When choosing a finishing material, it is necessary to take into account many parameters that classify wood according to its intended purpose. Depending on the conditions under which the product will be used, you should pay attention to its degree of humidity, grade and type of wood. But nevertheless, there is another important indicator that can also characterize the quality of the source material - sawing wood.

This criterion can indicate the level of strength, resistance to destruction, deformation and the general properties of the forest products product. Each type of wood sawing has its own characteristics.

Three types of cutting are used in lumber processing:

- radial;

- semi-radial;

- tangential.

The cost of the finished product depends not only on the type of wood and its natural properties, but also on the processing method, including cutting. Therefore, when deciding on a finishing material, you should be interested in how it was processed. This information can be indicated on control cards, where you can also see the proper dimensions of the log and compare them with the existing ones.

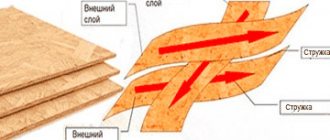

Tangential cutting in lumber processing

When using this type of cut, the cutting plane is focused in the area of the core of the log. Not in the center, but at some distance from the middle, tangential to the annual ring. The advantages of the tangential type include the ability to extract a rich shade and figured texture from a wooden piece. The disadvantages of this method are the low strength coefficient, shrinkage and swelling of the board during operation. But due to this, such boards will be more affordable in price compared to others.

Considering that many people choose lumber processed by tangential sawing purely because of its aesthetic appearance, you should count on the short service life of such cladding under extreme conditions. On the street, under the influence of weather conditions, boards sawn using this method will not be able to please with their appearance for long. But when installed in more favorable conditions, when the wood is protected from high humidity and direct ultraviolet rays, it will be able to last quite a long time without deforming or fading.

Beam or whetstone?

Beams and lumber are a type of lumber with a square or rectangular cross-section.

- Beam is lumber, the thickness and length of which is more than 10 cm. Beams can be two-edged, three-edged and four-edged, depending on the number of sawn planes (edges). In most cases today you can encounter four-edged timber.

A separate variety is laminated veneer lumber. Formally, it cannot be classified as lumber; it is made by gluing together several wooden lamellas.

- Bars are lumber, the sides of which should not exceed 10 cm, and the width cannot be more than two thicknesses.

Radial sawing of lumber

This type of processing focuses the cut line in the middle of the core of the log, and the direction of the growth rings will coincide with the grain of the tree. Sawing is carried out perpendicular to the annual layers. Radial cutting is considered the highest priority, due to the fact that this method allows you to preserve the most important properties. Using this type of cutting, you can get the highest quality products. This product has the best strength indicators, resistance to deformation, shrinkage and rotting.

Surprisingly, radial processed products are in less demand in the timber market. This is because with this type of cutting, much less finished material is produced (no more than 30%) and therefore their value, in comparison with other types, is much higher. And despite the low wear resistance, cheaper and weaker materials are a higher priority than high-quality products.

But if you have a need to equip the outside of your house, build a bathhouse or gazebo, then it would be more rational to purchase a good product that can last a long time. For example, radial sawing of larch is the most resistant material to external influences, the years of service of which are measured not in tens, but in hundreds of years.

Structure elements

Let's take a closer look at each element in cross section.

Transverse section of the trunk: 1 - pith, 2 - medullary rays, 3 - core, 4 - cork layer, 5 - bast layer, 6 - sapwood, 7 - cambium, 8 - annual layers

Core

The heartwood is the central area in the tree trunk. In some breeds this area is not clearly expressed. The core has a higher density compared to sapwood, since this layer does not take part in metabolic processes and does not perform transport functions. Most often, the heartwood is visible in cross section and has a darker color than the sapwood. But there are exceptions when the layers of wood are slightly subject to any chemical changes over several years. However, in many trees, the color of the heartwood changes with age. Some species do not have a core at all and consist of only sapwood: birch, aspen.

Different types of wood have different core colors. Here are some examples:

- Cherry (dark brown)

- Campshew tree (blue)

- Ebony (black)

- Hematoxylin (Haematoxylon campechianum): extracted from the kernel of the logwood tree.

- Yellow Morin: Extracted from the core of Maclura orange.

- Brasilin: Extracted from the kernel of Caesalpinia.

- Santalin: Extracted from the kernel of deep red Sandalwood.

