Today, one of the fashionable materials used in the decoration of any premises is aged wood. Under the natural conditions of its growth, any tree ages very slowly, so a special technique for working with wood - brushing - has been created and specially used. This process involves artificial aging of the required lumber.

The evolution of artificial aging

Years change, technologies change, but the craving for antique accessories and utensils remains unchanged.

Now everyone can afford the luxury of living in an old Russian mansion, with cracked, seemingly shabby walls and beams, furniture from those times, wooden benches and a dining table made of natural aged wood. And all this thanks to the wood brushing process. We constantly feel a craving for something new, observing the natural, natural processes of aging wood, the visual end result, the demand for such items, people decided to achieve a faster process of extinction of the life of wood and invented their own technology of artificial aging with a fairly short period of time.

Mechanical aging of wood

This method is usually called brushing or texturing wood. The name comes from the English language, where the word “brush” means “brush”.

It is known that the structure of wood has soft and hard fibers. If you remove soft fibers with a brush, the surface becomes embossed.

Only tree species with an easily processed structure are processed mechanically: walnut, oak, spruce, pine, larch. Texturing does not work for maple, cherry, or beech.

Wood processing is carried out with two brushes:

- Brass wire brush - breaks soft fibers. They will “fluff up” and stick out.

- Nylon abrasive brush - smoothes the surface. The abrasive material is contained in the nylon hairs of the brush.

The prepared planed workpiece is processed with a grinder. At this stage of brushing, disc grinders destroy the soft layers of wood.

Brushing with a grinder

Use a metal brush clamped in the drill chuck to smooth out sharp corners and protruding fibers left behind by the grinder.

The metal brush is replaced with an abrasive version. A new brush is used to polish the surface, and at the same time highlight the structure of the wood.

In any case, the workpiece acquires an antique appearance only after being coated with varnish or oil. Unlike debugging, oil penetrates deeper into the fibers and can change their color.

A dark shade of oil visually ages wood. It is applied with a wide brush along the fibers.

To better absorb the oil into the fibers, rub it with a rag. The procedure of applying, drying and rubbing in the oil is repeated several times. They strive to give the workpiece an antique look.

In addition, to protect the oiled surface from external influences, it is covered with a layer of varnish or paint. A good result is achieved by coating with a glossy or matte water-based varnish.

As a result, the varnish flows into the unevenness of the wooden workpiece and a smooth antique-looking surface is obtained.

Description

A brushed hand sander is a universal tool that makes it possible to remove old paint, varnish and traces of corrosion from various types of wood and metal surfaces, as well as to refine a wooden structure. This device has a high level of performance and is used in conjunction with other grinders. The weight of one device does not exceed 5 kg, the number of rotations can reach up to 3000 revolutions, and the roller diameter is 120 mm.

To perform this task, manufacturers suggest using a nylon cylindrical brush. The brushing attachment makes it possible to artificially age the wooden material and remove all loose layers. After treatment, the work surface not only changes its structure, but also its color.

On the shelves of specialized departments of construction stores you can see two types of grinders.

- A tool with a wide body, behind which a shaft with attachments is hidden. The main feature is the presence of two handles and a start button.

- An instrument that has common features with a grinder. Distinctive features are the presence of a cylindrical brush and a handle, which is located parallel to the working shaft. The disadvantage is the lack of ability to adjust the processing depth.

This device consists of the following parts:

- engine;

- charger or wire to the electrical network;

- platform;

- pen;

- regulation and control system;

- working disk.

Two types of brushes are used for surface treatment:

- nylon;

- metal.

The brush has the shape of a cylinder that makes circular movements at high speed. To perform non-standard types of work, experts recommend replacing brushes and special rings.

To perform brushing, cup nylon brushes with abrasive grain on polymer threads are used, which can be attached not only to grinding machines, but also to a conventional drill.

To make work easier, the designers have provided two handles, and special pipes are installed to connect the device to the vacuum cleaner.

The number of revolutions depends on the diameter of the brush surface.

The adjustment system allows you to process products at a high level and at the same time adjust the cleaning depth.

Nozzles can be changed using a hex wrench.

Most grinding machines have auxiliary parameters:

- adjustment of the number of revolutions;

- automatic speed control;

- grinding depth adjustment;

- protection against unauthorized start;

- presence of a dust collector;

- possibility of quick replacement of deformed parts;

- additional protection of the engine from contamination.

The device may include an organizer, a set of metal, abrasive, polymer and nylon brushes, as well as a charger.

What is wood brushing

Brushing is a technology for aging wood artificially. Using special tools, a relief surface is created, on which the growth rings become clearly visible. This creates the desired effect, the wood looks like old wood that has served for many years.

Anyone who is interested in what wood brushing is will know that the term comes from the word brush, which means “brush” in English. This is the tool that is used to remove soft fibers from the surface of wood. They form in a living tree in the spring, when its active growth begins.

The fibers are loose in structure, which is why they are more susceptible to abrasion than the hard rings that form in summer and autumn. This is how wood naturally ages, but it happens very slowly over many years. The purpose of brushing is to greatly speed up the process by removing soft fibers with a wire brush.

