), using special device technologies - for example, TISE, where the pillars “expand” at the bottom, giving additional strength to the structure. But even when using this technology, you should also take care of additional insulation and waterproofing, and this work must be performed together with the construction of the walls (that is, the places where the pillars adjoin the walls are processed together).

Considering that columnar foundations are suitable exclusively for ultra-light buildings - gazebos and the like, it can be argued that they do not have many disadvantages. But in any case, such foundations are not suitable for complex soils - loose, with a large freezing depth.

No specialist would use such a foundation for a residential building. In addition, it is strongly recommended not to experiment with such a foundation when building a house through the efforts of “gray” construction crews, who do not care what they build, because they do not bear warranty obligations.

If the soil is even slightly mobile or susceptible to heaving (and usually it is), then eliminating the consequences will cost a pretty penny.

Incorrect use of a columnar foundation - the work will have to be redone Source stroy-dom-pravilno.ru

See also: Catalog of companies that specialize in foundation repair and design.

Features of various supports for a columnar foundation

From the moment of actual manufacture and installation of the pillars, work is carried out in different ways:

- If the concrete support is installed in dense soil, it is permissible to pour concrete directly into the soil. As waterproofing, pieces of roofing felt are used, twisted along the diameter of the hole and inserted into it. Before pouring, an asbestos-cement or plastic thick-walled pipe is inserted into the well, inside which a U-shaped metal rod is installed as reinforcement. The concrete solution is poured. If an asbestos cement pipe was used for pouring, it remains in place as permanent formwork; the plastic pipe must be carefully removed.

- If TISE technology is used, then before manufacturing the narrow part of the support, the bottom of the well is pre-expanded using a special drill and filled with concrete. After its initial setting, pouring is performed according to the above method.

- Installation of wooden poles requires mandatory treatment of the poles with antiseptic agents against mold and mildew, as well as high-quality waterproofing. To do this, the end of a beam or log located in the ground is carefully wrapped in sheets of roofing felt, which are fastened together.

- Screw piles require virtually no preparation and are used on sites with any terrain complexity. For such supports, the only important thing is the installation location and the absence of large rocky inclusions in the drill’s path.

- If necessary, a hanging grillage is made on top of the pillars.

Example of a foundation with a hanging grillage

Pros and cons of a pile-screw foundation

After considering the main types of foundation, it would seem that choosing a pile-screw foundation is the most optimal, however, there are both advantages and disadvantages.

Advantages:

- Installation speed - just determine the freezing depth and order a drill, and literally within a day the piles will be installed;

- Simple process - does not require additional time or money;

- Versatility - good performance of this type of foundation was obtained on all types of soil, including peat;

There are only two disadvantages , but they must be taken into account:

- Calculation complexity - the heavier the building and the more complex its shape, the more careful calculations will be required;

- If a geological examination of the soil was not carried out before installing the pile field, then in the case of loose or peaty soil, a certain percentage of subsidence of the structure is possible - unfortunately, often uneven.

Pile field for a wooden house Source art-stroynn.ru

conclusions

Which type of foundation should be preferred for a log house?

From all of the above, the following conclusions can be drawn:

- A columnar foundation is not suitable for a full-fledged wooden house. It is intended only for light wooden structures of a small area, bathhouses, verandas, as well as supports for porches and gazebos.

- The recessed strip foundation is designed for multi-story heavy structures and is redundant for log houses.

- It turns out that the most suitable foundations for a wooden house will be shallow strip and pile-strip foundations. These types of foundations are reliable and durable. Which one is preferable depends on the specific geological conditions of your site.

- You should not skimp on geological surveys - their results will show exactly what type of foundation is suitable for your site. Often this knowledge saves up to 50% of the cost of the foundation, and will also allow you to be 100% confident in the correct type of foundation.

- Shallow strip foundations are more popular due to their efficiency and ease of installation. It can be successfully used for a house made of rounded logs and a wooden cottage on slightly heaving soils or with additional insulation.

- The tape-pile method has a fairly high cost; it is a fairly new method and is not used very often in construction.

In order to decide which foundation is better in each specific case, the entire set of factors should be taken into account, such as the area and weight of the building, the nature of the soil, the region of residence, etc.

Screw foundation with channel or beam strapping

If you choose a screw foundation for a wooden house, then after installation you need to decide on the type of strapping, which is divided into beam and channel strapping.

Bonding is a method of stabilizing a foundation of piles after they have already been installed and concreted.

