In construction terminology, dowels mean rounded rods or bars designed for fastening building parts by installing them in specially prepared holes. The main purpose of dowel connections is to counteract shear forces due to the elasticity of the dowel body.

A wooden dowel for timber is called a dowel or a wooden nail; dowel (dowel) connections are used in the construction of log houses for residential buildings, bathhouses and outbuildings, and are used in the installation of various wooden structures. The technology has a long history; similar fastenings were discovered in buildings of the 16th century on the territory of modern Austria and during excavations in Veliky Novgorod.

Advantages and disadvantages of dowel joints

The advantages of using wooden dowel connections have been tested for centuries, these include:

- Dowels for timber are resistant to deformation, retain elasticity for a long time, and withstand significant bending loads;

- Fastenings counteract the negative consequences of shrinkage, eliminate the causes of the formation of cracks, crevices and gaps between the crowns;

- The timber and dowels react equally to ambient humidity and climate changes, which avoids wall deformation;

- The use of wooden fasteners allows you to build a house without the use of construction equipment and special tools.

The disadvantages include: additional labor costs due to the need to drill installation holes; when selecting materials and carrying out work, certain rules must be followed.

Device

A dowel (another name is a screw) is a metal rod on which a thread is applied. On one side, the fastening element is pointed, which allows it to be inserted into a dense concrete mass. On the other side there is a head with a notch.

Hardware must withstand significant loads of torsion, compression and tension. Such properties are due to the characteristics of the metal from which concrete screws (pins) are made.

Possible options:

- carbon metal;

- stainless steel;

- brass (an alloy of copper and zinc).

The first option is characterized by strength and ductility. However, only high-alloy steels have these characteristics. They are designed for the production of structural and fastening elements that will be subject to significant loads.

Stainless steel differs from its analogues in its ability to withstand moisture. Products made from this material do not rust. They are more affordable in price when compared with some types of fasteners. Hardware is made from stainless steel containing alloying elements.

A concrete screw (nail) made of brass is characterized by high strength, but mediocre anti-corrosion properties. When environmental conditions change, the products do not become brittle, which is important for fasteners.

Despite a number of positive properties of other materials, self-tapping screws for concrete are often made from carbon steel.

Types of wooden dowels

Dowel cross-sectional shapes

Dowels for timber can have a round, square or rectangular cross-section. It is difficult to cut a square-shaped seat in the body of the beam; for this reason, at home, fasteners of any shape are installed in round holes; the diameter depends on the size of the dowel and should ensure installation “in tension.” Each type of fastening has its own advantages and disadvantages:

- Round dowels (cylindrical) provide maximum area of contact with the walls of the mounting holes, are able to withstand significant loads, and are used to strengthen external walls and corners of the log house. Installing such fasteners “in tension” requires considerable effort. Dowels for round-shaped timber are difficult to make at home; for this you need to have a lathe;

- Dowels for square beams are used in the construction of light buildings and when laying internal partitions. When installed “under tension”, the entire load falls on the sharp edges, which evenly crush and increase the contact area; it is much easier to hammer in such a dowel. You can make a square-shaped mount from cutting a board with your own hands using available tools;

- A flat dowel of rectangular cross-section is a lightweight version of a square dowel, used when installing door and window openings, assembling light and decorative structures.

According to GOST R 56711-2015B, cylindrical dowels are the main fastening element for holding and splicing solid and laminated lumber.

Master's note: to date there is no consensus on the question of which dowels are best to use when laying a log house; some craftsmen prefer dowels with a square cross-section. This fastening ensures freer movement of the timber relative to the dowel ribs and prevents the development of negative processes during shrinkage.

Material requirements

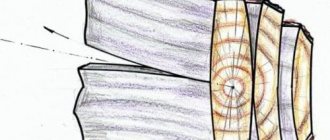

Dowel connections are subject to significant shear, bending and torsion loads. For this reason, round dowels are made of durable wood - this can be oak, larch and birch. For blanks, choose high-grade wood of natural moisture, without knots, with smooth and undamaged fibers. The surface of the finished fasteners is polished using abrasive.

