The carpenter often has to make angled cross cuts in the boards. The cut almost always needs to be precise because it forms a corner joint for a door casing, baseboard, picture frame or some other structure, and a miscalculation can result in an unsightly gap. The tool for this job is a miter saw.

Products for inventors Link to the store.

A miter saw is the tool you need to make angled cross cuts.

The simplest miter saw consists of a handsaw and an open box with pre-cut grooves to guide the saw, but a miter saw is easier to use, faster and more accurate. It is basically a cutting saw mounted on a vertical spindle that rotates 45 degrees in any direction from dead center. The compound miter saw, which you should consider purchasing if you don't already have a miter saw, also rotates around a horizontal spindle and allows you to cut bevels and sleeves.

Most power tools produce better results once you have learned how to use them properly, and a compound miter saw is no exception. It won't take long to develop this skill by practicing with a few pieces of wood before actually cutting

How to make a homemade cross-cutting machine (trimming machine) for wood with your own hands

The design of the miter saw is similar to a circular saw mounted above the workbench. Its main advantages: compactness and light weight. Thanks to this, saws are used not only in workshops, but also on construction sites. Unfortunately, homemade tools are quite bulky and heavy. They are convenient to operate in stationary mode. A miter saw is designed for the sole purpose of cutting the ends of lumber at various angles. Due to the fact that the workpiece is stationary on the table during cutting, the cut is neat and clean. Craftsmen who deal with wood processing prefer this particular tool. Moreover, self-made saws have been successfully used for years.

Advantages and disadvantages of homemade products

Having a device helps solve several issues:

- the edges of the parts become smooth without burrs;

- allows you to connect adjacent structures at an angle;

- When joining parts, there is no gap between them.

The main advantages of working with a homemade trim:

- firstly - savings on the purchase of building materials;

- secondly, you can select the technical properties of the tool you are creating yourself: motor power, cutting wheel size, cutting depth.

- the duration of operation depends on the type of material used in the development of equipment;

- homemade products are not equipped with security systems;

- home devices do not have special calibration.

For reference! You can see how to make a miter saw from a grinder on the YouTube channel.

Pendulum

A small machine with a cutting disc mounted on a pendulum. The blade moves back and forth, and the blade being processed can rise up and down and rotate. In this way, it is possible to adjust the cutting angle.

How to use the tool

Any newly purchased saw, regardless of the model and manufacturer, requires adjustments, as well as a tool that has already been in use, if the cutting accuracy is impaired. This procedure is performed as a type of maintenance on a complex tool designed to perform precise work operations. Setup operations include:

- adjusting the fit of the side stop to the surface of the turntable; it may have burrs, burrs, or an uneven surface that need to be cleaned and the bottom surface of the stop needs to be ground in with sandpaper;

- aligning and securing the stop on the frame strictly perpendicular to the cutting line using the small play provided in the mounting holes of this element;

- elimination of play of the turntable in the place where it is fixed by the rod;

- adjustment of the perpendicularity of the vertical cut, as well as the cut at an angle of 45o;

- adjusting the tension of the return spring so that when lowering the pendulum by the handle, you do not use excessive force, leading to deformation of the tool structure and disruption of the cutting accuracy.

The procedure for performing work on setting up a miter saw is presented very clearly and in detail in the following videos.

Setting up a miter saw - video

How to adjust the degree of inclination of the cutting head - video

The best manufacturers

A review of miter saws would not be complete without getting to know the best manufacturers in the industry today. The following companies are especially popular among them:

- Hammer. Czech line of professional electrical equipment. Instances are distinguished by a rotation speed of up to 5 thousand rpm, minimal operating noise and protection against overheating. With their help you can cut not only wood, but also metal.

- Makita. Japanese company with 100 years of history. Produces convenient, high-quality end installations. The average characteristics of the models are frequency 3-6 thousand rpm, power 1.6 kW, disk 200 mm.