Furniture made from aged wood that can also be placed in a modern home

Design and principle of operation

In terms of ergonomics, grinders are very convenient because they allow you to perform operations for a long time without tiring the operator. For each type of work, be it preliminary cleaning, grinding or polishing with a brush grinder, the design provides the ability to change attachments. All tools of this type are electric, powered by mains or batteries.

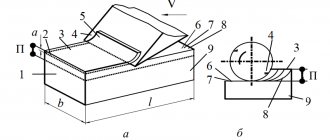

A standard brush grinder has the following basic structural elements:

- The case is usually plastic, on which handles are installed on top: one is the front guiding handle, the second is the pushing handle, where there is a button to turn on the device.

- A brush-type electric motor is installed inside the grinder body, from which torque is supplied to the transverse shaft through the gearbox.

- The front cross shaft also serves as a holder for the grinding cylinder; the shaft is supported by bearings.

- On the bottom of the grinder body there is a wide support roller on one side of the grinding cylinder, at the rear; on the other side of the cylinder, in front, there is a second adjustable support roller. Rollers allow you to smoothly move the tool along the plane in different directions and adjust the force of pressing the tool to the surface.

- The grinding cylinder is mounted on the cross shaft of the brush grinder using a special mechanism. The cylinder itself is made like a brush, the “pile” of which can be made of different materials, such as metal wire, nylon thread and others.

The operating principle of a brush grinder is very simple: when the engine is turned on, the grinding cylinder begins to rotate quickly; the tool is applied, supported by rollers, to a pre-fixed flat surface that needs to be ground, and with methodical movements the brush grinder is moved back and forth across the entire plane, visually assessing the quality of the treatment.

How to achieve the look of aged wood

So what is wood brushing and how is this effect achieved?

Naturally

Under the influence of time, sun, water and other physical and chemical processes, the softer layers of wood gradually become thinner. The spaces between the growth rings become deeper. The veins themselves remain hard and look more prominent. The sun gives the surface a characteristic color, further emphasizing the structure of the tree.

Naturally, this process is very lengthy. Finding similar interior and decor items is very difficult.

Under production conditions

To obtain the desired look, the top layer of the wooden surface is removed. In production, this result is achieved using special brushing machines, with replaceable brushes of varying hardness or sandblasting machines. In the first case, a more pronounced effect is obtained, in the second - having a relief appearance, the surface remains smoother to the touch. With industrial brushing using machines, the desired appearance of a wooden surface is achieved within a few hours.

With your own hands

In general, the name of the process itself comes from the English word brush. That is, in essence, this is surface treatment with brushes of varying hardness. The wood brushing technology itself is not that complicated. It consists of the gradual removal of softer layers of wood from the surface of the workpiece and its subsequent tinting. At home, you can make something with an aged surface in a period of several hours to several days, depending on the amount of work. The result is a unique, high-class item.

Rough processing

During rough processing, work is carried out with two main attachments - a roughing attachment and a disk plane. Grinder work with this type of disc is carried out with a protective casing, because pieces of wood may fly in different directions. The plane disk is used in cases where roughing is required, preparing fence supports, constructing a log house, etc.

Requires protection from flying wood chips, glasses, thick clothing, and tough gloves. The use of a protective casing is not necessary, because The disk is all-metal, its destruction is almost impossible. When sanding wood, a grinder is used only with a second handle; work must be done with both hands.

The process of trimming a workpiece, removing the hard top layer of wood, is carried out with a peeling disk. A qualified specialist is able to perform wood sampling using this type of attachment for an angle grinder. An angle grinder can replace a carpenter's ax if a log house is being built.

Types of brushing

There are two ways to do the job, which have different results:

- Mechanical. It is a classic version of the technology, when wood is treated with a stiff brush, and then painted and polished. The finished surface is embossed.

- Chemical. It involves treating wood with special compounds (acids or alkalis) that corrode soft fibers. The relief of the finished board will be less pronounced.

Some masters use a combined brushing method. First, the wood is rough processed using a chemical method, removing a significant part of the soft fibers. Then the finishing is done mechanically, completing the brushing process.

According to the depth (degree) of processing, brushed wood can be as follows:

- Structured. This type of treatment is superficial and is intended to highlight the growth rings and the natural appearance of the wood.

- Highly structured. Brushing creates deep furrows along the natural lines of the wood.

- Retro. It has an average processing depth, is combined with coloring with special compounds, and gives the “appearance” of a material that has been used for a long time.

- Retro 3D. Allows you to obtain highly aged material with sharply emphasized knots and uneven chamfers.

How is the density of wood species determined?

Method of brushing wood using a wire brush

The simplest method of artificially aging wood is to use a metal or nylon brush.

The algorithm of actions is as follows:

- The board or plank is processed with a metal brush along the location of the fibers; if this rule is not followed, there will be many scratches on the surface and the desired decorative effect will not be achieved.

- The fibers need to be removed by 1-1.5 mm; if it is necessary to achieve a deeper aging effect, it can be deepened to 3 mm.

- After this, the surface is sanded until smooth, first using coarse sandpaper and finally fine sandpaper.