Timber strapping looks good under wooden buildings - bathhouses and houses. The main requirement is that all piles be cut to the same height, but then the frame can play the role of the lower crown of your log house, taking into account that the floor joists are located quite high (at least 2-3 crowns higher).

Tying a pile foundation with timber Source 2gis.ru

A channel (rolled metal in the shape of the letter “P”, if viewed from the side) is used in cases where the alignment of all piles is difficult (for example, there are too many of them), and, in addition, the channel supports heavier structures. It is laid around the entire perimeter and along load-bearing partitions. It will be a little more expensive, because with this technology you will need to order special equipment. The channel can be laid on top of the piles (a more common option) or between them. It is also worth considering that channel tying must be done immediately after the stage of screwing in the piles in order to avoid changes in their position.

Anti-corrosion treatment is carried out after installation of the harness.

Tying a pile foundation with a channel Source korden.org

Slab bases

This type of foundation is widely used for construction on any soil. It is almost not buried.

Undoubtedly, this base will last a very long time and is considered the strongest and most reliable. But for all its positive features, a slab foundation will cost you a lot of money.

Installation of a slab foundation on the site

As with any other foundation, the initial stage in the work is marking the location of the future home. The depth to which the foundation should be poured depends on the mass of the structure. If the house is small, then a base of 10 centimeters is quite sufficient for it. And for more luxurious apartments it should be doubled or tripled.

The features of laying a foundation of this type are as follows:

- markings of the location of the building are made;

- they dig a pit and compact the earth at the bottom well;

- pour a layer of sand and gravel, making a “pillow”, so to speak;

- Cover it all with waterproofing on top;

- place formwork from wooden boards;

- tie a reinforced frame;

- make a concrete solution and fill the pit with it.

A very important aspect is that the pouring work should be completed in a day. This will promote uniform hardening of the mixture and protect the foundation from cracks.

For the mortar, you need to choose class M 300 cement. It will provide the structure with high strength.

The frame is usually made of embossed rods with a cross-section of 12 millimeters. The distance between them should be about 20-30 centimeters. The frame is knitted with a special knitting wire.

Vinyl film will provide reliable protection against high humidity. It covers the bottom of the pit.

A structure made on such a foundation will never sag under the influence of melt and groundwater. This option is perfect for complex, loose soils.

Filling a tape-type base

Criteria for choosing a base

The main criteria are, of course, the condition of the soil and the climatic features of the region:

- Freezing depth - the greater it is, the deeper the foundation should lie;

- Material consumption is also an important criterion;

- Aesthetics – the foundation of the house must be combined with the environment and the building itself;

- Position of the house - if possible, you should choose places away from cliffs and ravines;

- Plinth and its use - is the device planned to be installed in the basement of a garage or other ancillary premises? Depending on the answer to this question, you will need to use a certain type of foundation;

Strip foundation structures

Strip foundations occupy a significant segment of the individual housing construction market, and differ in the type of device and depth of installation. This is not just a classification for the sake of additional nomenclature - the principle of operation of the structure and the technological processes associated with the construction of the foundation depend on the depth of the foundation. Determining the geometric dimensions of a strip foundation for a log house is very simple; for this you need to follow a certain methodology.

Shallow tape

Shallow strip supports are characterized by low strength. But such a foundation for a log house is an excellent option for an economical and reliable solution. Cheaper than a shallow foundation can only be a non-buried strip or pile foundations, but they are not always suitable in terms of soil type and strength. The average depth of the shallow belt is 50-60 centimeters, which is almost always in the zone of soil freezing.

Log house on a strip base

Standard sizes of foundation blocks range from 300 to 1200 mm and are graduated in increments of 300 mm - this parameter will determine the width of the foundation slab. Whatever the depth of freezing, the foundation for a shallow log house will be located in the zone of soil freezing, which obliges the developer to install drainage systems to drain groundwater - otherwise neither a high base (from 400 to 1500 mm) nor durable concrete will save the structure from destruction under the influence of frost heaving.

Deep laying tape

It is necessary to use a deeply buried strip foundation for a log house measuring 6x6 m only if a two-story wooden house is being built or the groundwater level is in the freezing zone, which immediately makes the soil highly heaving. The depth of laying a capital strip foundation can range from 0.8 meters to almost infinity. A reasonable depth of the foundation base is 2.5-3 meters, taking into account the structure of the basement floor.