End installations from Makita Source makitaclub.ru

- Bosch. German brand of the premium segment. Saws are characterized by small dimensions, light weight, ergonomics, good build quality, convenient operation, and durable cutting elements.

- Bison Domestic manufacturer of ergonomic, reliable and cheap miter saws. The models are distinguished by high power, large diameter discs, and universal cutting angle settings.

- Metabo. Produces high-quality miter saws with powerful motors, wear-resistant discs and many useful features.

A competent choice of saw blade will ensure results Source ytimg.com

Who needs trimming and why?

This tool should not be confused with a circular saw. If the main purpose of a circular saw is the vertical or horizontal cutting of a wooden log, board or beam, then the miter saw is designed for an accurate, high-quality cut at a certain, fixed angle. Moreover, these units can work not only with wood, but also with plastic or metal.

Cutting fillets.

The scope of use of such devices is quite wide. Most often they are used for wood processing. Window frames, doors, various types of trimming of skirting boards, precise joining of timber, as well as fitting of fillets, moldings or false columns are done exclusively with a miter saw. You shouldn’t even start building a house from timber if you don’t have this tool.

When making the much-loved plastic window frames, doors and other similar structures, high-quality profile fitting is impossible without a miter saw. Enterprises specializing in the production of complex metal frames from profiled pipes use trim saws for precise cutting and joining of the profile. And this is only part of the capabilities of these units.

Portable devices.

Tip: If you want to get into professional tiling or construction, then any mobile construction team should have a miter saw in their arsenal. Without it, you simply will not be able to perform the work at the proper level and your business may falter.

Miter saw - purpose, device, types

Before you start choosing a miter saw, you need to find out whether the purpose of its use in a particular situation matches its intended purpose. It would be useful to study its structure and get acquainted with the main varieties. Let's look at these aspects in more detail.

Purpose

A miter saw is similar in appearance to a circulation saw. Both are based on a saw blade. However, the latter is intended for cutting mainly wood along the grain. The option under consideration is capable of sawing the workpiece in any direction of the material. Essentially, the mechanism is a stationary circular saw with a movable cutting element.

At the same time, the best miter saws are capable of cutting material in a vertical, horizontal plane, and diagonally, as well as cutting out grooves. Thanks to this, they are widely used in various industries:

- In carpentry industries.

- At facilities under construction.

- For equipping amateur carpentry workshops.

- Manufacturing of window and door structures.

- Installation of floors.

- Furniture manufacture.

- External and internal finishing.

Workshop with miter saw Source ytimg.com

Device

The functional trimming module includes an electric motor, a high-strength sawing disk, a gearbox for connecting them and a control handle with a power button. The block itself is based on a frame with a slot for a saw. It is on this that the workpiece that needs to be sawed is placed. It has a special device for setting the cutting angle. This is where the emphasis is located. The base frame can be made of various alloys.

However, for example, the best miter saws with broaching for wood from well-known brands are equipped with a lightweight aluminum or magnesium base. This significantly lightens the weight of the product and makes it more mobile, although it significantly increases the price.

The device of a miter saw Source orgstanki.ru

The functional module is attached to the frame through a rotary pendulum arm, which ensures its movement to the workpiece. Modern models are also equipped with a mechanism for rotating the desktop. More advanced models are equipped with an additional mechanism for vertical rotation of the pendulum lever. This allows you to set the cutting angle in two planes at once, which significantly expands the technical capabilities of the installation.

Varieties

A modern miter saw, the choice of parameters of which is determined based on the specific conditions of use, is characterized by a number of technical parameters:

- Engine type.

- A type of gearbox.

- Dust waste collection system.

- Protective casing.

- The depth of the saw.

- Availability of laser markings.

- Illuminated work area.

- Smooth start.

- Jamming prevention.

- Speed regulator.

- Maintaining stability during overload.

Miter saw with broach Source cdnmedia.220-volt.ru In addition, miter saws differ in their main part - the cutting tool. Saw blades are classified according to a number of parameters - outer and seat diameters, type of material, thickness, number and dimensions of teeth, their shape, angle, and recommended rotation speed.

