High-quality natural wood is extremely in demand in construction. It has a lot of positive characteristics and many advantages. Modern technologies make it possible to process wood in different ways to maximize its performance. In this case, all kinds of safe compounds are used. Wood that has undergone this treatment - impregnation - is widely used in everyday life and industry.

Impregnated boards are successfully used for landscaping the area around the house Source nasha-besedka.ru

Impregnated wood - what is it?

The impregnation procedure involves impregnating wood with compounds specially created to protect it from rotting, mold, and various insects. This method can significantly extend the life of wooden products. In addition, they will look presentable for many years.

Even with high-quality drying of wood, harmful fungus may remain inside it. As a result of impregnation, all residue that negatively affects the structure of the tree is completely destroyed.

Important! The impregnation procedure does not protect against external mechanical damage; the impregnated board should be protected from strong impacts.

Most furniture manufacturers use paint and varnish coatings to preserve the appearance of their products for a long time. But the applied layer wears off after a while, so it needs to be renewed periodically. Impregnation reaches greater depth in the structure of the tree, so the level of protection increases repeatedly.

The main advantage of the wood impregnation procedure is the use of safe compounds that are completely harmless to the human body, animals, and the natural environment. In addition, during operation, impregnated wood does not emit toxins or other harmful substances into the atmosphere.

Attention! After undergoing the impregnation process, the wood no longer requires re-treatment: the resulting impregnation will be sufficient for its entire service life.

Thanks to impregnation, the service life of decking boards can be extended to 60 years Source stroy-podskazka.ru

Is there any harm from impregnation?

Impregnation involves saturating wood with a special composition (Wolmanit CX-8, Tanaligh E 3494 and some others). As a result, rotting, mold, and other types of decomposition in environmental conditions are prevented. To treat natural wood, a special water-soluble preservative based on malachite and boric acid is most often used.

Timber treated with a compound to prevent rotting

Due to its composition, the impregnating solution is non-toxic and does not emit volatile substances. If previously chromium and arsenic compounds were used to impregnate wood, modern compounds are considered environmentally friendly and harmless to humans, animals, and the environment. That is why impregnated wood is widely used for cultivating grapes, and in Scandinavian countries it comes into contact with soil and water everywhere. After impregnation, the wood does not stain the skin or smell. Impregnations using this technology have all the necessary certificates and have been tested regarding their effect on human health.

Materials for processing

Building materials, as well as products made from them, which are often exposed to harmful factors, should be impregnated:

- blanks for the production of outdoor furniture;

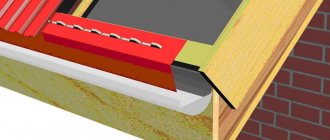

- flooring, balcony and terrace boards;

- material used in the construction of canopies, attics, fences, gazebos.

Impregnated lumber is extremely popular in construction because it has a long service life.

A fence made of impregnated boards looks original and does not require periodic updating Source facebook.com

Manufacturers' offers

There are Russian and foreign impregnation products on sale. The most popular brands are “Tex”, “Senezh”, “Healthy Home”, “Olympus”, “Optimist”, which are produced in Russia. Among the foreign compositions in demand:

- Belinka;

- Pinotex;

- Tikkurilla;

- Dufa;

- Maxima;

- Alpina.

Acrylic impregnation for wood Maxima

Wood processing can be done to order; this service is practiced by many medium and large logging companies. The cost of a cubic meter of impregnated wood is 18–30 thousand rubles or more, depending on the type of wood. The high cost is due to serious benefits for the user, because the service life of buildings and structures will increase significantly.

Types of compositions

All impregnates used today are divided into several subgroups. This classification is carried out based on the characteristics of the action of the funds and their components.

For deep protection

Most of the compositions were originally created for thoroughly impregnating wood. They penetrate deep into the workpieces, fill the pores, which guarantees reliable protection for a long time. Such solutions must certainly be environmentally friendly and not contain harmful ingredients at all. Then the impregnated lumber will also be safe for humans.