Construction of a log house

The width of the tape will depend on the width of the wall structures. The minimum cross-sectional dimensions are in the range of 300-400 millimeters, depending on whether a prefabricated or monolithic structure is used.

It should be understood that prefabricated strip supports consist of two types of blocks - a foundation slab (a trapezoid with a top from 300 to 600 mm) and a foundation block, the width of which corresponds to the upper edge of the foundation slab.

The width of the base of the slab is always greater than the width of the block, so a trench of appropriate dimensions should be constructed. After installing the supporting structure and lateral waterproofing, the soil is backfilled and compacted.

Non-recessed tape

The advantage of non-buried foundations is that they stand on the surface layer of soil, which eliminates the effect of frost heaving on the side walls of the foundation slab. Preparing the site for installation of a non-buried tape consists of constructing a solid foundation.

After this, the formwork can be installed. The height of the above-ground part of the foundation is determined taking into account the mass of the wooden house. The bearing capacity of well-prepared soil allows you to build a foundation for a log house with a height of at least 30 centimeters. Thus, we can assume that the minimum vertical size of a non-buried foundation, taking into account the prepared cushion, is 0.8 meters.

The dimensions in the plan must correspond to the dimensions of the house in the axes, while it is rational to arrange the foundation taking into account the presence of 10-centimeter protrusions of the base in and out of the walls. With an average thickness of wooden walls of 400 mm, the width of the foundation will be 420 mm - this size should be divided in half and the resulting value should be placed on both sides of the center lines of the walls.

We recommend watching a video on how to make a non-buried strip base yourself.

Strip foundation for a bathhouse

Often, a strip foundation is the best choice for building a wooden bathhouse. In addition to the reliability of the design, this option can also be considered from an aesthetic point of view - to play on the contrast of materials.

For the construction of a bathhouse, a shallow strip foundation is recommended - it is quite enough to support a structure that is not too heavy. If the soil is heaving and the freezing is deep (over 1.5 m), you will have to opt for a deep strip foundation.

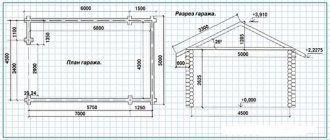

Preparing a working design for a wooden bath

The construction of a log bathhouse is a labor-intensive and responsible process that is carried out in stages. The initial stage is preparing the bathhouse project.

A typical project includes:

- choosing a suitable location for development;

- layout of the number of floors and interior spaces of the bathhouse;

- layout of the location of window and door openings;

- selection of heating, ventilation equipment and lighting devices;

- selection of construction and finishing materials;

- development of premises design;

- calculation of construction costs.

Finished projects are presented in the public domain, but to receive an individual sketch, you should contact the design office.

The most cost-effective type of foundation

Uneven areas with difficult terrain often cause inconvenience for builders. Which foundation to choose for a house if you are faced with this kind of problem?

Thanks to the columnar type of foundation, you will not only be able to build a house on a slope, hill or other uneven surface, but also save on materials. This foundation is considered the most cost-effective option.

But there is one “but” - it is not recommended to lay it in moving soil and where ground level differences reach two meters.

To correctly calculate the laying of a columnar foundation, you need to determine to what depth the soil freezes in winter. If all the calculations have been made, then construction can begin. Note that this type of foundation can be installed independently.

The structure itself consists of wooden piles, treated with an antiseptic and covered with a bitumen layer. Before immersing these parts in the ground, they must be wrapped in roofing felt.

The depth of the pits for the piles should be about two meters, and their bottom should be carefully covered with sand. How many piles need to be installed is calculated taking into account the size of the log house and its weight. These elements are buried around the perimeter of the house, that is, in the place where the walls of the future house will be located.

A wooden formwork is installed in each hole; it is shaped like a trapezoid, which helps to hold the structure in the ground rather than push it out.

Having completed the work of installing the formwork, a frame of reinforcement is lowered into it and everything is filled with cement mortar.

From above, cover the freshly poured structure with some material and wait for complete drying for at least one month.

Factors to consider when choosing

- When determining the depth, first of all, it is necessary to take into account the type of soil on the site. For this, a geotechnician is involved, who conducts a study of the site and makes a verdict, on the basis of which recommendations are made.

Depth of bookmarks.

- Shallow foundations can be laid on compact, stable soils. Porous, marshy and sandy soils, as well as quicksand, require deep embedding or slab pouring.

- The next important factor is the level of frost penetration into the soil. As a rule, in this case there is no need to conduct field studies; it is enough to use average data for the region. But in any case, it is recommended to lay strip and pile structures at a depth of more than 200 mm from the maximum freezing depth.