Miter saw: device, purpose and capabilities

A hand-held miter saw has a narrow purpose, and you are unlikely to be able to cut boards with it. Its tasks are slightly different - it can only perform short cuts. With its help, you can cut the board in half, align its end, or cut the end of the board at a certain angle. That, in principle, is all it can do, but believe me, this is a lot - other sawing equipment copes with such tasks much worse. Oh yes, I completely forgot that in addition to wood, depending on the equipment used, a miter saw can work with soft metals, plastic and, if necessary, thin-sheet iron, or rather with a profile made from it.

Miter saw capabilities

The universal miter saw has a rather complex design - it consists of two main units, which are by no means distinguished by their simplicity of design. This is a frame on which a rotary table and a movable cutting head with a powerful electric motor mounted on it are fixed.

- Stand with rotary table. As a rule, these two parts cannot do without each other. On the bed itself there is a guide that ensures a fixed position of the workpiece. The miter saw table itself can be rotated relative to the guide within 90˚ (45˚ in one direction and 45˚ in the other direction), thus providing simple trimming of the workpiece in any direction without reinstalling the part.

- Cutting head. Installed directly on the turntable - it changes its location along with it. For ease of use, a graduated scale is applied to the side of the rotary table on the bed - by aligning the table mark with a certain degree value, you can make cuts at any angle. And that's not all - the head itself, or rather its cutting part, can tilt left and right, thereby providing an oblique cut. In most cases, this tilt is performed in one or two fixed positions (30˚ and 45˚ in either direction). Also, some models can be equipped with a special broaching mechanism. A miter saw with a broach allows you to cut workpieces much wider than its ordinary counterpart.

What design does a miter saw have?

Types and differences of miter saws.

It would be more correct to divide miter saws into two large categories. The first category is saws in the usual version - and the second is a combined version. Below is a close-up of the compound miter saw:

As you can see, this saw has an additional sawing table in the upper part. Therefore, this type of saw is called combined, as it additionally combines the capabilities of a stationary circular saw. Considering that such saws are 2.5-3 times more expensive than regular saws, we do not recommend considering purchasing them for private use. This is clearly more professional (and in our opinion not always the most optimal) equipment. It may be more rational to have a regular miter saw and a separate stationary circular saw.

Additional options

Companies that produce end plates compete to provide their products with the maximum number of additional options. Some of these options are aimed at increasing safety, others at increasing productivity and developing new functions, and others at improving working conditions and ease of use.

Lighting the cutting area

Options such as:

- Lighting the cutting area.

- Speed maintenance system.

- Cutting depth limiters, allowing you to make grooves.

- Laser level indicator.

have become a de facto standard and are included in the equipment of almost every model.

Miter saw stand

A useful option at the top of the product line is a sturdy stand onto which the saw is mounted. With this addition, you don’t need to worry about mounting it on a workbench or making a separate desktop

Basic and additional functions

The main purpose and, accordingly, the main function of a miter saw with a broach is the end trimming of lumber strictly at a certain angle and in high quality cut. The presence of a broaching mechanism significantly expands the functionality of the tool in comparison with analogues that are not equipped with it, because It becomes possible to process larger workpieces.

Miter saws with broaching are equipped with a torsion lock, necessary when replacing the cutting element, a stopper function, necessary when clamping the saw blade during operation, and models with significant electrical power are equipped with soft-start devices for the engine. Additional functions that devices of this type can be equipped with are:

- electronic saw blade rotation speed controller;

- laser guidance of the direction washed down;

- connection to an external sawdust removal device (see the photo below, indicated by an arrow);

- extension of the saw table top.

Working with a vacuum cleaner to remove sawdust

Main selection criteria

There are certain criteria based on which you can choose tools for cross-cutting work.

Firstly, before purchasing, you should decide in advance how often the trimmer will be used. The minimum functional set that a very specific model should have will depend on this.

