A hacksaw, or as it is also called, a wood saw, is a tool that should be in every home, and even more so in every dacha. But choosing a hacksaw for wood is not as simple as it seems, and further on, we will analyze in detail the types of tools, you will learn about the configuration and purpose of various types of teeth, we will “go through” famous brands, and finally I will tell you what a reciprocating electric hacksaw for wood is and how to choose it.

Hacksaw rating

For testing, we selected a tool that can be found in every hardware store. We studied the quality and features of the product, ergonomics during use. When compiling the rating, we took into account user reviews, opinions of professional carpenters, mechanics, and gardeners. The main attention was paid to the following characteristics:

- Fabric – the quality and basic parameters of steel were studied;

- Purpose – a specialized and universal tool was tested;

- Teeth – analyzed the size, shape and their compliance with the processing material;

- Handle – should fit comfortably in your hand and not slip while sawing;

- Equipment - they produce kits with a carrying and storage case and a sharpener.

Low metal strength, poor sharpening quality, mechanical defects in the handle - a tool with such a defect was excluded from our rating.

The best manufacturers of imitation timber

Hacksaw blade

In principle, this is the instrument itself. The most important parameter of the canvas is its length. It is this that determines the range of application possibilities. However, the longer the blade, the stronger the spring, which makes working with hard wood such as oak, ash or maple especially difficult. For sawing small objects such as plinths, bars or narrow slats, a hand-held wood hacksaw with a blade length of 25-30 cm . For more serious work, you need a tool with a blade 45-50 cm .

A simple rule for determining the length: the blade should be twice the diameter of the logs that will be sawed with it. The teeth of a short hacksaw will jam in the wood, requiring much more effort to work, which will quickly cause fatigue. The width of the blade usually varies in the range of 10−20 cm. A narrower blade is not allowed, as it breaks at the slightest bend, but an overly wide blade is inconvenient to work with your hands.

The best hacksaws for wood

Boards, timber, floor lath, eurolining - all these materials are cut using a hand saw. The wood is processed along and across the grain, which is taken into account by tool manufacturers. A carpenter with 23 years of experience found out which hacksaw was better for wood. Out of 9 samples, the craftsmen chose 4 options, which attracted attention with the quality of the blade, good sharpening and ergonomic handles.

Armero A531/400

The model of the famous Spanish company was created for working with wood and blanks made from this material. The blade is made of tool carbon steel with a high chromium content, this has improved hardening. The metal holds its edge well, which reduces the cost of routine maintenance. It has good elasticity and resistance to mechanical stress. The protective coating prevents corrosion.

The length of 40 cm makes the saw convenient for cutting 150-200 mm boards, facing strips and moldings. Medium tooth size and pitch (9 pcs per inch), 3D factory sharpening ensures a neat cross cut. Works well with wood of different densities. Does not tear fibers and does not require strong pressure when sawing.

Advantages:

- Light weight;

- Does not deform during operation;

- Low price;

- High performance;

- Difficult to blunt.

Flaws:

- Not detected.

The saw has a two-component handle made of impact-resistant and anti-slip material. The shape takes into account the anatomical features of the palm: the instrument fits well in the hand and does not leave calluses during intensive use.

Gross Piranha 24111

A good hand saw for wood with a fine tooth (frequency 11-12 per inch), developed by German engineers. Easily copes with different species, can be used for cutting chipboard, fiberboard, HDF, laminate. Can be used for cutting expanded polystyrene. Equally effective for transverse and longitudinal cuts of dense, loose wood. Durability is ensured by carbon steel with a protective coating that contains corrosion inhibitors.

It has a 3D sharpening, the edge is treated with Teflon, which reduces the applied physical effort. The cut is smooth, according to user reviews, and is not inferior in quality to processing with a circular saw. The two-component handle is made of rubberized plastic and provides a secure grip. When used for a long time, it does not require effort and does not get stuck in the wood.

Advantages:

- Good sharpening;

- Protective case included;

- Storage hole on hooks;

- Suitable for fine finishing.

Flaws:

- Overcharge.