- To brush wood to obtain different textures, several types of metal brushes are chosen. The thickness of the wire matters.

To speed up processing, the hand brush can be replaced with special sanding discs. Externally, they differ little. The procedure is accelerated using an angle grinder. The nozzle is attached to the grinder. The thickness of the wire can also be selected to obtain different results.

A better artificial aging effect and greater decorativeness can be achieved by using thin-wire brush attachments. In this case, a light grinding process occurs at the same time, the surface becomes smooth, reminiscent of varnished.

Pre-firing or singeing method

The method also involves using a metal brush or grinder with a wire attachment. Brushing wood like this is a simple process.

The surface of the wood is burned using a gas burner.

- Then it is processed with a grinder equipped with a metal brush disk.

- It is also important to process wood along the grain, varying the depth of penetration.

- Preliminary singeing allows you to burn the outer soft layer and at the same time tint the wood.

The decorative processing process does not end there. Next comes stain and varnish. Depending on what color needs to be given to the product, colored stain is used. Processing is also not a complicated process. Water stain can be used in its pure form, then the color will be more saturated; if this is not necessary, it is diluted with water. The solution is applied in a thin layer with a brush for painting, if necessary - in several layers. If it is necessary to preserve the natural shade, a stain matching the color of the wood is used. After the composition has dried, the wood is coated with clear or colored varnish.

Tools for wood processing: brushes, machines and machines

At first glance, the process of artificial structuring may seem very complicated. But the method of brushing wood with your own hands is the most affordable and easiest way to visually age a natural material. Even an inexperienced master can do this.

To complete this task you will need a minimum of equipment. In addition, brushing technology allows you to achieve excellent results both manually and mechanized. Depending on the chosen method, the master will need different tools.

The brushing process requires the use of special tools; it is also necessary to follow all the technology for working with wood

Brushing wood: a tool for manual processing

During work, you will need certain tools for brushing wood.

Metal hand brushes are used to roughly remove soft fibers from the surface of the part, while leaving the hard ones intact. They are used for primary wood processing. The stiffness of the bristles depends on the length of the wire: the shorter it is, the stiffer the bristles. At the first stage of processing, it is better to give preference to a brush with the stiffest bristles. It is desirable that the brush has a wide end part and is close in shape to a roller. This shape guarantees a more uniform processing of the wood.

A hand chisel is a tool that can be used to make deep longitudinal grooves of various curvatures in wood fiber. With skillful use of this tool, you can obtain maximum realistic material by applying deep cracks.

Coarse sandpaper for polishing is used to highlight the texture of the material, making the natural pattern more clear. To achieve an optimal result during work, it is necessary to move the sandpaper along the fibers with pressure. By using paper with different grain sizes, you can get grooves of different depths and degrees of expression.

After all previously applied substances have dried, the surface is treated with sandpaper to create abrasions.

A grinder equipped with special attachments for brushing wood is used at the initial stage for roughing and final processing of wood. At the beginning of the work, a metal brush attachment is used on the grinder to brush the wood, at the final stage - with copper or sisal bristles. Nowadays abrasive-polymer brushes are very popular. This tool makes it possible to selectively remove soft fibers without affecting the hard ones.

Helpful advice! If you don’t have a high-hardness brush, you can use a grinder to trim the pile. This will make the bristles harder. When selecting brush bristles, it is necessary to take into account that the bristles are 7-10 times thinner than the soft fibers of the wood. It is better to use a brush with straight bristles. When working with an abrasive-polymer brush, it is necessary to ensure that the surface of the wood does not burn when the robot operates at high speeds.

After the first stage of processing, experts advise burning the wood using a kerosene burner. A gas burner is not suitable for this type of work.

At the beginning of brushing, the wood is fired, during which the soft fibers of the top layer are burned

Firing with a kerosene burner will help complete the following stages of work:

- remove small wood fibers;

- dry the top layer of wood;

- emphasize and highlight the natural structure of wood.

Related article:

Odorless wood paint for interior work: a variety of materials, their properties

Types of safe finishing materials for finishing premises, their specificity and features of use, prices.

Process automation: machines and machines for brushing wood

Mass production of artificially aged wood requires speed. Some stages of wood processing can be mechanized, which will simplify the work of obtaining aged wood. To do this, you will need drills with variable speed control and special brushing machines.

Let's look at the most popular models of specialized equipment for structuring wood.

There are many brushing machines on the market, but they are profitable to purchase when you need to process large volumes of surface

Festool rustofix ras 180 stripping router or brush machine for brushing wood. Along with this tool, you can buy brushes for brushing wood. They come in three types:

- steel wire brush for primary processing of boards;

- synthetic bristle brush for intermediate sanding;

- sisal or hair brushes for polishing the back surface of the product.

The Makita 974 sander is used for brushing wood. But during work, difficulties may arise with processing areas at the corners of the part. Therefore, at the joints, it is recommended to use a special angle grinder with different attachments or use a nylon brush attached to an angle grinder for brushing. This brush is highly wear-resistant and allows you to process the ends, edges and contours of parts with complex shapes.

The Felisatti AGF 110/1010E grinding machine is suitable for processing both smooth and uneven surfaces. Nylon and metal brushes are included with the tool.