In cases where it is intended to be used rarely at home, you can opt for a device with a minimum set of functions. And, on the contrary, when you plan to use this mechanism frequently, it is better to buy a professional model with a wide range of options.

Secondly, the device you purchase must be safe. Thus, the presence of a protective casing on the circular saw that covers the disk during end cutting will ensure safe working conditions.

You should estimate the total weight of the wood trim and its dimensions. If these indicators are too high, it will be difficult for the user to work with such a tool.

Characteristic versions of the mechanism

The principle of mobility of cutting units in single-saw machines is implemented by the following types of structures:

- Straightforward. The block moves on a rigid horizontal console, the height of which can be adjusted;

- Pendulum (PME). The location of the disk assembly on the suspensions allows it to move in an arc, lowering and rising;

- Balanced. The saw is located under the table, the knife is raised by pressing the pedal. Number of lifts 10 – 12 per minute;

- Stationary. The workpiece is fed to a fixed rotating wood knife.

Multi-saw installations include trimmers and slashers. On double-sided cross-cutting machines, the side and top sides of a wooden part are processed in one pass.

Pendulum type

Industrial CME (pendulum cross-cutting machine) has the following characteristic features:

- manual or pneumatic feed of the cutting unit;

- mechanized supply of parts;

- adjusting the length of the workpiece by installing stops;

- pneumatic clamp;

- electrodynamic braking.

The design of the manual feed of the DME disk works by ensuring a return to its original position under the influence of a counterweight.

The large radius of the CME installation increases the possible width of sawn timber trimming.

The suspended type of fastening makes it convenient to use the TsME machine in cutting production.

Straight stroke

Serial production of parts of a given size is carried out by a cross-cutting machine with several saw units. The distance between the disks on the wood corresponds to the required size. The lumber is pushed along a bed with rollers onto saws that cut it to size. In one shift, machines of this type process several dozen cubes of wood.

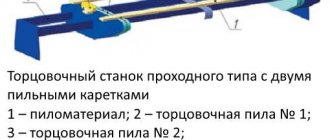

Cross-cutting machine with two saw carriages

Productivity and the accuracy of the angle between the edges of the timber are increased on double-sided equipment for trimming wood.

Machine design

A homemade and industrial cross-cutting machine has the following components:

- Table. Located on a stable support frame. The design allows the use of rotating, positioning mechanisms of the working plane to make cuts of complex configurations.

- Saw unit. The wood cutting disc is mounted on a shaft, connected through a drive to an electric motor, and the unit is assembled as a monoblock. There can be 2 or more of them on the machine (trimming several sides of logs at the same time).

- Mechanism for moving the saw unit. There are varying degrees of complexity and principles of operation: from a bracket with springs and shock absorbers to hydraulics or pneumatics. The functionality is expanded by the presence of a rotating mechanism, which allows you to set the circular knife at an angle to the workpiece.

Depending on the model (pass-through, automated), a wood cross-cutting machine includes various auxiliary devices, fixtures, programmable actuators, and a chip removal system. In large and medium-sized furniture production, it is better to use an automatic cross-cutting machine for serial processing of materials.

Common parameters

Each woodworking trimming machine includes the following general characteristics:

- electric motor power;

- number of revolutions of the saw shaft (indicating the possibility of adjustment);

- ø limits of the wood blade used;

- rotation angles of the saw unit;

- the height of the edge of the knife teeth above the table level.

Cutting different types of wood does not require the use of universal blades. Materials of different hardness and structure are cut with high quality saws with different numbers of teeth in the circumference of the disc.

Varieties

Trimmings are divided into the following types:

- pendulum;

- combined;

- with a broach.

The basis of the pendulum device is the frame. A table is attached to it, which is based on a rotation mechanism with a ruler. This mechanism solves the problem of setting the cutting angle with its adjustment. The cutting angle can be adjusted by moving the work table relative to the surface of the base. The saw component is fixed with a handle and spring-loaded with a hinge. The pendulum moves the saw vertically.