Weatherproof

The compositions increase the strength of the tree, which increases its resistance to external adverse factors. After drying, the treated material is not afraid of:

- precipitation in the form of rain, snow;

- temperature fluctuations;

- high humidity;

- ultraviolet;

- long heating.

The listed natural phenomena have a detrimental effect on untreated wood. A high-quality impregnated board can withstand this type of impact without consequences: it does not crack and retains its volume.

The use of stabilizing compounds helps protect wood from the negative effects of the external environment Source woodmart.org

Laminated panels for wall decoration

If it is necessary to decorate walls, it is usually customary to consider, first of all, either the option of painting or wallpapering, or covering with materials specially created for this purpose - PVC panels, MDF or clapboard. Each of these coatings has pros and cons. However, using laminate is often a better solution.

Benefits of use

This material has the following characteristics, the combination of which gives it an advantage over other methods of cladding wall surfaces:

- the simplicity of the installation technology allows you to install the laminate on the wall yourself;

- is an environmentally friendly material;

- high wear resistance guarantees preservation of operational properties and decorative qualities for several decades;

- has antistatic properties and attracts little dust;

- easy to clean with any cleaning products;

- It is distinguished by a wide variety of colors, patterns and surface textures, making it possible to create a unique apartment design.

Flaws

This coating has few disadvantages:

- intolerance to high humidity, which causes swelling of the panels, which often leads to the appearance of cracks on the outer surface;

- susceptibility to temperature fluctuations, which sometimes causes delamination and deformation of the material;

- Laying laminate flooring will cost more than wallpapering, whitewashing or painting a wall.

Where you can’t cover walls with laminated panels

The sensitivity of this material to water and temperature makes it unsuitable for wall coverings where there is high humidity or where water splashes onto the wall. This category includes, for example, bathrooms and kitchens. The best applications for this coating are bedrooms, halls, hallways and corridors.

But even here it is recommended to be careful and not sheathe walls near heating radiators

Impregnation methods

Impregnated wood is when it is treated with one of two existing methods: deep or surface. Most often, preference is given to the first option: the material is processed in most of it or in its entire volume.

Deep

In practice, thorough impregnation of wood is carried out in the following ways:

- Dipping. It’s not difficult to do; it can be used at home on a private construction site. This procedure does not require special equipment; just a tank filled with the appropriate liquid will be enough. Wood immersed in the solution intensively absorbs impregnates. The level of penetration of the latter is determined by the period of exposure of the workpiece in the liquid. It can last from several hours to a whole week.

- Under pressure. Requires expensive industrial equipment: these are special installations, autoclave conditions are automatically created inside them. As a result, the impregnation is quickly and deeply absorbed by the wood. Only those lumber whose moisture content is less than 30% are subject to this procedure.

- Diffusion. Sequence of actions: stacks of wood are carefully sprinkled with a mixture of a special preparation with sand (ratio 1:5), then wrapped in polyethylene. Soaking lasts about ten days. This method allows you to process the material entirely.

Important! Diffusion impregnation is quite effective, but it is rarely used. Wood impregnated by this method is expensive and is often used to create expensive structures.

Impregnation of wood under pressure is carried out only with the help of industrial equipment Source proffidom.ru

Surface

It is considered the simplest, yet ineffective option for protecting a tree. It is used often, mostly on the recommendation of designers.

Types of shallow processing:

- Coloring. It is performed using a brush or roller on horizontally located material. In this position, the solutions penetrate 3-5 mm deep into the material. To obtain the best effect, the mounted elements should be painted several times.

- Spraying. Used only for solid (flat) floors, decking, facades. This method is characterized by low efficiency, penetration is about 2 mm. It is often used to treat hard-to-reach areas of structures. Spray coating of small products is unprofitable due to the significant consumption of impregnate.

- Rubbing. Suitable for rough (rough) wood. It is difficult to paint it in other ways. Using a thick swab, the solution is thoroughly rubbed into the wooden surface.

Impregnated means protected. If desired, even at home it is possible to extend the service life of existing wooden structures. To do this, you need to purchase a suitable product and implement one of the processing options.