Using the Makita 974 sanding machine, it is possible to process wooden surfaces with alternating hard and soft layers - brushing

Helpful advice ! It only makes sense to buy a wood brushing machine if large volumes of work are planned. Brushes for brushing wood can be purchased either with the machine or purchased separately.

The secret to the popularity of brushing

The name of the technology is of English origin and means “brushing”. Brushing wood with your own hands is something that not only experienced craftsmen can do: with the right approach, anyone can master the craft of brushing.

Aged wood has not gone out of fashion for many years. Thanks to artificial aging, you can change the appearance and color of a particular type of wood, bringing a new personality to the room. Using brushing, they create a rustic, classic, vintage interior.

Artificially aged wood looks noble, a house with “antique” window frames and doors and patinated wall panels seems to have its own history. Today, aged wood is widely used not only in country houses, but also in city apartments.

Machine Applications

All three stages of finishing can be performed on special grinding machines or using other electrical equipment: grinders for smooth or angular surfaces. There are homemade brushing machines. It is difficult and expensive to make a full-fledged machine with your own hands, working like a thickness planer, so they use the same grinder with several metal and nylon attachments.

Full mechanization of work makes sense for large volumes of wood that require brushing. In such a situation, investments in the acquisition and operation of units will be justified. Common types of home repair and construction work can be quite successfully done with an angle grinder, which every craftsman has.

Chemical method

They are produced to facilitate the process of removing soft fibers, practically without the use of mechanical force. Chemical solutions have the ability to dissolve or soften wood fibers. Acids and some alkaline compounds are used. If you use products with a high concentration of active substances, then do without further use of brushes, just apply and rinse off the solution in several passes.

Work on this method must be carried out in the open air, as harmful and pungent odors are released.

All further processing is carried out in the same sequence as during mechanical finishing.

Advantages and disadvantages

This method of wood processing has its advantages and disadvantages. Any master takes them into account before starting to work with wood.

The advantages of brushing include:

- Improving the technological properties of wood by increasing strength and resistance to moisture.

- Achieving a visual effect, improving the texture and texture of the fibers.

- Variety of materials to work with.

- Possibility of subsequent processing and tinting.

The only downside is the complexity of the brushing technology itself. The work is energy-intensive and requires a certain amount of time. Dust can accumulate between the treated wood fibers, which requires constant care.

Self-brushing

Let's look at how to process wood yourself using brushing technology.

What tools and materials are needed for the job?

If you decide to age a buffet, chair or mantel yourself, then first prepare a set of tools. To use the brushing technique you will need:

- sandpaper of different grits (coarse-grained is suitable for roughing, fine-grained for finishing polishing of surfaces);

- two or three metal brushes of varying degrees of hardness;

- stain (to give individual elements additional decorativeness);

- paints for tinting;

- matte or glossy varnish for finishing.

Varnish coating

For large volumes of work, a stripping milling machine is used, which automates most of the aging processes. Replaceable attachments allow you to perform grinding, polishing, and brushing in stages.

Using a power tool speeds up the brushing process

When made by hand, the product looks more aesthetically pleasing, it looks like a piece product.

What breeds are suitable

You need to understand that only those wood species that alternate soft and hard fibers and have strong annual rings are suitable for processing.

These include:

- nut;

- oak;

- larch;

- ash.

Some exotic breeds are also suitable:

- wenge;

- Jatoba;

- kempas;

- merbau.

The wood for brushing must be dry. Otherwise, you can tear out not only the soft fibers, but also the annual rings. As a result, the workpiece will be damaged. The humidity level should not exceed 12% (in extreme cases - 15%). If it is higher, the workpiece must be dried again.

Beech, maple, alder, and cherry are not suitable. These trees have fairly homogeneous hard wood, which, when brushed, grinds down evenly. Thus, achieving an interesting texture is very difficult (and in some cases, completely impossible).

It is better if the wood for brushing is cut down in the spring. It is at this time that trees grow annual rings, so some of them will consist of very soft fibers. It is much easier to process such material. Therefore, if you have the opportunity to choose between material harvested at different times, you should give preference to spring.

Treatment

Here are the steps you will need to take to brush a tree:

- Prepare the material. To do this, the board being processed should be planed. There is no need to do this completely - after all, in the future the top smooth layer will still be removed. But it is imperative to remove burrs and make the surface smooth. The effectiveness of further work will depend on this.

- Processing with a grinder. It is necessary to put on the brush attachment, set the device to medium speed and evenly walk over the workpiece. As a result, the upper part of the soft layer is removed. The amount of wood removed can be controlled by increasing or decreasing the pressure, increasing or decreasing the rotation of the grinder. It is important not to overdo it and not damage the hard annual rings.

- Brush work. When the grinder has been passed over the workpiece, brushing is required. It allows you to remove imperfections and make the surface smoother.

- Creating contrasts. If you need to make some of the annual rings more contrasting, you can use a chisel. With its help, the grooves between the solid parts of the material are passed again and deepened. As a result, they begin to stand out even more from the general background. This can be done with all grooves. However, this is a very labor-intensive process, so most often I emphasize only a few.

