Articles

All photos from the article

Pins are a reliable fastening element that is used in the construction of log houses. On the one hand, they provide the necessary rigidity of the “box” of the building, and on the other hand, they do not interfere with uniform shrinkage. In this article we will take a closer look at what dowels for tying timber crowns are, and also get acquainted with all the nuances of their installation.

Wooden dowels

What is a dowel

If you are interested in a dowel, what it is, you should find out. Translated from German, this word means “nail”, but it is not typical. The product is a pin that can have a round or square cross-section. The fastener has neither a head nor a point. It is smooth, and threads in some connections are completely undesirable. The length can be 150 mm maximum. But the sizes are not regulated in practice.

If you want to purchase dowels, what they are, you should know. This information also includes the material at the base of the products. This is usually metal or wood. The latter option is more common, because it is used for the construction of wooden buildings. The main goal that builders are trying to achieve when installing wood dowels is to resist shear.

Boards, logs and beams change size when exposed to external factors such as humidity and temperature. This happens disproportionately, which depends on the direction of the fibers. Parts move in different directions during operation. If you use a pin holding them, a rotation will occur due to the creasing of the material.

Then bending is carried out. The area of contact between the fastener and the wood increases, and the shear resistance also increases. The connected elements and dowel are not subject to destructive deformations.

Dowels are often used in construction; you should know what they are if you are planning to build a wooden house. You should be aware that when the volume of wooden parts changes, a reverse shift will occur. In this case, the pressure on the fastener will decrease, and the pin will return to its original position.

The dowel is selected taking into account the expected load. Otherwise, the pressure may be critical and the pin will collapse.

Such a connection is more practical when moving parts, which occurs constantly. When deciding what a dowel is, you should know that this fastener is also offered for sale in the form of plastic products. But they are not so widespread today.

How to properly lay the crown molding?

The first and most important operation is laying the first (flashing) crown. The dimensions of the first row of the frame are determined at the design stage; they are commensurate with the length and width of the foundation. Using a building level, a basic horizontal line is applied to the flashing crown to control the current height of the masonry.

The foundation material and wood have different physical properties: the concrete base freezes and forms moisture when it thaws, dew also forms in the summer, concrete has a loose structure and is easily saturated with soil moisture. If waterproofing is insufficient, mold and mildew will appear on the lower beams and under the floor. The trim crown is reliably isolated from the negative effects of moisture.

To waterproof the base of a log house, roofing felt, fiberglass or woven geomaterial with bitumen impregnation are used. To adhere to the foundation, eliminate cracks and air cavities, the waterproofing layer is treated with open fire.

Main types of dowels by material: wooden fasteners

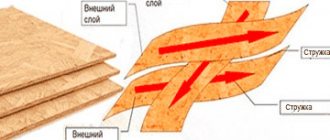

Wooden dowel has many advantages. Firstly, such a pin changes in volume and size, and this happens in proportion to the wooden beam, because the characteristics of the material and fasteners are similar.

Secondly, wood is a more flexible material compared to metal. Therefore, such a product is better able to withstand bending loads.

Thirdly, when the pin is exposed to moisture, it expands, which helps to increase the tightness of the entire structure. A similar effect has been used for many centuries in the construction of boats.

But it is worth considering that a wooden pin does not have a long service life, unlike a metal pin. It will not be able to withstand high pressure loads, which explains the installation features.

Selection of hardware and calculation of the required quantity

Application of dowel screws:

- fastening of PVC windows;

- wooden windows;

- door frames;

- metal profiles for plasterboard;

- hanging shelves, mirrors, paintings;

- fastening lathing for a ventilated facade to the façade wall, etc.

The concrete dowel is selected based on the expected load on it. For a load of 100 kg, the suitable screw length is 15 cm. For 10 kg, 7 cm is sufficient.

Typically, the pitch between screws is from 7 to 10 cm. When installing PVC windows, the maximum pitch is 6 cm. The distance from the edge/corner depends on the type of work. For example, windows are mounted 5-6 cm from the edge of the frame or further.

Knowing the pitch, it is easy to calculate the required number of fasteners: divide the perimeter of the structure by the distance between adjacent screws.

Metal pin

Metal fasteners are rods, which are used much less frequently. This fact remains true despite the durability and higher strength of such products. Among the main disadvantages, one should highlight the high fastening strength, which eliminates wood shear.

But metal dowels have many advantages, namely:

- consistency of size;

- ability to resist warping of the top layer of material;

- easy installation.