Irwin Xpert 10505538

The American brand hacksaw is made in Denmark. The blade is made of tool steel 1 mm thick. This makes the model reliable, durable, and tough. A special coating with inhibitors protects against corrosion. At the beginning of the blade there are small teeth that make cutting easy. The main blade is a medium-sized hardened tooth with 3D sharpening and special holes that increase the rate of chip removal.

The handle is two-component, made of impact-resistant polymer and rubberized material. It is secured with three bolts and does not loosen during intensive use. The side surfaces of the handle are made with strict adherence to angles of 45 and 90 degrees, which allows you to avoid wasting time using a measuring tool when cutting boards. Design features make sawing with raw wood easier.

Advantages:

- High performance;

- Wear resistance;

- Hole for hanging during storage;

- Sharp sharpening;

- Clean, neat cut.

Flaws:

- Not detected.

Bison Expert 15168-18

Small folding wood saw for auxiliary work on a construction site, cutting branches. The hacksaw blade is made of heat-treated carbon tool steel and is protected from external aggressive factors by an anti-corrosion coating. Medium-length teeth are arranged in increments of 9 pieces. per inch. The profile of the cutting edge and the length make it easy to cope with sawing 50x50 mm timber and trimming molded products.

The handle is a two-component format, made using durable materials and taking into account the anatomy of the human hand. Does not slip out in wet weather or when force is required. The blade folds and locks securely, providing a high level of safety. A good option for a hiking trip.

Advantages:

- High quality steel;

- High-quality factory sharpening;

- Possibility to replace the blade;

- Sawing raw wood.

Flaws:

- Not suitable for intensive use.

Criterias of choice

The main purpose of a hand saw is longitudinal or cross cutting of wood, as well as materials based on it or similar in properties. When choosing a tool, the following series of parameters are primarily taken into account:

- Purpose.

- Teeth parameters.

- Blade steel type.

- Length and geometry of the canvas.

- Handle shape.

Let us analyze in detail the features of choice for each of them.

Purpose

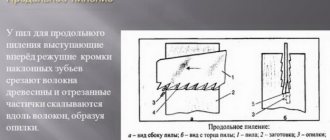

The first thing you need to know in order to choose the right hacksaw for wood is the type of work performed with it. At the same time, they are classified according to two criteria - type of cut and purpose. According to the nature of the cut, hand saws are divided into 3 main types:

- Longitudinal. They are equipped with teeth with a sharpening angle of about 45-60 degrees. Provides a unidirectional, uniform, precise cut. Therefore, they are used for finishing, in the manufacture of furniture and interior items.

- Transverse. They are characterized by a tooth sharpening angle of the order of 45-55 degrees. Used for cutting in both directions, mainly on dry material.

Cross cutting of a wooden blank Source domnomore.com

- Universal. The blade has two types of teeth - semicircular and triangular. The first ones set the direction of movement, the second ones expand the seam. The closer the teeth are located to each other, the higher the cutting accuracy.

According to their purpose, hand saws are classified into classic, tenon and circular saws. The former are used as a standard, the latter - for the formation of technological tongue-and-groove joints, the latter - for creating rounded shapes and holes.

Teeth parameters

The second important criterion when choosing a saw is the parameters of the teeth. This is primarily their size, which is also directly related to the distance between their tips - the pitch. There are three main groups:

- Small ones. The tooth size is 2-2.5 mm. In this case, the number of teeth (TPI index) for a given length (usually an inch) is 7-9. Used for high-quality precision cutting.

- Average. The teeth are 3-3.5 mm in size. The TPI indicator is 5-7. Used in carpentry work.

- Large ones. The dimensions of the teeth reach 4-6 mm. TPI – 3-5. A wood hacksaw with a large tooth is used for rough work - cutting firewood, building materials - when high speed is required.

Hand saw for wood with large teeth Source domnomore.com

On a note! Modern models of hand saws have a cutting part structure in which teeth alternate with voids. This makes it possible to use the tool on both dry and wet wood. When cutting fresh wood, wet sawdust can be easily removed through the gaps. Thanks to this, the saw does not get stuck and gets the job done quickly.

Blade steel type

Despite the fact that the wood saw is used in mild conditions, its blade is still made of high-quality steel alloys. These are mainly brands such as - 8ХФ, 65Г, У7 - У10, etc. Their main feature is wear resistance, achieved by the inclusion of silicon and carbon in the composition.