In the combined modification, it is possible to change the cutting angle in two directions. The structure is the same as that of the pendulum crosscut, the only difference is that one more hinge has been added. In terms of changing the cutting angle in a horizontal surface, it can be changed in the horizontal direction, which is also opposite to the installed drive.

Trimming with a broach allows you to move the cutting component both along the circumference of the hinge axis and directly along the length of the cut. This is achieved due to the existing guides.

How to choose a miter saw

Miter saws vary in technical features and are of the ordinary (ordinary) or combined type, which somewhat expands their functionality.

The difference between combined models and ordinary ones is that their design assumes the possibility of transforming a miter saw into a circular saw by performing slight movements of the main parts of the saw.

Model “Zubr ZPT-255-1800” with belt drive and broach

And in addition, a fundamental functional feature is the presence of a broach, which also expands the capabilities of the equipment used.

Miter saw with broach.

For stationary installation, it is better to use models that have a broaching function that allows you to process wide wood pieces.

Universal miter saw model “Makita Lh1040”

Trimming from a grinder

Technical characteristics of a cross-cutting machine with a broach, assembled by yourself:

- disk revolutions - 4500;

- cutting length - 350 mm (much higher than that of a middle-class factory tool).

The tool can be removed from the table and the grinder can be used for its normal purpose.

Manufacturing details:

- The turning device of the tool is installed on the turning axis of the car wheel (pin), it is held by a 150 mm ball bearing (if you can find more, it will do).

- We weld lugs onto the outside of the bearing to secure it to the base. It is fixed using M6 screws.

- To protect against chips, the clip is covered with a box.

- We make the broach from shock absorbers from a truck (broken ones will do). Oil is poured out of them, holes are drilled for ventilation, which should be covered with a mesh to remove dust and chips.

- To prevent a jerk from being felt when starting work, the saw is supplemented with a soft start module, which slightly reduces the speed.

- The last stage of work is the manufacture of protection for the disk.

Design disadvantages:

- very noisy;

- To adjust the accuracy of wood cuts, scraps of timber are used, after which the rod is fixed firmly and you can work cleanly.

Disc diameter and cutting parameters

Some of the most important parameters of the saw are the diameter of the blade and the cutting parameters. In a home workshop, a 250 mm disc with a seat diameter of 30 mm will be completely sufficient. Professional systems are equipped with larger diameter discs, reaching up to half a meter.

Characteristics by disc diameter and cutting parameter

The cutting length in entry-level systems usually does not exceed 150 mm. If you need to cut slab material, you will need a machine with a horizontal movement option and two guides of sufficient length. As a rule, devices of this class are equipped with a drawing system.

The maximum thickness of the material also depends on the class and power of the miter saw; for entry-level systems it is 50 mm, for professional units it reaches up to 150.

Another important parameter is the drive and transmission type. Miter saws are equipped with two types of electric motors - asynchronous or commutator. Asynchronous motors are less noisy and do not require maintenance; commutator motors have an excellent service life, but require maintenance and periodic replacement of brushes.

Torque from the engine axis to the axis of the working disk is also transmitted in two main ways - gear or belt transmission.

Geared Miter Saw

The gear drive ensures reliable operation and does not allow slipping during high loads. However, it is characterized by high noise and vibration at the resonant frequencies of the gearbox.

Belt drive is less noisy. The absence of vibration guarantees stable cutting. Needs periodic adjustment due to belt stretching and loosening.

Advantages and disadvantages of homemade products

Having a device helps solve several issues:

- the edges of the parts become smooth without burrs;

- allows you to connect adjacent structures at an angle;

- When joining parts, there is no gap between them.

The main advantages of working with a homemade trimmer:

- firstly, saving on the purchase of building materials;

- secondly, you can select the technical characteristics of the tool you are creating yourself: engine power, cutting wheel size, cutting depth.

Flaws:

- the duration of operation depends on the type of material used to create the equipment;

- homemade products are not equipped with security systems;

- home devices do not have special calibration.

