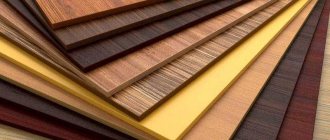

This is a beautiful, environmentally friendly finishing material made from natural wood. Made from dry planed boards, it is used for exterior and interior decoration. Service life: 15-20 years, and when using various impregnation liquids that protect the wood from moisture, insects, and direct sunlight, the service life increases.

The characteristics of the material are improved by the presence of special slots for ventilation, which do not allow condensation to accumulate on the reverse side. Adjacent planks fit together easily and tightly using grooves and projections that are deeper than those of a conventional clapboard board.

Dimensions of traditional eurolining:

- length from 1 to 6 meters;

- working surface width (excluding groove) 88 mm;

- overall width 96 mm;

- thickness 12.5 mm.

Knowing the features, it is easy to distinguish it from ordinary lining:

- more complex profile;

- presence of ventilation grooves;

- deep tongue-and-groove connection;

- specified humidity and high quality processing.

Types of wood lining

The number and location of irregularities, knots and roughness affects the class of the lining according to GOST:

- “Extra” class of lining – there are no defects, the surface is smooth and even.

- A-class lining - possible presence of knots. But other defects, such as cracks, holes, potholes in wooden panels of this class are unacceptable.

- B-class lining - there are cracks, knots, small depressions and holes, but elimination work - using putty - is carried out at the factory.

- C-class lining is the lowest quality class; the material contains holes and indentations, knots, and cracks.

“Extra” class cladding material is rarely made from solid wood. This is due to the fact that a single piece of wood is extremely difficult to turn into a smooth canvas, so the price for such a product would be catastrophically high. Therefore, the production of such panels is often carried out by splicing.

Production of Euromaterials

The production of eurolining is a lengthy process; it is understood as a multi-stage process, during which the following types of equipment cannot be avoided:

- Circular saw;

- End machine;

- Planing and thicknessing machines;

- Chamber for drying wood.

Modern production

The main component, without which it is impossible to imagine equipment for the production of eurolining, is a four-sided planing machine. It is necessary to install cutters on it, with the help of which a certain look is obtained.

Despite the presence of different classes of eurolining, their production technology is the same. After drying the raw material, wood, in a drying chamber, it is sent to the sawing stage, and then for processing. Direct separation into grades is carried out by a specialist while checking the quality of the resulting products.

This is interesting. There is another important parameter according to which eurolining is divided by quality type: GOST puts forward conditions that the moisture content of the material does not exceed 15%.

In order to obtain the highest quality cladding material, manufacturers are required to comply with all manufacturing rules, starting from the wood harvesting stage, which must be carried out taking into account seasonal conditions. An obligatory point is the implementation of the technology. It is also worth paying attention to such a stage as packaging, which should be done in a protective film, which will not only protect against damage, but also preserve its presentation.

Vozhega cladding board

Russia is distinguished by a large number of forests, which, of course, entails the development of the wood processing industry and the construction of wood processing plants in particular.

In construction hypermarkets (Leroy Merlin, Castorama and large construction markets) you can find products from such large companies as Velsky Les, VyatkaLesProm. Vozhega eurolining, manufactured in Vologda, has earned undoubted popularity.

Eurolining

The building materials market is gradually filling with a new type of cladding board - eurolining. It is produced from the part of the trunk located between the core and the bark. The structure of this layer of wood is uniform and durable.

The prefix “euro-” refers to the cross-section of the wood panel profile. The main difference is the board tenon, or rather its size. The length of the tenon of the eurolining is 8 mm, and the length of the regular canvas is 4 mm. Changes in ambient temperature or humidity can cause fluctuations in the width of wood paneling. This will cause gaps to appear if the width change is larger than the tenon size. Then the balcony will turn from a warm and cozy room into a ventilated room. Eurolining reduces the risk of such a situation, practically eliminating it: it is difficult to imagine natural conditions in which a tree, exposed to environmental influences, will increase in size by 8 mm.