- Processing with sandpaper. All irregularities on the workpiece are processed with sandpaper, making them smoother and more even. At this stage, you can use a grinder - it will greatly facilitate and speed up the work.

Painting

To treat the workpiece with stain, take a sponge and moisten it with the composition. Then the wood is blotted with it. There is no need to apply stain evenly - there should be more of it on the protruding parts and less in the recesses (or vice versa). This will provide the greatest contrast.

When the application of stain is completed, the board is allowed to dry. Usually it takes 10 – 12 hours. When the stain has completely dried, the workpiece is treated with oil or varnish.

In the case of oil, the procedure resembles the primary one. Moisten the sponge with the impregnation and spread it over the wood (evenly this time). There should not be too much oil - this can ruin the material. There should be just enough to form a thin protective layer on the surface of the board.

If varnish is used, it is applied with a brush.

During work, be sure to use a respirator. Inhalation of organic solvents can be harmful to the body.

The varnish is applied in a thin, even layer. If necessary, repeat the treatment. Typically, 2–3 layers are sufficient to reliably protect wood. If there are more of them, the varnish may begin to crack prematurely.

Final finishing

Aging of countertops, doors, panels, etc. ends with coloring. Several stages give a good result. First of all, you need to carefully remove sanding dust from the surface. The best way is a powerful air jet. Single products can be blown out with a vacuum cleaner, but in mass production you cannot do without a compressor.

It will also be needed for coating. There are several of them.

- Primer.

- Coloring. The classic brushing color is gray with all shades. There are 48 of them on the RAL scale: from squirrel gray to pearlescent mouse gray. This is what wood has that has spent ten years under the sun, precipitation and winds.

- Patination followed by polishing.

- Cleaning from dust, varnishing.

Wood oils are also used, which are capable of forming films due to their high content of linolenic acid. Wood oil is the marketing name for drying oil (boiled oil). The best of them is flaxseed: up to 80% acid (sunflower – 30%).

Working with oils requires skill: they must be rubbed in so that there are no mini puddles or streams left. Once dry, they cannot be removed.

What kind of circles are there for cutting wood?

Processing wood with a grinder is a safe process, unlike cutting. The process is very dangerous, the tool is not intended for cutting wood

Soft woods are processed with an angle grinder attachment with extreme caution, because the tool may jam and be torn out of your hands

The cutting process at high speeds implies a high temperature effect on the disc material, as a result of which it can simply shatter into small pieces.

Despite the fact that the grinder is not suitable for cutting wood products, manufacturers offer various cutting discs for use. It is recommended to use the grinder as a stationary station when sawing wood.

Circular saws

Circular saw attachments are dangerous when using an angle grinder. The diameter of the circle must be selected based on the parameters and dimensions of the tool in order to be able to use a protective casing.

There are more expensive modifications of circular nozzles; they have anti-jamming protection. The design has teeth set in different directions, smaller in size, the price of such a device is different, but you should not save on your health.

Chainsaws

The chain type of nozzles has a safer design. The sawing disc, which uses a chain from a chainsaw, eliminates jamming of the tool and reduces the risk of injury during work. The design has a system that allows the main element, which is attached to the angle grinder, to continue rotating, and the chain can remain stationary.

Chain disks come in many different modifications, with the help of which it is possible to carry out gardening work or use it for collecting small firewood. A disk of a chain design can be used instead of a peeling disk for cutting out cups in a log or removing a layer of bark.

Saws with few teeth

Increased safety when working with wood is achieved by using discs with a small number of teeth. Small discs usually have 3 teeth, those with a diameter of more than 180 mm - 4 teeth. This type of cutting disc is used for cutting both along and across the grain of wood. The saw wheel makes it possible to cut grooves and make tenons of various shapes.

It should be understood that when working with an angle grinder, you must adhere to technical regulations. There is no need to install larger diameter discs bypassing the protective casing; smaller discs can be used without loss of cutting properties.

Tungsten carbide discs

Tungsten carbide cutting discs have been produced relatively recently and are popular when working with an angle grinder. The universal tool is not equipped with teeth; instead of cutting elements, there are cutouts in the disk. The operation of the tool is most safe when cutting wood; it eliminates jamming when nails or thick rods of wood hit. The appearance is similar to a diamond blade for cutting concrete, the purpose is indicated on the packaging or instructions.

The price of such a disk is high, but it is justified. It is worth overpaying for a modified tool rather than going broke on the sad consequences of using a regular saw blade.

Other original aging methods

Naturally, the list of answers to the question of how to age wood does not end there, since representatives of creative professions related to works of art contributed. One of the well-known methods has already been discussed: this is patination, which allows you to give the products an antique look. However, there are other options - both simple and complex. In this case, the effect is achieved by experimenting with a decorative coating, and not with wood: it remains in its “pristine form.”

Crackle (craquelure)

This is the most effective way to get not only an “ancient” tree, but also to change any material beyond recognition. Crackle is a method of creating a web of cracks on the surface of objects. The set for such creativity is quite modest. It includes PVA glue, paints of two shades (acrylic or facade) and a hair dryer. There is a special varnish (primer, paste) for craquelure, but here we will only talk about the folk recipe for cobwebs.

