Glued laminated timber has found widespread use in the construction of economy-class housing and luxury houses. In addition to house construction, small batches of material are used to implement original projects for the creation of architectural miniatures, interior decoration and furniture manufacturing. For these purposes, rare wood is best suited; blanks of non-standard sizes and original profiles may be required. You can make a unique profiled beam with your own hands for the implementation of individual author’s projects in your own workshop or on rented equipment.

Before organizing your own production, you need to decide whether independent production will be justified. The motivation for making such a decision is often the desire to realize one’s own creative potential in the following areas of business activity:

- Production of exclusive furniture;

- Providing services in interior design of homes;

- Author's design of reception halls, restaurant interiors and art exhibitions;

- Business in the field of architectural miniatures.

A dream to finish the facade of a house or arrange a veranda according to your own design can motivate you to make your own laminated laminated timber.

Depending on the needs for material and available woodworking equipment, there are several ways to independently produce profiled timber. The implementation of such a project includes the main stages:

- Defining goals, quantity of products and estimating the project budget;

- Selection of material and organization of drying;

- Production of lamellas;

- Gluing;

- Profile recess.

Peculiarities

Currently, profiled timber is used literally everywhere. It is used to build both inexpensive and luxury homes, outbuildings and other structures of similar types. Many people use timber to make homemade eco-friendly furniture. All this indicates the relevance of the material under consideration and its relevance. But few users know that it is quite possible to make timber with your own hands.

The timber is made using special tools. Such work cannot be called too complex or inaccessible, which is why many people resort to them.

There are several most common reasons why users decide to make high-quality timber on their own.

- At the head of the “table” is the financial issue. In fact, in many cases, users can save a lot of money by making the timber themselves rather than buying it ready-made. But at the same time, we must not forget about the time factor - you will have to spend some time making a homemade product.

- Often people need timber that has dimensions that are far from standard. Such materials can be very difficult (or impossible) to find on sale. In such a situation, the solution to the problem can only be the independent production of such an environmentally friendly material with suitable dimensional parameters.

- The reason for making timber yourself may be the presence of a large number of leftovers, for example, edged boards, which are no longer profitable to put up for sale. From such components you can make high-quality timber and put it into use.

- If you really need powerful and strong load-bearing beams, then timber made from thick boards will be a good solution. The results are very good structures that do not crack, twist, rot or mold.

It should be taken into account that walls built from homemade profiled timber can be left without auxiliary finishing. Without paint, wallpaper and other materials, such bases look no less impressive and attractive.

There are several different ways in which users can make high-quality timber with their own hands. Each home master chooses the optimal technology for himself.

Bench made of wooden chairs

Necessary materials:

- four chairs;

- boards for sitting.

Manufacturing stages:

- remove the seats from all four chairs, saw off the front legs of two of them and remove the backs;

- if you want to remove old varnish or paint, apply a product to the surface that will dissolve the paint coating; the softened layer can be removed a little later with a spatula;

- drill holes for dowels in the racks; they will be required on the front and end sides;

- lubricate the dowels with glue and insert them into the drilled holes, connect the base of the bench with self-tapping screws for reliability and sand the surfaces of all parts;

- select boards or wooden slats of suitable size for the seat, which can be joined with wood glue;

- glue the resulting seat to the base, place heavy objects on top and leave to dry;

- Treat the finished product with stain; you can also paint it.

Photo source: www.postroiv.ru/2016/06/skamejka-svoimi-rukami/

Here are two more examples of how to make a bench out of chairs. The manufacturing process is not fundamentally different from the previous version, just a slightly different configuration.

But if you are interested in instructions on how to make a two-seater bench from chairs, visit the website of the author of this project using the link under the gallery.

Dining room chairs are usually attached with screws, wood dowels and glue, so a rubber mallet and a flexible handsaw are useful tools.

Although the glue on old chairs takes many years to dry, making disassembly easier, dowels are often very stubborn—be prepared for some to break.

Then you will need to drill a hole for the new dowel right in the place of the old dowel.

See below step-by-step photos on how to make a bench from chairs

Photo source: www.hometalk.com/4043763/bench-chair-set-diy-how-to

Or this example. Well, how can you throw away such beautiful chairs, even if they were made in the 50s of the last century.