Trimming based on a grinder

To solve this problem, a grinder is often used. It is ideal for making your own miter machine for processing end surfaces. The homemade version will have the following technical characteristics:

- The disc speed of the grinder should not be less than 4500 rpm;

- The cutting length is 350 millimeters. Note that this figure is significantly higher than that of a factory tool, which belongs to the middle class.

The created design allows you to remove the grinder from the table and use it as a regular tool.

When considering how to make a similar embodiment, we note the following points:

- the cutting tool is mounted on an axis, which is represented by a car wheel. This moment determines the possibility of facing at an angle. To fix the rotating mechanism, a bearing with a diameter of 150 millimeters is used. To fix the grinder, a special mechanism is used, which is mounted on a rotating axis. After a certain time, it is recommended to lubricate this axis, as there is a possibility of squeaking;

- To fix a certain angle during the production of a machine on a bearing, special ears are welded on the outside. Fixation is carried out using a screw, for example M6. The ears should be attached so that there is not a large distance between them. Otherwise, there is a possibility of strong backlash, which will significantly reduce the processing accuracy;

The last stage of production can be called creating a shield for the saw. This element eliminates the possibility of foreign bodies entering the cutting zone. You can use your own cross-cutting machine at home.

However, the design in question also has significant disadvantages that should be taken into account. These include:

- A DIY cross-cutting machine is very noisy. This is due to the peculiarities of the grinder’s work. During processing, noise appears, which is almost impossible to reduce;

- The cross-cutting machine is used for high-quality processing of end surfaces. That is why quite a lot of attention is paid to the accuracy of the position of the grinder with the disc relative to the workpiece. To adjust the position of the grinder with the disk, trimming bars are used. The rod should be fixed with a bolt, after which processing can be carried out.

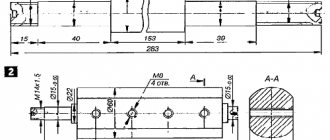

The drawings of the cross-cutting machine indicate that it can be quite easily installed in almost any workshop. One should take into account the fact that the structure is small in size, and the workpiece can be quite large. In order to eliminate the possibility of loss of accuracy during processing, the structure should be secured to the base.

Particular attention is paid to the type of disk installed. Initially, the grinder was intended for metal processing, which determines the presence of a large number of metal discs

But there are also discs for wood processing, which have their own characteristics.

In conclusion, there are quite a few blueprints that can be used when creating a cross-cutting machine. Some are quite simple to implement, others are difficult to implement.

If you find an error, please select a piece of text and press Ctrl+Enter.

Materials and tools

The easiest way is to make a homemade cutting machine from a grinder and grinders that can use wheels of different diameters. When choosing the grinder to use, you must remember that models that are capable of working with discs with a diameter of more than 150 millimeters are versatile in use, and such a machine can cope with processing lumber of various sizes. The optimal power of an angle grinder is 800 watts or more.

The easiest way to make the frame and bracket is from a metal corner, which is welded or fastened with rivets

The quality of fixation of the angle grinder should be given due attention, since subsequently, when processing materials, it is the existing fastening that bears an increased load, which can lead to breakdowns of the pendulum mechanism

Choosing the Right Miter Saw

There are several factors to consider when choosing a miter saw:

- Speed of revolutions. Some models have the ability to adjust engine speed. This allows you to optimally configure the machine to work with materials of different hardness.

- Cutting depth. To make a deeper cut, you need a unit with a large sawing disk. In appliances for domestic use, a disk with a diameter of 20 cm is usually installed, in professional equipment - 25 cm.

- Width of the groove for the disk. A groove is a special place where the disc goes. The quality of work depends on the width of the groove. If it is no more than 10 mm, then the cut will be of high quality, with a minimum amount of chips and sawdust.

- The maximum angle your saw can miter will determine the pieces you can cut with it, because a miter saw's performance increases the greater its maximum miter angle. The saw typically cuts perpendicular to the piece, so it starts at a 90-degree angle. The values given for the maximum bevel angle of a particular saw are how far the saw can turn in any direction.

