Furniture made from chipboard and MDF has long become commonplace. New, easier to process and use, cheaper materials are actively replacing traditional products made from various tree species. And this is not surprising. The performance characteristics of high-quality artificial materials based on sawdust are in no way inferior to solid wood. And in a number of parameters they are even superior.

When choosing furniture for their home or apartment or organization, many buyers ask a logical question: how reliable and durable are these materials, and what are their differences. You often hear that DSAMP and MDF are practically the same thing, made according to common recipes, and there is no point in choosing. Is it so? In order not to make a mistake when choosing furniture, you need to clearly understand the differences between these two materials. What nuances need to be taken into account when purchasing furnishings for certain needs. Let's try to figure it out together with the experts.

What are the differences between laminated chipboard and MDF?

At first glance, indeed, furniture made from chipboard and MDF looks the same. The products look good, almost the same colors and textures are used. Even the shape and style of many models of kitchen, bedroom or living room sets are made according to the same design. Meanwhile, the difference between them is huge: in quality, in operating conditions, and even in price. All the differences are hidden in the depths, behind the attractive facades. They are associated with the peculiarities of production technologies for particle boards and finely dispersed fractions.

Varieties

Taking into account the scope of their use, manufacturers give additional properties to certain types of MDF:

- The waterproof panel is intended for use in wet rooms (kitchen, hallway, bathroom). The surface of the plate is covered with a layer of plastic or sealed film; they repel liquid and its vapors.

- Glossy slabs create an aesthetic furniture façade. The shine of the panels is given by a polymer coating, polyester or acrylic. In the latter case, the decorative layer turns out to be absolutely smooth and mirror-like. It often imitates the texture of different types of wood.

- Flexible slabs are used to make radius, shaped, arched furniture elements. The raw material can be one- or two-layer. During production, the material is not coated with anything, so after manufacturing furniture items, they need to be painted or laminated.

- Kronospan has a high degree of density and large thickness (from 1 cm). This type is used for the production of facades, doors, and lightly loaded countertops.

All types of MDF can be milled, giving furniture elements the desired shape and relief - this is one of the popular ways of decorating interior items.

For use in wet areas, special moisture-resistant panels are used

The polymer coating gives the material a glossy shine.

Radius or shaped facades are made from flexible slabs

Kronospan is used for the production of facades, doors, and lightly loaded countertops.

Disadvantages of laminated chipboard

- Due to the large number of large chips and heterogeneity of the structure, chipboards are prone to chipping of individual particles and the appearance of chips. Products can only be sawed in straight lines. They are not subject to fine milling or laser engraving. Therefore, it is very rare to find beautiful furniture facades made of chipboard, with figured cutouts, 3D relief images, and complex patterns. Mostly even, smooth doors are made from this material, suitable for modern styles.

- If water regularly gets into the joints and seams, the surface in these places swells and bulges into a hump. The product increases its volume up to 30%. The film begins to peel off. Inside the slab, the mass becomes loose, crumbles, and black mold appears. To avoid this, you should choose furniture with laser-cut edges (soldered joints). Such products are more durable. In addition, spilled liquids must be promptly removed by wiping the surface with a soft, clean cloth.

- Due to the low density of the base, the places where the fittings are attached gradually crumble. The fasteners begin to move freely in the socket. Furniture made from chipboard is not intended for frequent assembly and disassembly. It is enough to transport the set 1-2 times to a new place of residence, and it will warp in the most unimaginable way due to completely loose fastenings. To remedy the situation, you can use wood glue or use thicker screws. Or initially purchase products that use not ordinary fasteners, but bolts with wide washers.

- Low-grade types of chipboard negatively affect the health of children, adults, and pets. To produce the cheapest materials, large amounts of resins that emit formaldehyde are used. If new furniture has a specific, chemical smell, it is better to refuse the purchase. Living next to such a time bomb is simply dangerous.

Perhaps the most important disadvantage of laminated chipboard is its short service life. Such furniture lasts on average 5-7 years, subject to the rules of operation.

Chipboard production? How to define quality?

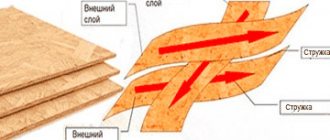

To produce chipboard, sawdust and shavings are compressed and impregnated with formaldehyde resins for gluing, and the resulting board is usually laminated with melamine film.

The letter “L” at the beginning of the abbreviation indicates that the chipboard is laminated. The film not only protects the slab from moisture and other external influences, but also prevents the release of formaldehyde into the external environment. There is a safety classification for laminated chipboards based on the concentration of formaldehyde:

- E1 – formaldehyde emission class, considered safe for furniture production (this board is made according to European standards;)

- Class E2 - strictly prohibited for use in the production of children's furniture;

- Class E 0.5 – also complies with European quality standards. However, its use is not always necessary, since the film prevents the evaporation of the harmful compound;

- E 3 – strictly prohibited for use in production.

When buying furniture, be sure to ask the seller about the safety class and ask for certificates.

Advantages of MDF

- Since formaldehyde resins are not used in the production of MDF boards, they are much safer than chipboard. In fact, it is the same wood, with a small content of natural or urea resins, only more uniform and durable. The material is used in the manufacture of children's furniture, cribs and changing tables for newborns, products for children's and medical institutions. By purchasing furniture made from high-quality MDF, the buyer can be completely confident in its safety for health.