While you may not need a ton of chairs, you can create a comfortable place to sit, as a small bench takes up less space than several chairs.

Instructions for the step-by-step assembly of a bench from chairs are on the website. Although the chairs are different, the essence of the work is basically the same.

A step-by-step master class can be viewed below.

Photo source www.instructables.com/id/Make-a-Settee-Bench-from-Two-Chairs/

Bench from the back of the bed

The headboard of the bed is an excellent source material for making a bench. You practically don’t have to do anything, just connect the necessary parts into the desired design.

In the photo instructions presented here, the entire process of making a bench from a headboard is shown very well, although there are some nuances that are worth paying attention to. For example, wood glue must be used not only in the holes, but also along all the edges of the boards

You can read all these details on the author’s website, the link to which is located under the gallery.

See step by step photos below.

Photo source www.addicted2decorating.com/diy-project-turning-a-headboard-and-footboard-into-a-bench.html

Bench from a chest of drawers

Transforming an old chest of drawers into a beautiful garden bench is definitely worth the effort you put into it. This tutorial gives you the opportunity to use your old furniture and transform it into something truly stunning for your garden.

See the step-by-step master class below

Photo source www.commatose.ca/2013/09/diy-from-old-dresser-to-pretty-vintage-bench.html

Profiled timber

What are the benefits of making it yourself?

Note. Of course, it will take a lot of time to process it yourself, but, for example, budding - profiled timber is offered without intermediaries, and you save a lot of time.

But don't forget that all these savings come at a cost!

List of reasons for self-production:

- Of course, the most important reason is the price - if you make such products yourself, the savings will be up to 5,000 rubles per cubic meter of material.

- You can choose the shape of the wooden profile yourself, taking into account that it is not blown through. Plus, you will do it according to your needs.

- In this case, the insulation will be hidden in the grooves, so the walls will not need additional finishing.

- The crowns will fit most accurately, therefore, the fit will be tighter.

Where should you build a house?

“The area where the house is installed should not be temporary”

The task of choosing a place for a children's house is difficult. You need to manage to place it so that it is hidden in the shade of the trees and at the same time remains in plain sight. The child should not disappear from your field of vision, so look for a well-warmed, draft-free clearing in front of the house, framed by treetops.

The crown of the tree will protect children from direct sunlight

The installation area of the house should not be temporary. If this, of course, is not a mobile option, then the building must be erected in such a way that it does not have to be demolished in the near future. Do not plan to build it in areas where there may be garden paths, future wells, or garage access. Calculate the situation for years to come and place the house under those trees that you won’t have to uproot in the coming fall.

Stationary playhouse in the shade of trees

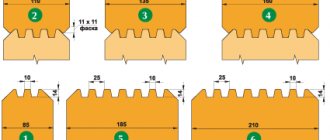

Profile types

When choosing the type of profile for yourself, you first need to take into account your professionalism and what kind of cutters you have for profiling the timber. It's best to stick with the simplest options so that you don't need a lot of different tools and don't have to do the same amount of calculations. To determine this, you can use GOST 9330-76, with which you can make all the calculations most correctly.

Basically, home equipment for profiled timber is quite simple and craftsmen prefer such types of profiling as:

- through a block;

- through a triangle.

It should not be forgotten that GOST always indicates the depth and width of the groove in accordance with the cross-section of the timber being processed.

The main advantages of metal siding under timber compared to other types of material

In addition to metal, other types of siding are also available :

- Vinyl;

- Wood;

- Cement;

- Acrylic.

The most common types of siding considered are metal and vinyl siding..

All the advantages of metal siding under the beam lie in the specific features of the material.

Metal siding is divided into the following types:

- Under the tree;

- Ship plank;

- Under a stone;

- Under the brick;

- Under a log.

Metal compares favorably with other types of siding material in the following ways::

- Plasticity . A sharp blow or pressure that breaks vinyl siding will cause a dent, but not a fracture;

- The ability to change shape without destruction , lack of material memory. This refers to the ability of metal parts to undergo some shape correction without returning to their previous state. They can be easily bent to the required configuration, while the vinyl elements will be under stress or break;

- Much lower coefficient of thermal expansion than vinyl panels;

- Does not emit odorous substances , as happens with vinyl siding in the first months of operation;

- Does not break under loads during frosts.