- Width of broach. The length that the saw can pass through the workpiece material. Everything is simple here: the wider the broach, the wider the workpieces can be processed on the machine. You need to choose taking into account what materials will be processed: for skirting boards, a saw with a broach of up to 100 mm is enough; if the products are larger, then a machine will be required with a larger broach.

- Safety features such as: dust removal, operation blocking when replacing the saw blade, electrodynamic brake for a smooth stop of the motor when turned off, automatic stop of the machine in emergency situations.

- Features of accuracy. If you have a miter saw with regular miter stops and a laser guide, you can easily set it to the correct miter/bevel angle in a couple of seconds. You can then level the workpiece to ensure you are cutting to the correct length. This type of precision feature can save you hours of production on an industrial scale because your job will essentially be reduced to placing the item against a fence and cutting it.

- Rotary saw design. The miter saw design has guides that allow you to adjust the angle of inclination when cutting. For professional devices, the tilt angle is up to 57°, for simpler options – 45°.

- Weight. The mobility of the unit largely depends on it. The less it weighs, the easier it is to take it for field work to sites.

- Performance Features. It completely depends on your preference and how you will use the miter saw! You may be looking for productivity features that will make your work easier.

Some of the most popular ones are purchasing a cordless kit, purchasing extra blades, or purchasing motor power (basically, the more powerful the motor, the easier the saw will cut through hard material).

So, a broach miter saw is a regular saw with a circular blade that can swing down to make a cross cut at a right angle.

Having familiarized yourself with the main technical characteristics, popular manufacturers and models of miter saws, the choice will be easy to make. The main thing is that the machine meets the performance requirements and is convenient to use.

What to look for when choosing a unit

As mentioned earlier, there is no clear line between professional and amateur models. At this point, the fundamental factor is usually the price of the miter saw.

But here, too, not everything is so simple; in a narrowly focused niche, which is the miter saw, the name of the manufacturer is of great importance. It is often better to take a modest but proven device from a reliable company than a cross-cutting machine with a large number of functions from an unknown manufacturer.

Normal operation depends on two factors:

- the quality of the device itself;

- correct selection of disk.

Main components of the unit.

Choosing a Miter Saw Mechanism

- Naturally, before going to the store, you should clearly determine for what specific purpose this tool is being purchased. If you need a trimmer for a home workshop and you will turn it on from time to time, then there is no need to shell out a lot of money for a complex, high-precision unit. Often, the instructions for such devices are designed for professionals and it is not a fact that you will thoroughly understand it.

- It’s a completely different matter when the device is purchased for installation in a production workshop or for the needs of a mobile construction team. Here you should first look at the name of the manufacturer and only then at the number of functions. The fact is that in production the device will work every day and for many hours. Only really high-quality machines can withstand such a load. After all, you must admit that stopping production will cost more than buying a high-quality trimmer.

Unit with laser illumination.

Advice: the length of the warranty period, as well as the availability and accessibility of branded technical service points, play an important role. This information is taken from the World Wide Web in a couple of minutes.

- The next important factor that you need to pay attention to is the range of profile disks that can be installed on a specific device model. In this case we are talking about diameter. For a home workshop, a cutting head designed for a disc up to 200 mm is quite sufficient. Professionals, as a rule, work with 210, 250 or 305 mm discs.

- Almost all units of this type are considered portable. But their weight and dimensions can differ significantly. Both of these indicators are important not only from a transportation point of view, but also from an operational point of view.

Scale for setting.

- After all, if you plan to process profiled metal pipes or bulky, heavy laminated wood beams, then a lightweight, even a very high-quality miter saw is not suitable for this; you need a powerful frame with the possibility of stationary fastening.

- But at the same time, the modest dimensions do not at all indicate the same low power. Motors of 1.5 - 2 kW are capable of quickly and efficiently handling any job.

High precision equipment.

Important: engine power and speed are often inextricably linked. Any machine is suitable for rough work, but if accuracy and quality of the cut are important, you should take machines with high speeds. A completely acceptable option is 4 – 5 thousand revolutions.