As for the first factor, the same cannot be said about wooden dowels, which will come out of the holes when dry. If ease of installation is an important point for you, then you will choose metal fasteners, since during its installation it is possible to use spring ties, which simplifies construction. But metal has high thermal conductivity, which certainly causes the formation of cold bridges.

Such fasteners hold wood extremely rigidly, while the difference in thermal conductivity causes condensation to appear in the places where the fasteners were made. Typically, metal pins have corrugated surfaces, which leads to damage to the material. In order to achieve positive results, quite often builders combine the fasteners described above.

Types of corners in a log house

Corner joints can be “with remainder” or “without remainder”. The difference is in the ends of the timber, which will either extend beyond the frame or not.

Connecting corner beams with the rest is more expensive (material consumption increases). But the heat capacity and protective functions of such an angle are higher. The most used option for fastening timber with the remainder is “in the fat tail”.

Connection without residue

The splicing of timber without any residue is carried out using several types of knots: “into the bowl”, “into the okhop” or “into the okhryap”. The most common option is in a bowl.

Bowls in timber are made on a special bowl cutter or manually using a saw. The specialists have a mobile cup cutter that they can carry out work right on the construction site. The timber is laid one bowl on top of the other. Felt or jute insulation is laid between them.

The connection of the beam “into the clap” is similar to that “into the bowl”, but differs in the location of the drink. The bowl is cut from the top, not the bottom.

If we compare it with the main types, the connection “in the okhryap” is similar to the “in the paw”. Only in this design the end of the beam is removed, thereby forming an angle without a protrusion. The beam is connected to such a corner using dowels and crosscuts. This type of connection does not have high wind resistance, so often a straight cut is replaced with a trapezoidal one.

Any connection must be discussed with specialists, since the choice must be based on the design features. For profiled timber, connections in length are allowed only according to certain parameters, in accordance with GOST 30974-2002 “Connection of corner wooden and log low-rise structures. Dimensions, design and classification."

Any connection breaks the tightness of the walls, so before installation you need to lay a special insulation and treat the joints with antiseptics, since this will be difficult to do in the future, especially with profiled timber.

There are two main types of log frame corners:

- "without a trace"

- "with the remainder."

When starting construction, you should decide what kind of building it will be, what load the foundation and walls will have to bear, and, accordingly, what kind of timber connection in the corners should be chosen in each specific case.

We invite you to familiarize yourself with: Warm floors in the bathhouse - do-it-yourself options

Considering that correctly set corners are the key to the strength and reliability of the entire structure, corresponding requirements are also imposed on them. This:

- Reliability of fastening. The corner of the house, regardless of how it is constructed, should not be made of lumber with cracks and splits. Wood for construction must be taken with a drying level of up to 20%, which ensures its ability to withstand deformation and environmental changes without damaging the structure.

- Air tightness. The absence of cracks that allow drafts to enter the home is the main requirement for wood corner joints.

Connecting corners to build a house made of timber is divided into:

- Angle with remainder.

- Angle without remainder

The corner connections of the house with the remainder are also called “in oblo”. The design of the unit is key, it can be assembled in several types:

- One-sided.

- Two-way.

- Quadrilateral.

Lap knitting is a universal connection of lumber, used when laying walls made of logs and timber. The workpieces are placed at right angles into cut-out grooves; the size of this groove depends on the size of the material used. Such a lock is used in the construction of log houses and ceilings, the construction of bridges, and the construction of canopies. The main methods of cross fastening:

- Half-tree connection;

- Quarter and third wood joint;

- Notch in one row.

The most widespread cross-shaped connection in half a tree is when cutting corners into a bowl; it is used in the construction of utility structures, residential buildings and baths. The structure is reinforced with building brackets, dowels and dowels.

A variation of the cross-shaped connection is the method of fastening the beams together without any residue; in this case, the two sides of the cross-shaped connection have no continuation. This connection is used when laying corners and is called “no residue in the paw.” Cutting a castle without leaving any residue does not require the use of special tools; the construction of a log house using this method is popular among individual developers.

A more complex method of corner mounting is dovetail installation; a dovetail lock is a reliable but complex fastening. Marking and complex cutting of such a connection requires professional skills; the technology is widely used in the construction of low-rise economy class housing.

Application

The use of dowels for timber is very limited. With its help, wooden buildings are built. That is why installation features are associated with laying timber or logs. Holes for fastening are drilled through the top of the log, and only halfway from the bottom. The nest is made vertically.