Metal siding under l beam

Description of methods for self-production of profiled timber

Depending on the experience and technical equipment of the home workshop, several options can be distinguished according to their level of complexity.

Making timber from boards

If there is practically no woodworking equipment available, then the easiest way out would be to make timber from boards.

- For these purposes, the “fifty board” is best suited, having suitable dimensions in length and width.

- First of all, you need to build a slipway from available materials, on which all the work will be performed;

- Then special templates are made according to which the boards will be laid, so as not to measure the dimensions of the tenon and groove of the future beam every time and so that all products are the same;

- To produce one beam, you will need three boards, which are stacked on top of each other in length, with the middle board being laid with an offset specified according to the template. As a result of this overlap of boards, a profile is formed in the cross section, where a tenon is formed on one side and a groove on the opposite side;

- After the boards are laid properly, all that remains is to securely fasten them together. The simplest thing is to nail them together on both sides with ordinary nails; for a more reliable connection, you can use metal screws, but in this case you can’t do without a screwdriver;

- Also, to give strength, you can glue the timber with your own hands, for which, before laying the boards on top of each other, they are thoroughly coated with glue. In any case, after this they must be fastened with nails or self-tapping screws, since at home it is very difficult to achieve perfectly strong bonding of such surfaces. The result will be a simplified version of laminated veneer lumber.

A simple way to modify a rectangular beam

In this case, profiling timber with your own hands requires at least a hand-held circular saw, but otherwise it will not cause any difficulties even for a novice carpenter.

- Here you will also need to construct a stable slipway or workbench for the entire length of the workpiece being processed;

- In this case, the main goal will be to cut identical V-shaped grooves on opposite sides of the rectangular workpiece;

- To accurately mark future grooves, it is necessary to make a template from a block with the width of the future groove, which will be installed along the entire length of the beam exactly in the center. Using the template, two parallel lines are drawn along which the cuts will be made;

- Along the control lines, using a hand-held circular saw set at an angle of 45?, an incision is made along the entire length from opposite sides to a given depth. The result should be a smooth V-shaped groove.

Now, if you place two beams on top of each other with the sides where the grooves are cut, then along the entire length a diamond-shaped cavity with a square cross-section will be formed, into which a standard 50×50 beam should be laid, the dimensions of which should be used to make the grooves.

As a result of these simple steps, you can very quickly turn a rectangular wooden blank into a profiled beam. These are the two simplest and most accessible manufacturing methods.

But in any case, before doing anything, it would be a good idea to familiarize yourself with GOST 9330-76, which is called “Basic connections of parts made of wood and wood-based materials.” This document contains all the necessary information to correctly calculate the profile depending on the size of the workpiece.

Profile cutting using a hand router

In this case, the workpiece will be a four-edged rectangular edged beam, and the main working tool will be a powerful hand router.

By the way, you should again calculate how cost-effective this is, because the price of a good tool cannot be small either, and using a low-power and cheap one, you are unlikely to achieve the desired quality of processing, and the time costs will be much higher.

Step-by-step instructions in this case will look like this:

- We build a solid base in the form of a slipway or workbench for the entire length of the workpieces being processed. The support must be stable without play or wobble, and also allow the workpiece to be firmly secured;

- In addition to the router itself, you will also need a set of special milling attachments, the shape and size of which will depend on the complexity of the profile that needs to be selected. With proper experience and high-quality material, you can obtain products as close as possible to industrial designs;

- When working with a milling cutter, it is important to maintain the accuracy of guiding the tool along the intended path. It is desirable that it moves smoothly along stably installed guides, without jerking or lateral play. The quality of the pairing of elements, and, accordingly, such operational parameters of the future home as thermal insulation and wind protection depend on the accuracy of the work;

Important! If you use a high-speed router with sharp cutters, you can do without additional grinding.

The use of this technology allows, in everyday conditions, to cut profiles of varying complexity on timber, which are in no way inferior to industrial designs. There are other profiling methods, but they require more complex self-made technical equipment and equipment.

In the future, regardless of what type of timber will be used for construction, it is important to adhere to the technology, which requires the use of dowels (dowels) to reliably connect the crowns to each other.