Surface treatment of wood is considered ineffective, but it can be organized at home Source proffidom.ru

Details

Purposes of impregnation

It is the fungus that causes wood to rot. Spores of various types of fungus are almost always present on the tree, and they remain passive until conditions are suitable for development. The task of impregnation was to destroy such fungi and create such conditions that there would simply be no re-infection! Yes, everything is exactly as one of the satirists said: “Cut off all the bushes at the roots: pests will appear, but there is nothing to eat!”

We even decided to conduct an experiment - we took a piece of timber that was cut from a thin log and placed it in a warm and humid place. Already on the third day, blue discoloration appeared on the tree, and three weeks later the fungus was already actively growing and covering the entire sapwood part of the wood. After this, the fungus stopped a little - it reached the heartwood, which was dead. Since there was no nutrient medium in that place, the cellular connections were broken and the fungus stopped completely. As can be seen from the experiment, the sapwood part of the tree needs protection most of all, since it provides an excellent breeding ground for fungi.

Impregnation depth

Although impregnation is a simple process, it is quite responsible and requires appropriate equipment and the implementation of each link in the process chain. The goal of the procedure is to impregnate 95% of the sapwood part and 0.2 to 0.5 cm of the core with a preservative. It turns out that the larger the wood core, the smaller the impregnation depth.

The phenomenon of heartwood is called natural impregnation. Phenolic substances, which are present in the core and impregnate the cell walls, help to significantly increase the “life” of wood. It turns out that it will not be possible to saturate the core with an antiseptic even deeper. Biologically, the heartwood of oud is dead, which is why it is valuable. Before processing, the wood should be dried to at least 25%, otherwise a lot of moisture will remain in the sapwood and the process will be carried out with violations, and this does not provide any guarantees.

Rotting on saw cuts and inside

As for the rotting of the impregnated board from the inside, this does not happen if the technology was carried out impeccably. This doesn’t happen with the British and Finns either. But it is possible that this is quite possible even if the process is carried out correctly, if the process is carried out for round timber posts. If the sapwood part is not sufficiently dried, it may not be completely saturated. As a consequence, the sapwood will be destroyed from the inside, in the place where the air and earth meet, but this is just a guess.

As for rotting along the edge, the chance is almost zero if there is no contact with the ground. In any case, the sapwood part will be saturated. On the cut, it will be enough to paint the core part with oil so that it is not noticeable and provides the proper level of protection, or you can cover it with sealant for the ends. Is it a different matter if the gash is in contact with the ground. In this case, it is better to first trim everything to size, and then carry out impregnation. When making boards for fences, the board is first cut to size, and only after that it is impregnated. This helps eliminate the need to paint the ends and provides an additional layer of protection when in contact with the ground.

Areas of application

Impregnated boards are widely used in everyday life and industry. For example, wooden poles are installed as support structures for power lines. By using fire retardants, logs are protected from multiple pests and their service life is extended. The processed materials are also used in the production of sleepers. In order to increase the efficiency of the impregnated solution, the workpieces are processed in an autoclave.

Nowadays, wooden buildings have become especially popular. Protected lumber is used in their construction. They are also used to make fences, terraces, build gazebos, and arrange children's areas.

A canopy erected from impregnated wood will decorate the garden area and serve as a cozy place to relax. Source zaggo.ru

Impregnated terrace boards are especially in demand. When laid around the house, it creates special comfort for residents and has an attractive appearance. It is also worth noting the installation of flooring on balconies and verandas. Since impregnated edged boards can withstand enormous loads, they are suitable for arranging flooring in garages and areas. This material is often used by craftsmen to make attractive garden furniture.

Properly processed wood is in great demand in various fields of human activity due to its high performance and quality properties.

A building finished with impregnated boards looks modern and quite attractive Source zaggo.ru

How is thermowood made?

1.

Drying.

vacuum chamber

2.

Heat treatment.

After drying, we increase the temperature inside the chamber to 240 C. At the same time, the moisture content of the wood decreases to almost zero. As a result of the action of the press and high temperature, wood acquires its dimensional stability, resistance to fungus formation, and durability.

3.

Cooling.

Next, we reduce the temperature inside the chamber. All! Thermally modified wood has been obtained and is ready for use in the production of small architectural forms!