- MDF, even in its natural, uncovered form, is not afraid of water. Its dense structure simply does not allow liquids to be quickly absorbed, unlike some types of natural wood and, especially, chipboard. And an additional protective coating in the form of a laminating film or veneer gives it excellent moisture-resistant characteristics. Even many hours of exposure to puddles of water or other liquids are not dangerous for MDF surfaces. That is why furniture made from this material is recommended for “wet areas” - kitchens, bathrooms, swimming pools, toilets, dressing rooms.

- Dense sheets can be bent if necessary: they do not break or crack, and retain their shape perfectly. This feature is widely used in the manufacture of curved or concave facades and other elements.

- MDF sheets, thanks to their homogeneous structure, make it possible to produce richly decorated furniture facades. They perfectly withstand all types of processing: sawing, shape cutting, milling. The possibilities of milling this material are limited only by the designer’s imagination. Craftsmen form products with relief figures and designs, carve complex recesses and patterns, apply entire pictures to slabs, and make carved platbands and moldings.

- The edges and front part of the products have no joints or seams, as they are covered with one sheet of protective and decorative material. That is why products made from MDF successfully resist moisture and chemicals. The coating is so dense that it is very difficult to scratch or make a dent.

- You can spill water, caustic fruit acids, or soda solution on MDF countertops and kitchen aprons. If you wipe up the resulting puddle in a timely manner, there will be no consequences for the coating.

- Furniture made from MDF perfectly withstands repeated assembly and disassembly when moving and moving to other rooms. In this respect, it is comparable to products made from natural solid wood.

- Consumers are offered a huge number of finishing options: PVC film with the most fantastic shades and textures; glossy, mirror, matte and semi-matte coatings; products with metallic, mother-of-pearl effects, interspersed with sparkles and metal threads, patina; veneer from elite wood species; surfaces that perfectly imitate any type of wood, stone, textiles, leather. Even the most picky buyer will definitely find a product to his liking!

Material installation methods

There are only two ways to install products. The first of them is direct installation on a frame, the second method involves installation on a wall using glue.

Frame mounting

This installation method is chosen in cases where the difference at the walls or ceiling exceeds 1 cm. Most often, the frame consists of wooden beams, but in some cases metal profiles are also used. The dimensions and cross-sections of the timber are selected depending on how uneven the wall is. This is done in order to compensate for the difference in height. The installation step of the beams is 40 cm. In the case when the height of the room is more than 2.8 m, the joints of the sheets will be under the plank.

Under the panels, jumpers made of beams are installed in a vertical position; their pitch depends on the size of the sheets, for example:

- sheet width 2170 – pitch 54 cm;

- sheet width 1270 – pitch 42 or 63 cm.

Also, the pitch parameters are also affected by the thickness of the material; the thinner it is, the smaller the step; for a thicker product the step should be smaller.

The sheets are attached directly to the mounted frame; to perform hidden fastening, holes for fasteners are drilled. Because the fastening element simply will not fit into a dense slab. In order to hide the caps, wider holes are made for them using a drill with a large diameter.

The resulting holes are sealed using putty, after drying they are sanded over to remove all irregularities, and then the surface is dusted off. Only after this can you begin finishing the surface of the walls.

Glue mounting

If the walls in your room are smooth, the material can be mounted directly on them using glue. You can use both liquid nails and any other compositions. The operating principle is as follows:

- applying the composition to the surface of the sheet;

- the panel is installed on the wall and pressed tightly, while it is necessary to control the horizontal and vertical position using a level;

- it is necessary to fix the panel for several minutes;

- proceed to the installation of the next panel;

- After installing all the sheets and drying the adhesive, the joints are sealed.

If you are worried that the sheet may lose its required position, you can make holes in the corners, and after installing the material in the design position, fix it. There is no need to tighten the screw to a great depth; just a small recess is enough. This method will be sufficient, since it is necessary to fix the position only until the glue dries.

This method seems less expensive and simple, but fixing and installing MDF panels is quite difficult due to their size. It is recommended to start with small areas to see how well you can do it. After all, with this installation method, you can disassemble the coating only if you completely destroy the casing. Therefore, before choosing a method, you should weigh everything carefully.

What are the disadvantages of MDF?

- Quite a high price compared to chipboard - 30-50% higher. High-quality MDF boards, coated with natural veneer, elite types of plastic or durable enamel, are close in cost to solid wood. However, they last two to three times longer than products made from chipboard or even solid wood.

- Plates consisting of small, homogeneous particles are prone to burning, even despite special impregnation with fire retardants.

- Dense material has more weight than particle boards, which affects the weight of the finished products. This must be taken into account when transporting and choosing an installation location.

To reduce the final cost of products and increase the number of sales, furniture manufacturers offer compromise options:

- cabinets for kitchens, living rooms, and bedrooms are made from straight, laconic chipboard plates;

- and beautifully decorated, carved facades are made from MDF.

Such furniture is affordable and lasts longer, thanks to durable, high-quality facades that take the brunt of the impact.

The production technology consists of 4 stages:

- The first stage is the preparation of raw materials. To produce MDF, round logs are used, the bark is removed from them using special equipment, chopped into small chips, sorted, washed, removing dirt, sand and pebbles, and heated with steam.

- In the second stage, the fibers are prepared. In the refiner, the material is crushed, the resulting mass is dried and receives a mass of equal moisture content, after which the air is drawn out of it.

- The third stage is pre-compression. The fibers are processed on a special forming machine, where the plate is formed. It is leveled, pre-weighed and pre-pressed, thereby losing air.

- The final stage. Last pressing. The slab goes through the main press, from which the finished MDF strip comes out. It is further cut and cooled for half an hour.