Installation work

Imitation timber can be used to cover walls made of different materials (concrete, brick, logs, etc.). When covering the walls with imitation timber, the impression is created that the building was built from natural timber. Installation work is easy. Each profile is equipped with a tongue and groove , which allows you to fit the boards tightly to each other. But it should be noted that the imitation timber boards are attached exclusively horizontally.

Imitation timber is a universal material. It goes with glued or profiled timber. Very often you can find the premises of houses and baths lined from the inside with imitation timber. For exterior finishing it is used in buildings made of concrete, frames and foam blocks.

Installation features at the installation stage of the sheathing:

- Imitation timber is attached to the walls using lathing. It is made in the form of bars located along the entire perimeter of the wall at a distance of 50 centimeters.

- Due to the fact that the imitation timber is fixed strictly horizontally, the bars are fastened in a vertical position, secured every 40 centimeters with self-tapping screws.

- It is necessary to lay a layer of waterproofing material under the sheathing .

- To improve the thermal insulation properties, it is recommended to lay insulation made from natural materials (mineral wool, ecowool, etc.) between the sheathing.

- Another layer of waterproofing is fixed on top of the sheathing.

After the preparatory work, you can begin finishing with imitation timber. The installation of a row of boards begins from the bottom, since the casting board is attached below.

The imitation timber is laid with the ridge up . Self-tapping screws are screwed into the tenon of the board to secure it (the head of the screw is recessed by about 1-2 millimeters). When laying the next row, the board is installed with a groove in the tenon and tightly adjusted to one another (a self-tapping screw is driven into the tenon at an angle of 50°). The last row, like the first, is also screwed on with self-tapping screws. The places where the screws were screwed in can be sealed with dowels and sanded. After completing the installation work, you can proceed to puttying and painting the timber.

Making dowels

This type of fastener consists of wooden cylindrical elements of a certain diameter, which are driven into pre-drilled holes in beams lying on top of each other, thus additionally fastening them together.

Making dowels for timber with your own hands is not difficult and anyone can do it, however, any business has its own subtleties that you need to know.

- According to the technology, dowels should be made from harder wood species;

- Their diameter should be such that they can be driven into the technological holes with a slight tension. If the fastener is loose in the hole, it is practically useless, and if it is too tight or protrudes above the surface, it can cause problems with settling of the house.

- You can split birch logs of the required length into many square pieces, and then manually trim them to a round shape of the required diameter;

- If you have a wood lathe available, then these elements can be quickly turned;

- Cuttings for shovels and other garden tools that have become unusable can be used as dowels. In this case, you just need to cut them into pieces of the required length.

Advice! You can also use metal pipe scraps of suitable diameter as dowels.

Imitation as a decorative finishing option

Quite often, to create a certain style or interior atmosphere in the interior of a house, imitation timber is used with your own hands. This approach makes it possible to achieve an almost complete visual analogy with real timber and has a number of advantages:

Exterior finish with imitation timber

- Imitation can be performed on a surface made of any material;

- Wood consumption is significantly reduced, and, accordingly, financial costs and time for implementation;

- Such finishing can be done after the construction of the house at any time, both inside and outside.

It is quite easy to make a set of decorative elements for such an imitation at home. To do this, you will need a pre-calculated volume of boards with a thickness of at least 50 mm, as well as an electric plane and a sander.

The manufacturing process will be as follows:

- Using a plane, you need to smoothly round the edges of one of the sides of the board, giving it the rounded shape that a beam has;

- Then, using a sander, you should sand everything thoroughly, removing all the blemishes and marks from the plane.

A board processed in this way can very realistically imitate not only timber, beams and ceiling beams. To achieve complete similarity, in the corners where the planes of the walls meet, the boards must be shifted relative to each other by half their width, simulating cutting the corner of a log house.

If desired, such a “timber” can be tinted to resemble valuable wood species, further enhancing the imitation effect.

Reworking a rectangular beam

There is a method that will make it easy to profile a finished rectangular beam. Let's consider what stages it consists of.

In this case, it will be necessary to build a high-quality structure, in the form of a strong, non-shaky slipway or workbench. The length of this structure must correspond to the length of the raw material.

In the work under consideration, the main goal of the master will be to correctly cut the same type of V-shaped grooves. They should be located on opposite sides of the wooden piece.