However, in order to save money, some manufacturers make blades from ordinary steel and make the cutting part high-strength. Moreover, if the teeth have a hardened structure, which is usually reflected in their characteristic black color, then after inevitable wear they cannot be repaired. At the same time, analogues made of non-hardened steel can be periodically undermined as they wear out.

Sharpening the cutting part of a hand saw for wood Source domnomore.com

See also: Catalog of companies that specialize in finishing materials and related work

Length and geometry of the canvas

In order to choose the right wood hacksaw for optimal and fast sawing in accordance with specific application conditions, it is necessary to take into account the length of the blade. This parameter, as a rule, has a direct relationship with the characteristics of the pitch and size of the teeth, and divides saws into 3 main categories:

- Narrow canvas 250-350 mm long. Equipped with small, frequently spaced teeth.

- Universal saw with a blade of 350-550 mm. Has medium sized teeth.

- Wide canvas with a length of 550-650 mm. equipped with large teeth with increased pitch.

The geometry of the canvas can also vary depending on the purpose. Thus, standard saws have the shape of a beveled rectangle. Special models are equipped with a curved canvas. For example, a branch cutter has the shape of a curved saber, which makes it easy and convenient to work with when trimming garden trees and shrubs.

To trim branches of garden trees, it is convenient to use a specially shaped saw Source domnomore.com

Important! When choosing a saw for specific application conditions, the ratio of the length of the blade and the thickness of the workpiece is not the least important. It should be at least 2 times larger. Otherwise, it will be inconvenient for her to saw: the amplitude of the cut will be insufficient, and the blade will constantly jam.

Handle shape

The shape and size of the handle can have a wide variety of variations - this depends on the type of work being carried out, conditions, anthropometry and user requirements. The main thing is that it is comfortable, fits ergonomically in your hand and does not slip.

Recommendation! For thrifty owners, when equipping a home workshop, the best option for a wood hacksaw would be a model with removable blades. It takes up less storage space and ultimately costs much less than a whole set of hand saws for each application.

The best hacksaws for metal

A special feature of a manual hacksaw for metal is a short and narrow blade with a very small multi-directional tooth. The blade is fixed in a steel frame, replacement is carried out quickly. The tool is characterized by mandatory hardening and the use of high-speed steel. The cutting element is under constant high thermal loads and periodically fails, so several blades are needed to complete the task. Used in home and locksmith workshops.

Vira 801010

The metal model is lightweight; the body is made of durable, corrosion-resistant aluminum alloy. The structure is rigid and does not deform under load. A cutting element 30 cm long is installed; the set includes a 24 TPI blade made of heat-resistant tool steel. The screw clamp allows you to fix the file at a convenient angle.

The handle is made of impact-resistant plastic and rubberized material, fits well in the palm of your hand and does not slip. According to reviews, the profile reduces the load on the hand during intensive and prolonged work. There is no play in the handle, which has a positive effect on the quality of the cut. Designed for processing metal workpieces.

Advantages:

- Quick blade replacement;

- Low price;

- Anatomical handle;

- High strength.

Flaws:

- Not the most reliable blade included.

Matrix 77593

A metal hacksaw for a blade 30 cm long. To replace the cutting element, a screw clamp is provided, with which you can vary the angle of inclination. Two positions are available - 55 and 90 degrees, which expands the application possibilities. The delivery set includes a bimetallic blade with a fine tooth, which ensures accurate cutting of workpieces.

The rigid, reinforced frame has a rectangular cross-section and is protected from corrosion by powder coating. The design has a cavity - this container can store 5 replacement sheets. The tension mechanism securely fixes the blade, which contributes to precision when performing metalwork.

Advantages:

- Light weight;

- The tensioning mechanism does not become loose during use;

- Effectively processes laminate, chipboard;

- Low price;

- Comfortable handle.

Flaws:

- Weak fixation of the container stopper.

Stanley Heavy Duty 1-20-110

It has a durable steel frame that is resistant to deformation and mechanical stress. There is a container in the upper part in which you can store replacement blades. The blade is mounted using a screw spring mechanism, which makes the tension stable. The rigidity of the structure improves productivity and allows the processing of metal workpieces made of hard alloys.