During the process of turning sapwood into heartwood, several changes occur the chemical composition of the wood Some substances disappear from the wood, and some are actively deposited in the structure. For example, phosphoric acid and potassium compounds, which are important for chemical processes, disappear, and starch also disappears. But, despite this, inorganic and organic substances are formed in the structure. For example, in the core of some species (elm, chelkova, beech) significant amounts of calcium carbonate are formed. Other rocks have amorphous silica deposited in their core. Organic substances are also often found: resins, gums, tannins and dyes. Here are some examples of organic dyes extracted from one or another rock:

We can conclude that the wood core has properties that differ from the properties of sapwood: high strength and density, as well as other physical, mechanical and chemical properties that depend on the species.

Sapwood

Sapwood, also known as sapwood or subbark, includes the outer young layers of wood that are physiologically active. Sapwood performs the function of transporting water and storing reserve substances. Compared to the core, sapwood has low strength and density, and is more easily attacked by insects and fungi. In industrial terms, sapwood contains a very useful material - the resinous thick mass “Zhivitsa”.

Core

The core is wood consisting of loose, soft tissue. The core is located in the central part of the trunk. On a cross section it looks like a light or light brown spot of a round or star-shaped shape. Together with the primary wood, the pith forms the pith tube. Often the buds of small knots extend from the core tube, which negatively affects the physical and mechanical properties.

Core rays

Core rays - directed from the core to the cortex along the radii of the line. All breeds have such lines, but in some they are wide and therefore visible to the naked eye. Heart-shaped rays serve as a means of transporting moisture in a horizontal direction in a growing tree. There are primary and secondary medullary rays. Primary divide the xylem part of the stem and root into radial sectors. Secondary ones do not reach the middle of the stem, that is, they appear in the growth rings of subsequent years.

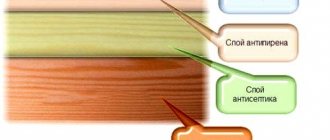

Bark

The bark is divided into two layers: the bast layer and the cork layer.

The cork layer is the top layer of the cortex, which is a collection of dead cells. It is the densest layer and performs a protective function. There were cases when it was the cork layer that protected the tree from the effects of flame! It protects the tree from the effects of adverse factors (rotting, insects, etc.) In particular cases, the cork layer is a valuable material: the bark of the cork oak has an amazing structure, the main property of which is the absence of intercellular space. This layer is periodically removed from the trunks, and after this procedure the tree does not die, but forms a new cork layer.

The bast layer is the inner layer of the bark, which performs the functions of both protection and transportation of juices that nourish the tree. Juice refers to a liquid containing organic substances produced in the leaves. The bast layer is also used on the farm, for example, the bast layer of linden is used for weaving various things.

When constructing wooden houses, care should be taken when debarking and planing logs.

Cambium

Cambium is the layer between the bast layer and the sapwood. The cambium gives rise to secondary conducting tissues and has an educational function, ensuring the growth of these tissues in width. Depending on the season, the activity of the cambium affects the formation of tree rings.

Tree rings

Tree rings (annual layers) are areas of cyclical tissue growth in trees. The appearance of annual rings is caused by the uneven development of the body, combined with the influence of external factors. Each ring consists of two parts - light and dark. The number of rings on a cut indicates the age of the tree and its growth rate, depending on the height at which the cross-section was made. Tropical plants do not form tree rings because, due to climatic conditions, they grow all year round.

Semi-radial cut

With this type of processing, it is possible to reduce the angle of inclination of the growth rings to the level of 45⁰. Thus, the quantity of finished products increases several times. With lower raw material costs, the cost of the finished product will be lower than with radial cutting. But the quality of a semi-radial cut will also be inferior to a radial one, but not as much as a tangential one. The choice of material for facing work depends on the requirements for the facility, the purpose of construction and the budget. These parameters are the main ones when determining the type of products required. If you want a durable, beautiful and high-quality building, then it is better to achieve a high quality finish using radial sawing, because semi-radial lumber is not very suitable for implementing this idea. It is better to leave them for rough types of work.

As a result, in order to choose the right lumber, you should pay attention to the following characteristics of wood:

- type;

- variety;

- humidity level;

- natural properties;

- processing technology.

Low-quality lumber can also be among expensive products. Therefore, it is worth paying attention to the appearance of the blanks. It is also worth asking in what conditions they were stored. If any doubts arise, the buyer has every right to ask the distributor for documents and control cards that can inform about the origin of the tree, its species, age, type of processing, date of receipt at the warehouse, size, etc.