- First, the surface is covered with dark-colored paint, then wait for it to dry completely.

- Apply the next layer: this time it is PVA, and there should be a lot of it. But one condition must be fulfilled: the layer must be thick but uniform.

- To speed up the process, the glue is treated with a hair dryer so that a thin dried film forms on the surface. Complete drying at this stage is not only not required, but it is harmful because it will not allow you to achieve the desired effect.

After obtaining the PVA crust, a layer of lighter paint is applied to the surface, which is also left to dry on its own. Then the glue is applied again in a thick layer. The last step is to dry the surface until the PVA film begins to crack. Thus, cobwebs will begin to appear on the surface, which is the best proof of the age of the product.

If traditional “wooden colors” are not used for objects, then you can swap the shades: first apply light paint, and then dark composition (contrasting).

Dry brush

This method was invented by artists, but now it is actively used by decorators who successfully use the dry version for “forced” aging of wood products. The work requires a minimum set - paint, a wide but thin synthetic brush and sheets of thick paper, which is necessary to rid it of excess mixture.

- Use a brush to pick up a small amount of paint, then move it across the paper until the tool begins to leave thin lines on the sheet.

- Then, with a brush, stripes are drawn along the growth of the fibers. Here, order is also contraindicated: the best results are guaranteed by erratic movements.

It should be noted that the “Dry Brush” operation is optimal for aging furniture or other products with convex elements.

Spray

These are droplets that age the product in a chaotic manner. This creates the image of an antique item that has passed through decades.

The spray looks nice and is textured to the touch. It leaves an impression of antiquity; a product with such decor brings coziness to the house. For processing you will need: a hard brush or toothbrush, paints, a glass of water.

Wood aging technology:

- Wet the brush and pick up some paint.

- Perform a test spray on a white surface to determine the droplet size. To do this, run your finger or a toothpick along the bristles of the brush.

- If the brush is wide, then you can simply tap on it and the drops will fall.

- The product should be placed on paper, which can then be thrown away so as not to spoil the table.

- Spray the product and wait until it dries completely.

- Cover with varnish. If there is a desire to achieve a three-dimensional effect of antiquity, the drops are sprayed in a second layer on top of the varnish. They will not look so bright, but they will age with a double layer of drops.

Spraying is combined with other techniques for aging.

Glaze

This is the application of two or more layers of paint, the first of which is brighter, and the subsequent ones are translucent. The advantage of this method is that it produces a non-uniform, iridescent, changeable surface. For such aging, you can use different types of paints. The largest assortment of colors is distinguished by acrylic compositions, watercolors and oils are a little more modest. Even strong tea leaves can serve as a “decorator”. Any wood can be processed. For glazing, use either a sponge or a synthetic brush.

The first layer is applied unevenly, trying to achieve the natural shade of the wood. If this does not work, then add another thin layer. After the operation is completed, the product is left to dry completely. When several tones are applied, they create an interesting translucent effect.

Brushing technology - main stages

So, all the necessary tools have been purchased, wooden boards lie in front of us. Let's start brushing.

All surface treatment technology is carried out in accordance with this scheme:

- Treating wood with metal brushes to remove soft fibers

- Sanding cleaned wood using synthetic abrasive brushes

- Painting with special solutions that help give a visual aging effect

Wood polishing and varnishing

Step 1. Preparatory work. We check the tree with which we have to work. If it is too wet, it is necessary to dry it, but if it is too dry, then, on the contrary, moisten it, since with dry wood the amount of waste, sawdust and dust increases significantly. At this stage we will use a wire brush. It should be remembered that only soft fibers must be removed.

If the brush is so hard that it even touches hard fibers, the tool should be replaced immediately. Movements are made at low speed along the direction of movement of the fibers.

Step 2: Sanding. Now we need an abrasive brush with which we will polish the wood. Carefully pass over the cleaned surface in order to remove all remaining fibers and eliminate roughness. As a rule, this does not require much time; it is enough to carefully sand the wood several times to achieve the desired result.

Step 3: Polishing. To give the brushed treated wood a polished look, we use sisal brushes. It is worth noting that this tool allows you to achieve a unique decorative texture of a wooden surface. You may also need fine-grit sandpaper to polish the material. After completing all the work, we once again carefully remove all debris, dust, and dry the surface.

Step 4. Painting. A beautiful decorative look can be obtained as a result of gilding, painting, patination and other effects. If you apply several layers of stain to wood, you can observe the appearance of beautiful contrasting textured images. Products are also brushed with gold paints, which look original in microcracks and depressions. After applying the paint and its complete drying, the surface will need to be polished again.

This is due to the fact that during painting various irregularities and roughness may appear, including paint sagging, but polishing will completely eliminate these defects.

Step 5. Varnishing. Coating with various compounds to protect the surface, increase its durability and reliability. If parquet boards are brushed, then a special parquet varnish is required to preserve the basic positive consumer qualities of the floor throughout its entire service life.

A couple of antique wood recipes

You can find many recipes for aging wood using improvised means, but all of them are derivatives of the processing methods already described. Let's look at some of them.