- To accurately mark the areas with future grooves, you will need to prepare a template from a block, the width of which will correspond to the size of the future groove. This template will need to be installed along the entire length of the main beam, exactly in the center.

- In accordance with the indicators of the template, the master will need to cut 2 parallel lines along which cuts will subsequently be made.

- Along the marked lines, using a circular saw set at an angle of 45 degrees, you will need to make a neat cut along the entire length of the base on opposite sides, to a given depth level. If you cut everything correctly, you will end up with a perfectly straight V-shaped groove.

How to clean a surface from dried glue?

It makes sense to remove excess glue from the surface of the wood either while it is completely fresh or when it has completely hardened. If you rush to sand a damp area of wood, you will most likely end up with an even greater aesthetic defect when the fibers deformed by sanding dry. The hardened glue is cleaned by hand sanding (along the fibers) or cut with a chisel.

Before applying decorative finishing, check to see if there are any stained areas on the product. Otherwise, traces of dried glue will appear under the finishing compound. To more effectively detect defects, wipe the surface of the wood with a cloth soaked in white spirit.

Useful tips and tricks

If you decide to build high-quality timber with your own hands, then you should take on board some useful tips and recommendations that will allow you to carry out all the work without errors and shortcomings.

Before making a beam using a milling machine, the master must take into account that a high-speed tool with very sharp cutters will avoid the further process of grinding a homemade beam.

- The most convenient way to cut a log to make timber is using a chainsaw equipped with a special frame. Such a device will allow you to correctly cut the workpiece, refusing the services of a sawmill.

- Before starting a chainsaw to cut workpieces, the master must make sure that the tool contains chains intended for longitudinal cutting of wood (the same type of cutting is suitable for dissolving a log - this is the easiest way to dissolve it into boards and slats). Only in this case will the sawing process be simple, fast and of high quality.

- When working with various tools for cutting or sawing wood, it is very important to follow safety precautions. The user must act as carefully, carefully and strictly as possible according to technology. In such work, excessive haste and anxiety can lead to very bad consequences.

- It is most convenient to make timber using high-quality and properly working tools. Excellent quality is demonstrated by branded devices, for example, devices from Makita, Bosch, Dexter. These products are very convenient and effective to use.

- When making timber using a router, we must not forget that a special attachment for such work should be ideal for it. Often craftsmen are faced with the fact that the equipment they just purchased for a router does not fit their tool. Nozzles must be selected in accordance with the specific model of the machine.

- It is strongly recommended to make timber only from high-quality boards or logs. Materials must not show signs of rot, mold or other serious defects. From such raw materials it will not be possible to obtain truly reliable and strong bars that will be used for further construction work.

When making homemade laminated veneer lumber, the prepared wooden layers (boards) should be sewn together using a special glue for woodworking. The composition must be designed for indoor use. It is advisable to find an environmentally friendly adhesive solution.

Making timber yourself is not the fastest process. If a master is afraid to get involved with such work or does not want to waste time, then it makes sense to think about buying ready-made bars. This is the easiest way out.

Foam timber

Polyurethane foam has a number of advantages. Thanks to its low thermal conductivity, the house retains heat longer . It occupies all the space inside the frame. Thanks to this, cold air practically does not penetrate into the premises, that is, there are practically no cold bridges.

But in order to properly use insulated timber during construction, you need to organize good internal ventilation of the walls, because it has low vapor permeability. For this reason, glued material can quickly lose its properties.

Using a Circular Saw

The second way to make a connection with your own hands is to use available tools. For example, using a hand-held circular saw. Such a tool costs 2-5 thousand rubles, depending on the manufacturer. The main thing is that it can be cut at a back angle and make a cut with a depth of at least 65 mm.

The advantages of this option:

- Ability to control the accuracy of the cutting depth.

- Easy cutting of a straight and smooth groove.

- Disadvantages of working with a circular saw:

- The cutting depth may not be sufficient.

- It is impossible to clean the groove with this tool.

- Each time you need to readjust the cutting depth.

- Low operating speed.

- Best used for cutting a triangular groove.

Finishing the swing

We made the basis for the swing in the previous stages. Now let's complete the design. We assemble a bench with a seat 130x50 cm and a backrest about 30-35 cm high. You can change the dimensions at your discretion. To fasten the seat, it is convenient to use chains or ropes - we hang the bench from the crossbar using them and you’re done.