Application options

Do-it-yourself finishing of eurolining walls inside a house involves preliminary preparation of the material. To ensure that the slats do not rot or swell from excess moisture during use, they must first be treated with a special protective agent.

Advice! To give the material additional expressiveness, you can use wood stain.

Drying impregnated wooden slats requires 2-3 days. During this time, the material will completely absorb the impregnation, and the rail will “get used” to the microclimate of the room. Next you need to make a sheathing for the slats. To do this, one-inch wooden blocks are attached to the wall at a distance of 50-60 cm. The lathing guarantees the creation of natural ventilation and prevents rotting of the eurolining.

Attention! If necessary, you can place insulating material, for example, tepid wool, between the wall and the sheathing bars.

After the preparatory stage is completed, you can begin installing the eurolining with your own hands. Installation of prepared slats can be done vertically or horizontally. The horizontal method is chosen by homeowners who plan to visually expand the space in the room. The vertical method helps to achieve the effect of “raising the ceiling”. If the ceiling is also made of natural wooden slats, you can install the lining on the walls in any way.

Horizontal method

During such an installation, it is advisable to place the grooves of the slats downwards, in which case dust and debris will not accumulate in them. Among the features of this method we highlight:

- the need to control the installation level through 7-10 rails;

- difficulty in fitting the last board;

- installation duration

Vertical method

Eurolining of different sizes is suitable for it. Installation begins from the corner of the room. Next, the boards are fastened into the groove of the previous batten; this is done similarly to the horizontal method of fastening eurolining.

Nuances of vertical mounting technology:

- The first board is fastened to the wooden sheathing using nails, the heads of which are hidden under decorative caps;

- the clamps are attached to the back wall, nailed to the sheathing;

- the edge board is fixed with nails

Tips for choosing

The first piece of advice applies to the purchase of cladding boards of all classes and types: be careful, unfortunately, cases of deception are not so rare. Unscrupulous sellers, offering the buyer high-quality lining, replace the canvases inside the package with lower quality ones. Ask to see all items before purchasing. If the seller refuses to fulfill the stated condition, it is better to protect yourself and find another place to buy.

Advice on choosing a tree

Conifers, as already mentioned, are the most popular: the resin they contain has an antifungal effect and helps reduce humidity levels. Therefore, such boards are often used for exterior finishing of buildings.

Hardwood panels are suitable for interior cladding of ceilings and walls in a living room, bathroom or bathhouse. Such boards (aspen, linden or alder) are able to withstand humidity and high temperatures without heating up.

Hardwood linings do not contain resins, which will save you from worrying about the appearance of the finish when doing interior work.

Advice on choosing a class

Facades, balconies, walls of baths and saunas are objects for which cladding with class A wooden panels will be a suitable solution both in terms of functionality and in terms of presentable appearance.

Class C is only suitable for finishing utility buildings: sheds, garages, and so on.

“Extra” and B classes are used by everyone depending on the amount of funds allocated for the purchase of wood.

Any class and type of cladding wood will last a long time and live up to expectations. The main thing is to choose boards whose functions will meet the assigned tasks.

For example, A-class panels made of hardwood when covering the walls of a bathhouse or sauna will enhance the healing effect of staying in such a place. And thanks to “Extra” coniferous cladding boards, you won’t have to worry about the reliability and strength of the cladding - the facade of the house will be reliably protected.

Classification

Currently, eurolining is divided by the wood chosen for production, as well as by profile.

Subdivision by profile. Manufacturers offer regular eurolining. In its manufacture, GOST 8242-88 is used. In addition, you can purchase eurolining made according to the DIN 68126 standard. Eurolining and lining have differences in dimensions, humidity, and technology for processing the front surface.

Regardless of the type, this material has a special tongue and groove, located at opposite ends of the board. Eurolining calm has additional ventilation strips that are located along the entire length of the board. They allow you to remove condensation from the surface and increase the performance characteristics of the board. Eurolining made of pine has a deep groove joint, so when the wood dries out, there are no gaps between the boards.