The handle has an anatomical shape and is made of rubberized material. When sawing, it does not slip, does not rub, or cut the palm. The inclined frame design optimizes force. It is equipped with a blade made of tool hardened steel, the teeth are small, frequent, and sharply sharpened. The blade has increased wear resistance.

Advantages:

- Increased service life of all structural elements;

- Reliable fixation of tension force;

- Light weight;

- Carefully cuts metal;

- Good protection against rust.

Flaws:

- Overcharge.

Manual option

Any tool, regardless of its purpose, has its basic characteristics. A hand saw for wood is classified according to the length of the blade, the type of steel from which the blade is made and the configuration of the handle.

But the main parameter is the size, inclination, pitch and type of tooth, and this characteristic is common for both manual and electric tools.

Profile characteristics of a hand saw

The length of the hacksaw blade depends, first of all, on the purpose for which and how often you plan to use the tool. In a city apartment, for periodic, one-time use, 280 - 300 mm is quite sufficient. A folding wood hacksaw works well here.

Removable short panels.

For a private home, construction site or dacha, it is advisable to buy a tool with a blade of about half a meter. Longer models already belong to a narrowly professional area and are not suitable for a wide range of consumers.

Tip: there is a simple rule - the length of the blade should be at least twice the length of the workpiece you are going to cut. Otherwise, the sawdust will not be completely removed, the cut will constantly become clogged and the hacksaw will jam.

As for the steel grade, now manufacturers often make combined blades with a hardened cutting edge. The main body is made of HRC45 grade metal, and the cutting edge with teeth is made of HRC55 or HRC60 steel. These models are easily distinguished by their dark cutting edge.

Hardened edge.

The handles of hand saws for wood can be reversible or stationary. The removable flip-over version is more preferable, since you can buy several profile sheets and change them if necessary.

The type of tooth is important

The effectiveness of your work will depend on this characteristic. Moreover, these parameters are the same for both electric and hand tools. A fine-tooth wood saw is used for precise and even cutting, but the work speed here will be low. If you work in the garden or simply cut wood, then a wood hacksaw with a large tooth will be more suitable for you.

Miniature model.

All types of hacksaws for wood have markings that characterize the number of teeth per 1 inch, this is about 30 mm, this is designated as TPI. The higher this value, the smaller the tooth and the cleaner the cut. For chipboard and other similar materials, take TPI-7 or 9. For firewood, TPI-3 or 6. For non-target home use, it is better to take the middle option.

- The dagger-type tooth is made in the form of an isosceles triangle. It is sharpened at an acute angle, on both sides. This configuration allows cutting in any direction, but predominantly across the grain. When moving along the fibers, the blade does not cut, but splits the wood, which is why the hacksaw will constantly wedge.

Dagger tooth.

- The chisel-shaped tooth configuration has the shape of a triangle inclined towards the cut. Sharpening here is done from the side that is across the blade and acts like a chisel. This shape works well along the grain, but you cannot cut across it.

Chisel tooth.

- An oblique inclined tooth is considered universal. Having an asymmetrical shape, such a tooth is something in between. It is no longer dagger-shaped, but also not chisel-shaped. The leading edge here is sharpened at 60º, thanks to which it cuts well lengthwise. When cutting across, the sharp vertices of the triangles bite into the solid well, so a blunter sharpening angle does not affect the quality of the cut.

Oblique universal tooth.

- A tooth that has a sharpened top is often called triangular, although in fact this is not entirely true. In this way, a dagger or oblique universal tooth can be sharpened. The ground top forms additional cutting surfaces, which allows you to cut the array in any direction.

A tooth with a ground tip.

- The Japanese saw tooth is a rather complex sharpening configuration that allows you to do without setting. It uses a wedge-shaped blade. The triangle is inclined towards the handle, and the cut occurs only when the blade moves towards the worker. This technology is typical for Japan, hence the name.

Japanese tooth.

- This type of wolf tooth is characterized by the presence of wide gaps between the teeth and is intended for cutting raw wood. There are several other similar forms with passes, their names are different, but the purpose is the same.

Wolf tooth.

Tip: the instructions for sharpening and setting teeth have a lot of subtleties and small nuances. Therefore, it is not recommended to do such work with your own hands without appropriate training. In this case, it is better to pay a specialist.