It is more convenient to attach the seat at this stage, because if installed earlier, the bench will interfere with the installation of other structural elements.

With this our playground is ready. All that remains is to paint the elements of the complex at your discretion.

PlaygroundPlaygroundSwingSwingSwingSwingSwing

Follow the instructions, check the photos and everything will work out.

Decor for the playgroundDecoration for the playgroundDecoration for the playgroundDecoration for the playgroundDecoration for the playground at the dacha

Good luck!

A few important notes

1. Properly manufactured laminated veneer lumber is superior in its structural, mechanical and other parameters to solid timber made from the same wood and with the same dimensions.

2. Modern adhesive compositions for wood, if used correctly, make it possible to obtain an adhesive joint that is stronger than the wood itself. I once wanted to tear off the glued block to the tabletop. The end result was that the block itself split along its length, but at the place of the adhesive connection it did not lag behind one iota.

3. In many cases (including at home in a city apartment), it is possible to make laminated veneer lumber without the use of special expensive tools, if you use purchased parts (floor slats, boards) for its production.

Before moving directly to the manufacturing technology of laminated veneer lumber, let's consider some definitions.

The figure below shows the main parts of laminated veneer lumber and how to connect them. In fact, there are many more connection methods, but the figure shows the easiest ones to make at home. An important condition for timber is the relative position of the annual rings; the lamellas must be glued together in such a way that their relative positions in the manufactured timber are in different directions for adjacent lamellas. In this case, the timber will be least susceptible to warping.

Professional tricks for flawless gluing

A tape clamp is an excellent assistant in matters of miter gluing. This clamp evenly distributes pressure on all corner joints, ensuring perfect gluing without deformation of corners or other defects. The absence of a tape clamp is not a reason to give up perfect gluing of miter joints. When gluing large surfaces at home, it is advisable to use a toothed spreader. If desired, it will not be difficult to make it yourself, for example, from an unnecessary plastic card. Use masking tape to protect the surface from squeezed out adhesive. Plastic covers used as gaskets will prevent unpleasant surprises in the form of dents in the fixation areas. Tape and quick-release clamp will be your assistant when gluing large projects at home.

Technology for making laminated veneer lumber at home

Necessary tools (the list of tools, of course, depends on what kind of timber you want to make):

- Hacksaw or two-handed saw

- Clamps

- Planing tools (plane, electric plane, circular saw)

- Milling machine (circular saw with interchangeable cutters), desirable, but not required

- Belt sander, preferable, but not necessary

- Paint brushes, hair brushes, synthetic

- Marking tools (tape measure, steel meter ruler, square, etc.).

Necessary materials:

- Lumber (boards, beams, slats)

- Wood glue or universal

- Solvent 646 (acetone) - for degreasing.

The manufacturing technology of laminated veneer lumber will be discussed using the example of the production of laminated veneer lumber for the manufacture of window frames at home.

Requirements for source material. The lumber used must be dry and healthy. In this case, I used pine and larch timber (100 by 100 mm), which was stored under a canopy, i.e. natural drying.

- We cut the pieces to the required length, with an allowance of 5 cm on each side.

- We select three blanks (lamellas) to make one beam. What is important? Since at the first stage only those edges (sides) of the lamellas that are to be glued and in which the groove will be selected are planed and jointed, it is necessary to determine in advance the relative position of the lamellas in such a way that the pattern of the annual rings is multidirectional. To connect the lamellas I used a dowel connection. After sharpening the glued sides, select a groove for the outer lamellas on one side and two grooves for the middle lamella (on both sides). Based on the dimensions of the grooves on the circular saw, we make blanks for the keys.

- After manufacturing all the parts of the future block, for preliminary assessment and adjustment, we assemble the timber “dry”, without glue.

- Preparing the surfaces to be bonded is an important operation. Depending on the glue used, the order of preparatory steps may vary (see instructions on the glue packaging). But the basic operations, as a rule, are still the same. Usually you need:

- Sand the mating surfaces with sandpaper or, more conveniently, with a grinder.

- Dust the surface with a brush or vacuum cleaner.

- Degrease (I used solvent 646 and a brush), let dry.

- All manufactured parts (joints) should be treated with fire protection, twice with intermediate drying.

After completing these operations, you can begin gluing the timber.