Using wax

Using regular wax you can achieve a good effect; you only need 2 types of wax (colored and regular), as well as a wood sanding machine. This method is convenient because it does not require additional steps such as brushing the wood or using acid to remove soft parts of the wood.

The technology for doing the work will look like this:

- first the board is sanded, and the direction is strictly along the grain;

- then colored wax is applied; at the previous stage, the pores of the wood have opened, so it will penetrate well. It takes about a day for the coating to harden;

- Next, you will have to apply colorless wax on top of the colored one, and some of the colored wax will inevitably be removed.

An example of wood processing with colored wax

Bleached wood

Bleached wood will look unusual in any interior. It costs a lot, but you can achieve the same effect with your own hands when painting wood. The main task in this case is to ensure that the white color does not completely “clog” the texture of the wood; ideally, the wood should have a slightly grayish tint and the wood pattern should be visible through the layer of white paint.

Bleached wood

You can get the desired effect using brushing technology, and the key point will be how to paint an antique board so that the wood pattern remains noticeable after painting.

To do this, you can use tinted and transparent varnishes, and painting will be carried out in several stages:

- if the wood is dense and does not absorb varnish well, then you can immediately treat the prepared surface with tinted varnish in a couple of layers;

- then a clear varnish is applied over it to protect the tint.

Tinted varnish from a renowned manufacturer

The same effect can be achieved using white paint, but here you need to take into account that it is easy to paint over the wood pattern 100%. Therefore, after applying the paint, you can carefully blot it with a sponge so that the texture of the board becomes visible.

Is an angle grinder suitable for working with wood?

The only operations with wood that can be performed with an angle grinder (angle grinder) without danger are grinding and roughing, and then using special attachments. Of course, you can cut wood, but it is strictly prohibited! The Internet is full of shocking photos showing what can happen when using an angle grinder as a cutting tool for wood.

The main arguments that can be made against using an angle grinder for sawing are as follows.

- This machine is not designed for sawing wood.

- Since wood has a viscous and soft structure, the saw blade can jam in it. As a result, the grinder is often torn out of the hands, and it flies in an unpredictable direction (in the leg, along the arms, in the stomach, etc.), causing deep wounds or amputation of fingers. Even fatal cases have been reported.

- When cutting wood, the saw blade heats up very quickly, causing it to begin to lose strength. The slightest misalignment or excessive pressure may cause it to fly apart. Since the spindle speed of an angle grinder is high, tool fragments fly away at the speed of shrapnel and penetrate deeply under a person’s skin. The user will be lucky if the fragments do not fly into the head or eyes.

- Despite the dangers of using saw blades with teeth, some angle grinder users ignore this fact and continue to install compass disks with large teeth or improved with carbide tips. If, when cutting wood, a hard knot or nail residue gets caught in it, the tooth or solder breaks off, gets caught by the next saw tooth and is thrown out at the speed of a bullet. One can only guess about the consequences.

- Ignoring all the warnings, users of grinders install a circular saw on the machine with a larger diameter than the protective casing. This is the most dangerous option for using an angle grinder.

If you have to cut wood constantly, it is better to purchase a special machine for this purpose, or use a jigsaw. In extreme cases, the grinder can be used as a drive and made into a circular saw, securing the device rigidly to the frame.

Pine with an antique effect - brushing yourself

To give the desired shade, a variety of stains and impregnations are used and are chosen to suit any interior or exterior. Special impregnations help protect wood from rotting and various external influences if the product is used in outdoor conditions.

Brushing and burning wood are decorative finishing technologies. Methods allow you to preserve the pattern of the material, give the table an antique look, and change its shade.

Some impregnation manufacturers provide a guarantee of up to 15 years for two layers. Experience shows that at least half of this time the product actually remains protected.

How to choose material?

It should be borne in mind that not every type of wood can be processed by brushing - this is due to the difference in the structure of the fibers. Soft varieties of wood, as well as wood of medium hardness, undergo aging well, since the texture of their annual rings is more clearly defined.

These include:

- oak;

- wenge;

- ash;

- nut;

- pine;

- larch;

- birch;

- cedar;

- acacia;

- Apple tree;

- aspen;

- alder;

- acacia.

After processing, such boards have a clearly visible relief, and the pattern takes on an expressive appearance. The structure of the grooves is visible on the surface, and color contrasts appear. Moreover, the softer the rock, the more textured the surface will be. Most often, type-set or unedged timber is processed.

Certain types of wood are unsuitable for artificial aging:

- teak;

- beech;

- maple;

- pear;

- cherry;

- Linden.

The fibers of such trees are weakly expressed. The technology will also be ineffective for tropical trees - due to the climate, they do not have annual rings at all. Light aging can be done on clapboard or plywood.

Brushing does not change the performance characteristics of the material; it remains just as dense. But at the same time the surface becomes as expressive as possible.

Show sugi ban

The worldwide term for what is known in Japan as yaki-sugi-ita (or simply yakisugi), which literally translates to “burnt cedar board.” Although "sugi" colloquially means cedar in English, it is actually Cryptomeria japonica, a species of the cypress family native to Japan.