When choosing a material, the following recommendations must be taken into account:

- For beams made of pine or spruce, it is better to use birch dowels;

- When building from larch timber, the fastenings can be made of the same material;

- For laminated veneer lumber and LVL timber, chamber-dried oak is used.

Dowels for square and flat beams can be made from specially selected high-quality lumber used in construction.

Pin sizes and hole diameters

Recommendations for choosing the size of dowel connections are set out in regulatory documents on construction design (SNiP), including: the cross-sectional diameter of round dowels should be no more than 1/6 of the width of the beam, the length should be 1.5 times the height of the beam. The diameter of the landing holes is made 0.5-1.0 mm less than the diameter of the dowel.

It is easy to calculate that when building from 180x180 timber, it is necessary to use dowels with a diameter of 30 mm, a length of more than 270 mm, and the diameter of the holes for installing fasteners is 31 mm. Specialized stores offer dowels in the following sizes: cylindrical with a diameter from 15 to 30 mm, square with a side from 20 to 25 mm, length of blanks - up to 1100 mm.

Purpose and classification of dowel

The purpose of the dowel is to ensure reliable fastening of various structures to solid foundations. The adhesion strength is due to the notches, which is why the fasteners hold well in substrates of different compositions. The deeper the dowel is fixed, and the longer its length, the higher its load-bearing capacity. Therefore, the tool is most often used when installing doors, windows, hanging furniture, chandeliers, and radiators.

Concrete dowels can be classified according to:

- type of protective layer (color);

- head type;

- threading.

The color of the dowel is a type of protective layer. The following types exist:

- blackened (oxidized), which is suitable for interior work in rooms with normal humidity levels;

- brass is used only for interior work;

- galvanized (zinc treatment is used) - universal, can be used anywhere, it is resistant to kinks, scratches and rust.

Shape of the screw head (dowel) for concrete - TORX

Based on the shape of the head, the following can be distinguished:

- stud with threaded fitting for fastening the nut;

- countersunk head in the form of a cone with cross-shaped slots;

- hexagon: to tighten it, you will need a box or open-end wrench;

- the head of a rectangle (croc) in the form of a loop-shaped anchor. Used for chandeliers, cornices, hanging swings, cabinets;

- type of torx head - specific dowels for an imbus wrench.

Type of thread of the screw (dowel) for concrete - screw

Thread form:

- herringbone thread - universal fastener, used in conjunction with a dowel pair: you need to drill a hole for the dowel, and then, using a screwdriver, screw the hardware into it;

- screw thread. Hardware with this type of thread is universal and is used to perform a wide range of tasks: it can be used either independently or in combination with a dowel;

- replaceable threading facilitates adhesion, ensuring a tight connection and does not allow the fastener to become loose. The hardware is used independently; it is necessary to pre-drill the hole.

How to make a dowel with your own hands

DIY Nagel

It is advisable to buy a complete set of dowels for building a house; if a few pieces are not enough, you can make dowels yourself. If your household does not have a lathe, you can use a shovel handle. The diameter of the handle is 39-40 mm - this is a lot for a dowel; the excess must be removed with an ax and a plane. A chamfer is removed from the seating edge to form a cone 7-10 mm high, and the surface is cleaned of unevenness using sandpaper. Rectangular dowels for timber are cut from scrap boards using a circular saw or jigsaw, on the seating side the edges of the ribs are cut at an angle of 45-60 degrees, the surface is subjected to finishing (grinding).

Fastening technology

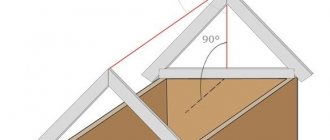

Diagram of the dowel connection device

To install the dowel, you will need to perform a number of operations in the following sequence: make markings, drill a mounting hole, install the mount in the prepared hole.

Calculations and markings

The requirements for dowel connections are determined by SNiP 2.01.07-85; when installing dowels, the following rules must be observed:

- The crowns of the log house, corners and junctions of internal walls are subject to fastening;

- Seating places are located along the entire perimeter of the log house at a distance of 1.5-2.0 m;

- Each beam must be fastened to the lower and upper rows with a separate dowel;

- In each crown, the landing hole is shifted by 0.5 m, repeating the configuration is allowed after 2-3 rows;

- Holes are drilled in the center of the beam, with a depth of 15-20 mm greater than the length of the dowels.