Tooth pitch.

How to choose a handsaw

In the market, you may come across the question of whether you need a hacksaw for carpentry or carpentry? This refers to the cleanliness of the cut; the carpentry tool comes with a large number of teeth and is designed for delicate work with dry solids. Naturally, the carpenter's blade is designed for rough but quick work with any mass.

Hand saw option.

Pay attention to the sharpening and presence of wiring. Now you can come across a raw canvas, the so-called blank. Its price is low, but such a tool additionally requires wiring and sharpening. If you are far from this topic and are buying a saw for periodic work in the country, then it is better to immediately take a hacksaw with a hardened blade. It cannot be sharpened, but its lifespan will last you a long time.

Tip: the quality of steel is easy to check. Take the canvas and check that it is initially even. Then bend it 30 - 45º and release. Upon subsequent inspection, the deviation at the bend location should not exceed 2 mm. If more, then the steel is of low quality.

The best garden hacksaws

A hand saw for pruning garden trees is used by summer residents, owners of personal plots, and personnel of municipal municipal services. A special feature of the design is a small, tapered blade, the shape of which is convenient for use in the branchy crown of trees. The size and shape of the tooth make sawing dry and wet wood equally effective. Some models are equipped with devices for cutting at high heights.

Skrab 28154

Garden saw for processing tree crowns. Equipped with a lightweight, durable telescopic aluminum rod that extends up to 5 meters. The pole saw is equipped with a hook that limits slipping, allowing you to quickly and accurately saw off a branch at a great height. The handle is rubberized, made of anti-slip material and provides a comfortable grip. According to user reviews, its shape reduces the load on the hand when working without a barbell.

The blade is made from hardened tool steel, resistant to wear. Protective anti-corrosion coating prolongs service life. The teeth with variable pitch are sharpened and easily cope with branches with a diameter of 10-15 cm. High quality steel stabilizes the quality of the cut. This allows you to do without additional wiring and sharpening.

Advantages:

- Light weight;

- It is convenient to work among branches;

- Blade protection cover;

- Free return.

Flaws:

- Soft metal limiters.

Grinda 8-151853

The model is designed for routine maintenance of garden trees. It has an ergonomic curved handle, the shape of which simplifies sawing in cramped conditions. The handle is made of two-component plastic, does not slip, does not rub during intensive use. There is a hole for hanging storage.

The 30 cm long blade is made of carbon steel and has a chrome-plated surface that is resistant to corrosion. Reverse bevel teeth are designed for cutting dry and wet branches. Induction hardening and triangular sharpening ensure high performance. Supplied with a plastic sheath with belt mounts.

Advantages:

- Good at sawing workpieces of various types;

- Long service life;

- No constant sharpening required;

- Sawing effortlessly.

Flaws:

- Not detected.

Opinel №12

The world-famous French knife manufacturer produces the best garden saws. Wear-resistant tool steel with increased strength, 1 mm thick, is used for production. The model has a folding design, which makes it relevant for summer residents and tourists. It is equipped with a vibrating locking ring that protects against accidental folding and serious injuries.

The fine, double-pointed tooth effectively cuts through dry and damp wood. The “pull” working movement allows you to reduce physical stress on the user. The handle is made of beech wood and is highly durable and resistant to shock loads. The shape of the handle takes into account the specific anatomy of the user's palm.

Advantages:

- Long service life;

- Reliable folding mechanism;

- No regular sharpening required;

- Copes well with branches of any thickness.

Flaws:

- High price.

Types of hand saws for wood

It is impossible to say for sure which hacksaw is better for wood. There are different options for different types of work. Let's describe them.

- Small narrow saw . The components are a straight flat blade and a handle. This tool is used to perform delicate tasks: sawing out curved parts, making through cuts. The blades have triangular double-sided teeth or parallel sharpening. The disadvantage is that when pressed, the blade may deviate from the specified direction.

- Standard hand saw . It can have any type of teeth and is often equipped with replaceable blades of different types and designs. Despite their stated versatility, these saws are not advisable to use for furniture making.

- With a butt . Narrow and ordinary saws tend to bend when processing materials of increased rigidity. In such cases, it is effective to use a fabric with a backing, which serves as a kind of stiffening rib. Thanks to this element, the saw cannot make a cut deeper than the width of the blade, as it prevents the blade from passing further into the material.