It's a counterintuitive but brilliant idea: burning boards to make them fireproof. If you've ever tried to start a fire using charred firebrands, you get the idea. Combustion destroys the cellulose in the wood.

These are carbohydrates that insects, fungi and bacteria love. Fire makes lumber uninteresting to pests and resistant to rotting. The resulting carbon layer repels water and protects from the sun. According to some estimates, boards that go through this process can last 100 years or more.

Useful tips

Here are some useful tips that will make your work easier and make your results even better:

- Before starting work, the workpiece can be fired. This is done using a torch. Firing performs two functions - practical and aesthetic. The first is that during the procedure the soft fibers of the wood soften even more. As a result, they are easier to remove, so the texture of the workpiece becomes more prominent.

- The aesthetic function is that part of the burnt wood remains in the depth of the grooves on the board. This makes the material more contrasting and beautiful.

- If you need a less pronounced, non-contrasting texture, use special brushes for brushing. Their fibers are not wire, but polymer. Thanks to this, such brushes act more gently on the wood and leave less deep grooves without completely removing the soft fibers.

- If polymer brushes are used, it is better to sprinkle them with abrasive. This will make the processing more effective and better emphasize the texture of the wood.

- The finished board can be treated not only with stain, but also with silver or gold paint. It should be applied to protruding parts or recesses. This will emphasize the contrast of texture. Apply silver or golden paint with a sponge and lightly blot the surface with it.

- If you need to paint the recesses, use a thin brush. If silver or golden paint is applied to the wood, it must be varnished - otherwise the paint will quickly wear off.

What mistakes are often made at work? Adviсe

Working with wooden blanks requires care and attention. Sometimes defects obtained during work are very difficult to correct.

- It is important to use high-quality and proven varnishes and paints. The same goes for etching chemicals.

- A common mistake: they do not allow the already applied layers of paint to dry completely and begin further processing. Information about curing times is indicated on the paint cans.

- Be sure to take into account the air temperature and relative humidity. The drier and warmer it is, the faster varnishes or paints will dry.

- Before using varnish, surfaces should be thoroughly cleaned and dirt removed.

Working with wooden workpieces requires care and attention.

Sources

- https://LesoBirzha.ru/articles/brashirovanie-drevesiny-sovety-byvalogo-stolyara.html

- https://metnor.ru/stroitelstvo/brashirovanie-drevesiny-metody-instrument-i-oborudovanie-shhetki

- https://proffstroygroup.ru/dekor/brashirovanie-dereva.html

- https://ArmRinok.ru/oborudovanie/broshyurovka-dereva.html

- https://drevesina.net/brashirovanie-drevesiny-obshhie-svedenija-i-osnovnye-jetapy/

- https://tehno-gid.net/inf/brashirovanie-drevesiny-chto-eto-za-tehnologiya-i-mozhno-li-obrabotat-derevo-samomu.html

- https://stroyizdereva.ru/chto-takoe-brashirovanie-drevesiny/

- https://stroy-okey.ru/house/interier/brashirovanie-drevesiny-svoimi-rukami-poetapnoe-rukovodstvo/

- https://sdelai-lestnicu.ru/besedka/obrabotka-dereva-pod-starinu-svoimi-rukami-sposoby-foto-video

Suitable tree

The technology of relief structuring is most effective when working with loose species with clearly defined rings: oak, jatoba, pine, kempas, walnut, poplar, spruce, wenge, larch, doussia, merbau, ash.

This technique is not used for trees with a homogeneous trunk, fine-fiber structure, and the absence of clearly defined layers, as it is considered ineffective. Therefore, the artificial aging procedure is not suitable for alder, beech, willow, chestnut, pear, birch, linden, apple, cherry, teak, elm, aspen, cedar and maple.

Step-by-step instruction

The technique of brushing wood is not difficult if you stock up on all the required tools, patience and strictly follow the step-by-step instructions:

- Prepare everything required;

- Moisten the wood piece with a small amount of water to prevent excessive dust formation;

- Select the hardness of the brush, checking the quality removal of soft fibers without disturbing hard structures;

- Carry out rough cutting by checking the tool;

- Get to work, guiding the brush only longitudinally, following the grain;

- Change the hard nozzle to a polymer one, which has a special coating with an abrasive layer;

- Remove soft wood residues and roughness from the surface;

- Carefully examine the resulting result. If the quality is not satisfactory, then repeat the steps;

- Structure the texture: deepen previously made grooves and grooves, add new cracks using a chisel;

- Polish the product with a sisal brush or small-grit sandpaper to obtain a perfectly flat and smooth surface;

- Dry and clean the wood from dust, dirt and sawdust;

- Decorate the workpiece by painting it with a golden or silver color;

- For an expensive look, patina the layer by painting deep cracks with dark shades;

- Re-polish the wood;

- Wash, clean and dry the product thoroughly;

- Cover with parquet varnish, which is more wear-resistant, durable and glossy.

There is also a chemical brushing method, which requires certain knowledge in the field of chemicals: acids, alkalis, ammonia. Through the use of caustic agents, rapid erosion of soft fibers is achieved, the remains of which are subsequently removed with a brush.