It is worth noting that it is not necessary to certify lumber and many people neglect this point. Although a conscientious manufacturer always requests a certificate of compliance of its products with the GOST standards system in order to convince the consumer of the quality and safety of the manufactured products. Mandatory certification of lumber is carried out if the product participates in a tender.

It is difficult to notice irregularities in processing, but if there are pronounced defects (rips, potholes, chips), then this is a clear sign of a manufacturing defect. This can happen due to outdated or poorly configured technical equipment, which during the sawing process affected the final result. Violation of drying technologies plays a big role in the wear resistance of wood, so you should purchase lumber from a trusted supplier.

Sawing hardwood

The sawing operation involves decisions about board thickness, turning the log, and compensating for the log's taper. This depends on many factors: the type of wood, the quality of the log, its size, the design of the machine and the grade of lumber that needs to be obtained. There are 3 standard cutting patterns:

Simple sawing

The log is sawed until its core is exposed, and then turned 180° and sawed to the end. This is the fastest and easiest sawing method; however, with this method, each piece of lumber must be cut on the sides. Lumber sawn in this way is somewhat wider and heavier, of lower quality and has a lot of waste. It is extremely susceptible to warping during drying. Therefore, simple sawing or sawing through is justified only in the case of very low quality logs, when all of the above disadvantages are no longer particularly important.

Circular sawing

When sawing in a circle, a cut is first made, and the log is turned over to a new edge, sawed, and turned over again until at least 5 turns have occurred. From a financial point of view, this is the best way for medium and high quality logs, although at the same time, at some sawmills, turning over the logs in this way is difficult, and the daily productivity will be low. Of course, a machine with hydraulics solves this problem.

Sawing timber

Jumbo sawing maximizes sawmill productivity (boards per day) and is typically used in industry for medium to large sized logs. In this case, the log is first sawn as in circular sawing, but the central part of the log, which can have dimensions of 18x23 or 25x25 and so on, is either transferred for processing to another machine along the production line, or sold as a large and heavy beam. Basically, logs of medium and low quality are sawn in this way, when it is impossible to obtain valuable lumber from the central part of the log. This saves time and effort in producing a product that is not of very high quality and therefore not of very high price.

Deciding which side of the log to start cutting on, which cut surface to open first, is the most important part of sawing. We divide the log into 4 sides, each of which extends along the entire length of the log and occupies a certain part of its circumference. The choice of the first face is determined by the position of all the others.

When sawing in a circle and sawing timber, two basic rules apply:

The worst edge of the log is sawn first without any consideration for the taper of the log. Counting the slope of a log means raising or tilting the log so that the saw cuts parallel to the bark. Since this is the worst part of the log, this means that it will produce short boards and a lot of slabs. Since we do not take into account the taper of the log, this gives us the opportunity to cut parallel to the bark from the opposite, better side of the log, without lifting or tilting the log. This means that from this best part of the log more boards of high quality will come out, which also match the length of the log.

Cut the best edge of the wood first, taking into account the taper of the log. This means that the log needs to be raised or tilted so that the first cut is made parallel to the bark.

The end result of both methods will be approximately the same, but the second method has one advantage. In this case, it is easier for the sawyer to rotate the log, because the open edge is the cleanest and has no defects. In the case of the first rule, the best part of the tree is the part opposite the open edge. It is not visible, and it is impossible to accurately rotate the log. Usually, if the wood is of good quality, then both rules work almost the same. But if you encounter a worse log, it is better to use the second rule.

Main types

In general, haircuts are divided into two types: contrasting and non-contrasting!

- Contrasting - hair has different lengths (structure) on the surface of the head.

- Non-contrasting - hair has the same length (structure) on different parts of the head (haircut "headless" and haircut "on the fingers").

In addition, there are classical concepts of types of haircuts - simple and model.

A simple type of haircut “on the fingers” is a uniform shortening of the length of the hair throughout the entire mass or in its individual sections.

What types of model haircuts are there:

- Basic (performed using strictly developed technology).

- Modeling (performed on the basis of basic ones, but taking into account the individual characteristics of the client).

- Combined (combine two or three basic haircut technologies).

The main types of haircuts are shown in these photos:

General principles for laying tiles

The sandy base is compacted and leveled

- Preparing the base. The path is marked (using stakes and ropes), and the soil is removed. The bottom is leveling out.

- A sand base is made , leveled and compacted up to three centimeters thick;

- The pattern for laying paving slabs is selected. It depends on the shape of the tile and path, and on the result that you want to get upon completion of the work;