- The enemy of all buildings without exception is the so-called frost splash. As you know, when water freezes, it expands and can push even strong structures out of the ground. To minimize this effect, the posts and straps can be arranged in a trapezoidal shape, where the cone runs from bottom to top.

Types of strip foundations.

- Nearby groundwater can not only undermine the foundation, but also destroy the concrete monolith. Therefore, experts recommend waterproofing structures and using concrete that is resistant to constant exposure to moisture.

- With the exception of auger piles, all other types of foundations must be mature before construction begins. Ideally, the structure should winter or stand for at least 6 months. The point is that the foundation will naturally shrink and you should let it finish before you start building your log home. Otherwise, cracks and distortions will appear.

Mixed design option.

The video in this article gathers more information on the topic.

Shallow or non-buried foundation

This type of foundation is built on gravel, sand and other drainage materials and is suitable for undulating soils with high groundwater levels. In this case, part of the soil around the foundation is replaced with a cushion, and the foundation itself is built above the ground level or buried at a very small depth - 0.4-0.5 m. Can be used for log and wooden houses.

Foundation for a log house with your own hands

Before starting construction, first of all, you should make a verified calculation of the foundation for the log house, marking the construction site accordingly. It is extremely difficult to redo such a foundation later.

It is also necessary, regardless of the type of foundation, to waterproof the log house in several layers, and also treat the initial log of the log house with an antiseptic to protect the walls from moisture.

The amount of water in the concrete solution should not exceed 60%, and if the sand is wet, another 10% less. The components of the solution must be clean and free of any impurities. You can use any proportions, but take into account that there should be 2 times less sand than gravel.

During cold months, it is advisable to heat the water for the concrete solution to allow it to harden faster. During hot periods, only cold water should be used for this solution to avoid rapid cooling.

Tape type bases

If your site has sandy-stone soil, and the groundwater is still very deep, and you don’t know what kind of foundation is best to build on it, then the answer is simple - strip.

This type of foundation is quite common in the construction of log houses. The principle of work is similar to the previous one. But there is some difference, for example, pouring is carried out only along the perimeter of the future building.

You can transfer all the fertile soil removed when laying a trench to a flowerbed or garden.

The sand “cushion” laid at the bottom of the ditch must be well compacted. After this, brick material is placed on it, which is fastened together with cement mortar. It is imperative to check how level the structure is so that the foundation is not subsequently skewed.

Having brought the base to ground level, waterproofing material (roofing felt folded in two layers) is laid on it. Then the masonry continues according to the same scenario, only it is necessary to leave small ventilation holes in it.

That part of the foundation that will be visible above the ground, after completing the construction of the house, will need to be covered with some kind of cladding material (siding or lining).

Plinths of a log house (building)

Before laying the first crown of rounded logs, it is necessary to waterproof the foundation.

The basement plays a significant role in the operation of the building and is a continuation of the foundation. The basement part of the structure rises above the ground and the temperature in the house and the level of humidity depend on its quality. In small houses, the basement is often the ground part of the foundation, but its height is rarely more than 50 cm. The basement can reach 1.5 meters or more and becomes the lower basement floor of the building. In such a basement you can equip a basement for storing vegetables, a garage, and even make a heated room for various purposes.

To install the base, it is recommended to use high-quality materials that can withstand any weather conditions, including rain, snow, repeated freezing, ultraviolet rays, hail, etc. Therefore, brick, rubble concrete, stone and some other building materials are more often used. In appearance, the above-ground part of the base can be sinking, that is, located deeper than the outer part of the wall, protruding - protruding beyond the edge of the house or being flush with it.

During the construction of the basement, it is advisable to insulate it, for example, with modern perforated insulating panels, which perfectly ventilate the basement space and at the same time are a good heat-insulating material.

Return to contents

The best option

A good option when choosing a foundation for a wooden house is a very vague concept that depends on a large number of factors:

- But if we take the average indicators that the structure will be small, a basement is not needed in the house, and the soil is not too heaving, then in terms of price and speed of construction, columnar or pile construction is best.

- For self-arrangement, the easiest way is to make a shallow strip one, since it is simple in execution and you can make a basement, and a deeply buried one allows you to make a full-fledged basement.

- The use of a monolithic base is recommended only as a last resort, since it does not correspond well with the needs for wooden houses due to its excessive price and massiveness.