- Bow saw . A rather bulky tool - an analogue of an electric jigsaw. The heaviness and threaded connections of the handles ensure easy overcoming of knots, making cuts along curved patterns and radii.

- Finish cutting saw . Has an adjustable handle. Used for sawing grooves and grooves, cutting profile and straight planks.

- Award . With two handles. Very reminiscent of a plane. Used for cutting grooves and tenons, deepening holes and making slots.

- Two-handed saw . The most productive tool. Has two wooden handles. Naturally, it is recommended to work with a partner. This tool is mainly used for cutting trees and large logs.

- Pocket chain saw . A small chain with two handles at the ends. This tool is easy to operate either alone or with an assistant. The chain wraps around the branch and the sawing begins. An excellent hiking option.

Depending on the design and purpose of the saw, there are:

- Sweeping - for longitudinal cutting.

- Transverse - for sawing across the grain.

- Circular - for making holes, figure sawing, making roundings.

- Tenoning - for cutting connecting tenons and cutting out simple geometric shapes.

You can cut the material lengthwise and crosswise only with a bow saw, cutting blanks with complex lines. The work can be done without an assistant.

The best Japanese hacksaws

The best steel for cutting tools is made in Japan. The Japanese hand saw has an original shape and works when pulled towards itself. The fabric is flexible, durable, and small in thickness. The original mixed tooth shape ensures a very accurate cut. Used for cutting precise grooves, sawing complex tenons, suitable for working in the garden, with decorative materials.

Stanley FatMax 0-20-501

A Japanese wood saw has two cutting edges. Designed for high-precision carpentry work. Provides accurate cutting of cross fibers. Edges with pitches of 7 and 14 TPI allow you to choose the best option, taking into account the density of the wood being processed and the requirements for sawing speed. The blade is flexible, convenient for performing operations in difficult, cramped situations, when there is a shortage of space. Quick replacement of the cutting element is provided.

Equipped with an ergonomic two-component anti-slip handle. The textured surface provides a secure grip. There are holes for easy hanging storage. The absence of play in the handle ensures precision when performing complex cuts.

Advantages:

- High performance;

- Clean cut;

- Long service life;

- Corrosion resistance;

- Wear resistance.

Flaws:

- It is necessary to adapt to flexibility.

Bahco ProfCut PC-9-9/17-PS

The products of the famous Swedish brand are manufactured for a European holding company in Japan. Carbon steel with high wear resistance is used, which ensures long service life. The model is designed for angular and longitudinal cuts of wood of different densities. The unique tooth shape allows you to make a neat cut. Quality - allows you to refuse scheduled sharpening.

The cutting planes are located on both sides, have a pitch of 6-8.5 and 17 TPI. This allows you to perform intensive sawing or make high-precision cuts. The cutting width is less than 1 mm, the absence of chips and burrs allows it to be used when creating decorative elements. The two-component handle fits well in the hand, providing a secure grip.

Advantages:

- Flexible, durable metal;

- Easy replacement of the cutting element;

- Good hardening quality;

- Accurate longitudinal cut;

- Light weight.

Flaws:

- Shortage of replacement sheets.

The best circular saws

Teeth parameters

Accuracy and performance mainly depend on tooth size .

The defining indicator is “TPI” - the number of teeth per inch.

There is an inverse relationship between these technical parameters:

- Blades with large teeth allow you to work at high speed, but the cut is sloppy and rough.

- Using a blade with fine teeth guarantees a clean and precise cut, but the speed of work is relatively low.

When determining the size of the teeth, focus on the material being processed. To work with chipboard, for example, greater cutting accuracy is required, so a tool with a high TPI of 7-9 is selected. For cutting logs and gardening work, where the cleanliness of the cut is not so important, TPI 3-6 is enough.

The difference between a hardened tooth and an ordinary tooth is that the first one does not become dull for a long time in everyday use. But a saw with hardened teeth cannot be sharpened again; it can only be thrown away after use. Ordinary teeth can be sharpened, which is done with a special file marked with an accident (for sharpening saws). It is enough to pass over each tooth several times.