You can purchase various types of profiles:

- American (“under the beam”);

- block house

Attention! High-quality eurolining has a length of 2 meters, a width of 10 cm, and a thickness of at least 1 cm.

The “American” profile imitates natural timber. This type is distinguished by its massive dimensions, the width of the board is from 14 centimeters, the thickness reaches 2-2.5 cm, and the length is offered in the range of 2-6 meters. Such massive dimensions make this finishing material inappropriate for interior decoration.

The “block house” profile is an imitation of round logs. The board has a rounded shape on the front side, suitable for exterior decoration.

According to the wood used, eurolining is divided into several types.

- Hardwoods are used for the manufacture of finishing materials, ideal for interior decoration of steam rooms. Deciduous wood has increased rigidity, perfectly retains its texture and shape, and protects walls from excess moisture accumulation.

- Coniferous wood is suitable for interior decoration and is distinguished by its aesthetic appearance. Spruce and pine are not suitable for lining bathhouses, the reason is the pungent odor, as well as the release of resin.

You can watch the video for more information on how to decorate rooms.

Self-installation of lining

Wooden panels are not only an aesthetically pleasing, but also an easy-to-install finishing option. The main advantage in installation is the tongue-and-groove fastening method. In order to cover a balcony yourself, you do not need knowledge or skills, only a minimum set of tools and assembly instructions. Lining is a dry material that does not require special conditions for work: only damp weather for external work and heating for internal work in the cold season.

Exterior decoration

The scope of application of wooden panels is wide due to the pleasant appearance and strength of the material. The external cladding of the building requires laying the canvas horizontally, from bottom to top. The cladding planks must be laid on top of each other, and the joints must be treated with special means. For example, polyurethane mastic is used to avoid problems with excessive moisture, as well as to provide thermal and sound insulation.

Internal lining

Decorating the inside of a room does not require special settings for the position of the panels: the boards can be laid both vertically and horizontally. In rooms where the humidity is higher than normal, it is advisable to position the linings vertically so that water does not accumulate in the grooves.

A factor that is important to remember when decorating a building is ventilation. Special openings are required to allow air movement. Protect the system from excess moisture; 20-40 cm are not covered with panels.

Wood care

Caring for wooden cladding panels is simple. Just remember the rules:

Firstly, excessive moisture leads to a decrease in the quality of the wood, so wooden cladding should not be wetted. The use of abrasive detergents and solvents is also unacceptable - this will destroy the surface of the wood. Contaminants are removed from the canvas with a dry or slightly damp soft cloth. In cases where it is necessary to remove caustic stains, a weak solvent is allowed.

Secondly, to extend the life of wooden cladding, the material should be treated with special compounds. Similar measures are recommended when the façade of a house or a room with a high level of humidity (saunas, baths, baths) is covered with wooden clapboard.

Advantages of finishing

- Natural wood is harmless and suitable for finishing rooms and buildings for any purpose.

- By creating a special microclimate in the room, the material absorbs excess moisture and keeps the room warm.

- Has soundproofing properties.

- Large price range. Inexpensive wood, the presence of minor defects in the form of knots allows you to choose the ideal option for a room of any size.

- Easy installation thanks to perfectly straight sides and a tongue-and-groove connection.

Finishing material with dark knots can be painted with opaque paints if desired. Installation is carried out using clamps - galvanized steel brackets or special nails. Watch the video for the installation process of eurolining:

Difference by class, video

In stores there are mixed grades, for example, euro-lining grades A, B or calm lining B, C. Differences in varieties vary from manufacturer to manufacturer. Some in the premium class do not allow the presence of knots at all, while others allow them in the smallest quantity, as they are guided by their parameters.

In any case, when choosing a blade, you will have to take into account all the parameters of the differences between the models, conduct a visual inspection and apply knowledge of the capabilities of the wood used.