Gluing timber

Gluing timber is the most critical process. It is especially important to choose the right glue here. That is, depending on where (outdoors, indoors) under what conditions (humidity, temperature) the future product will be used, and also depending on the requirements for the appearance of the adhesive joint (color of the glue), it is necessary to select the appropriate adhesive. Now on the market there are practically no problems with the choice of glue.

The gluing technology depends on the chosen adhesive and is usually also indicated on the packaging.

As you can see in the photo, the glue is yellow in color (the color issue was not important for me), the glue is intended for use in outdoor work, on wood, the pattern of annual rings on the timber is multidirectional. Defects and chips along the edges of the timber will be removed during finishing of the timber. After gluing, I used clamps to compress and secure the parts to be glued.

Drying of the adhesive joint must be carried out in accordance with the recommendations of the adhesive manufacturer. As a rule, the following conditions must be met:

- Direct exposure of the product to the sun and water should be avoided (for example, I dried it under a canopy)

- The parts to be joined must be pressed firmly along the plane being glued

- Drying times must be maintained in accordance with the manufacturer's recommendations.

- I will mention one more non-standard (optional) operation. Taking into account the fact that laminated veneer lumber was created for the production of window blocks, and the force impacts when performing caulk work when installing window blocks are not small. I decided to further strengthen the structure of the beam by installing it on dowels. I used homemade dowels made of oak, with a diameter of 22 mm, using a hole in the lower part of the dowel for a conical wedge (the dowel fits into the spacer on the wedge - when driven in). First I drilled the holes. The dowels and conical wedge were placed on glue. I hammered the dowels in with a sledgehammer.

After thoroughly drying the products, we finally process the laminated timber. In particular, we plan timber. When planing, you need to maintain the same dimensions for all beams; the clean dimensions of the beam (in cross-section) are 90 by 275 mm. Next, we treat the glued timber on all sides with fire protection, twice.

The finished glued timber is shown in the photo below (end view and side view).

Varieties

The class of imitation timber largely affects the cost of this type of lumber. The product range includes 3 main categories, each of which must meet certain standards.

"Extra"

High quality material, virtually free from defects. Imitation timber of the “Extra” grade is suitable for finishing the interior and facade of buildings, has an aesthetic appearance, and can also be used to form a rafter system and cover cornices. Among the acceptable defects, the standard indicates the presence of small cracks in the end part, resin pockets with a diameter of up to 2 mm each.

The middle class of false timber is characterized by the presence of acceptable defects, including knots, on an area of no more than 10% of the surface. This material is most often used in the outer cladding of buildings.

Imitation timber of this class is made from inexpensive raw materials, abundantly covered with knots and resin pockets. The presence of traces of rot in the form of black spots and stripes is acceptable. The volume of permissible defects can reach 70% of the entire board area. This greatly influences her choice. But if the affected areas are not too densely located, such false beams are suitable for exterior cladding of a house or finishing functional areas inside it.

Comment

In order not to get hung up on the word BRUS, we need to add that this technology is quite applicable in the manufacture of other parts. For example, to make a tabletop for a computer desk, I used a purchased floorboard, from which I glued the shield.

Tip: When making small workpieces (for furniture repair) or small structures (wall shelves, drawers), when making grooves or quarters is not convenient, or you do not have such an opportunity, gluing is often done using a smooth fugue. In this case, for more reliable gluing and fixation, a set of center markers will be very helpful. I advise you to buy it. You can buy markers in construction stores; they cost pennies, but they help remarkably. Large markers, in the photo on the right, homemade, turned on a lathe, are used for larger jobs.

How tight should I tighten the clamps?

It is important to understand that the strength of the gluing does not depend on the amount of pressing force, but on the quality of surface treatment and their accuracy of fit. There is no need to tighten the clamps too much. A small amount of glue showing through is a sure sign that sufficient clamping pressure has been created.

The use of clamps is not always advisable. If we are talking about gluing small crafts, for example, wooden boxes and boxes for tightening, you can use adhesive tape or masking tape, but, again, provided that the joints are well fitted.

When will independent production be justified?