Depending on the type of teeth, there are three types of hacksaws for different types of sawing:

- Longitudinal . The teeth of the tool have the shape of an oblique triangle and resemble hooks. This tool cuts along the grain. The teeth are sharpened on both sides, which ensures cutting when moving forward and back.

- Transverse . The teeth have the shape of an isosceles triangle. Thanks to this design, the material can be easily sawed when moving back and forth. This type of teeth is suitable only for working with dry workpieces; it cannot cut fresh wood.

- Mixed . In such products, triangular edges are combined with slightly elongated semicircular notches. Thanks to this solution, when moving the hand forward, semicircular teeth make a guiding cut, and when returning, triangular teeth expand the channel, from which sawdust is removed.

Some modern instruments have trapezoidal . This increases strength and wear resistance, but sharpening such a blade is not easy, since the trapezoidal teeth are difficult to shape. Because of this, the service life is greatly reduced, and after it has expired the blade has to be replaced.

The market also offers modernized hacksaws. They are effective for cutting raw wood. During operation, wet chips easily come out through the gaps between the teeth, and the movement of the tool is not hampered.

How to choose a hacksaw

To buy a good hacksaw, you need to take into account the scope and intensity of use, requirements for the quality of the cut, and the strength characteristics of the materials. The length and quality of steel used for production are assessed. Performance depends on the shape and size of the teeth, the ergonomics of the handle, and the presence of outlet channels. Only taking these features into account can you buy a good tool that will help solve your problems.

Purpose

They produce different types of hacksaws for working on wood, metal and alloys, which differ in the heat-resistant characteristics of the blade and the size of the teeth. For garden work, they produce models with specific ergonomics, which allow you to comfortably cut branches in the crown of trees and care for tough bushes. For thin, neat cuts of small width, Japanese saws are designed, which resemble abutment models. With their help you can perform complex carpentry work.

Canvas

It is made from tool steel of different grades, which is characterized by strength, flexibility, and resistance to thermal loads. To further improve technical characteristics, the best manufacturers use hardening. The metal must be protected from corrosion. Performance and scope of application depend on the length. Models 25-35 cm are used in the garden, when working with 100x100 mm timber or narrow boards.

It is better for roofers and carpenters to choose a tool with a length of more than 40 cm, this will ensure high productivity and allow them to work with timber 150x150 mm and boards 20-25 cm wide.

Shape and size of teeth

A large wood hacksaw is used for sawing boards, timber used in the installation of power structures, and large-sized workpieces. Large teeth provide high performance, but the cutting width can be several millimeters. For accurate work with eurolining, baseboards, tongue-and-groove floorboards, and fillets, models with a medium tooth are recommended. The best choice for a finisher is a saw with small ones at the beginning of the blade and medium ones along the main length. This format will help you make neat cuts.

The shape in the form of an isosceles triangle is intended for cross cutting. For longitudinal cutting, models with teeth in the shape of an asymmetric triangle are used. A pointed tooth with a ground top is universal, sawing equally well along and across wood fibers. With a pronounced tilt in only one direction, it will be easier to work with the tool, but only in one direction.

Lever

Should provide a comfortable, secure grip. Manufacturers of professional models take into account the anatomical features of the palm, which reduces the vibration load on the hand and eliminates calluses. To prevent the handle from slipping, a composite compound of two materials is used in production: impact-resistant and rubberized plastic. The blade is attached in several places, which protects against play and strong vibrations during the sawing process.

The best manufacturers of laminated timber

What is a reciprocating saw and how to choose one

Now let's figure out how to choose an electric hacksaw for wood; in the language of professionals, such a tool is called a reciprocating saw. Compared to hand tools, the selection criteria are slightly different. So, in addition to the reciprocating motion, the reciprocating saw also has a pendulum stroke.

For pruning trees with a reciprocating saw, the tool has a pendulum operating mode.

Vibrations of the blade based on the pendulum principle allow you to work much more efficiently, for example, when pruning trees or other rough work. And the standard mode is good for unraveling sheets of different densities.

In this case, the question of which hacksaw is better for wood will not be entirely correct, because in reciprocating saws the effectiveness of the tool depends on the correct choice of blade. There are blades designed for working on wood, metal, stone, drywall, etc.

Each reciprocating saw blade is designed to work with a specific material.