- The motor itself, which drives the disk, can be asynchronous or commutator. The asynchronous type is considered more durable and less noisy in operation. But the collector option does not require such careful care.

- As you know, starting currents are many times higher than operating currents, so a soft start function for the unit would be useful. It is especially relevant for use in private homes, where wiring is often not designed to withstand heavy loads and can burn out.

Portable device with movable head.

- Some models are equipped with a fast and smooth braking device, which is very convenient and, most importantly, safer.

- Any such unit must be equipped with protection against sudden, unplanned activation. It is also desirable to have an emergency shutdown device in case of overloads or voltage surges in the network.

Advice: based on experience, we can say that models with a function for limiting the depth of cut are much more convenient to work with. Their price is slightly higher, but you can make grooves and work with parts of strictly limited thickness.

Detailed analysis of nodes.

- The electric motor itself can be placed either directly on the cutting head on the right, or slightly behind the device. In the first case, the device will be more functional, and in the second, the visibility increases.

- The transmission can be either gear or belt. A gear reducer is usually used on powerful, high-speed units, as it completely eliminates disc slippage. But cross-cutting machines with a belt drive have a much lower noise level, and vibration of the disk is almost completely eliminated. Devices with a belt drive are considered more durable.

- Both domestic and imported models are now often equipped with a laser disc aiming system. Or with special lighting, in which the shadow from the rotating disk exactly falls on the cut site. This is a very useful feature for performing high-quality wood cutting.

Machine with top sawing table.

Types of disks

Disks are classified according to several criteria. First of all, these are the internal and external diameters. Everything is simple here, the internal mounting hole can be 25 or 30 mm. There are several sizes in terms of outer diameter, but the maximum is 305 mm.

Universal disc for high speeds.

A more important parameter is the size and configuration of the tooth on the blade. A disc with a large tooth is designed for rough work with wood. Even at high speeds, you are unlikely to be able to make a clean cut on a laminated, varnished or painted surface; for this, there are disks with medium or fine teeth.

In general, all disks are divided into three types. These are products designed for longitudinal cuts, cross cuts, and also for finishing cuts. Finishing discs come only with fine teeth and are considered universal. With high quality steel and high speeds, they can successfully cut not only wood, but also plastic or thin metal.

Disc with cuts.

For heavy loads and long-term operation, special disks are produced. Such products have deep through cuts from the edge to the center. The length of the cut and the size of the gap depend on the type of material being processed.

The cuts compensate for temperature deformations and reduce noise levels. Thanks to this original design, the disc can safely withstand many hours of stress on any material.

Safety first

Working with any cutting and especially rotating units requires special, enhanced safety measures. Here, as in the rules of the road, it is better to repeat it one more time than to suffer later.

Cutting options.

If you do not have experience operating a machine, it would be a good idea to practice before performing important operations. Anywhere you can find scraps of material on which you can “get your hands on.”

Initially, the workpiece is placed and clearly fixed on the sawing table. Then the saw motor turns on. You can start cutting only after a full set of revolutions, you will understand this by the sound.

Important! On each table there are visually designated areas where you cannot put your hands.

If you want to get a beautiful and high-quality cut, then the pressure should be smooth and uniform, without jerking. You should not try to work with your arms crossed or swap your arms. That is, if you are supposed to hold the workpiece with your left hand and move the cutting head with your right, then you need to do so.

Means of protection.

Despite the presence of high-quality protective covers, shavings or sawdust fly off from all rotating units, and they fly out at high speed and can cause serious injury to the eyes. Therefore, before turning on the device, put on safety glasses.

Tip: some well-known manufacturers equip their devices with a movable casing that covers the disk during idle. But as soon as you press the handle and start moving the head, the casing automatically moves. This simple device has saved many people from serious injuries. Therefore, if you have the opportunity to buy, you should not waste money on this option.

Technical characteristics of different units.

The video in this article gives an overview of trimming units.