Depending on the situation, each developer will have his own motivation for action:

- First of all, this is a financial issue. Indeed, in some cases you can save significantly, but here you still need to take into account the time factor;

- Quite often there is a need for non-standard dimensions of timber, which cannot be found from manufacturers, and then this is practically the only way out of the situation;

- When there is already a sufficient supply of edged boards and timber, but it is unprofitable to sell it, and profiled material is needed for construction;

- If there is a need for powerful load-bearing beams, and in this case, you can make laminated veneer lumber with your own hands from thick boards. This design is not subject to torsion and cracking, and can also withstand higher loads than a similar solid wood beam.

Which breed is best for exterior cladding?

So, which wood is best to choose for the outer cladding of a frame structure? The best option would be larch, which is not afraid of water, is easy to process and is not subject to severe deformation when wet and dry.

Spruce will be cheaper, but such wood usually has a lot of knots, which then turn into cracks.

Hardwoods, such as cedar, look gorgeous. But such wood is difficult to process, and in addition, it often cracks from nails. And in terms of cost, such cladding cannot be called economical.

How to go around windows and doorways with siding

The technology for designing window and door openings is almost the same, only ebb sills are additionally installed on the windows. For the installation of slopes, platbands, J-planks or, for large depths, a set of short pieces of panel are used .

To install all the elements, a sheathing of wooden or (better) galvanized metal strips is pre-installed. Installation of extensions is carried out based on the installation depth of the window or door.

For blocks installed in the same plane as the panels, platbands are used . In other cases, a J-profile or pieces of panels cut to length are used. To install, first a finishing strip is attached around the perimeter of the box, and the corner joint is formed with a regular corner.

Installation of window openings

Installation of finishing strips

The finishing strip completes the paneling, covering the top edge of the panel. To install, the last panel is cut to the required width and the edge is tucked under the curl of the finishing strip.

The presence of such an element protects the canvas from rainwater entering from above . Installation of the finishing strip is carried out simultaneously with the installation of the top panel.

IMPORTANT!

All self-tapping screws are loosely tightened so that the parts can move with temperature changes in size. To avoid corrosion, self-tapping screws must have a protective coating (galvanized) , with a head diameter of at least 1 cm.

Installation of finishing strips

Equipment

Metal siding requires additional elements to design corners, slopes of window or door openings and other necessary details.

Without them, the cladding will look sloppy, all connections will look makeshift and unattractive . Such elements are called additions; they are produced together with the main panels, finished with the same compositions, which makes them absolutely corresponding design details.

The siding package includes:

- Start and finish bar;

- H-profile for connection along the length;

- External and internal corner strips;

- Soffits;

- Platbands, J-platbands;

- Moldings;

- Window slopes, near-window profiles.

ATTENTION!

Each manufacturer strives to present the finishing set as fully as possible, so in some cases other types of additions may be present.

Equipment

Popular manufacturing companies

There are many siding manufacturers in the world.

The most famous manufacturers include:

- Mitten;

- Variform;

- Elixir;

- Vytes;

- Gentek;

- Kaycan;

- Foundry and many others.

From domestic:

- Dock;

- Grand Line.

The list of manufacturers can be continued for a long time, but there is little point in this, since all products on today’s market are of high quality, since they must meet certification requirements.

Little-known companies that are forced to save on production are of lower quality . It is better not to purchase such products, since with a very long service life of the cladding (50 years or more), the lack of a quality guarantee is not attractive.

One of the manufacturing companies

Installation of vertical strips - corners and H-shaped connector

Corner strips have two types of design - complex and ordinary. Complex corner profiles have special recesses into which the ends of the panels are inserted.

They are installed strictly vertically along a plumb line, fastenings with self-tapping screws are made in increments of 0.2-0.3 m . Installation of complex corner profiles is carried out after installation of the starting strip.

Simple corners are installed after installing the panels. It is much easier to work with them, since they simply cover the joint of the planes. Such corners are fastened with self-tapping screws or rivets. Experts recommend that everyone who independently installs siding on their home use this type of corner .

The joint of the panels along the length can be made with a simple overlap, but the connection with an H-profile, which has recesses on opposite sides for installing the ends of the panels into them, looks more aesthetically pleasing. The H-profile allows you to design the connection more accurately, on one vertical line, which improves the appearance of the house.

It is also installed immediately after installing the starting strip; the vertical is checked with a plumb line.

Installation of vertical strips - corners and H-shaped connector