By the way, we produce thermowood from almost any suitable type of wood - ash, oak, pine, larch and so on. It all depends on the wishes of the customer.

Can it be painted?

As a result of using impregnation, the wood may acquire a green tint, reminiscent of an unpleasant swamp color. A bluish tint is often observed in the area of knots. But after a month, under the influence of ultraviolet radiation, the greenish tint will transform into a more pleasant yellow. It is possible to prevent such consequences of the impregnation process by painting. If you follow the proportions, it is easy to get the desired color.

When preparing the impregnation, you can add color. In this case, the tree will turn brown. In this case, the performance characteristics of the material will not be affected at all. At the same time, wood will look much more expensive and luxurious.

It is worth remembering: the sun's rays and periodic atmospheric changes in any case affect the painted surface. Therefore, over time, unfortunately, it will acquire a gray tint. To avoid such a problem, experts advise protecting impregnated wood with oils that have a UV filter effect.

If you add color to the impregnation, then the impregnated board can be given the desired shade Source nasha-besedka.ru

Suitable breeds

Despite the fact that impregnated pine needles are the most popular and famous, any (!) can be subjected to this process (and which tree is best for a bathhouse can be found out here). After all, wood impregnation itself has little to do with the structural characteristics of a particular species.

The question is: does every type of wood need to be subjected to this procedure? After all, resistance to decay is not the only important characteristic; there are also characteristics that influence whether a given type of wood can be used as a structural material - withstand static and dynamic loads, what is its hardness and elasticity, etc.

Therefore, it is preferable to impregnate those types of wood that are themselves suitable for one or another construction purpose (of course, we are not talking about fences, but about more important elements of the structure - beams, rafters, logs, etc.).

The second important question is whether impregnation reduces the strength of wood. It turns out that there are methods that actually reduce strength . Firstly, strength decreases when high temperature . Secondly, it is affected by the specific method in which the wood is pricked - narrow short punctures are made on it to a depth of about 5 cm to ensure access of the impregnation to the deep layers of the tree.

Since there are ways to obtain impregnated wood without heat and pricking, it can be said that the strength can remain the same as that characteristic of the given type of wood in itself. And if we are talking about structural materials made of wood, then it will be primarily coniferous species.

There are two factors at work here: they are widespread in Russia, and equally or even more durable hardwoods are less common and therefore more expensive (oak, for example). And this is not to mention the exotic, which can be a much better construction material, but the cost of importing it to Russia makes the idea unjustified.

BY THE WAY! Impregnation is successfully used for wood species of any density - only the time and aggressiveness of the impact on this species varies.

Choosing a decking board

The decking board has an anti-slip relief coating.

For the flooring of verandas and terraces, it is better to choose a long and wide board. A narrow and short deck looks good around the pool and on garden paths. For piers and decks, it is better to use a large board. Range of board sizes: thickness 26-45 mm, width 95-141 mm, length 2-6 m.

The decking board has anti-slip corrugation (anti-slip). It is easy to slip on a wet smooth surface. And on a corrugated shoe, water accumulates in the depressions, leaving the ridges, which come into contact with the sole or foot, dry. The corrugation pattern is called "corduroy". Based on the frequency of the ridges, the board can have a “large corduroy”, “wide corduroy”, etc. profile.

The influence of the seasons

Humidity indicators depend on certain factors.

Experts have identified 3 main ones:

- weather;

- climate change;

- season.

The last of these has a significant impact, as humidity levels change with the changing seasons.

The most susceptible tree species are pear, kempas and beech. They are most affected by external changes. The following types are considered the most stable - bamboo, merbau, oak, as well as other varieties that boast hardness and high strength.

Most experts with experience working with wood recommend using material harvested in winter in construction. Such boards contain less moisture compared to wood harvested in the warm season.

Studies have been conducted that have confirmed that the “winter” tree has improved performance qualities.

This is a special substance similar to starch. It prevents moisture evaporation. Wood harvested in winter tolerates drying better. After this treatment, the surface remains as smooth as possible, and the number of burrs is reduced. The material is also less subject to deformation.