The beam must slide along the rod during the shrinkage process. The holes should be centrally located. The dowel for the timber is usually installed at a distance of 50 cm from the corner. The remaining holes are made in a checkerboard pattern. The minimum distance between them should be 150 cm.

Characteristics

Main parameters of hardware:

- outer section does not exceed 7.65 mm;

- thread pitch varies from 2.5 to 2.75 mm;

- internal cross-section reaches 5.45 mm;

- head height does not exceed 3.2 mm;

- cap diameter - up to 11.82 mm;

- if there is a head, a slot is always provided;

- the length of the fastening element varies over a wide range, the upper limit of which is 184 mm;

- the hole for the screw is always smaller than the external cross-section of the fastener;

- the depth of the holes in the concrete mass is 1.5 cm greater than the length of the hardware;

- The minimum permissible distance between adjacent screws is also regulated; when installing fasteners in the most durable material (concrete), it is allowed to leave at least 3 cm between the holes.

Installation features

The depth of the holes must be 2 cm greater than the length of the dowel itself. This requirement is due to the fact that when shrinking the log should not hang on the fasteners. The connection with dowels is accompanied by a tight fit of the rod into the socket. However, you don't have to make any special efforts. But the mallet must still be used. It is important to note that the fasteners should not be loose in the hole.

Design errors

When independently calculating a project, there is a risk of unprofessional design. For the same reason, one should not very much demand from the project developer significant savings in construction. It has been established through repeated experience that the attic provides a large increase in living space, but does not lead to a significant increase in construction costs.

By including a basement in a house construction project, you do not significantly increase its cost, but you significantly improve the quality of life in this home. Try to make the house proportional. The abundance of small rooms in a large house and vice versa will make living in it not very comfortable. Consider zoning in advance. You, most likely, will not really like it when smells from the kitchen hover in your bedroom.

Wall mount

For concrete, the screw selected is short enough, since the recommended depth for inserting hardware into such structures is 45 mm. For comparison, the holes in a brick wall are deeper - up to 55 mm. For cellular concrete, a depth of up to 75 mm is recommended. The less durable the material, the larger the fastener should be. Screws are placed using the same principle. If the structure of the material is loose, then holes are made in the wall into the structure as far apart as possible.

When studying the question of how to use such fasteners, it is necessary to assess the condition of the structures. Strength is ensured if the wall does not collapse. Concrete should not crumble; if there are cracks, the reliability of the structure is reduced. In this case, the use of the largest dowel will not provide the required result.

When work begins, determine the area for installing the first screw. For example, it is necessary to deviate from the corner by at least 60 mm. If you break this rule, the strength of the fastening will decrease. Under the influence of significant load, the structure will begin to collapse. This will lead to the collapse of the element, which was fixed with a screw in the concrete.

Recommendations for using the dowel:

- work is carried out according to a pre-drawn up project;

- markings are made on the structure;

- prepare the holes, and it is necessary to ensure that the cement does not crumble, and there should be no chips;

- if the material is porous, it is impossible to put pressure on the tool when inserting a screw into the concrete mass, since there is a risk of damaging the structure, as a result the screws will not hold, the structure will deform over time or immediately as soon as increased pressure is applied to the fastener .

During the work process, there are many nuances that should be taken into account.

Installation begins with preparing the tool. You will need a screwdriver, drill or screwdriver, concrete screws, hammer drill, and a container filled with water.

Instructions for performing the work:

- To prevent chipping, you need to clean the surface. If the structure has defects, you can level it using cement compounds and plaster.

- The load on the fastener is determined. Based on this, drills of the required length are selected.

- Work begins after marking the site.

- Concrete is a dense, durable material. The tool will get hot when drilling. To cool it, water is used. An alternative option is oil.

- If it is not possible to drill the concrete to the required depth, use a hammer. You need to hit the head with the screw several times. However, this method is used when the fasteners will not be subject to significant load.

Safety precautions at work

Equipment for drilling holes is characterized by complex operation and significant weight. You need to work with it carefully. In addition, as holes are made in the concrete for the dowel, solid particles fly in different directions.

To protect yourself, you need to follow the rules:

- You should not work with power tools while wearing gloves, as the material may get caught on the drill, which will lead to injury;

- use safety glasses, clothing should be closed, which will avoid injury from concrete splinters;

- the drill is periodically cooled - immersed in water;

- There should be no children or animals near the area where the work is being carried out.

If dust or solids get into the eyes or mucous membranes, rinse with running water and consult a doctor.