But the choice of a reciprocating saw does not end only with the purchase of a high-quality blade for the appropriate material; there are also a number of subtleties:

- I, like most craftsmen in this field, believe that buying an electric hacksaw with a power of up to 600 W is simply a waste of money. With it you can cut branches up to 20 mm in diameter and no more. From 600 W to 1 kW is suitable for a variety of country work, and a tool with a power of 1.2 kW is already classified as semi-professional and can effectively cut any materials;

- It is advisable to choose a model where a special key is not needed to change the blade;

- It is better to take a tool with a cutting depth limiter, which, by the way, can also be adjusted with a key or without a key; accordingly, the second type of hacksaw is more convenient;

- Pay attention to the head that holds the blade. There are universal models into which any blade can be inserted, while there are heads “sharpened” only for branded blades from a given manufacturer. It’s not a fact that the store will have the right model of branded canvas, so take a station wagon;

- Theoretically, all reciprocating saws have the ability to disable the pendulum stroke, but when purchasing, it is advisable to check how adequately this option works;

- A reciprocating saw with a speed regulator will significantly expand your work capabilities, and it is desirable that this regulator has a fine-tuning function;

- Another useful function is the ability to rotate the blade at different angles; this option is especially useful when working on the ceiling and in hard-to-reach, tight spaces;

A reciprocating saw with a battery, compared to corded models, has less power, but it is more convenient to use.

Which hacksaw is better

A tool designed for carpentry work is poorly suited for caring for trees, and cannot handle metal workpieces at all. There are no universal models, so the VyborExperta.ru team recommends the following brands, taking into account the scope of application:

- Armero A531/400 – for woodworking in the home workshop;

- Gross Piranha 24111 – the choice of a professional carpenter;

- Vira 801010 – for a locksmith workshop;

- Skrab 28154 – for treating tall trees in the garden;

- Opinel No. 12 – the choice of summer residents and tourists;

- Stanley FatMax is a professional solution for complex tasks.

All the models presented in the review are worthy of buyers’ attention, but only the most reliable, productive and convenient tools were awarded the title of best in their class.

Recommendations for selection

To choose the right hand saw for wood, you need to follow a number of recommendations. You need to pay attention to the following:

- Target . For carpentry work, you need a saw with fine teeth, which will ensure high cutting accuracy. Carpenters need a blade with large teeth.

- Uniformity of the canvas . Gently bend the fabric at an angle of 30-45° and release it. The slightest deviations on the fold line (even within 2 mm) indicate low quality of the metal.

- Frequency of use . If you need a saw for one-time work, it is better to take a tool with hardened teeth. The service life is quite long, and you don’t have to worry about sharpening and setting.

- Price . High-quality models from leading manufacturers are an order of magnitude more expensive than consumer goods. But the high price is a kind of guarantee of wear resistance and durability. However, for one-time work it is not advisable to buy an expensive tool.

Decide on the purpose of the tool, see how it fits in your hand. Please read the included instructions, if available. These minimal “wisdoms” will greatly reduce the risk of choosing a bad tool .

Hacksaw blades

Blades differ from each other mainly in their design and the material from which they are made.

Tooth geometry

There are four types of teeth on a hacksaw:

- wavy - used for straight cutting,

- inclined ones are used for the most precise cutting,

- large ones are distinguished by very fast and smooth operation. However, the disadvantage of this type of teeth is that they can leave a rough cut, that is, a mark on the material;

- fine with open sharpening - provides fast rough cutting.

Tooth spacing

Also called pitch, the smaller the gap, the more teeth working simultaneously in the material. This in turn makes the cutting process smoother and vibration-free. For metal saw blades the distance is about 1.2 mm, and for wood products it increases to about 4 mm.

Blade thickness and width

The thickness of the blade affects the processing accuracy and durability of the tool itself. The thicker the blade, the stiffer it is and the more accurate the cut is possible (only straight and at a slight angle). The width of the blade also plays an important role.

If it is necessary to make curved cuts, purchase a narrow blade (about 4 mm), which can be easily maneuvered. Wide blades are used for straight cutting only.

Handle type

There are three types of blades on the market based on handles, that is, according to the method of attaching the handle and hacksaw. This can be a universal or T-shaped mount.