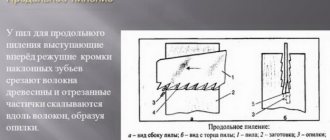

Drilling

To drill mounting holes with a diameter of more than 12 mm, use low-speed drills with a power of at least 1200 W with two handles. The drill must meet the following requirements: exceed the length of the mounting pins by 30-35 mm and ensure chip removal. The best solution would be to use wood router bits. It is necessary to decide on the diameter of the drill and dowel at the design stage; you should have 7-8 drills in stock.

A hole is drilled in two crowns at once; to prevent shifting, the upper and lower beams must be securely fixed; for this you can use construction staples.

Installation

The dowels are installed in the mounting holes with tension; for this, significant force must be applied; the deeper the rod goes into the hole, the greater the force must be applied. The danger is that when driven into the timber, the dowel may crack and the upper part may become wet. You can reduce friction with a soap solution; you cannot use paraffin or technical lubricants for these purposes.

You should have a wooden or rubber mallet, a heavy and a light hammer on hand. The blows are applied strictly vertically; when using a metal tool, it is necessary to use a protective pad made from a piece of thin board or multi-layer plywood. If a crack develops in the rod during installation, it must be drilled out and the operation repeated.

How to choose the right dowel

When you plan to purchase concrete screws, the application (intended purpose) of such fasteners is one of the criteria. This is due to the fact that the parameters are determined by the material and the type of thread of the hardware.

Criterias of choice:

- the type of structure, the material from which it is made, while considering different screws that differ in properties, type of coating, for example, to fix heavy structures of more than 100 kg, products with a length of 150 cm are used;

- choose products according to the type of head: protruding, hidden;

- The type of slot also plays a role, and you need to choose the right tool;

- a type of thread, which determines the method of installing hardware (with dowels, in a finished hole, etc.);

- operating conditions, some types of fasteners are negatively affected by moisture.

Difference between wood and metal nails

The question is often asked on various construction forums: can a wooden dowel for timber be replaced with metal nails or rods. Despite the fact that it is easier to work with metal nails, such a replacement is unacceptable for the following reasons:

- The main purpose of dowel connections is to resist shear forces due to elasticity; mass-produced metal nails do not have such properties;

- Metal fasteners form a rigid coupling of wooden parts; such fastening prevents shrinkage processes and can lead to distortion of the walls, contributes to the formation of cracks and cracks;

- When driven, nails tear wood fibers, deep internal cracks form, and together with the metal, this contributes to the formation of cold bridges.

Wooden dowel for timber and logs. Assembly and connection features

A large number of foreign words have become entrenched in Russian wooden architecture. They became so firmly established in everyday life that they began to change their original meaning. One of these words is “nail”. Let’s figure it out: “ What is a dowel ?”

The German word " Nagel " translates as "nail", which is any nail, regardless of material or shape and size. If the nail is made of wood, then it will be “ Holznagel ”. Like the carriage, the dowel has come into common use so tightly that even a separate concept of “dowel joints” has been included in regulatory documents.

A dowel connection (GOST R 56711 - 2015) is a connection of structural elements made using cylindrical or plate dowels made of different materials, which are tightly installed in pre-prepared holes and work in shear, which is accompanied by bending of the dowel.

Splicing logs in a bowl using a dowel

Splicing a log in a bowl using an iron staple

According to the description, a dowel connection is very similar to a dowel connection: a hole is also pre-drilled. But, if the dowel works in conjunction with another fastening element: a screw, a self-tapping screw, a nail, then the dowel is this fastening element. In addition, the dowel works for shear, transverse displacement, and the dowel works for tearing out.

The dowel can be made from materials that have sufficient elasticity: wood, metal, plastic.

Dowel (in construction) - a mechanical connection of a cylindrical or plate shape for the perception of shear forces. In wooden house construction, a dowel is understood as a wooden fastener of different lengths, diameters and shapes . In fact, a dowel and a dowel are one and the same thing, but if the latter is more often used for end connections (this can be seen even from the name “edge” ~ “end”), then the dowel is used for planes.